About Exhaust Fans

More

About Sound Levels

Measured in decibels (dB), volume ratings indicate how much noise equipment makes. Some common volume levels include a whisper @ 20 dB, a refrigerator @ 40 dB, a conversation @ 60 dB, and a light machine shop @ 90 dB. OSHA recommends hearing protection for exposure to 80 dB and greater.

About Calculating the Airflow Required for Air Cleaning

More

Economy Wall-Mount Fans

Position these wall-mount fans to direct air where it’s needed. All of these fans have a direct-drive motor, which has fewer moving parts than belt-drive motors for less maintenance. They also have a totally enclosed motor enclosure, which can be used in dirty and dusty environments.

For technical drawings and 3-D models, click on a part number.

| Blade Dia. | Airflow, cfm | Volume | Motor Speed, rpm | No. of Speeds | Power, hp | Current, A | Cord Lg., ft. | Blade Material | Guard Material | Mount. Fasteners Included | Mount. Hole Dia. | Each | |

120V AC, Single Phase—Three Prong Plug | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Oscillating | |||||||||||||

| 20" | 4,100 | 63 dBA @ 15 ft. | 1,075 | 2 | 1/4 | 3.0 | 10 | Aluminum | Powder-Coated Steel | No | 3/8" | 00000000 | 0000000 |

Rack-Mount Fans

Mount these fans directly to a rack. They have a pivoting extension arm and tilting fan head, so you can direct air where it’s needed and move them out of the way when not in use.

For technical drawings and 3-D models, click on a part number.

| Blade Dia. | Arm Reach | Airflow, cfm | Volume | Motor Speed, rpm | No. of Speeds | Power, hp | Voltage (Current) | Cord Lg., ft. | Housing Material | Blade Material | Guard Material | Mounting Fasteners Included | Mounting Hole Dia. | Each | |

120V AC/240V AC, Single Phase—Three Prong Plug | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Non-Oscillating, Tilting | |||||||||||||||

| 18" | 17" | 3,800 | 68 dBA @ 15 ft. | 1,725 | 1 | 1/2 | 120V AC (6 A) 240V AC (3 A) | 12 | Powder-Coated Polypropylene Plastic | Galvanized Aluminum | Powder-Coated Steel | Yes | 9/16" | 0000000 | 000000000 |

| 22" | 19" | 5,500 | 69 dBA @ 15 ft. | 1,725 | 1 | 1/2 | 120V AC (6 A) 240V AC (3 A) | 12 | Powder-Coated Polypropylene Plastic | Galvanized Aluminum | Powder-Coated Steel | Yes | 9/16" | 0000000 | 00000000 |

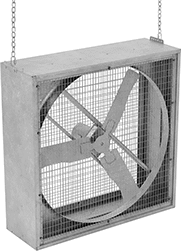

Hanging Box Fans

Easily hang these fans from your ceiling using the attached bracket and a mounting chain kit (sold separately). They're more powerful than our standard box fans. Made with a heavy duty 12-gauge welded wire mesh guard, these fans will stand up to tough environments. Plastic guard clips help reduce vibration between the housing and the guard, making these fans quieter. They require little maintenance thanks to their totally enclosed, high-efficiency motor and sealed ball bearings.

Direct-drive fans have fewer moving parts than belt-drive fans for less maintenance.

For technical drawings and 3-D models, click on a part number.

Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blade Dia. | Airflow, cfm | Motor Speed, rpm | No. of Speeds | Voltage (Current) | Power, hp | Ht. | Wd. | Dp. | Drive Type | Housing Material | Blade Material | Mounting Fasteners Included | Mounting Hole Dia. | Each | |

Single Phase—Hardwire | |||||||||||||||

Non-Oscillating | |||||||||||||||

| 36" | 9,600 | 850 | 1 | 120V AC (6.1 A) 240V AC (3 A) | 1/2 | 40 5/8" | 40 5/8" | 14 1/8" | Direct | Galvanized Steel | Steel | No | 3/8" | 0000000 | 0000000 |

Chains | ||||

|---|---|---|---|---|

| No. of | Lg. | Includes | Each | |

| 3 | 72" | Six Threaded Connecting Links, Three Eyebolts, Six Nuts for Eyebolts | 0000000 | 000000 |

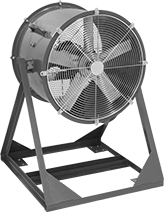

Hazardous Location Jet Stream Fans

UL listed for use in hazardous environments, these fans are often used to cool warehouse aisles and production lines. They generate a stream of air that travels farther than air from conventional fans. All fans have a totally enclosed motor enclosure, which can be used in dirty, dusty, and damp environments.Direct-drive fans have fewer moving parts than belt-drive fans for less maintenance.

Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blade Dia. | Airflow, cfm | Volume | Motor Speed, rpm | No. of Speeds | Power, hp | Current, A | Ht. | Wd. | Dp. | Fan Head Movement | Drive Type | Housing Material | Blade Material | Guard Material | Each | |

120/230V AC, Single Phase—Hardwire | ||||||||||||||||

| 18" | 4,000 | 76 dBA @ 10 ft. | 1,750 | 1 | 1/3 | 6.0/3.0 | 38" | 24" | 32" | Non-Oscillating | Direct | Steel | Aluminum | Steel | 0000000 | 000000000 |

230/460V AC, Three Phase—Hardwire | ||||||||||||||||

| 24" | 7,800 | 69 dBA @ 5 ft. | 1,750 | 1 | 1 | 3.0/1.5 | 41" | 30" | 32" | Non-Oscillating | Direct | Steel | Aluminum | Steel | 0000000 | 00000000 |

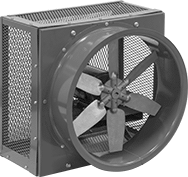

Hazardous Location Exhaust Fans

These fans have a motor that is UL listed for hazardous environments. Use them to draw stagnant and humid air out of a room or area.

Direct-drive fans have fewer moving parts than belt-drive fans for less maintenance. Add a collar (sold separately) to connect a wall-mount fan these fans to a louver.

For technical drawings and 3-D models, click on a part number.

Fans | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Collars | |||||||||||||||

| Blade Dia. | Airflow, cfm | Volume | Drive Type | Motor Speed, rpm | No. of Speeds | Power, hp | Ht. | Wd. | Dp. | Housing Material | Blade Material | Environmental Rating | Each | Each | ||

120/230V AC, Single Phase—Hardwire | ||||||||||||||||

| 16" | 2,800 | 61 dBA @ 15 ft. | Direct | 1,725 | 1 | 1/3 | 20 1/8" | 20 1/8" | 15" | Steel | Aluminum | NEC Class I Divisions 1, 2 Group D; NEC Class II Divisions 1, 2 Groups F, G | 0000000 | 000000000 | 0000000 | 0000000 |

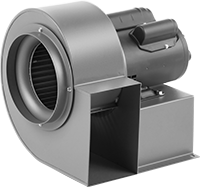

Blowers

These blowers install in ductwork similar to duct fans, but are for use where high static pressures are present. Use them for equipment cooling, material conveying, drying, ventilating, and exhausting. All blowers have an open dripproof motor enclosure for relatively clean, dry, indoor locations.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

For technical drawings and 3-D models, click on a part number.

Blowers | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Outlet | Overall | Replacement Wheels | ||||||||||||||||

| Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Ht. | Wd. | Inlet Dia. | Wheel Dia. | Ht. | Wd. | Dp. | Wt., lbs. | Temp. Range, °F | Mount. Fasteners Included | Mount. Hole Dia. | Each | Each | ||

With Rectangular Outlet and Round Inlet—Open Dripproof Motor Enclosure | ||||||||||||||||||

120/230V AC, Single Phase—Hardwire | ||||||||||||||||||

| 865 cfm @ 3/4 in. of H₂O 1,000 cfm @ 1/4 in. of H₂O | 50 dBA @ 15 ft. | 1,750 | 1/3 | 8 1/4" | 5 3/8" | 8" | 7 3/4" | 16 1/2" | 16 1/4" | 13 5/8" | 44 | -15° to 180° | No | 3/8" | 0000000 | 0000000 | 0000000 | 0000000 |

230/460V AC, Three Phase—Hardwire | ||||||||||||||||||

| 1,500 cfm @ 3/4 in. of H₂O 1,800 cfm @ 1/4 in. of H₂O | 55 dBA @ 15 ft. | 1,150 | 3/4 | 11 3/4" | 8" | 10" | 10 5/8" | 22 1/2" | 18 7/8" | 17 1/4" | 67 | -15° to 180° | No | 3/8" | 0000000 | 00000000 | 0000000 | 000000 |

Hazardous Location Spark-Resistant Blowers

These blowers have an explosion-proof motor that is UL listed for hazardous locations. They also have an aluminum housing for spark resistance. These blowers install in ductwork similar to duct fans, but are for use where high static pressures are present. Use them for equipment cooling, material conveying, drying, ventilating, and exhausting.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water. It is the responsibility of users in California to follow local energy efficiency regulations. Operating these blowers at a high airflow may violate these regulations.

