Filter by

Food Industry Standard

Environment

Flow Rate

Housing Material

Wetted Parts Material

Discharge Connection

Discharge Connection Port

Maximum Flow Rate

For Drum Opening Pipe Size

Air Pressure

Intake Tube Material

Intake Connection

Impeller Material

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Air-Powered Drum Pumps for Food and Beverage

Temp., ° F | Intake | Discharge (Pump Body) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Connection | For Tube ID | Gender | Food Industry Std. | Each | |||

| 32 | 55 | 1,200 | -30 | 210 | 43 to 85 | 29 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 5/8" | 39" | Pump Body | Barbed | 1" | Male | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600 | 00000000 | 000000000 | ||

Drum Pumps for Food and Beverage

|  |  |  | |

Style A | Style B | Style C | Style D | Style E |

Temp., ° F | Intake | Discharge | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Tube ID | Tube Lg. | Tube Material | Drum Pump Type | Food Industry Std. | Choose a Strap Color | Each | |||

| A | 1 | 1 | 10,000 | 0 | 140 | 38 mm | Drum Connector | 1/4" | 6 1/2" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 177.1520 | — | 0000000 | 00000 | ||

| A | 1 | 5 | 10,000 | 0 | 140 | 38 mm | Drum Connector | 1/4" | 15" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 177.1520 | — | 0000000 | 0000 | ||

| B | 12 | 5 | 8,800 | 35 | 140 | 2 NPT | 5 Gallon Pail Adapter, Drum Connector | 1 5/8" | 16 1/2" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | White | 0000000 | 00000 | ||

| B | 15 | 5 | 8,800 | 40 | 120 | 2 NPT | 5 Gallon Pail Adapter, Drum Connector | 1 1/2" | 16 1/2" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | Black , Blue | 00000000 | 00000 | ||

| B | 15 | 15, 30 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 30" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | Green | 0000000 | 00000 | ||

| B | 15 | 30 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 11/16" | 30" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | White | 0000000 | 00000 | ||

| B | 15 | 55 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 36" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | Black , Blue , Green , Orange , Purple | 00000000 | 00000 | ||

| B | 15 | 55 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 11/16" | 45" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | White | 0000000 | 00000 | ||

| C | 12 | 5 | 8,800 | 35 | 140 | 2 NPT | 5 Gallon Pail Adapter, Drum Connector | 1 5/8" | 16 1/2" | Tube End | 3/4" | 33" | PVC | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | White | 0000000 | 00000 | ||

| C | 15 | 55 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 36" | Tube End | 3/4" | 32 1/2" | PVC | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | Black , Blue , Yellow | 00000000 | 00000 | ||

| D | 15 | 275 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 46 1/2" | Spout End | — | — | — | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | — | 0000000 | 000000 | ||

| E | 15 | 15, 30 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 30" | Tube End | 3/4" | 32 1/2" | PVC | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | — | 0000000 | 00000 | ||

| E | 15 | 55 | 8,800 | 40 | 120 | 2 NPT | Drum Connector | 1 1/2" | 36" | Tube End | 3/4" | 32 1/2" | PVC | Plunger | FDA Compliant 21 CFR 174.5, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297, FDA Compliant 21 CFR 178.3400 | — | 0000000 | 00000 | ||

Air-Powered Drum Pumps with Sanitary Quick-Clamp Fittings for Food and Beverage

Temp., ° F | Intake | Discharge | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Connection | For Tube OD | Food Industry Std. | Each | |||

| 2.5 | 55 | 25,000 | 35 | 180 | 100 | 6 | 2 NPT | Drum Connector | 3/8 Female NPT | 2" | 37 1/2" | Pump Body | Quick Clamp | 1" | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 000000 | 000000000 | ||

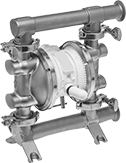

Air-Powered Double Diaphragm Pumps for Food and Beverage

Quick Clamp Bottom/Top Intake and Quick Clamp Bottom/Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 40 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity, cP | Air Consumption, ft³/min | Air Connection Size | For Intake Tube OD | For Discharge Tube OD | Lg. | Wd. | Ht. | Food Industry Std. | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

227 ft. Maximum Feet of Head—100 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 16 | 12 | 9 | 3/32" | 5,000 | 28 | 1/4 Female NPT | 1" | 1" | 7" | 11" | 13" | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick Clamp Bottom Intake and Quick Clamp Top Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | @ 40 ft. of Head | @ 120 ft. of Head | @ 160 ft. of Head | Max. Solids Dia. | Max. Viscosity, cP | Air Consumption, ft³/min | Air Connection Size | For Intake Tube OD | For Discharge Tube OD | Lg. | Wd. | Ht. | Food Industry Std. | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

227 ft. Maximum Feet of Head—100 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41 | 40 | 30 | 23 | 1/8" | 10,000 | 50 | 1/2 Female NPT | 1 1/2" | 1 1/2" | 8" | 16" | 16" | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 90 | 68 | 51 | 3/16" | 10,000 | 130 | 1/2 Female NPT | 2" | 2" | 10" | 20" | 20" | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||