Filter by

Voltage

Airflow @ Static Pressure

Power Source

Maximum Flow Rate @ Pressure

Overall Height

Maximum Pressure

Motor Speed

Housing Material

Drive Type

Export Control Classification Number (ECCN)

Height

DFARS Specialty Metals

Direct-Drive Exhaust Fans

208V AC, Three Phase (Hardwire)—Open Dripproof (ODP) Motor Enclosure

Blade Dia. | Airflow @ SP | Volume (Sound) @ Distance | Drive Type | Motor Speed, rpm | No. of Speeds | Power, hp | Overall Ht. | Base Wd. | Max. Ambient Temp., ° F | Housing Material | Blade Material | Features | Specs. Met | Certification | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16" | 3,000 ft³/min @ 1/2 in. H₂O 3,500 ft³/min @ 0 in. H₂O | 71 dB @ 5 ft. | Direct | 1,650 | Variable | 1 1/2 | 59 3/4" | 32 5/8" | 350 | Steel | Aluminum | Grease Pan | UL 705, UL 762, ULC-S645 | ETL Listed | 4706N13 | 000000000 | |

| 19" | 3,800 ft³/min @ 1/2 in. H₂O 4,500 ft³/min @ 0 in. H₂O | 76 dB @ 5 ft. | Direct | 1,175 | Variable | 1 1/2 | 66 1/8" | 37 1/2" | 350 | Steel | Aluminum | Grease Pan | UL 705, UL 762, ULC-S645 | ETL Listed | 4706N14 | 00000000 | |

| 21" | 5,000 ft³/min @ 1/2 in. H₂O 5,500 ft³/min @ 0 in. H₂O | 77 dB @ 5 ft. | Direct | 1,275 | Variable | 3 | 71 7/8" | 38 1/4" | 350 | Steel | Aluminum | Grease Pan | UL 705, UL 762, ULC-S645 | ETL Listed | 4706N15 | 00000000 | |

| 25" | 5,500 ft³/min @ 1/2 in. H₂O 6,500 ft³/min @ 0 in. H₂O | 72 dB @ 5 ft. | Direct | 900 | Variable | 3 | 80 3/8" | 49 1/4" | 350 | Steel | Steel | Grease Pan | UL 705, UL 762, ULC-S645 | ETL Listed | 4706N16 | 00000000 | |

| 31" | 7,000 ft³/min @ 1/2 in. H₂O 8,500 ft³/min @ 0 in. H₂O | 72 dB @ 5 ft. | Direct | 675 | Variable | 5 | 85 7/8" | 52 1/4" | 350 | Steel | Steel | Grease Pan | UL 705, UL 762, ULC-S645 | ETL Listed | 4706N17 | 00000000 | |

| 37" | 12,000 ft³/min @ 1/2 in. H₂O 14,000 ft³/min @ 0 in. H₂O | 72 dB @ 5 ft. | Direct | 575 | Variable | 7 1/2 | 93 1/4" | 59" | 350 | Steel | Steel | Grease Pan | UL 705, UL 762, ULC-S645 | ETL Listed | 4706N18 | 00000000 |

Direct-Drive Downdraft Roof-Mount Exhaust Fans

Exhaust Fans | Mounting Bases | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Blade Dia. | Airflow @ SP | Volume (Sound) @ Distance | Motor Speed, rpm | Power, hp | Dia. | Ht. | Base Wd. | Wt., lb. | Ambient Temp., ° F | Housing Material | Certification | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open Dripproof (ODP) Motor Enclosure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

