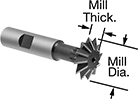

High-Speed Steel Double-Chamfer End Mills

Use these end mills for general purpose work in most material, such as aluminum, brass, bronze, iron, and steel. The teeth are angled in two directions so you can make top and bottom chamfers without having to flip the workpiece.

Carbide-Tipped Double-Chamfer End Mills

Made of carbide-tipped high-speed steel, these end mills provide a sharper, harder edge at high temperatures than plain high-speed steel. Because they aren’t as brittle as solid carbide, they can be used in less rigid setups, such as manual milling machines. The teeth are angled in two directions so you can make top and bottom chamfers without having to flip the workpiece.

Use uncoated end mills for general purpose milling and short production runs. They stay sharper than coated end mills when used on soft materials like aluminum, leaving a better finish. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated end mills. Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Aluminum-titanium-nitride (AlTiN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

Mill | |||||||

|---|---|---|---|---|---|---|---|

| Dia. | Thick. | Shank Dia. | Lg. of Cut | Overall Lg. | For Use On | Each | |

Uncoated | |||||||

60° Cutting Angle | |||||||

| 2 1/4" | 3/4" | 7/8" | 3/4" | 4 5/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 0000000 |

90° Cutting Angle | |||||||

| 2 1/4" | 3/4" | 7/8" | 3/4" | 4 5/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

Titanium Nitride (TiN) Coated | |||||||

60° Cutting Angle | |||||||

| 2 1/4" | 3/4" | 7/8" | 3/4" | 4 5/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

90° Cutting Angle | |||||||

| 2 1/4" | 3/4" | 7/8" | 3/4" | 4 5/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

Titanium Carbonitride (TiCN) Coated | |||||||

60° Cutting Angle | |||||||

| 2 1/4" | 3/4" | 7/8" | 3/4" | 4 5/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

90° Cutting Angle | |||||||

| 2 1/4" | 3/4" | 7/8" | 3/4" | 4 5/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

Aluminum Titanium Nitride (AlTiN) Coated | |||||||

60° Cutting Angle | |||||||

| 2 1/4" | 3/4" | 7/8" | 3/4" | 4 5/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

90° Cutting Angle | |||||||

| 2 1/4" | 3/4" | 7/8" | 3/4" | 4 5/32" | Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

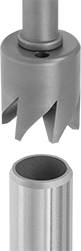

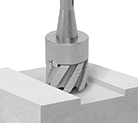

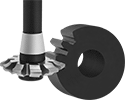

Outside Chamfer End Mills for Pipes, Tubes, and Rods

Mill an angled edge to the entire outside diameter of pipe, tubes, and rods in a single pass with more speed and precision than a handheld scraper. These end mills deburr pipe and tube for butt welds and shape rods for sliding into housings and holes. They attach to screw machines, lathes, and drill presses and can be set up to repeat cuts for multiple pipes. Staggered cutting edges reduce vibration, resulting in a smooth finish. They have teeth that distribute cutting force and extend the life of the tool. Made of high-speed steel, they work with a variety of metals. Attach to your machine with a shank (sold separately).

Mill | |||||||

|---|---|---|---|---|---|---|---|

| For OD | For Pipe Size | Dia. | Thick. | Thread Size | For Use On | Each | |

Uncoated—30° Cutting Angle | |||||||

| 1/2"-1 3/4" | 1/8, 1/4, 3/8, 1/2, 3/4, 1, 1 1/4 | 2 1/4" | 2 15/16" | 1"-14 | Aluminum, Brass, Bronze, Copper, Iron, Nickel, Plastic, Stainless Steel, Steel | 0000000 | 0000000 |

Shank | |||||

|---|---|---|---|---|---|

| Dia. | Lg. | Shoulder Dia. | Overall Lg. | Each | |

1"-14 Thread | |||||

| 1" | 2" | 1 3/16" | 2 3/4" | 0000000 | 000000 |

High-Speed Steel Corner-Rounding End Mills

Use these versatile end mills for milling in most material, including aluminum, brass, bronze, iron, and steel. They have scooped corners for rounding the sharp edges of your workpiece.

Use uncoated end mills for general purpose milling and short production runs. They stay sharper than coated end mills when used on soft materials like aluminum, leaving a better finish. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated end mills.

Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Aluminum-titanium-nitride (AlTiN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

| Cut Radius | Tip Dia. | Mill Dia. | Shank Dia. | Overall Lg. | Flute Spacing | For Use On | Each | |

Uncoated | ||||||||

|---|---|---|---|---|---|---|---|---|

4 Flute | ||||||||

| 3/4" | 5/8" | 2 1/4" | 3/4" | 4 1/8" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 0000000 |

| 3/4" | 5/8" | 2 1/4" | 1" | 4 5/16" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

Titanium Nitride (TiN) Coated | ||||||||

4 Flute | ||||||||

| 3/4" | 5/8" | 2 1/4" | 3/4" | 4 1/8" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 3/4" | 5/8" | 2 1/4" | 1" | 4 5/16" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

