Filter by

Thread Size

Width

Wing Nut Profile

Thumb Nut Profile

Height

Thumb Nut Grip Type

Base Diameter

Color

Thread Fit

Export Control Classification Number (ECCN)

Container Features

Thumb Nut Grip Type

Hex Head

Twist on by hand, then crank with a wrench for an extra-tight fit

0 products

Environment

Sanitary

Free of crevices where bacteria can grow

0 products

Wing Nuts

Style 1 | Style 4 | Style 5 | Style 6 |

|  | ||

Style 7 | Style 8 | Style 9 |

The easiest nuts to twist on and off by hand, these are commonly used to fasten parts that need to be frequently disassembled, such as access panels and covers. The wings give you more leverage than knurled-head nuts, so you can apply greater torque and achieve a tighter fit.

Steel

Style 1 | Style 4 | Style 5 | Style 6 |

|  | ||

Style 7 | Style 8 | Style 9 |

Zinc-Plated Steel—A step up from plain steel, the zinc plating withstands occasional exposure to moisture.

Black Corrosion-Resistant-Coated Steel—Combines a finished appearance with the rust resistance of stainless steel. The coating has been tested to extreme standards, including 1,000 hours of salt spray resistance, to hold up in wet and outdoor environments. Also known as black luster.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Wd. | Ht. | Base Dia. | Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | 1-9 | 10-49 | 50-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 3/4" | 3/8" | 21/64" | — | — | 25 | 90866A005 | 000000 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 5/8" | 3/8" | 19/64" | — | — | 100 | 90866A007 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 7/8" | 1/2" | 13/32" | — | — | 100 | 90866A009 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 7/8" | 1/2" | 13/32" | — | — | 100 | 90866A011 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 7/8" | 1/2" | 13/32" | — | — | 100 | 90866A111 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12-24 | 1 1/8" | 1/2" | 31/64" | — | — | 25 | 90866A116 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/8" | 1/2" | 31/64" | — | — | 100 | 90866A029 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 1/8" | 1/2" | 31/64" | — | — | 100 | 90866A129 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/4" | 5/8" | 9/16" | — | — | 100 | 90866A030 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1 1/4" | 5/8" | 9/16" | — | — | 25 | 90866A130 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 3/8" | 3/4" | 11/16" | — | — | 50 | 90866A140 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1 1/2" | 3/4" | 45/64" | — | — | 10 | 90866A145 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-14 | 1 7/8" | 7/8" | 7/8" | — | — | 25 | 90866A150 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-20 | 2" | 1" | 15/16" | — | — | 5 | 90866A155 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 7/8" | 7/8" | 7/8" | — | — | 25 | 90866A160 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 2" | 1" | 15/16" | — | — | 5 | 90866A165 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2 3/4" | 1 3/8" | 1 5/32" | — | — | 5 | 90866A170 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2 3/4" | 1 3/8" | 1 5/32" | — | — | 5 | 90866A180 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 × 0.5 mm | 19.5 mm | 10 mm | 8 mm | ISO Class 5 | — | 25 | 94300A120 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 × 0.7 mm | 17.6 mm | 8.6 mm | 8 mm | ISO Class 5 | DIN 315 | 50 | 94300A310 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 22.5 mm | 11 mm | 10.3 mm | ISO Class 5 | DIN 315 | 25 | 94300A320 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 27.8 mm | 13.6 mm | 12.7 mm | ISO Class 5 | DIN 315 | 25 | 94300A330 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 30.3 mm | 14.8 mm | 13.8 mm | ISO Class 5 | DIN 315 | 20 | 94300A340 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 36.2 mm | 17.7 mm | 16.5 mm | ISO Class 5 | DIN 315 | 10 | 94300A350 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 49.4 mm | 24.1 mm | 22.5 mm | ISO Class 5 | DIN 315 | 5 | 94300A360 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 × 0.7 mm | 20 mm | 10.5 mm | 8 mm | ISO Class 5 | DIN 315 | 10 | 94300A411 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 26 mm | 13 mm | 11 mm | ISO Class 5 | DIN 315 | 10 | 94300A412 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 33 mm | 17 mm | 13 mm | ISO Class 5 | DIN 315 | 10 | 94300A413 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 39 mm | 20 mm | 16 mm | ISO Class 5 | DIN 315 | 5 | 94300A414 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 51 mm | 25 mm | 20 mm | ISO Class 5 | DIN 315 | 5 | 94300A415 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 65 mm | 33.5 mm | 23 mm | ISO Class 5 | DIN 315 | 1 | 94300A416 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 73 mm | 37.5 mm | 29 mm | ISO Class 5 | DIN 315 | 1 | 94300A417 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 5 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 3/8" | 5/8" | 1/2" | — | — | 5 | 90876A560 | 00000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2 1/4" | 1" | 13/16" | — | — | 1 | 90876A228 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 34.9 mm | 15.9 mm | 12.7 mm | — | — | 5 | 94309A150 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 36.5 mm | 17.5 mm | 12.7 mm | — | — | 5 | 94309A155 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 69.9 mm | 30.2 mm | 26.99 mm | — | — | 1 | 94309A170 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 3/4" | 3/8" | 13/32" | — | — | 100 | 94225A300 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 