Carbide Square End Mills

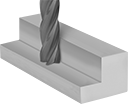

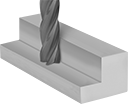

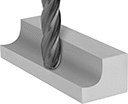

For longer tool life and a better finish in general purpose milling applications, these solid carbide end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel end mills. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. They stay sharper than coated end mills when used on soft materials like aluminum, leaving a better finish. Use coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills. Titanium-nitride (TiN) coated end mills create less friction than uncoated end mills, which means they last longer when run at similar speeds. Titanium-carbonitride (TiCN) coated end mills have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum. Titanium-aluminum-nitride (TiAlN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

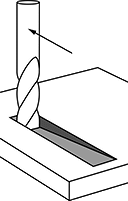

Center-cutting end mills allow plunge cuts into a surface.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

3 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

4 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Nitride (TiN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

3 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

4 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Carbonitride (TiCN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 000000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 00000 |

3 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 00000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 00000 |

4 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 00000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 00000000 | 00000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Nitride (TiAlN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

3 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

4 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

| 5mm | 5mm | 32mm | 75mm | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

Fast-Cutting Carbide Square End Mills

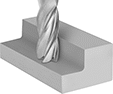

Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life on hard materials. Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a square end for milling square-bottomed slots, pockets, and edges.

A titanium-aluminum-nitride (TiAlN) or aluminum-titanium-nitride (AlTiN) coating allows them to dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication. Aluminum-titanium-nitride (AlTiN) has a higher percentage of aluminum than titanium-aluminum-nitride (TiAlN).

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Center-cutting end mills allow plunge cuts into a surface.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

End Mills | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Titanium Aluminum Nitride (TiAlN) Coated—4 Flute | |||||||||

| 5mm | 6mm | 13mm | 57mm | Variable | 35°-38° | Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

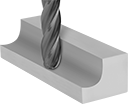

Fast-Cutting Carbide Square End Mills with Chamfer Corner

A 45° corner chamfer improves cutting edge strength, so these end mills last longer than standard square end mills when milling hard material; however they do not create as sharp of a corner. Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life on hard materials. They have a square end for milling square-bottomed slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

Titanium-aluminum-nitride (TiAlN) and aluminum-titanium-nitride (AlTiN) coated end mills dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication. Titanium-aluminum-silicon-nitride (TiAlSiN) coated end mills are extremely resistant to wear and diffusion because they have especially high hardness, even at high temperatures.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

End mills for extreme ramping and plunging are good for both angled and vertical cutting. Choose these end mills so you can have one tool for ramping and plunging. They can enter the material at up to a 45° ramping angle to reach your desired depth faster than standard end mills, which typically machine at 1° to 3° angles. These end mills also evacuate chips faster and last longer.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Chamfer Wd. | Corner Cutting Angle | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

End Mills | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Titanium Aluminum Nitride (TiAlN) Coated—5 Flute | |||||||||||

| 5mm | 6mm | 13mm | 57mm | 0.05mm | 45° | Variable | 45° | Stainless Steel, Titanium | Center Cutting | 00000000 | 000000 |

Titanium Aluminum Nitride (TiAlN) Coated—6 Flute | |||||||||||

| 5mm | 6mm | 13mm | 57mm | 0.05mm | 45° | Variable | 45° | Stainless Steel, Titanium | Center Cutting | 00000000 | 00000 |

Aluminum Titanium Nitride (AlTiN) Coated—4 Flute | |||||||||||

| 5mm | 6mm | 13mm | 57mm | 0.15mm | 45° | Variable | 36°-38° | Stainless Steel, Titanium | Center Cutting | 00000000 | 00000 |

Titanium Aluminum Silicon Nitride (TiAISiN) Coated—3 Flute | |||||||||||

| 5mm | 6mm | 13mm | 57mm | 0.08mm | 45° | Variable | 41°-45° | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

Titanium Aluminum Silicon Nitride (TiAISiN) Coated—4 Flute | |||||||||||

| 5mm | 6mm | 13mm | 57mm | 0.05mm | 45° | Variable | 36°-38° | Iron, Nickel, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 00000 |

End Mills for Extreme Ramping and Plunging | |||||||||||

Aluminum Titanium Nitride (AlTiN) Coated—4 Flute | |||||||||||

| 5mm | 6mm | 10mm | 57mm | 0.1mm | 45° | Variable | 37°-39° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 00000 |