For technical drawings and 3-D models, click on a part number.

Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Outlet Dia. | Inlet Dia. | Wheel Dia. | Ht. | Wd. | Dp. | Temp. Range, °F | Mount. Fasteners Included | Mount. Hole Dia. | Each | |

With Round Outlet and Inlet | ||||||||||||||

120/230V AC, Single Phase—Hardwire | ||||||||||||||

| 295 cfm @ 1 in. of H₂O 505 cfm @ 1/4 in. of H₂O | 55 dBA @ 15 ft. | 1,750 | 1/3 | 6" | 6" | 6 1/4" | 14 1/8" | 12 1/4" | 13 1/4" | 0° to 150° | No | 7/16" | 0000000 | 000000000 |

Hazardous Location Chemical-Resistant Blowers

These blowers have an explosion-proof motor that is UL listed and CSA certified for Class I, Divisions 1 and 2, Group D; and Class II, Divisions 1 and 2, Groups F and G hazardous locations. For resistance to chemicals as well as corrosion, they have a plastic housing. They install in ductwork similar to duct fans, but are for use where high static pressures are present. Use them for equipment cooling, material conveying, drying, ventilating, and exhausting. All blowers have a totally enclosed motor enclosure, which can be used in dirty, dusty, and damp environments.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

Fiberglass housing withstands organic chemicals, such as ammonia, antifreeze, and mineral oils.

For technical drawings and 3-D models, click on a part number.

Blowers | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Mounting | Replacement Wheels | |||||||||||||

| Airflow @ Static Pressure | Motor Speed, rpm | Power, hp | Outlet Dia. | Inlet Dia. | Wheel Dia. | Ht. | Wd. | Dp. | Housing Material | Fasteners Included | Hole Dia. | Each | Each | ||

120/230V AC, Single Phase—Hardwire | |||||||||||||||

| 810 cfm @ 1 in. of H₂O 960 cfm @ 1/2 in. of H₂O | 1,725 | 1/3 | 8" | 8" | 7" | 16 3/4" | 15 1/8" | 21 1/2" | Fiberglass | No | 3/8" | 0000000 | 000000000 | 0000000 | 0000000 |

Chemical-Resistant Blowers

For resistance to chemicals as well as corrosion, these blowers have a plastic housing. They install in ductwork similar to duct fans, but are for use where high static pressures are present. Use them for equipment cooling, material conveying, drying, ventilating, and exhausting. All blowers have a totally enclosed motor enclosure, which can be used in dirty, dusty, and damp environments.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

Fiberglass housing withstands organic chemicals, such as ammonia, antifreeze, and mineral oils.

For technical drawings and 3-D models, click on a part number.

Blowers | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Mounting | Replacement Wheels | ||||||||||||||

| Airflow @ Static Pressure | Motor Speed, rpm | Power, hp | Outlet Dia. | Inlet Dia. | Wheel Dia. | Ht. | Wd. | Dp. | Wt., lbs. | Housing Material | Fasteners Included | Hole Dia. | Each | Each | ||

120/230V AC, Single Phase—Hardwire | ||||||||||||||||

| 810 cfm @ 1 in. of H₂O 960 cfm @ 1/2 in. of H₂O | 1,725 | 1/3 | 8" | 8" | 7" | 16 3/4" | 15 1/8" | 18 1/2" | 53 | Fiberglass | No | 3/8" | 0000000 | 000000000 | 0000000 | 0000000 |

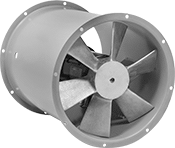

High-Output Direct-Drive Duct Fans

Produce three times the airflow as standard direct-drive duct fans. All of these direct-drive fans have fewer moving parts than belt-drive fans for less maintenance. Also known as axial duct fans, they install inline in ductwork for use as an exhaust, supply, or booster fan. All have a TEFC (totally enclosed fan cooled) motor enclosure, which can be used in dirty, dusty, and damp environments.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

Overall | Mounting | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Duct Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Dia. | Ht. | Dp. | Bolt Circle Dia. | Max. Temp., °F | Housing Material | Blade Material | Fasteners Included | For Screw Size | Hole Dia. | No. of Holes | Each | |