208/230V AC Three Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 19" | 4,500 ft³/min @ 1/2 in. H₂O 5,000 ft³/min @ 0 in. H₂O | 75 dBA @ 5 ft. | 1,300 | 2 | 38 15/16" | 32 3/4" | 28" | 189 | 120 | Aluminum | AMCA Certified, ETL Listed | 2011K23 | 000000000 | 2230K35 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 21" | 6,200 ft³/min @ 1/2 in. H₂O 6,700 ft³/min @ 0 in. H₂O | 82 dBA @ 5 ft. | 1,400 | 5 | 38 15/16" | 32 1/4" | 28" | 201 | 120 | Aluminum | AMCA Certified, ETL Listed | 2011K24 | 00000000 | 2230K35 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 24" | 8,100 ft³/min @ 1/2 in. H₂O 9,000 ft³/min @ 0 in. H₂O | 73 dBA @ 5 ft. | 925 | 3 | 43 7/16" | 37 1/4" | 33" | 288 | 120 | Aluminum | AMCA Certified, ETL Listed | 2011K25 | 00000000 | 2230K39 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 30" | 10,400 ft³/min @ 1/2 in. H₂O 11,500 ft³/min @ 0 in. H₂O | 69 dBA @ 5 ft. | 700 | 5 | 52 13/16" | 44" | 40" | 467 | 120 | Aluminum | AMCA Certified, ETL Listed | 2011K26 | 00000000 | 2230K94 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 36" | 11,000 ft³/min @ 1/2 in. H₂O 13,500 ft³/min @ 0 in. H₂O | 64 dBA @ 5 ft. | 450 | 5 | 63 5/16" | 49 1/2" | 44" | 532 | 120 | Aluminum | AMCA Certified, ETL Listed | 2011K27 | 00000000 | 2230K57 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

