Filter by

Step Tread

Width

Overall Width

Overall Depth

Landing Height Range

Depth

Landing Height

Weight Capacity

Climbing Angle

Specifications Met

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Assembly

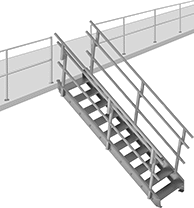

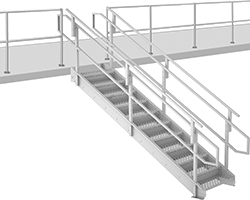

Top-Mount Stairs

|  |

OSHA Compliant | IBC Compliant |

|  |

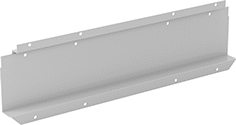

Stair Risers |

Stairs | Stair Risers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Step | Handrail | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

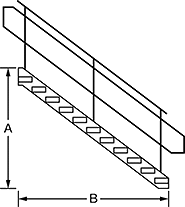

Landing Ht. (A) | Wd. | Dp. (B) | Climbing Angle | No. of Steps | Dp. | Tread | Wt. Cap., lb. | Ht. | Color | Mounting Hardware Included | Assembly | Includes | Specs. Met | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30" Wide Steps | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38" to 44" | 43" | 39" to 43" | 35° to 42° | 4 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 000000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 47" to 53" | 43" | 48" to 53" | 35° to 42° | 5 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 54" to 61" | 43" | 60" to 64" | 35° to 42° | 6 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62" to 69" | 43" | 69" to 75" | 35° to 42° | 7 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70" to 78" | 43" | 79" to 85" | 35° to 42° | 8 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 79" to 86" | 43" | 90" to 93" | 35° to 42° | 9 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 87" to 95" | 43" | 99" to 105" | 35° to 42° | 10 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96" to 104" | 43" | 109" to 115" | 35° to 42° | 11 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 105" to 113" | 43" | 119" to 125" | 35° to 42° | 12 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 114" to 130" | 43" | 139" to 150" | 35° to 42° | 14 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

36" Wide Steps | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" to 42" | 47" | 56" to 59" | 28° to 33° | 5 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38" to 44" | 49" | 39" to 43" | 35° to 42° | 4 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 43" to 48" | 47" | 67" to 71" | 28° to 33° | 6 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 47" to 53" | 49" | 48" to 53" | 35° to 42° | 5 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 49" to 55" | 47" | 78" to 82" | 28° to 33° | 7 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 56" to 61" | 47" | 89" to 94" | 28° to 33° | 8 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62" to 69" | 49" | 69" to 75" | 35° to 42° | 7 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62" to 70" | 47" | 100" to 106" | 28° to 33° | 9 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 72" to 84" | 47" | 121" to 129" | 28° to 33° | 11 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85" to 98" | 47" | 144" to 153" | 28° to 33° | 13 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96" to 104" | 49" | 109" to 115" | 35° to 42° | 11 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 114" to 130" | 49" | 139" to 150" | 35° to 42° | 14 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

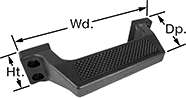

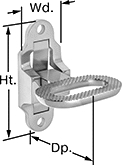

Step Handles

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Material | Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Color | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Ctr.-to-Ctr. Wd. | Assembly | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bolt On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Plastic | 1 5/8" | 6 3/8" | 2 1/2" | 3 1/4" | 1 1/8" | Diamond Tread | 2 1/2" | 0.22 | Black | No | 4 | 1/4" | 3/4" | 5 1/2" | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Weld On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Steel | 1 3/4" | 7 3/4" | 4 1/8" | 6 3/4" | 1 5/8" | Diamond Tread | 4 1/8" | 3.2 | — | — | — | — | — | — | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum | 1 5/8" | 7 3/4" | 4 1/8" | 7" | 1 5/8" | Diamond Tread | 4 1/8" | 1.12 | — | — | — | — | — | — | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

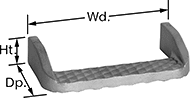

Fold-Up Steps

|  |

Style 1 | Style 2 |

|  |

Style 3 | Style 4 |

Style 1

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Wt. Cap. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Assembly | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | 1 3/4" | 3 3/4" | 4 3/8" | 2 1/8" | Diamond Tread | 3 3/4" | 2 | Not Rated | No | 2 | 5/16" | 3 7/8" | Assembled | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 3 1/2" | 6 5/8" | 6 1/2" | 5 1/4" | Diamond Tread | 6 5/8" | 4 | Not Rated | No | 2 | 5/16" | 3 7/8" | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | 1 3/4" | 3 3/4" | 4 3/8" | 2 1/8" | Diamond Tread | 3 3/4" | 2 | Not Rated | No | 2 | 5/16" | 3 7/8" | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/8" | 1 7/8" | 3 1/2" | 3 3/8" | 2" | Diamond Tread | 3 1/2" | 1 | Not Rated | No | 2 | 5/16" | 3 5/8" | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

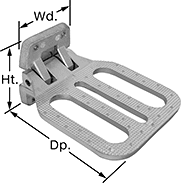

Style 2

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Wt. Cap. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Ctr.-to-Ctr. Wd. | Assembly | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chrome-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 7/8" | 4" | 8 1/2" | 6 3/4" | 6 3/8" | Diamond Tread | 8 1/2" | 5 | Not Rated | No | 4 | 5/16" | 4" | 2 1/4" | Assembled | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

