Filter by

Backing Material

System of Measurement

Performance

Dynamic Radial Load Capacity @ Speed

P Max

Lubrication

Plain Bearing Type

For Housing ID

Bearing Material

For Load Direction

Shaft Mount Type

Maximum Temperature

Shaft Type

Minimum Temperature

REACH

DFARS Specialty Metals

Export Control Classification Number (ECCN)

RoHS

About Sleeve Bearings

Choose a sleeve bearing that matches your load and speed requirements and that's right for your environment.

Dry-Running Sleeve Bearings

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | For Housing ID | Lg. | Dynamic Radial Load Cap. @ Speed | Color | Temp. Range, ° F | 1-24 | 25-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extreme-Load Ultra-Chemical-Resistant Fiberglass-Backed PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/8" | 1/2" | 1,250 lb. @ 120 rpm | Gray | -55 to 280 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/8" | 1" | 2,500 lb. @ 120 rpm | Gray | -55 to 280 | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | 3/4" | 1,850 lb. @ 120 rpm | Gray | -55 to 280 | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | 1" | 2,500 lb. @ 120 rpm | Gray | -55 to 280 | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 7/8" | 3/4" | 3,750 lb. @ 60 rpm | Gray | -55 to 280 | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 7/8" | 1" | 5,050 lb. @ 60 rpm | Gray | -55 to 280 | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | 3/4" | 3,750 lb. @ 60 rpm | Gray | -55 to 280 | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | 1 1/4" | 6,300 lb. @ 60 rpm | Gray | -55 to 280 | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1" | 1" | 5,050 lb. @ 60 rpm | Gray | -55 to 280 | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1" | 5,050 lb. @ 60 rpm | Gray | -55 to 280 | 0000000 | 00000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1 1/2" | 7,550 lb. @ 60 rpm | Gray | -55 to 280 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 2" | 10,100 lb. @ 60 rpm | Gray | -55 to 280 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 1/2" | 2" | 20,200 lb. @ 30 rpm | Gray | -55 to 280 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 1/2" | 3" | 30,350 lb. @ 30 rpm | Gray | -55 to 280 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 3/4" | 2" | 20,200 lb. @ 30 rpm | Gray | -55 to 280 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 1 1/2" | 15,150 lb. @ 30 rpm | Gray | -55 to 280 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/4" | 3" | 30,350 lb. @ 30 rpm | Gray | -55 to 280 | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrically Insulating Linear Sleeve Bearings

Fixed Alignment

Bearings | Retaining Rings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

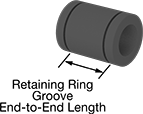

For Shaft Dia. | Shaft Clearance | Overall Lg. | OD | For Housing ID | With Retaining Ring Grooves | Retaining Ring Groove End-to-End Lg. | With End Seals | Dynamic Linear Load Cap. @ Speed | Static Load Cap., lb. | Min. | Max. | For Shaft Material | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE-Lined Fiberglass Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.001" | 1 1/4" | 7/8" | 0.8750" to 0.8755" | Yes | 0.975" | No | 150 lb. @ 100 fpm | 3,100 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.001" | 1 1/2" | 1 1/8" | 1.1250" to 1.1255" | Yes | 1.116" | No | 250 lb. @ 100 fpm | 4,600 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.001" | 1 5/8" | 1 1/4" | 1.2500" to 1.2505" | Yes | 1.178" | No | 350 lb. @ 100 fpm | 6,100 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.001" | 2 1/4" | 1 9/16" | 1.5625" to 1.5630" | Yes | 1.765" | No | 600 lb. @ 100 fpm | 11,000 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Skate Wheels

Wheel | Bearing | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Dia. | Wd. | Color | For Axle Dia. | Wt. Cap., lb. | Overall Wd. | Type | Material | Ball Bearing Material | Temp. Range, ° F | 1-9 | 10-99 | 100-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fiberglass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| K | 2 7/8" | 1 1/4" | Black | 5/16" | 330 | 1 5/8" | Ball | Steel | Steel | -40 to 250 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||