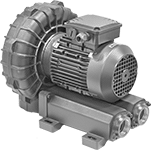

High-Flow Low-Pressure Compressed Air Blowers

Single Stage

Blowers | Air Intake Filters | Valves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Pipe Size | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Pressure | Max. Flow Rate @ Pressure | Vacuum Rating | Power, hp | Full Load Current @ Voltage | Volume (Sound) | Lg. | Wd. | Ht. | Temp. Range, ° F | Inlet | Outlet | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Phase, 120/208/230V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 psi 29 in. H₂O | 27 ft³/min @ 0 psi | 1.9 in. Hg 27 in. H₂O | 1/8 | 2.3 amp @ 115V AC 1.2 amp @ 208V AC 1.2 amp @ 230V AC | 57 dBA | 9" | 8" | 9" | 32 to 100 | 1 | 1 | 9960K51 | 0000000 | 9960K823 | 0000000 | 9960K821 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 psi 39 in. H₂O | 42 ft³/min @ 0 psi | 2.6 in. Hg 35 in. H₂O | 1/3 | 3.8 amp @ 115V AC 2 amp @ 208V AC 1.9 amp @ 230V AC | 63 dBA | 10" | 9" | 9" | 32 to 100 | 1 | 1 | 9960K52 | 00000000 | 9960K823 | 000000 | 9960K821 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 psi 52 in. H₂O | 156 ft³/min @ 0 psi | 3.8 in. Hg 51 in. H₂O | 2 | 19.7 amp @ 115V AC 10.6 amp @ 208V AC 9.9 amp @ 230V AC | 71 dB | 14" | 13" | 14" | 5 to 100 | 2 | 2 | 4393K51 | 00000000 | ——— | 0 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 42 in. H₂O | 52 ft³/min @ 0 psi | 3 in. Hg 40 in. H₂O | 1/2 | 6 amp @ 115V AC 3.2 amp @ 208V AC 3 amp @ 230V AC | 68 dBA | 13" | 10" | 10" | 32 to 100 | 1 1/4 | 1 1/4 | 9960K54 | 00000000 | 9960K824 | 000000 | 9960K821 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 52 in. H₂O | 92 ft³/min @ 0 psi | 3.5 in. Hg 48 in. H₂O | 1 | 9.8 amp @ 115V AC 5.2 amp @ 208V AC 4.9 amp @ 230V AC | 68 dBA | 13" | 11" | 12" | 32 to 100 | 1 1/2 | 1 1/2 | 9960K57 | 00000000 | 9960K825 | 000000 | 9960K821 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 65 in. H₂O | 127 ft³/min @ 0 psi | 4.4 in. Hg 60 in. H₂O | 1 1/2 | 17.5 amp @ 115V AC 10 amp @ 208V AC 9 amp @ 230V AC | 74 dBA | 16" | 13" | 14" | 32 to 100 | 1 1/2 | 1 1/2 | 9960K58 | 00000000 | 9960K825 | 000000 | 9960K821 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Phase, 208/230/460V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 43 in. H₂O | 53 ft³/min @ 0 psi | 2.9 in. Hg 40 in. H₂O | 1/2 | 2 amp @ 208V AC 2 amp @ 230V AC 1 amp @ 460V AC | 68 dBA | 11" | 10" | 10" | 32 to 100 | 1 1/4 | 1 1/4 | 9960K45 | 00000000 | 9960K824 | 000000 | 9960K821 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 52 in. H₂O | 92 ft³/min @ 0 psi | 3.5 in. Hg 48 in. H₂O | 1 | 3.4 amp @ 208V AC 3.2 amp @ 230V AC 1.6 amp @ 460V AC | 68 dBA | 13" | 11" | 12" | 32 to 100 | 1 1/2 | 1 1/2 | 9960K56 | 00000000 | 9960K825 | 000000 | 9960K821 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 65 in. H₂O | 127 ft³/min @ 0 psi | 4.4 in. Hg 60 in. H₂O | 1 1/2 | 5.1 amp @ 208V AC 4.9 amp @ 230V AC 2.5 amp @ 460V AC | 74 dBA | 14" | 13" | 14" | 32 to 100 | 1 1/2 | 1 1/2 | 9960K59 | 00000000 | 9960K825 | 000000 | 9960K821 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Phase, 208/230/460V AC (Inverter Rated) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 psi 52 in. H₂O | 156 ft³/min @ 0 psi | 3.8 in. Hg 51 in. H₂O | 2 | 5.7 amp @ 208V AC 5.7 amp @ 230V AC 2.8 amp @ 460V AC | 71 dB | 14" | 13" | 14" | 5 to 100 | 2 | 2 | 4393K52 | 00000000 | ——— | 0 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 80 in. H₂O | 156 ft³/min @ 0 psi | 6.6 in. Hg 89 in. H₂O | 3 | 8.2 amp @ 208V AC 8.3 amp @ 230V AC 4.1 amp @ 460V AC | 71 dB | 14" | 13" | 14" | 5 to 100 | 2 | 2 | 4393K53 | 00000000 | ——— | 0 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 psi 110 in. H₂O | 216 ft³/min @ 0 psi | 8.1 in. Hg 110 in. H₂O | 5 1/2 | 14.6 amp @ 208V AC 15.1 amp @ 230V AC 7.5 amp @ 460V AC | 74 dB | 15" | 15" | 15" | 5 to 100 | 2 | 2 | 4393K54 | 00000000 | ——— | 0 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 psi 105 in. H₂O | 207 ft³/min @ 0 psi | 6.5 in. Hg 88 in. H₂O | 5 | 13 amp @ 208V AC 12 amp @ 230V AC 6 amp @ 460V AC | 72 dBA | 19" | 15" | 15" | 32 to 100 | 2 | 2 | 9960K63 | 00000000 | 9960K826 | 000000 | 9960K821 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 psi 110 in. H₂O | 265 ft³/min @ 0 psi | 6.6 in. Hg 90 in. H₂O | 6 | 16 amp @ 208V AC 15 amp @ 230V AC 7.5 amp @ 460V AC | 79 dBA | 17" | 17" | 18" | 32 to 100 | 2 | 2 | 9960K64 | 00000000 | 9960K826 | 000000 | 9960K821 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 psi 110 in. H₂O | 307 ft³/min @ 0 psi | 8.9 in. Hg 121 in. H₂O | 7 1/2 | 19.8 amp @ 208V AC 19.5 amp @ 230V AC 9.7 amp @ 460V AC | 75 dBA | 22" | 18" | 19" | 5 to 100 | 3 | 3 | 4393K85 | 00000000 | ——— | 0 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 psi 125 in. H₂O | 420 ft³/min @ 0 psi | 8.1 in. Hg 110 in. H₂O | 10 | 35 amp @ 208V AC 29.5 amp @ 230V AC 15 amp @ 460V AC | 78 dBA | 22" | 18" | 20" | 32 to 100 | 2 1/2 | 2 1/2 | 9960K65 | 00000000 | 9960K827 | 000000 | 9960K821 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two Stage

