How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Sleeves for Nickel-Plated Brass Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Lubricants, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 550° F

- Tubing: Use with copper

- Specifications Met: DIN 3861

Use these sleeves with compression nuts and fittings to create a strong seal on copper tubing. Made of brass, they gently bite into tubing as you tighten the nut, and have good corrosion resistance. All meet DIN 3861, which is an international standard for tube fitting dimensions.

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Sleeve Material | Maximum Pressure | Each | |

| 4 | 1 | Brass | 1,800 psi @ 72° F | 00000000 | 00000 |

| 6 | 1 | Brass | 2,500 psi @ 72° F | 00000000 | 000 |

| 8 | 1 | Brass | 2,100 psi @ 72° F | 00000000 | 000 |

| 10 | 1 | Brass | 1,600 psi @ 72° F | 00000000 | 000 |

| 12 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

| 14 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

| 15 | 1 | Brass | 1,000 psi @ 72° F | 00000000 | 000 |

Nuts for Nickel-Plated Brass Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Lubricants, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 550° F

- Tubing: Use with copper

- Specifications Met: DIN 3870

Create a strong seal on copper tubing when you couple these nuts with compression sleeves and fittings. Made of nickel-plated brass, they resist corrosion better than plain brass. All meet DIN 3870, which is an international standard for tube fitting dimensions.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Maximum Pressure | Length, mm | Each | |

Short Nuts | ||||||

| 4 | 1 | Nickel-Plated Brass | 1,800 psi @ 72° F | 11 | 00000000 | 00000 |

| 6 | 1 | Nickel-Plated Brass | 2,500 psi @ 72° F | 12 | 00000000 | 000 |

| 8 | 1 | Nickel-Plated Brass | 2,100 psi @ 72° F | 12 | 00000000 | 000 |

| 10 | 1 | Nickel-Plated Brass | 1,600 psi @ 72° F | 16 | 00000000 | 0000 |

| 12 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 16 | 00000000 | 0000 |

| 14 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 19 | 00000000 | 0000 |

| 15 | 1 | Nickel-Plated Brass | 1,000 psi @ 72° F | 17 | 00000000 | 0000 |

Sleeves for Vibration-Resistant Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Lubricants, Mineral Oil, Water

- Temperature Range: -30° to 270° F, except fluoroelastomer rubber sleeves are -15° to 450° F

- Tubing: Use with copper

Use these sleeves with vibration-resistant compression nuts and fittings. They are rubber instead of metal, so they cushion the tubing and absorb vibration while creating a tight seal. They are also known as ferrules.

| For Tube OD | Sleeve Color | Max. Pressure | Each | |

Buna-N Rubber | ||||

|---|---|---|---|---|

| 1/8" | Black with Green Stripe | 300 psi @ 72° F | 00000000 | 00000 |

| 3/16" | Black with Green Stripe | 300 psi @ 72° F | 00000000 | 0000 |

| 1/4" | Black with Green Stripe | 300 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Black with Green Stripe | 220 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Black with Green Stripe | 170 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Black with Green Stripe | 100 psi @ 72° F | 00000000 | 0000 |

Fluoroelastomer Rubber | ||||

| 3/16" | Black with Red Stripe | 300 psi @ 72° F | 00000000 | 00000 |

| 1/4" | Black with Red Stripe | 300 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Black with Red Stripe | 220 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Black with Red Stripe | 170 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Black with Red Stripe | 100 psi @ 72° F | 00000000 | 00000 |

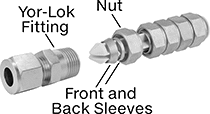

Front and Back Sleeves for Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on copper tubing. Sleeves are brass for good corrosion resistance. They are also known as ferrules.

Sleeves with a dispenser come with 10 sets of front and back sleeves. Rather than stacking sleeves in your hand, the dispenser stages them for quick alignment with your Yor-Lok fitting. Insert the dispenser into the fitting, then slide the sleeves into place.

Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

| 1/16" | Brass | 3/32" | 1 | 1/16" | 1 | 5,400 psi @ 72° F | 00000000 | 00000 |

| 1/8" | Brass | 3/16" | 1 | 3/32" | 1 | 2,900 psi @ 72° F | 00000000 | 0000 |

| 3/16" | Brass | 3/16" | 1 | 3/32" | 1 | 2,300 psi @ 72° F | 00000000 | 0000 |

| 1/4" | Brass | 3/16" | 1 | 3/32" | 1 | 1,600 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Brass | 3/16" | 1 | 3/32" | 1 | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Brass | 3/16" | 1 | 3/32" | 1 | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Brass | 19/64" | 1 | 5/32" | 1 | 800 psi @ 72° F | 00000000 | 0000 |

| 5/8" | Brass | 19/64" | 1 | 5/32" | 1 | 900 psi @ 72° F | 00000000 | 00000 |

| 3/4" | Brass | 19/64" | 1 | 5/32" | 1 | 700 psi @ 72° F | 00000000 | 0000 |

| 7/8" | Brass | 9/32" | 1 | 5/32" | 1 | 1,100 psi @ 72° F | 00000000 | 00000 |

| 1" | Brass | 3/8" | 1 | 13/16" | 1 | 800 psi @ 72° F | 00000000 | 0000 |

| 6mm | Brass | 5mm | 1 | 3mm | 1 | 2,030 psi @ 72° F | 00000000 | 0000 |

| 8mm | Brass | 5mm | 1 | 3mm | 1 | 1,450 psi @ 72° F | 00000000 | 0000 |

| 10mm | Brass | 5mm | 1 | 3mm | 1 | 1,160 psi @ 72° F | 00000000 | 0000 |

| 12mm | Brass | 7mm | 1 | 4mm | 1 | 870 psi @ 72° F | 00000000 | 0000 |

Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

| 1/8" | Brass | 3/16" | 10 | 7/64" | 10 | 2,800 psi @ 72° F | 00000000 | 000000 |

| 3/16" | Brass | 3/16" | 10 | 7/64" | 10 | 1,800 psi @ 72° F | 00000000 | 00000 |

| 1/4" | Brass | 3/16" | 10 | 7/64" | 10 | 1,300 psi @ 72° F | 00000000 | 00000 |

| 5/16" | Brass | 3/16" | 10 | 7/64" | 10 | 1,300 psi @ 72° F | 00000000 | 00000 |

| 3/8" | Brass | 3/16" | 10 | 7/64" | 10 | 1,100 psi @ 72° F | 00000000 | 00000 |

| 1/2" | Brass | 19/64" | 10 | 9/64" | 10 | 1,200 psi @ 72° F | 00000000 | 00000 |

| 5/8" | Brass | 3/16" | 10 | 7/64" | 10 | 1,250 psi @ 72° F | 00000000 | 00000 |

| 3/4" | Brass | 9/32" | 10 | 5/32" | 10 | 1,000 psi @ 72° F | 00000000 | 00000 |

| 7/8" | Brass | 9/32" | 10 | 5/32" | 10 | 1,100 psi @ 72° F | 00000000 | 00000 |

| 1" | Brass | 9/32" | 10 | 5/32" | 10 | 1,000 psi @ 72° F | 00000000 | 000000 |

Sleeve and Nut Sets for Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each set includes a front sleeve, a back sleeve, and a nut. The sleeves are also known as ferrules.

Front Sleeve | Back Sleeve | Nut | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Includes | Each | |

| 1/8" | Brass | 3/16" | 5 | 7/64" | 5 | 15/32" | 5 | 2,800 psi @ 72° F | Dispenser | 0000000 | 000000 |

| 3/16" | Brass | 3/16" | 5 | 7/64" | 5 | 15/32" | 5 | 1,800 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 1/4" | Brass | 3/16" | 5 | 7/64" | 5 | 1/2" | 5 | 1,300 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 5/16" | Brass | 3/16" | 5 | 7/64" | 5 | 17/32" | 5 | 1,300 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 3/8" | Brass | 3/16" | 5 | 7/64" | 5 | 9/16" | 5 | 1,100 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 1/2" | Brass | 3/16" | 5 | 7/64" | 5 | 11/16" | 5 | 1,200 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 5/8" | Brass | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 1,250 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 3/4" | Brass | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 1,000 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 7/8" | Brass | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 1,100 psi @ 72° F | Dispenser | 0000000 | 000000 |

| 1" | Brass | 9/32" | 5 | 5/32" | 5 | 13/16" | 5 | 1,000 psi @ 72° F | Dispenser | 000000 | 000000 |

| 4mm | Brass | 5mm | 5 | 3mm | 5 | 12mm | 5 | 2,500 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 6mm | Brass | 5mm | 5 | 3mm | 5 | 13mm | 5 | 1,600 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 8mm | Brass | 5mm | 5 | 3mm | 5 | 14mm | 5 | 1,450 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 10mm | Brass | 5mm | 5 | 3mm | 5 | 15mm | 5 | 1,450 psi @ 72° F | Dispenser | 0000000 | 00000 |

| 12mm | Brass | 7mm | 5 | 4mm | 5 | 17mm | 5 | 1,150 psi @ 72° F | Dispenser | 0000000 | 00000 |