230/460V AC, Three Phase—Hardwire | |||||||||||||||||

| 18" | 3,900 cfm @ 3/8 in. of H₂O 4,500 cfm @ 1/8 in. of H₂O | 60 dBA @ 15 ft. | 1,750 | 3/4 | 20 1/16" | 20 1/16" | 20" | 19 1/8" | 100° | Steel | Aluminum | No | 3/8" | 7/16" | 8 | 0000000 | 000000000 |

| 24" | 4,900 cfm @ 3/8 in. of H₂O 5,800 cfm @ 1/8 in. of H₂O | 65 dBA @ 15 ft. | 1,750 | 3/4 | 26 11/16" | 26 11/16" | 21" | 25 13/16" | 100° | Steel | Aluminum | No | 3/8" | 7/16" | 8 | 0000000 | 00000000 |

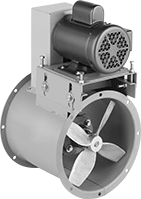

Belt-Drive Duct Fans

Belt-drive fans are quieter and have a longer life span than direct-drive fans because components can be replaced if worn or damaged. Also known as axial duct fans, these install inline in ductwork for use as an exhaust, supply, or booster fan. All fans have a totally enclosed motor enclosure, which can be used in dirty, dusty, and damp environments.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Duct Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Dia. | Ht. | Dp. | Max. Temp., °F | Housing Material | Blade Material | Mounting Fasteners Included | Mounting Hole Dia. | Each | |

230/460V AC, Three Phase—Hardwire | ||||||||||||||

| 18" | 4,400 cfm @ 3/8 in. of H₂O 4,800 cfm @ 1/8 in. of H₂O | 65 dBA @ 15 ft. | 2,150 | 1 | 20 1/16" | 30 3/16" | 12" | 175° | Steel | Aluminum | No | 7/16" | 0000000 | 000000000 |

| 36" | 13,300 cfm @ 3/8 in. of H₂O 15,200 cfm @ 1/8 in. of H₂O | 65 dBA @ 15 ft. | 1,000 | 2 | 39 1/4" | 49 1/4" | 16" | 175° | Steel | Aluminum | No | 7/16" | 0000000 | 00000000 |

Belt-Drive Corrosion-Resistant Duct Fans

A 304 stainless steel housing offers good corrosion resistance. All of these belt-drive fans are quieter and have a longer life span than direct-drive fans because components can be replaced if worn or damaged. They install inline in ductwork for use as an exhaust, supply, or booster fan. The fans have a totally enclosed motor enclosure, which can be used in dirty, dusty, and damp environments.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Duct Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Dia. | Ht. | Dp. | Max. Temp., °F | Housing Material | Blade Material | Mounting Fasteners Included | Mounting Hole Dia. | Each | |

230/460V AC, Three Phase—Hardwire | ||||||||||||||

| 24" | 7,200 cfm @ 3/8 in. of H₂O 7,900 cfm @ 1/8 in. of H₂O | 65 dBA @ 15 ft. | 1,700 | 2 | 26 11/16" | 38 3/4" | 21" | 200° | 304 Stainless Steel | Stainless Steel | No | 7/16" | 0000000 | 000000000 |

Direct-Drive Hazardous Location Duct Fans

These fans have an explosion-proof motor that is UL listed for Class I, Divisions 1 and 2, Group D; and Class II, Divisions 1 and 2, Groups F and G hazardous environments. All are direct-drive fans that have fewer moving parts than belt-drive fans for less maintenance. Also known as axial duct fans, they install inline in ductwork for use as an exhaust, supply, or booster fan. The fans have a TEFC (totally enclosed fan cooled) motor enclosure, which can be used in dirty, dusty, and damp environments.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Duct Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Dia. | Ht. | Dp. | Max.Temp., °F | Housing Material | Blade Material | Mounting Fasteners Included | Mounting Hole Dia. | Each | |

230/460V AC, Three Phase—Hardwire | ||||||||||||||

| 18" | 3,900 cfm @ 3/8 in. of H₂O 4,500 cfm @ 1/8 in. of H₂O | 60 dBA @ 15 ft. | 1,750 | 3/4 | 20 1/16" | 20 1/16" | 20" | 100° | Steel | Aluminum | No | 7/16" | 0000000 | 000000000 |

| 24" | 4,900 cfm @ 3/8 in. of H₂O 5,800 cfm @ 1/8 in. of H₂O | 65 dBA @ 15 ft. | 1,750 | 3/4 | 26 11/16" | 26 11/16" | 21" | 100° | Steel | Aluminum | No | 7/16" | 0000000 | 00000000 |

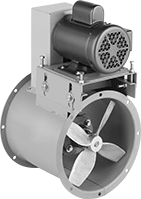

Belt-Drive Hazardous Location Duct Fans

These fans have an explosion-proof motor that is rated for hazardous environments. All are belt-drive fans that are quieter and have a longer life span than direct-drive fans because components can be replaced if worn or damaged. They install inline in ductwork for use as an exhaust, supply, or booster fan. Fans rated IP44 have a motor enclosure that's rated for protection in damp environments. UL and CSA standards apply to the motor.

