Filter by

Length

Screw Size

Maximum Temperature

Thickness

Shape

Threading

Gender

Mount Type

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

Electrical-Insulating Unthreaded Spacers

|

Lg. | For Screw Size | ID | Dielectric Strength, V/mil | Temp. Range, ° F | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ultra-High-Temperature Grade L5 Ceramic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | No. 3 | 0.115" | 275 | 50 to 1,700 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | No. 4 | 0.140" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | No. 3 | 0.115" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | No. 4 | 0.140" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | No. 3 | 0.115" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | No. 4 | 0.140" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | No. 4 | 0.140" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | No. 4 | 0.140" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | No. 4 | 0.140" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | No. 8 | 0.192" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | No. 8 | 0.192" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | No. 8 | 0.192" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | No. 8 | 0.192" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | No. 8 | 0.192" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | No. 10 | 0.250" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | No. 10 | 0.250" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | No. 10 | 0.250" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | No. 10 | 0.250" | 275 | 50 to 1,700 | 1 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Insulating Sleeve Washers

Flat Edge

Sleeve | Temp. Range | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | Ht. | OD | ID | OD | Thk. | Overall Ht. | Min. | Max., ° F | Color | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extra-High-Temperature Ceramic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.062" | 0.281" | 0.150" | 0.500" | 0.125" | 0.187" | Not Rated | 1,700 | Off-White | 5 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.250" | 0.281" | 0.150" | 0.500" | 0.187" | 0.437" | Not Rated | 1,700 | Off-White | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.062" | 0.406" | 0.175" | 0.625" | 0.125" | 0.187" | Not Rated | 1,700 | Off-White | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.250" | 0.406" | 0.175" | 0.625" | 0.218" | 0.468" | Not Rated | 1,700 | Off-White | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.062" | 0.468" | 0.200" | 0.750" | 0.156" | 0.218" | Not Rated | 1,700 | Off-White | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.250" | 0.468" | 0.200" | 0.750" | 0.218" | 0.468" | Not Rated | 1,700 | Off-White | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.062" | 0.593" | 0.265" | 0.875" | 0.188" | 0.250" | Not Rated | 1,700 | Off-White | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.250" | 0.593" | 0.265" | 0.875" | 0.250" | 0.500" | Not Rated | 1,700 | Off-White | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.500 mm | 3.000 mm | 2.100 mm | 4.200 mm | 1.500 mm | 4.000 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 1.500 mm | 4.000 mm | 3.100 mm | 6.200 mm | 1.500 mm | 3.000 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.500 mm | 4.000 mm | 3.100 mm | 6.200 mm | 1.500 mm | 5.000 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 7.500 mm | 4.000 mm | 3.100 mm | 6.200 mm | 1.500 mm | 9.000 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 3.000 mm | 6.000 mm | 4.100 mm | 8.400 mm | 1.500 mm | 4.500 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 5.000 mm | 6.000 mm | 4.100 mm | 8.400 mm | 1.500 mm | 6.500 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 3.000 mm | 7.000 mm | 5.100 mm | 10.200 mm | 2.000 mm | 5.000 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.000 mm | 7.000 mm | 5.100 mm | 10.200 mm | 2.000 mm | 7.000 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 4.000 mm | 8.000 mm | 6.100 mm | 12.200 mm | 2.000 mm | 6.000 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 10.000 mm | 8.000 mm | 6.100 mm | 12.200 mm | 2.000 mm | 12.000 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 4.000 mm | 10.000 mm | 8.100 mm | 14.200 mm | 2.500 mm | 6.500 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.000 mm | 10.000 mm | 8.100 mm | 14.200 mm | 2.500 mm | 10.500 mm | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrical-Insulating Female Threaded Standoffs

Round

Lg. | OD | Threading | Thread Lg. | Min. Thread Lg. | Dielectric Strength, V/mil | Voltage Rating | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High-Temperature Grade L5 Ceramic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6-32 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/4" | Fully Threaded | 1/4" | — | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/8" | Threaded on Both Ends | — | 1/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1/4" | Threaded on Both Ends | — | 3/16" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/8" | Threaded on Both Ends | — | 1/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1/2" | Threaded on Both Ends | — | 5/32" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1/4" | Threaded on Both Ends | — | 1/4" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3/8" | Threaded on Both Ends | — | 1/4" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1/2" | Threaded on Both Ends | — | 1/4" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1/4" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3/8" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1/2" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1/4" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1/4" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 3/8" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1/2" | Threaded on Both Ends | — | 9/16" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1/2" | Threaded on Both Ends | — | 1/2" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 1/2" | Threaded on Both Ends | — | 1/2" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1/2" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8-32 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/8" | Threaded on Both Ends | — | 5/32" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3/8" | Threaded on Both Ends | — | 3/16" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3/8" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 3/8" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3/4" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 3/4" | Threaded on Both Ends | — | 3/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1" | Threaded on Both Ends | — | 1/2" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/4" | Threaded on Both Ends | — | 5/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 3/4" | Threaded on Both Ends | — | 3/4" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1" | Threaded on Both Ends | — | 5/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1 1/4" | Threaded on Both Ends | — | 5/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 3/4" | Threaded on Both Ends | — | 3/4" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3/4" | Threaded on Both Ends | — | 3/4" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | Threaded on Both Ends | — | 5/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/4" | Threaded on Both Ends | — | 5/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 3/4" | Threaded on Both Ends | — | 3/4" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 3/4" | Threaded on Both Ends | — | 3/4" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1" | Threaded on Both Ends | — | 5/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 1/4" | Threaded on Both Ends | — | 5/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 1 1/4" | Threaded on Both Ends | — | 5/8" | 275 | Not Rated | 50 to 1,700 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-High-Temperature Ceramic Washers

Temp. Range | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID | OD | Thk. | Min. | Max., ° F | Specs. Met | Color | Each | ||

| No. 0 | 0.068" | 0.188" | 0.022" to 0.028" | Not Rated | 3,000 | — | Off-White | 000000000 | 00000 | |

| No. 2 | 0.094" | 0.250" | 0.028" to 0.036" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| No. 4 | 0.125" | 0.375" | 0.036" to 0.045" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| No. 5 | 0.141" | 0.406" | 0.036" to 0.045" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| No. 6 | 0.156" | 0.438" | 0.036" to 0.045" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| No. 8 | 0.188" | 0.500" | 0.036" to 0.045" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| No. 10 | 0.203" | 0.562" | 0.036" to 0.045" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| No. 12 | 0.234" | 0.625" | 0.056" to 0.071" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| 1/4" | 0.281" | 0.734" | 0.056" to 0.071" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| 5/16" | 0.344" | 0.875" | 0.056" to 0.071" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| 3/8" | 0.406" | 1.000" | 0.056" to 0.071" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| 7/16" | 0.469" | 1.125" | 0.056" to 0.071" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| 1/2" | 0.531" | 1.250" | 0.090" to 0.112" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| 9/16" | 0.594" | 1.469" | 0.090" to 0.112" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| 5/8" | 0.656" | 1.750" | 0.090" to 0.112" | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| 3/4" | 0.812" | 2.000" | 0.090" to 0.112" | Not Rated | 3,000 | — | Off-White | 000000000 | 00000 | |

| 7/8" | 0.938" | 2.250" | 0.146" to 0.174" | Not Rated | 3,000 | ASME B18.21.1 | Off-White | 000000000 | 00000 | |

| 1" | 1.062" | 2.500" | 0.146" to 0.174" | Not Rated | 3,000 | ASME B18.21.1 | Off-White | 000000000 | 00000 | |

| M2 | 2.6 mm | 6.0 mm | 0.6 mm to 0.9 mm | Not Rated | 3,000 | ASME B18.22M | Off-White | 000000000 | 0000 | |

| M3 | 3.6 mm | 10.0 mm | 0.8 mm to 1.2 mm | Not Rated | 3,000 | ASME B18.22M | Off-White | 000000000 | 0000 | |

| M4 | 4.8 mm | 12.0 mm | 1.0 mm to 1.4 mm | Not Rated | 3,000 | ASME B18.22M | Off-White | 000000000 | 0000 | |

| M5 | 5.6 mm | 15.0 mm | 1.2 mm to 1.8 mm | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| M6 | 6.8 mm | 18.8 mm | 1.2 mm to 1.8 mm | Not Rated | 3,000 | — | Off-White | 000000000 | 0000 | |

| M8 | 9.0 mm | 25.4 mm | 1.6 mm to 2.3 mm | Not Rated | 3,000 | ASME B18.22M | Off-White | 000000000 | 0000 | |

| M10 | 11.0 mm | 28.0 mm | 2.0 mm to 2.8 mm | Not Rated | 3,000 | ASME B18.22M | Off-White | 000000000 | 0000 | |

| M12 | 13.4 mm | 34.0 mm | 2.5 mm to 3.5 mm | Not Rated | 3,000 | ASME B18.22M | Off-White | 000000000 | 0000 | |

| M14 | 15.4 mm | 39.0 mm | 2.5 mm to 3.5 mm | Not Rated | 3,000 | ASME B18.22M | Off-White | 000000000 | 00000 | |

| M16 | 17.4 mm | 44.0 mm | 3.0 mm to 4.0 mm | Not Rated | 3,000 | ASME B18.22M | Off-White | 000000000 | 00000 | |

| M20 | 22.0 mm | 50.0 mm | 3.5 mm to 4.6 mm | Not Rated | 3,000 | ASME B18.22M | Off-White | 000000000 | 00000 | |