Blowers | Valves | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Pipe Size | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Pressure | Max. Flow Rate @ Pressure | Vacuum Rating | Power, hp | Full Load Current @ Voltage | Volume (Sound) | Lg. | Wd. | Ht. | Temp. Range, ° F | Inlet | Outlet | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Phase, 120/208/230V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 psi 98 in. H₂O | 35 ft³/min @ 0 psi | 7.2 in. Hg 97 in. H₂O | 3/4 | 8.3 amp @ 115V AC 4.1 amp @ 208V AC 4.2 amp @ 230V AC | 64 dB | 14" | 10" | 11" | 5 to 100 | 3/4 | 3/4 | 4393K56 | 000000000 | 4393K41 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 psi 120 in. H₂O | 35 ft³/min @ 0 psi | 8.1 in. Hg 110 in. H₂O | 1 | 9.4 amp @ 115V AC 5.5 amp @ 208V AC 5 amp @ 230V AC | 64 dB | 16" | 10" | 11" | 5 to 100 | 3/4 | 3/4 | 4393K58 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 psi 140 in. H₂O | 65 ft³/min @ 0 psi | 11.1 in. Hg 151 in. H₂O | 2 | 19.7 amp @ 115V AC 10.6 amp @ 208V AC 9.9 amp @ 230V AC | 72 dB | 15" | 13" | 14" | 5 to 100 | 1 1/4 | 1 1/4 | 4393K63 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 psi 141 in. H₂O | 81 ft³/min @ 0 psi | 11.1 in. Hg 151 in. H₂O | 3 | 29.4 amp @ 115V AC 16.6 amp @ 208V AC 14.8 amp @ 230V AC | 73 dB | 15" | 14" | 15" | 5 to 100 | 1 1/4 | 1 1/4 | 4393K65 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 psi 161 in. H₂O | 41 ft³/min @ 0 psi | 10.3 in. Hg 140 in. H₂O | 1 1/2 | 14.6 amp @ 115V AC 7.6 amp @ 208V AC 7.3 amp @ 230V AC | 69 dB | 14" | 11" | 12" | 5 to 100 | 1 1/4 | 1 1/4 | 4393K61 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Phase, 208/230/460V AC (Inverter Rated) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 psi 98 in. H₂O | 35 ft³/min @ 0 psi | 7.2 in. Hg 97 in. H₂O | 3/4 | 2.3 amp @ 208V AC 2.2 amp @ 230V AC 1.3 amp @ 460V AC | 64 dB | 14" | 10" | 11" | 5 to 100 | 3/4 | 3/4 | 4393K57 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 psi 120 in. H₂O | 35 ft³/min @ 0 psi | 8.1 in. Hg 110 in. H₂O | 1 | 2.9 amp @ 208V AC 2.9 amp @ 230V AC 1.4 amp @ 460V AC | 64 dB | 16" | 10" | 11" | 5 to 100 | 3/4 | 3/4 | 4393K59 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 psi 140 in. H₂O | 65 ft³/min @ 0 psi | 11.1 in. Hg 151 in. H₂O | 2 | 5.8 amp @ 208V AC 5.2 amp @ 230V AC 2.8 amp @ 460V AC | 72 dBA | 16" | 13" | 14" | 5 to 100 | 1 1/4 | 1 1/4 | 4393K47 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 psi 140 in. H₂O | 147 ft³/min @ 0 psi | 11.8 in. Hg 160 in. H₂O | 5 1/2 | 14.6 amp @ 208V AC 15.1 amp @ 230V AC 7.5 amp @ 460V AC | 77 dBA | 17" | 18" | 19" | 5 to 100 | 2 | 2 | 4393K87 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 psi 141 in. H₂O | 81 ft³/min @ 0 psi | 11.1 in. Hg 151 in. H₂O | 3 | 8.3 amp @ 208V AC 7.4 amp @ 230V AC 4 amp @ 460V AC | 73 dBA | 16" | 14" | 15" | 5 to 100 | 1 1/4 | 1 1/4 | 4393K38 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 psi 161 in. H₂O | 41 ft³/min @ 0 psi | 10.3 in. Hg 140 in. H₂O | 1 1/2 | 4.3 amp @ 208V AC 4.3 amp @ 230V AC 2.1 amp @ 460V AC | 69 dB | 14" | 11" | 12" | 5 to 100 | 1 1/4 | 1 1/4 | 4393K62 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 psi 191 in. H₂O | 65 ft³/min @ 0 psi | 11.1 in. Hg 151 in. H₂O | 3 | 8.2 amp @ 208V AC 8.3 amp @ 230V AC 4.1 amp @ 460V AC | 73 dB | 15" | 13" | 14" | 5 to 100 | 1 1/4 | 1 1/4 | 4393K64 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 psi 201 in. H₂O | 81 ft³/min @ 0 psi | 11.1 in. Hg 151 in. H₂O | 4 | 10.9 amp @ 208V AC 11.1 amp @ 230V AC 5.5 amp @ 460V AC | 73 dB | 15" | 14" | 15" | 5 to 100 | 1 1/4 | 1 1/4 | 4393K66 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 psi 200 in. H₂O | 177 ft³/min @ 0 psi | 13.3 in. Hg 180 in. H₂O | 10 | 26.1 amp @ 208V AC 25 amp @ 230V AC 12.5 amp @ 460V AC | 78 dBA | 19 1/2" | 19" | 20" | 5 to 100 | 2 | 2 | 4393K89 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 psi 220 in. H₂O | 147 ft³/min @ 0 psi | 13.3 in. Hg 180 in. H₂O | 7 1/2 | 19.8 amp @ 208V AC 19.5 amp @ 230V AC 9.7 amp @ 460V AC | 78 dBA | 18" | 18" | 19" | 5 to 100 | 2 | 2 | 4393K88 | 00000000 | 4393K41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

