High-Speed Steel Square End Mills

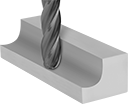

Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use titanium-nitride (TiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills, which means they last longer when run at similar speeds.

Center-cutting end mills allow plunge cuts into a surface.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 15/16" | 7/8" | 1 1/2" | 3 3/4" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 000000 |

4 Flute | |||||||||

| 15/16" | 7/8" | 1 7/8" | 4 1/8" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 00000 |

Titanium Nitride (TiN) Coated | |||||||||

2 Flute | |||||||||

| 15/16" | 3/4" | 1 1/2" | 3 3/4" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

4 Flute | |||||||||

| 15/16" | 7/8" | 1 7/8" | 4 1/8" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

High-Speed Steel Ball End Mills

Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

End mills with two flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts. Use uncoated end mills for general purpose milling and short production runs. Use titanium-nitride (TiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills, which means they last longer when run at similar speeds.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 15/16" | 3/4" | 2 1/4" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 0000000 |

Titanium Nitride (TiN) Coated | |||||||||

2 Flute | |||||||||

| 15/16" | 3/4" | 2 1/4" | 4 1/2" | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |