Material Handling Chutes

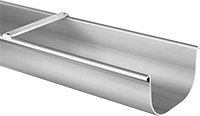

Let gravity move your material from one area to another by connecting these chutes to conveyors and other machinery. Originally designed for cement trucks, the extruded aluminum construction makes chutes both strong and lightweight. Chutes can be cut to shorter lengths.

Flared chutes have a wide opening to prevent material from jamming.

Wall-Mount Bulk Dispensers

Pull the handle to dispense bulk material quickly through a gravity-fed, wide-mouth opening.

Dispensing Opening | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., lbs. | Wd. | Dp. | Ht. | Wd. | Dp. | Material | Color | Mounting Fasteners Included | Includes | Each | |

| 40 | 16" | 10" | 25" | 4" | 4 3/4" | Polyethylene Plastic | Black | Yes | Dispensing Cup | 0000000 | 000000 |

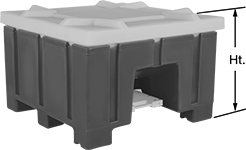

Food Industry Bulk Dispensers

FDA compliant for direct contact with food, these dispensers are often used to store or quickly dispense dry ingredients in food and pharmaceutical plants. Made of durable polyethylene, which resists chemicals and corrosion, they have a smooth, seamless interior to minimize the space where bacteria can grow. They’re also lightweight, so you can easily move them, even when they are full.

These dispensers have an open top for easy filling and cleaning; they have a V-shaped bottom for easy dispensing. Pull the handle to open the slide gate and release the contents. The farther you pull the handle, the faster you will dispense the contents. Both dispensers fit into an included base, which creates a double wall to protect the bottom from damage. It also keeps the slide gate from accidentally opening. You can use a forklift or pallet jack to lift the base and move these dispensers around your plant. A removable lid keeps contaminants out of your ingredients.

When full, you can stack these dispensers two-high. Empty dispensers can be nested even higher to save more space.

| Cap., lbs. | Wd. | Dp. | Ht. | Dispensing Opening Dia. | Material | Color | Space Saving Features | Specifications Met | Includes | Each | |

| 2,000 | 44" | 44" | 31" | 10" | Polyethylene Plastic | Blue/White | Nestable | FDA Compliant 21 CFR 177.1520 | 24" × 13" Slide Gate, Removable Lid | 0000000 | 000000000 |

| 2,000 | 44" | 44" | 50" | 10" | Polyethylene Plastic | Blue/White | Nestable | FDA Compliant 21 CFR 177.1520 | 24" × 13" Slide Gate, Removable Lid | 0000000 | 00000000 |

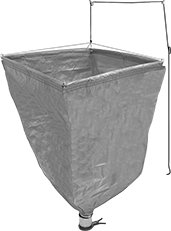

Foam Peanut Dispensers

Guide peanuts into a shipping container. A valve controls the flow.

Dispenser | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cap., cu. ft. | Wd. | Ht. | Mounting Location | Min. Ceiling Ht., ft. | Mounting Fasteners Included | Includes | Each | |

| 30 | 40" | 69" | Ceiling | 10 | No | Bag with Frame, Pulleys, Rope, Valve, 6" ID × 1 ft. Lg. Flexible Tube | 00000000 | 0000000 |

Gravity-Feed Bin Boxes

The sloped bottom of the picking bin allows parts to flow forward while the shallow-angle lip makes them easily accessible.

Add up to two feeding bins on top. They have an adjustable front panel and adjustment screw to control the amount of material that flows into the picking box.

| Wd. | Dp. | Ht. | Cap., lbs. | Material | Space Saving Features | Color | Each | |

Picking Bins | ||||||||

|---|---|---|---|---|---|---|---|---|

| 4 1/2" | 8" | 2 1/2" | 25 | Painted Steel | __ | Green | 0000000 | 000000 |

| 6 1/2" | 12" | 4" | 25 | Painted Steel | __ | Green | 0000000 | 00000 |

| 11 1/2" | 12" | 4" | 25 | Painted Steel | __ | Green | 0000000 | 00000 |

Feeding Bins | ||||||||

| 4 1/2" | 6" | 5 1/4" | Not Rated | Painted Steel | Stackable | Green | 0000000 | 00000 |

| 6 1/2" | 9 1/2" | 8 1/2" | Not Rated | Painted Steel | Stackable | Green | 0000000 | 00000 |

| 11 1/2" | 9 1/2" | 8 1/2" | Not Rated | Painted Steel | Stackable | Green | 0000000 | 00000 |