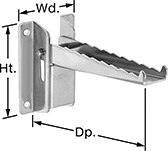

Style 3

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Wt. Cap. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Ctr.-to-Ctr. Wd. | Assembly | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/8" | 2 3/8" | 5 5/8" | 1" | 4 1/4" | Serrated | 5 5/8" | 1 | Not Rated | No | 4 | 3/16" | 2 5/8" | 1 3/4" | Assembled | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

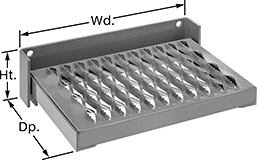

Style 4

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Wt. Cap., lb. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Wd. | Assembly | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gray Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 15" | 10 3/4" | 14 1/4" | 9 1/2" | Serrated | 10 3/4" | 11 | 350 | No | 2 | 9/16" | 13" | Assembled | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gray Powder-Coated Steel with Spring-Loaded Hinge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 15" | 10 3/4" | 14 1/4" | 9 1/2" | Serrated | 10 3/4" | 11 | 350 | No | 2 | 9/16" | 13" | Assembled | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Yellow Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 15" | 10 3/4" | 14 1/4" | 9 1/2" | Serrated | 10 3/4" | 11 | 350 | No | 2 | 9/16" | 13" | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

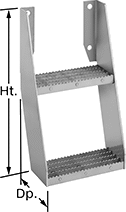

Wall-Mount Steps

Foldaway Stairs

Manual

Overall | Step | Handrail | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Landing Ht. (A), ft. | Wd. | Dp. (B) | Climbing Angle | No. of Steps | Dp. | Tread | Wt. Cap., lb. | Ht. | Color | Mounting Hardware Included | Assembly | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24 1/4" Wide Steps | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 33" | 43" | 58° | 7 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 33" | 50" | 58° | 8 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 33" | 58" | 58° | 9 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 33" | 65" | 58° | 10 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 33" | 73" | 58° | 11 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 33" | 80" | 58° | 13 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric

Overall | Step | Handrail | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Landing Ht. (A), ft. | Wd. | Dp. (B) | Climbing Angle | No. of Steps | Dp. | Tread | Wt. Cap., lb. | Ht. | Color | Motor Input Voltage, V AC | Connection | No. of Blades | Mounting Hardware Included | Assembly | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

23 5/8" Wide Steps | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 32" | 73" | 58° | 11 | 7" | Serrated | 350 | 32" | Yellow | 120 | Straight Blade | 3 | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

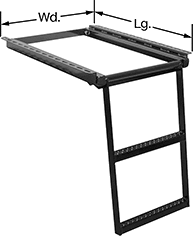

Under-Mount Foldaway Steps

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Climbing Ht. | Lg. | Wd. | Ladder Wd. | No. of Steps | Step Tread | Wt. Cap. | Mounting Hardware Included | No. of | Lg. | Wd. | Assembly | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" | 25 1/2" | 19 3/4" | 14 1/4" | 2 | Perforated | Not Rated | No | 28 | 1 3/16" | 3/8" | Assembled | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19" | 30 1/4" | 19 3/4" | 14 1/4" | 3 | Perforated | Not Rated | No | 32 | 1 3/16" | 3/8" | Assembled | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

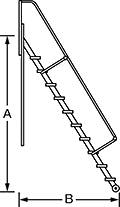

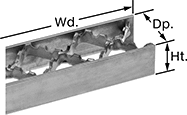

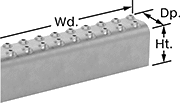

Ladder-Style Steps

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Weight Capacity | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 1/8" | 540 lb. | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 7/8" | 540 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 7/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 20 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 20 ft. | 1 7/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 250 lb. for 18" to 24" Cut Lengths, 330 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 330 lb. for 18" to 24" Cut Lengths, 450 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 570 lb. for 18" to 24" Cut Lengths, 760 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 250 lb. for 18" to 24" Cut Lengths, 330 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 330 lb. for 18" to 24" Cut Lengths, 450 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 570 lb. for 18" to 24" Cut Lengths, 760 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 17" | 2" | 540 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 7 ft. | 2" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 220 lb. for 18" to 24" Cut Lengths, 290 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 310 lb. for 18" to 24" Cut Lengths, 410 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 540 lb. for 18" to 24" Cut Lengths, 720 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 1/8" | 540 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 230 lb. for 18" to 24" Cut Lengths, 300 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 380 lb. for 18" to 24" Cut Lengths, 510 lb. Up to 18" Cut Lengths | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

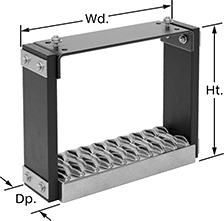

Under-Mount Steps

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | No. of Steps | Wd. | Dp. | Tread | Material | Wt. Cap. | Mounting Hardware Included | No. of | Dia. | Assembly | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" | 13 1/2" | 4 3/4" | 1 | 12" | 4 3/4" | Serrated | Galvanized Steel | Not Rated | Yes | 2 | 3/8" | Unassembled | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" | 31 1/2" | 4 3/4" | 1 | 30" | 4 3/4" | Serrated | Galvanized Steel | Not Rated | Yes | 2 | 3/8" | Unassembled | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||