3/4" | 3/8" | 13/32" | — | — | 100 | 94225A310 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 7/8" | 1/2" | 33/64" | — | — | 50 | 94225A320 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 7/8" | 1/2" | 33/64" | — | — | 50 | 94225A330 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/8" | 1/2" | 39/64" | — | — | 50 | 94225A340 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 3/8" | 5/8" | 53/64" | — | — | 50 | 94225A360 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 7 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1" | 1/2" | 3/4" | — | — | 5 | 90876A650 | 00000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/8" | 3/4" | 5/8" | — | — | 5 | 90876A600 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/2" | 5/8" | 7/8" | — | — | 5 | 90876A655 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/2" | 5/8" | 7/8" | — | — | 5 | 90876A660 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 5/8" | 1" | 7/8" | — | — | 5 | 90876A605 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 5/8" | 1" | 7/8" | — | — | 5 | 90876A610 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 25.4 mm | 11.9 mm | 19.05 mm | — | — | 5 | 94309A350 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 27 mm | 17.5 mm | 16 mm | — | — | 5 | 94309A250 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 38.1 mm | 14.3 mm | 22.22 mm | — | — | 1 | 94309A355 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 38.1 mm | 14.3 mm | 22.22 mm | — | — | 1 | 94309A360 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 41.3 mm | 25.4 mm | 22.23 mm | — | — | 5 | 94309A255 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 41.3 mm | 25.4 mm | 22.23 mm | — | — | 1 | 94309A260 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 76.2 mm | 19.1 mm | 24.5 mm | — | — | 1 | 94309A412 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 76.2 mm | 19.1 mm | 24.5 mm | — | — | 1 | 94309A413 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 76.2 mm | 19.1 mm | 24.5 mm | — | — | 1 | 94309A414 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Corrosion-Resistant-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 3/4" | 3/8" | 23/64" | — | — | 5 | 98671A110 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 7/8" | 1/2" | 13/32" | — | — | 5 | 98671A130 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 7/8" | 1/2" | 13/32" | — | — | 5 | 98671A150 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 7/8" | 1/2" | 13/32" | — | — | 5 | 98671A190 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/8" | 5/8" | 15/32" | — | — | 5 | 98671A210 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/4" | 5/8" | 9/16" | — | — | 5 | 98671A230 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 1/2" | 3/4" | 5/8" | — | — | 5 | 98671A250 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 1" | 1/2" | 1/4" | — | — | 1 | 90876A140 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 3/8" | 5/8" | 15/32" | — | — | 5 | 90876A355 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/2" | 3/4" | 5/8" | — | — | 5 | 90876A315 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 5/8" | 7/8" | 11/16" | — | — | 5 | 90876A320 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2 1/2" | 1 1/4" | 1 1/16" | — | — | 1 | 90876A331 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 5 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 1" | 7/16" | 1/4" | — | — | 5 | 90876A146 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 3/8" | 5/8" | 1/2" | — | — | 5 | 90876A150 | 00000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/2" | 3/4" | 1/2" | — | — | 5 | 90876A155 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 5/8" | 7/8" | 5/8" | — | — | 5 | 90876A160 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 2 1/4" | 1" | 13/16" | — | — | 1 | 90876A126 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2 3/4" | 1 1/4" | 1 1/16" | — | — | 1 | 90876A170 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 3" | 1 1/4" | 1 1/4" | — | — | 1 | 90876A175 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 7 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1" | 1/2" | 3/4" | — | — | 5 | 90876A335 | 00000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/8" | 3/4" | 5/8" | — | — | 5 | 90876A180 | 00000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/2" | 5/8" | 7/8" | — | — | 5 | 90876A340 | 00000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/2" | 5/8" | 7/8" | — | — | 5 | 90876A345 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 5/8" | 1" | 7/8" | — | — | 5 | 90876A185 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 5/8" | 1" | 7/8" | — | — | 5 | 90876A190 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3" | 3/4" | 1" | — | — | 1 | 90876A445 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3" | 3/4" | 1" | — | — | 1 | 90876A450 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 76.2 mm | 19.1 mm | 24.5 mm | — | — | 1 | 94309A441 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 76.2 mm | 19.1 mm | 24.5 mm | — | — | 1 | 94309A442 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 76.2 mm | 19.1 mm | 24.5 mm | — | — | 1 | 94309A443 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 9 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 7/8" | 1 3/8" | 11/16" | — | — | 1 | 90876A370 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 7/8" | 1 3/8" | 11/16" | — | — | 1 | 90876A375 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 7/8" | 1 3/8" | 11/16" | — | — | 1 | 90876A380 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

