Filter by

System of Measurement

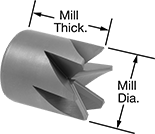

Mill Diameter

Number of Teeth

Cut Style

Finish

Material

Number of Milling Ends

REACH

Sold As

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

DFARS Specialty Metals

Export Control Classification Number (ECCN)

RoHS

Thread Size

Outside Chamfer End Mills for Pipes, Tubes, and Rods

Mill an angled edge to the entire outside diameter of pipe, tubes, and rods in a single pass with more speed and precision than a handheld scraper. These end mills deburr pipe and tube for butt welds and shape rods for sliding into housings and holes. They attach to screw machines, lathes, and drill presses and can be set up to repeat cuts for multiple pipes. Staggered cutting edges reduce vibration, resulting in a smooth finish. They have teeth that distribute cutting force and extend the life of the tool. Made of high-speed steel, they work with a variety of metals. Attach to your machine with a shank (sold separately).

End Mills

End Mill

Mill | |||||||

|---|---|---|---|---|---|---|---|

| For OD | For Pipe Size | Dia. | Thick. | Thread Size | For Use On | Each | |

Uncoated—30° Cutting Angle | |||||||

| 1"-3" | 3/4, 1, 1 1/4, 1 1/2, 2, 2 1/2 | 3 3/4" | 3 3/4" | 1 1/4"-12 | Aluminum, Brass, Bronze, Copper, Iron, Nickel, Plastic, Stainless Steel, Steel | 3500N18 | 000000000 |

Uncoated—45° Cutting Angle | |||||||

| 1"-3" | 3/4, 1, 1 1/4, 1 1/2, 2, 2 1/2 | 3 3/4" | 2 7/8" | 1 1/4"-12 | Aluminum, Brass, Bronze, Copper, Iron, Nickel, Plastic, Stainless Steel, Steel | 3500N27 | 00000000 |

Shanks

Shank

Shank | |||||

|---|---|---|---|---|---|

| Dia. | Lg. | Shoulder Dia. | Overall Lg. | Each | |

1 1/4"-12 Thread | |||||

| 1" | 2" | 1 1/2" | 2 3/4" | 3500N49 | 000000 |