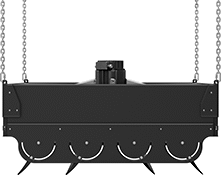

Low-Profile Direct-Drive Ceiling-Mount Fans

Fans with Totally Enclosed Motor Enclosure

Blade | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Material | Airflow | Volume | Motor Speed, rpm | No. of Speeds | Power, hp | Current | Ht. | Wd. | Dp. | Drive Type | Housing Material | Enclosure Rating | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

190/208/240V AC, Three Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Non-Oscillating Fan | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58" | Plastic | 40,100 ft³/min | Not Rated | 600 | 1 | 3 | 10.9 amp 11.7 amp 10.1 amp | 65 1/4" | 65 1/4" | 31" | Direct | Polyethylene | IP65 | Mounting Chain Kit | 4736N12 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Flow Low-Pressure Hazardous Location Compressed Air Blowers

Single Stage

Overall | Pipe Size | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Pressure | Max. Flow Rate @ Pressure | Vacuum Rating | Power, hp | Full Load Current @ Voltage | Volume (Sound), dBA | Lg. | Wd. | Ht. | Temp. Range, ° F | Inlet | Outlet | Hazardous Location Rating | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Phase, 208/230/460V AC (Inverter Rated) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 50 in. H₂O | 556 ft³/min @ 0 psi | 3.7 in. Hg 50 in. H₂O | 10 | 24.3 amp @ 208V AC 22.4 amp @ 230V AC 11.2 amp @ 460V AC | 81 | 25" | 20" | 22" | 5 to 100 | 4 | 4 | NEC Class I Divisions 1, 2 Group D NEC Class II Division 2 Groups F, G | 4393K74 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 60 in. H₂O | 471 ft³/min @ 0 psi | 4.4 in. Hg 59 in. H₂O | 10 | 24.3 amp @ 208V AC 22.4 amp @ 230V AC 11.2 amp @ 460V AC | 81 | 25" | 19" | 22" | 5 to 100 | 4 | 4 | NEC Class I Divisions 1, 2 Group D NEC Class II Division 2 Groups F, G | 4393K73 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 68 in. H₂O | 381 ft³/min @ 0 psi | 5 in. Hg 67 in. H₂O | 7 1/2 | 18.9 amp @ 208V AC 17.8 amp @ 230V AC 8.9 amp @ 460V AC | 80 | 23" | 18" | 19" | 5 to 100 | 3 | 3 | NEC Class I Divisions 1, 2 Group D NEC Class II Division 2 Groups F, G | 4393K72 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 psi 116 in. H₂O | 294 ft³/min @ 0 psi | 8.8 in. Hg 119 in. H₂O | 7 1/2 | 18.9 amp @ 208V AC 17.8 amp @ 230V AC 8.9 amp @ 460V AC | 80 | 23" | 16" | 19" | 5 to 100 | 3 | 3 | NEC Class I Divisions 1, 2 Group D NEC Class II Division 2 Groups F, G | 4393K71 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two Stage