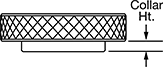

Low-Profile Knurled-Head Thumb Nuts

Twist these thumb nuts into spaces without a lot of clearance. They have a short, slip-resistant head, so you can grip them easily and make controlled adjustments in cramped spots. You can also use them as jam nuts by threading them against another nut to hold it in place.

Steel

|  |

Black-Oxide Steel—A dark, matte coating creates a finished look. These nuts offer minimal corrosion resistance, so they're best for dry environments.

Collar | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Dia. | Ht. | Head Dia. | Ht. | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1/2" | 1/16" | 3/4" | 7/32" | — | 1 | 92815A111 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1/2" | 1/16" | 3/4" | 7/32" | — | 1 | 92815A115 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1/2" | 1/16" | 3/4" | 5/16" | — | 1 | 92815A119 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1/2" | 1/16" | 3/4" | 5/16" | — | 1 | 92815A123 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 3/4" | 1/8" | 1" | 3/8" | — | 1 | 92815A127 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 3/4" | 1/8" | 1" | 3/8" | — | 1 | 92815A131 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 × 0.7 mm | 8 mm | 0.5 mm | 16 mm | 4 mm | DIN 467 | 1 | 92815A201 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 10 mm | 1 mm | 20 mm | 5 mm | DIN 467 | 1 | 92815A202 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 12 mm | 1 mm | 24 mm | 6 mm | DIN 467 | 1 | 92815A203 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 16 mm | 2 mm | 30 mm | 8 mm | DIN 467 | 1 | 92815A204 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 20 mm | 2 mm | 36 mm | 10 mm | DIN 467 | 1 | 92815A205 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 20 mm | 2 mm | 36 mm | 10 mm | DIN 467 | 1 | 92815A206 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Torque Low-Profile Knurled-Head Thumb Nuts

Twist the slip-resistant head by hand, then insert a T-handle hex key into one of the holes to apply extra torque for a tight fit. Nuts have a low-profile head that fits into cramped spaces. You can also use them as jam nuts by threading them against another nut to hold it in place.

Steel

|

Black-Oxide Steel—A dark, matte coating creates a finished look. These nuts offer minimal corrosion resistance, so they're best for dry environments.

Heavy Duty Wing Nuts

These rugged nuts have a taller base than other wing nuts with more threads to engage for a better hold. They also have a thicker body so they won’t weaken under high stress. Strong enough for use on tanker trucks, they are designed for large, heavy assemblies that need to be opened and closed often. The wings give you more leverage than knurled-head nuts, so you can apply greater torque and achieve a tighter fit.

Wing Nut Assortments

|

With a range of sizes on hand, you can use these assortments to fasten a variety of machinery and equipment. Wing nuts are the easiest nuts to twist on and off by hand, so they are commonly used to fasten parts that need to be frequently disassembled, such as access panels and covers. The wings give you more leverage than knurled-head nuts to apply greater torque and achieve a tighter fit.

Zinc-Plated Steel—A step up from plain steel, the zinc plating withstands occasional exposure to moisture.

Thread Size | No. of Pieces | Container Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32, 8-32, 10-24, 1/4"-20, 5/16"-18, 3/8"-16 | 175 | Plastic Box | 98191A416 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Finish-Your-Own Wing Nuts

|

Tap your own threads to create a custom wing nut. The easiest nuts to twist on and off by hand, these are commonly used to fasten parts that need to be frequently disassembled, such as access panels and covers. The wings give you more leverage than knurled-head nuts, so you can apply greater torque and achieve a tighter fit.

Steel—Best for dry environments since moisture will cause these nuts to rust.

Wd. | Ht. | Base Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 1 1/2" | 1 1/4" | 92902A650 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||