Aluminum Titanium Nitride (AlTiN) Coated | ||||||||

4 Flute | ||||||||

| 3/4" | 5/8" | 2 1/4" | 3/4" | 4 1/8" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 3/4" | 5/8" | 2 1/4" | 1" | 4 5/16" | Equal | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

Cobalt Steel Corner-Rounding End Mills

With better heat and wear resistance than high-speed steel, these cobalt steel end mills run at higher speeds and provide better performance on hard material. They have scooped corners for rounding the sharp edges of your workpiece.

| Cut Radius | Tip Dia. | Mill Dia. | Shank Dia. | Overall Lg. | Flute Spacing | For Use On | Each | |

Uncoated | ||||||||

|---|---|---|---|---|---|---|---|---|

4 Flute | ||||||||

| 3/4" | 5/8" | 2 1/4" | 3/4" | 4 1/8" | Equal | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 0000000 |

High-Speed Steel Dovetail End Mills

Use these versatile end mills for milling in most material, including aluminum, brass, bronze, iron, and steel. They create dovetail slots for connecting two components with a sliding fit.

Uncoated end mills are for general purpose milling and short production runs. They stay sharper than coated end mills when used on soft materials like aluminum, leaving a better finish. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated end mills.

Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Aluminum-titanium-nitride (AlTiN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

Mill | ||||||

|---|---|---|---|---|---|---|

| Dia. | Thick. | Shank Dia. | O'all Lg. | For Use On | Each | |

Uncoated | ||||||

45° Chamfer Angle | ||||||

| 2 1/4" | 11/16" | 1" | 3 3/4" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 0000000 |

60° Chamfer Angle | ||||||

| 2 1/4" | 1 1/16" | 1" | 3 3/4" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

Titanium Nitride (TiN) Coated | ||||||

45° Chamfer Angle | ||||||

| 2 1/4" | 11/16" | 1" | 3 3/4" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

60° Chamfer Angle | ||||||

| 2 1/4" | 1 1/16" | 1" | 3 3/4" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

Titanium Carbonitride (TiCN) Coated | ||||||

45° Chamfer Angle | ||||||

| 2 1/4" | 11/16" | 1" | 3 3/4" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

60° Chamfer Angle | ||||||

| 2 1/4" | 1 1/16" | 1" | 3 3/4" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

Aluminum Titanium Nitride (AlTiN) Coated | ||||||

45° Chamfer Angle | ||||||

| 2 1/4" | 11/16" | 1" | 3 3/4" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

60° Chamfer Angle | ||||||

| 2 1/4" | 1 1/16" | 1" | 3 3/4" | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 0000000 | 000000 |

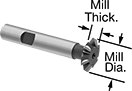

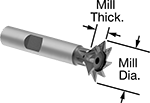

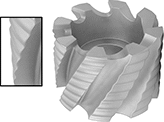

Face Milling Cutters

With larger diameters than end mills, these cutters remove greater amounts of material to create a smooth, flat channel in the face of a plate, bar, or other wide workpiece. Compared to fly cutters, they’re more rigid, which makes for a better finish. Also known as shell cutters. Cutters with fewer teeth provide better chip clearance for high-volume, high-speed cuts. Those with more teeth provide a finer finish and generate less vibration at high speeds.

High-speed steel cutters are good for general purpose milling in most materials including aluminum brass, bronze, and steel. Cobalt steel cutters have better heat and wear resistance than high-speed steel. They can run at higher speeds and provide better performance on hard material such as iron, stainless steel, titanium, and tool steel.

Use uncoated cutters for general purpose milling and short production runs. They stay sharper than coated cutters when used on soft materials like aluminum. Use coated cutters for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated cutters.

Titanium-nitride (TiN) coated cutters create less friction than uncoated cutters, which means they last longer when run at similar speeds. Aluminum-titanium-nitride (AlTiN) coated cutters dissipate heat better than other cutters, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

Mill | |||||||

|---|---|---|---|---|---|---|---|

| Thick. | Dia. | Number of Teeth | Arbor Hole Dia. | Helix Angle | For Use On | Each | |

Uncoated High-Speed Steel | |||||||

| 1 1/2" | 2 1/4" | 10 | 1" | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 0000000 |

Titanium-Nitride (TiN) Coated High-Speed Steel | |||||||

| 1 1/2" | 2 1/4" | 10 | 1" | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 00000000 | 000000 |

Aluminum-Titanium-Nitride (AlTiN) Coated High-Speed Steel | |||||||

| 1 1/2" | 2 1/4" | 10 | 1" | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 00000000 | 000000 |

Uncoated Cobalt Steel | |||||||

| 1 1/2" | 2 1/4" | 10 | 1" | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

Titanium-Nitride (TiN) Coated Cobalt Steel | |||||||

| 1 1/2" | 2 1/4" | 10 | 1" | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

Aluminum-Titanium-Nitride (AlTiN) Coated Cobalt Steel | |||||||

| 1 1/2" | 2 1/4" | 10 | 1" | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 00000000 | 000000 |

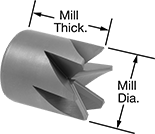

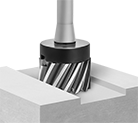

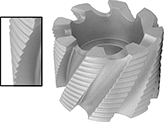

Roughing Face Milling Cutters

Serrations along the cutting edge act as chip breakers, so these cutters can remove large amounts of material at high speeds without sacrificing tool life. With larger diameters than end mills, they remove greater amounts of material to create a smooth, flat channel in the face of a plate, bar, or other wide workpiece. Compared to fly cutters, they’re more rigid, which makes for a better finish. Also known as shell cutters. With better heat and wear resistance than high-speed steel, these cobalt steel cutters can run at higher speeds and provide better performance on hard material, such as hardened steel, iron, and titanium.