Overall | Pipe Size | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Pressure | Max. Flow Rate @ Pressure | Vacuum Rating | Power, hp | Full Load Current @ Voltage | Volume (Sound), dBA | Lg. | Wd. | Ht. | Temp. Range, ° F | Inlet | Outlet | Hazardous Location Rating | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Phase, 208/230/460V AC (Inverter Rated) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 psi 110 in. H₂O | 220 ft³/min @ 0 psi | 8.1 in. Hg 110 in. H₂O | 7 1/2 | 18.9 amp @ 208V AC 17.8 amp @ 230V AC 8.9 amp @ 460V AC | 78 | 27" | 19" | 22" | 5 to 100 | 4 | 4 | NEC Class I Divisions 1, 2 Group D NEC Class II Division 2 Groups F, G | 4393K77 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 psi 115 in. H₂O | 274 ft³/min @ 0 psi | 8.5 in. Hg 115 in. H₂O | 10 | 24.3 amp @ 208V AC 22.4 amp @ 230V AC 11.2 amp @ 460V AC | 81 | 27" | 20" | 22" | 5 to 100 | 4 | 4 | NEC Class I Divisions 1, 2 Group D NEC Class II Division 2 Groups F, G | 4393K78 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 psi 150 in. H₂O | 167 ft³/min @ 0 psi | 11 in. Hg 149 in. H₂O | 7 1/2 | 18.9 amp @ 208V AC 17.8 amp @ 230V AC 8.9 amp @ 460V AC | 77 | 23" | 18" | 19" | 5 to 100 | 2 | 2 | NEC Class I Divisions 1, 2 Group D NEC Class II Division 2 Groups F, G | 4393K76 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 psi 240 in. H₂O | 128 ft³/min @ 0 psi | 11.9 in. Hg 161 in. H₂O | 7 1/2 | 18.9 amp @ 208V AC 17.8 amp @ 230V AC 8.9 amp @ 460V AC | 75 | 27" | 16" | 19" | 5 to 100 | 2 | 2 | NEC Class I Divisions 1, 2 Group D NEC Class II Division 2 Groups F, G | 4393K75 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

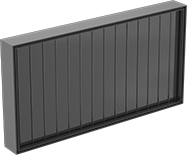

Oil- and Coolant-Removing Air Purifiers

Purifiers | Replacement Filters | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | ||||||||||||||||||||

Airflow, ft³/min | Volume (Sound) @ Distance | Power, hp | Voltage | Current | For Inlet Duct Dia. | Ht. | Wd. | Dp. | Mounting Fasteners Included | Mounting Hole Dia. | Housing Material | No. of Speeds | Includes | For Removing | Cannot Be Sold To | Each | Each | |||

| 165 | 56 dB @ 15 ft. | 1/2 | 208V AC 240V AC 460V AC | 1.1 amp 2.2 amp 2.4 amp | 4" | 19" | 15" | 15" | No | 9/16" | Steel | 1 | Disposable Filter (Captures 98% of mist particles down to 1 micron) | Oil, Coolant | — | 2210K1 | 000000000 | 2210K14 | 000000 | |

| 380 | 58 dB @ 15 ft. | 1 | 208V AC 240V AC 460V AC | 2.1 amp 4.2 amp 4.6 amp | 4" | 21" | 17" | 22" | No | 9/16" | Steel | 1 | Disposable Filter (Captures 98% of mist particles down to 1 micron) | Oil, Coolant | California | 2210K3 | 00000000 | 2210K15 | 00000 | |

| 1,000 | 60 dB @ 15 ft. | 3 | 208V AC 240V AC 460V AC | 4.8 amp 9.6 amp 10.6 amp | 6" | 23" | 21" | 22" | No | 9/16" | Steel | 1 | Disposable Filter (Captures 98% of mist particles down to 1 micron) | Oil, Coolant | California | 2210K6 | 00000000 | 2210K16 | 00000 | |