Carbide Square End Mills for Carbon Fiber, Fiberglass, and Graphite

A diamond or diamondlike coating on these end mills makes them good for machining abrasive material, such as carbon fiber, fiberglass, and graphite. Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a square end for milling square-bottomed slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Diamondlike-carbon (DLC) coated end mills are an economical option for short runs and intermittent use.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Diamondlike Carbon (DLC) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

4 Flute | |||||||||

| 5mm | 5mm | 20mm | 50mm | Equal | 33° | Carbon Fiber, Fiberglass, Graphite | Center Cutting | 00000000 | 000000 |

Carbide Square End Mills for Aluminum, Brass, and Bronze

Either an aluminum non-ferrous (ANF) coating or a titanium-carbonitride (TiCN) coating prevents soft material, such as aluminum, brass, and bronze, from accumulating on the cutting edge and creating an uneven finish. Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a square end for milling square slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

End mills with three flutes provide a finer finish and operate with less vibration when run at high speeds.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Carbonitride (TiCN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

3 Flute | |||||||||

| 5mm | 5mm | 14mm | 50mm | Equal | 45° | Aluminum, Brass, Bronze | Center Cutting | 00000000 | 000000 |

Fast-Cutting Carbide Square End Mills for Aluminum, Brass, and Bronze

Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life. Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish. Their extreme hardness means they are brittle, so a highly rigid setup is necessary to prevent breakage. End mills are uncoated for use on soft material, such as aluminum, brass, and bronze. They have a square end for milling square slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

4 Flute | |||||||||

| 5mm | 6mm | 13mm | 57mm | Variable | 40°-42° | Aluminum, Brass, Bronze | Center Cutting | 0000000 | 000000 |

Carbide Square End Mills for Stainless Steel and Titanium

With a wear-resistant coating and high helix angle, these end mills provide excellent shearing and chip removal in stainless steel and titanium. Made of solid carbide, they are harder, stronger, and more wear resistant than high-speed steel and cobalt steel end mills for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. The coating allows them to dissipate heat better than other end mills, especially at high speeds. At high temperatures, it creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication. End mills have a square end for milling square slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

End mills with five flutes provide a finer finish and operate with less vibration when run at high speeds.

Aluminum-titanium-nitride (AlTiN) coated end mills have a higher percentage of aluminum than titanium-aluminum-nitride (TiAlN) coated end mills.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Aluminum Titanium Nitride (AlTiN) Coated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

5 Flute | |||||||||

| 5mm | 6mm | 16mm | 65mm | Equal | 45° | Stainless Steel, Titanium | Center Cutting | 0000000 | 000000 |

Fast-Cutting Roughing Carbide Square End Mills with Chamfer Corner

Serrations along the cutting edge act as chip breakers, so these end mills can remove large amounts of material at high speeds without sacrificing tool life. Variable spacing between the flutes reduces vibration, also allowing these end mills to provide fast cuts. A 45° corner chamfer improves cutting edge strength, so these end mills last longer than standard square end mills when milling hard material; however they do not create as sharp of a corner. With a high helix angle and wear-resistant titanium-aluminum-nitride (TiAlN) or aluminum-titanium-nitride (AlTiN) coating, these end mills provide excellent shearing and chip removal in stainless steel and titanium. They have a square end for milling square-bottomed slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Chamfer Wd. | Corner Cutting Angle | Flute Pitch | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Aluminum Titanium Nitride (AlTiN) Coated | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

4 Flute | ||||||||||||

| 5mm | 6mm | 13mm | 57mm | 0.2mm | 45° | Coarse | Variable | 36°-38° | Iron, Stainless Steel, Steel, Titanium | Center Cutting | 00000000 | 000000 |

High-Speed Steel Square End Mills

Use these end mills for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use titanium-nitride (TiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They’re more wear resistant than uncoated end mills, which means they last longer when run at similar speeds.

Center-cutting end mills allow plunge cuts into a surface.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 5mm | 9.5mm | 12.7mm | 59mm | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 000000 |

4 Flute | |||||||||

| 5mm | 9.5mm | 15.9mm | 62mm | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 00000 |

Titanium Nitride (TiN) Coated | |||||||||

2 Flute | |||||||||

| 5mm | 9.5mm | 12.7mm | 59mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

High-Speed Steel Square End Mills with Two Milling Ends

When one end wears out, switch to the opposite end for two times the life of a standard high-speed steel end mill. Made of high-speed steel, these end mills are for general purpose milling in most material, such as aluminum, brass, bronze, iron, and steel. Their square ends make them good for milling square slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 5mm | 9.5mm | 11.1mm | 83mm | Equal | 30° | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | Center Cutting | 0000000 | 000000 |

Cobalt Steel Square End Mills

With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as iron, hardened steel, titanium, and tool steel. They have a square end for milling square slots, pockets, and edges.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs. Use titanium-carbonitride (TiCN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. They have a hard, smooth finish that resists chipping and wear and prevents material from accumulating on the cutting edge. They’re especially good for use in aluminum.