Note: Airflow depends on the resistance created by ductwork. This resistance, known as static pressure (SP), is measured in inches of water.

Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Duct Dia. | Airflow @ Static Pressure | Volume | Motor Speed, rpm | Power, hp | Dia. | Ht. | Dp. | Max. Temp., °F | Housing Material | Blade Material | Mount. Fasteners Included | Mount. Hole Dia. | Each | |

230/460V AC, Three Phase—Hardwire | ||||||||||||||

| 18" | 4,400 cfm @ 3/8 in. of H₂O 4,800 cfm @ 1/8 in. of H₂O | 65 dBA @ 15 ft. | 2,150 | 1 | 20 1/16" | 30 3/16" | 12" | 175° | Steel | Aluminum | No | 7/16" | 0000000 | 000000000 |

Surface-Drying Fans

Dry large flat surfaces such as floors with a concentrated stream of air.

Outlet | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Airflow, cfm | Volume | Motor Speed, rpm | No. of Speeds | Power, hp | Current, A | Ht. | Wd. | Ht. | Wd. | Dp. | Cord Lg., ft. | Housing Material | Color | Each | |

120V AC, Single Phase—Three Prong Plug | ||||||||||||||||

Non-Oscillating | ||||||||||||||||

| A | 1,625 | 60 dBA @ 15 ft. | 1,075 | 3 | 2/5 | 3.0 | 4 1/4" | 15" | 20 5/8" | 20 7/8" | 17" | 25 | Plastic | Gray | 0000000 | 0000000 |

Bench-Top Air Cleaner Hoods

Filtering away dust and particles, these hoods create a clean space for demanding work, such as bioprocessing, pharmaceuticals, electronics, and optics. They have a HEPA H14 filter to catch 99.995% of particles down to 0.1 microns, as well as a pre-filter to pull out large particles before they reach the HEPA filter. To draw air from outside the hood into the filters, they have a fan; there’s no need to connect them to ductwork. A flow monitor tracks the airflow and alerts you with a visible and audible alarm if the fan fails. They meet Fed. Std. Class 100 and ISO Class 5 clean room requirements.

As an alternative to filtering the air of an entire room, these hoods leave a large enough opening for comfortable access inside and have internal fluorescent lighting to help you see your work. Their work surface is 304L stainless steel, which resists bacteria and chemicals, and also is easy to clean. Mount them on workbenches and carts that are designed to hold them, or place them on your own bench top.

For technical drawings and 3-D models, click on a part number.

Overall | Work Surface | Housing | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Airflow, cfm | Volume | Voltage | Current | Ht. | Wd. | Dp. | Wd. | Dp. | Material | Color | Panel Cutout Dia. | Environmental Rating | Each | |

304L Stainless Steel Work Surface with Acrylic Enclosure | ||||||||||||||

Hoods | ||||||||||||||

| 185 | 59 dBA @ 5 ft. | 120V AC | 3A | 47 3/4" | 31 3/4" | 24 1/4" | 26 1/2" | 20 1/2" | Plastic | Black, Blue, White | 2 7/8" | Fed. Std. Class 100, ISO Class 5 | 0000000 | 000000000 |

Overall | ||||||

|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Material | Wheel Configuration | Each | |

Mobile | ||||||

| 34 7/8" | 30 3/4" | 24 1/4" | Galvanized Steel | Four Swivel Casters (Two with Brakes) | 0000000 | 0000000 |

Portable Air Cleaners

Small enough to carry from job to job. Cleaners remove odors when paired with an optional odor-removal filter and an optional 1" prefilter.

Add duct (sold separately) to exhaust filtered air outside of the space that you are cleaning.

For Duct | Overall | Housing | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Airflow, cfm | Volume | Power, hp | Voltage | Current | Inlet Dia. | Outlet Dia. | Ht. | Wd. | Dp. | Material | Color | Includes | For Removing | Each | |

| 700 | 73 dBA @ 5 ft. | 1/2 | 120V AC | 3A | 14" | 14" | 23" | 26" | 17" | Plastic | Blue | Disposable HEPA Filter (Captures 99.97% of particles down to 0.3 microns), Disposable Prefilter | Dust and Particles, Odors and Fumes | 00000000 | 000000000 |

| Per Ft. | ||

| Blo-N-Vent Duct Hose | 0000000 | 000000 |