Use uncoated cutters for general purpose milling and short production runs. They stay sharper than coated cutters when used on soft material, such as aluminum. Use coated cutters for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated cutters.

Titanium-nitride (TiN) coated cutters create less friction than uncoated cutters, which means they last longer when run at similar speeds. Aluminum-titanium-nitride (AlTiN) coated cutters dissipate heat better than other cutters, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

Coarse pitch cutters create large chips for better performance on soft metals, such as aluminum, brass, and bronze. Fine pitch cutters last longer than coarse-pitch end mills and produce smaller chips for better performance on hard metals, such as hardened steel, iron, and titanium.

Mill | Coarse Pitch | Fine Pitch | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Thick. | Dia. | Number of Teeth | Arbor Hole Dia. | Helix Angle | For Use On | Each | Each | ||

Uncoated Cobalt Steel | |||||||||

| 1 1/2" | 2 1/4" | 8 | 1" | 30° | Aluminum, Brass, Bronze, Copper, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Wood | 0000000 | 0000000 | 0000000 | 0000000 |

Titanium-Nitride (TiN) Coated Cobalt Steel | |||||||||

| 1 1/2" | 2 1/4" | 8 | 1" | 30° | Aluminum, Brass, Bronze, Copper, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Wood | 0000000 | 000000 | 0000000 | 000000 |

Aluminum-Titanium-Nitride (AlTiN) Coated Cobalt Steel | |||||||||

| 1 1/2" | 2 1/4" | 8 | 1" | 30° | Aluminum, Brass, Bronze, Copper, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Wood | 0000000 | 000000 | 0000000 | 000000 |

Gear Cutters

Also known as involute gear cutters, these tools work with a milling machine to create 14½° or 20° pressure angle spur gears. If worn, they can be sharpened and used again.

Cutters for 14½° Gear Pressure Angle—The former industry standard, these gears are often found in older machinery.

Cutters for 20° Gear Pressure Angle—These gears are the current industry standard and have thicker, stronger teeth than 14½° pressure angle gears.

To select a gear cutter, follow these steps:

1. Determine the pitch of the gear you're cutting. Gear pitch = (No. of Teeth + 2) / OD. Round to the nearest whole number.

2. Select the cutter that matches your gear's pitch and number of teeth.

Mill | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Number of Gear Teeth | Cutter Trade Number | Thick. | Dia. | Arbor Hole Dia. | Keyway Wd. | Material | For Use On | Each | |

For 14 1/2° Gear Pressure Angle | |||||||||

For 12 Gear Pitch | |||||||||

| 55-134 | 2 | 0.315" | 2 1/4" | 7/8" | 0.125" | High-Speed Steel | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 00000000 | 000000 |

| 35-54 | 3 | 0.315" | 2 1/4" | 7/8" | 0.125" | High-Speed Steel | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 00000000 | 00000 |

| 21-25 | 5 | 0.315" | 2 1/4" | 7/8" | 0.125" | High-Speed Steel | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 00000000 | 00000 |

| 17-20 | 6 | 0.315" | 2 1/4" | 7/8" | 0.125" | High-Speed Steel | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 00000000 | 00000 |

| 14-16 | 7 | 0.315" | 2 1/4" | 7/8" | 0.125" | High-Speed Steel | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 00000000 | 00000 |

| 12-13 | 8 | 0.315" | 2 1/4" | 7/8" | 0.125" | High-Speed Steel | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 00000000 | 00000 |

For 20° Gear Pressure Angle | |||||||||

For 24 Gear Pitch | |||||||||

| 135 and Up | 1 | 0.187" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 55-134 | 2 | 0.187" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 35-54 | 3 | 0.187" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 26-34 | 4 | 0.25" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 21-25 | 5 | 0.25" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 17-20 | 6 | 0.25" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 14-16 | 7 | 0.25" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 12-13 | 8 | 0.25" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

For 32 Gear Pitch | |||||||||

| 135 and Up | 1 | 0.125" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 55-134 | 2 | 0.187" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 35-54 | 3 | 0.187" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 26-34 | 4 | 0.187" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 21-25 | 5 | 0.187" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 17-20 | 6 | 0.187" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 14-16 | 7 | 0.187" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |

| 12-13 | 8 | 0.187" | 2 1/4" | 1" | 0.25" | High-Speed Steel | Aluminum, Brass, Bronze, Plastic, Stainless Steel, Steel | 0000000 | 000000 |