Center-cutting end mills allow plunge cuts into a surface.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 5mm | 6mm | 13mm | 57mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

4 Flute | |||||||||

| 5mm | 6mm | 13mm | 57mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

Titanium Carbonitride (TiCN) Coated | |||||||||

4 Flute | |||||||||

| 5mm | 6mm | 13mm | 57mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 00000 |

Cobalt Steel Square End Mills with Two Milling Ends

When one end wears out, switch to the opposite end for two times the life of a standard cobalt steel end mill. With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as iron, hardened steel, titanium, and tool steel. Their square ends make them good for milling square slots, pockets, and edges. All are center cutting, allowing plunge cuts into a surface.

End mills with four flutes provide a finer finish and operate with less vibration when run at high speeds.

| Mill Dia. | Shank Dia. | Lg. of Cut | O'all Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

4 Flute | |||||||||

| 5mm | 9.5mm | 14.3mm | 83mm | Equal | 30° | Aluminum, Brass, Bronze, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 000000 |

Carbide Ball End Mills

Ball Cut Style | 2 Flute |

4 Flute |

For longer tool life and a better finish in general purpose milling applications, these solid carbide end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel end mills. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Use uncoated end mills for general purpose milling and short production runs.

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

2 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

| Mill Dia. | Shank Dia. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Uncoated | |||||||||

|---|---|---|---|---|---|---|---|---|---|

4 Flute | |||||||||

| 5mm | 5mm | 16mm | 50mm | Equal | 30° | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 00000000 | 000000 |

Long-Reach Carbide Ball End Mills for Mold Making

These end mills have an extended neck with a reduced diameter that prevents them from rubbing against your workpiece when deep milling. Also known as runner cutters, they cut channels with precise angles and dimensions, reducing the need for additional finishing. They have a ball end for milling rounded slots, slopes, and contours. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking.

Use aluminum-titanium-nitride (AlTiN) coated end mills for demanding, high-speed jobs in hard material as well as for longer production runs. The coating reduces friction and vibration as they’re used, making them more wear resistant than uncoated end mills. They dissipate heat better than other end mills, especially at high speeds. At high temperatures, the coating creates a layer of aluminum oxide that transfers heat to the chips, keeping the tool cool, even when used without lubrication.

End mills with fewer flutes provide better chip clearance for high-volume, high-speed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run at high speeds.

Neck | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mill Dia. | Shank Dia. | Dia. | Lg. | Lg. of Cut | Overall Lg. | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Aluminum Titanium Nitride (AlTiN) Coated | |||||||||||

2 Flute | |||||||||||

| 5mm | 6mm | 4.9mm | 5mm | 6mm | 57mm | Equal | 30° | Hardened Steel, Iron, Nickel, Stainless Steel, Steel, Titanium, Tool Steel | Center Cutting | 0000000 | 0000000 |

Carbide Rounded-Edge Square End Mills for Copy Milling

Replicate the shape of complex parts with these end mills. Also known as torus end mills, they have a rounded edge for precision contouring. These end mills are also used for slotting and pocketing cuts in mold and die making. Their 90° profile and rounded corners reduce flute breakage and chipping. All are center cutting, allowing plunge cuts into a surface.

Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Their extreme hardness means they are brittle, so a highly rigid setup, such as a CNC machine, is necessary to prevent the end mill from breaking. A titanium-aluminum-silicon-nitride (TiAlSiN) coating makes them extremely resistant to wear and diffusion because they have especially high hardness, even at high temperatures.

For Max. Hardness Rockwell C65 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mill Dia., mm | Shank Dia., mm | Lg. of Cut, mm | Corner Cut Radius, mm | Overall Lg., mm | Flute Spacing | Helix Angle | For Use On | End Mill Type | Each | |

Titanium Aluminum Silicon Nitride (TiAISiN) Coated | ||||||||||

4 Flute | ||||||||||

| 5 | 6 | 5 | 0.2 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 000000 |

| 5 | 6 | 5 | 0.5 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |

| 5 | 6 | 5 | 1 | 57 | Equal | 30° | Hardened Steel, Iron, Steel, Tool Steel | Center Cutting | 0000000 | 00000 |