Front and Back Sleeves for Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Mineral Oil, Fuel Oil, Gasoline, Diesel Fuel, Cutting Oil, Hydraulic Fluid

- Temperature Range: -20° to 800° F

- Tubing: Use with seamless steel

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on steel tubing. They are also known as ferrules.

Zinc-plated steel sleeves have fair corrosion resistance. 316 stainless steel sleeves have excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Each | |

| 1/8" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 6,800 psi @ 72° F | 00000000 | 00000 |

| 3/16" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 6,700 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 4,850 psi @ 72° F | 00000000 | 0000 |

| 5/16" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 3,800 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 3,100 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 2,300 psi @ 72° F | 00000000 | 00000 |

| 5/8" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 1,800 psi @ 72° F | 00000000 | 00000 |

| 3/4" | 0.049" | Zinc-Plated Steel | 316 Stainless Steel | 2,150 psi @ 72° F | 00000000 | 00000 |

| 1" | 0.065" | Zinc-Plated Steel | 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 | 00000 |

| 2mm | 0.3mm | Zinc-Plated Steel | 316 Stainless Steel | 3,000 psi @ 72° F | 00000000 | 0000 |

| 3mm | 0.8mm | Zinc-Plated Steel | 316 Stainless Steel | 10,000 psi @ 72° F | 00000000 | 0000 |

| 4mm | 0.8mm | Zinc-Plated Steel | 316 Stainless Steel | 7,200 psi @ 72° F | 00000000 | 0000 |

| 6mm | 0.8mm | Zinc-Plated Steel | 316 Stainless Steel | 4,400 psi @ 72° F | 00000000 | 0000 |

| 8mm | 1mm | Zinc-Plated Steel | 316 Stainless Steel | 4,200 psi @ 72° F | 00000000 | 0000 |

| 10mm | 1mm | Zinc-Plated Steel | 316 Stainless Steel | 3,300 psi @ 72° F | 00000000 | 0000 |

| 12mm | 1mm | Zinc-Plated Steel | 316 Stainless Steel | 2,700 psi @ 72° F | 00000000 | 0000 |

| 15mm | 1.5mm | Zinc-Plated Steel | 316 Stainless Steel | 3,300 psi @ 72° F | 00000000 | 0000 |

| 16mm | 1.5mm | Zinc-Plated Steel | 316 Stainless Steel | 3,000 psi @ 72° F | 00000000 | 0000 |

| 18mm | 1.5mm | Zinc-Plated Steel | 316 Stainless Steel | 2,700 psi @ 72° F | 00000000 | 0000 |

Front and Back Sleeves for Ultra-Corrosion-Resistant

Yor-Lok Fittings for Nickel Alloy Tubing

- For Use With: Acetic Acid, Air, Bleach, Cutting Oil, Diesel Fuel, Formic Acid, Fuel Oil, Gasoline, Hydraulic Fluid, Iron Chlorides, Mineral Oil, Salt Water, Steam, Water

- Temperature Range: 0° to 1,000° F

- Tubing: Use with seamless soft C276 nickel

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these C276 nickel Hastelloy sleeves with Yor-Lok nuts and fittings to create a strong, leak-resistant seal. With the best corrosion resistance of any Yor-Lok sleeves we offer, they stand up to aggressive chemicals and resist pitting and cracking from stress. They are also known as ferrules.

Front and Back Sleeves for Acid-Resistant

Yor-Lok Fittings for Nickel Alloy Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydrofluoric Acid, Mineral Oil, Salt Water, Steam, Sulfuric Acid, Water

- Temperature Range: -325° to 900° F

- Tubing: Use with seamless soft 400 Nickel

- Specifications Met: ASTM B164

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these 400 nickel Monel sleeves with Yor-Lok nuts and fittings to create a strong, leak-resistant seal. They have the corrosion resistance to handle hydrofluoric and sulfuric acid. They are also known as ferrules.