Insulating Cup Washers

Temp. Range | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID | OD | Cup ID | Inside Dp. | Thk. | Overall Ht. | Min. | Max., ° F | Color | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extra-High-Temperature Ceramic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.130" | 0.440" | 0.250" | 0.125" | 0.100" | 0.225" | Not Rated | 1,700 | Off-White | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.160" | 0.500" | 0.312" | 0.150" | 0.100" | 0.250" | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.180" | 0.560" | 0.375" | 0.170" | 0.100" | 0.270" | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.200" | 0.625" | 0.437" | 0.190" | 0.100" | 0.290" | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.260" | 0.750" | 0.531" | 0.250" | 0.100" | 0.350" | Not Rated | 1,700 | Off-White | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Ultra-Thin Linear Sleeve Bearings

Fixed Alignment

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | Shaft Clearance, mm | Overall Lg., mm | OD, mm | For Housing ID | With Retaining Ring Grooves | With End Seals | Dynamic Linear Load Cap. @ Speed | Static Load Cap., lb. | Min. | Max. | For Shaft Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic-Lined 6061 Aluminum Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 0.038 | 22 | 12 | 12.000 mm to 12.018 mm | No | No | 70 lb. @ 100 fpm | 760 | -200 | 400 | Stainless Steel, Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 0.038 | 24 | 15 | 15.000 mm to 15.018 mm | No | No | 80 lb. @ 100 fpm | 1,100 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 0.038 | 26 | 17 | 17.000 mm to 17.018 mm | No | No | 250 lb. @ 100 fpm | 1,500 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 0.038 | 28 | 19 | 19.000 mm to 19.021 mm | No | No | 250 lb. @ 100 fpm | 1,950 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 0.038 | 28 | 21 | 21.000 mm to 21.021 mm | No | No | 300 lb. @ 100 fpm | 2,250 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 0.05 | 30 | 24 | 24.000 mm to 24.021 mm | No | No | 350 lb. @ 100 fpm | 2,750 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 0.05 | 40 | 35 | 35.000 mm to 35.025 mm | No | No | 600 lb. @ 100 fpm | 5,800 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

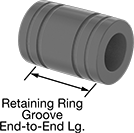

Linear Sleeve Bearings

Self-Aligning with 2° Misalignment Capability

Bearings | Retaining Rings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

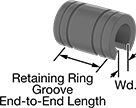

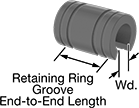

For Shaft Dia. | Shaft Clearance | Overall Lg. | OD | For Housing ID | With Retaining Ring Grooves | Retaining Ring Groove End-to-End Lg. | With End Seals | Dynamic Linear Load Cap. @ Speed | Static Load Cap., lb. | Min. | Max. | For Shaft Material | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE-Lined 6061 Aluminum Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.001" | 3/4" | 1/2" | 0.5000" to 0.5005" | Yes | 0.517" | No | 50 lb. @ 100 fpm | 935 | -400 | 375 | Aluminum, Stainless Steel | 000000 | 000000 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.001" | 7/8" | 5/8" | 0.6250" to 0.6255" | Yes | 0.642" | No | 90 lb. @ 100 fpm | 1,600 | -400 | 375 | Aluminum, Stainless Steel | 000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.001" | 1 1/4" | 7/8" | 0.8750" to 0.8755" | Yes | 0.971" | No | 150 lb. @ 100 fpm | 3,100 | -400 | 375 | Aluminum, Stainless Steel | 000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.001" | 1 1/2" | 1 1/8" | 1.1250" to 1.1255" | Yes | 1.116" | No | 250 lb. @ 100 fpm | 4,600 | -400 | 375 | Aluminum, Stainless Steel | 000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.001" | 1 5/8" | 1 1/4" | 1.2500" to 1.2505" | Yes | 1.178" | No | 350 lb. @ 100 fpm | 6,100 | -400 | 375 | Aluminum, Stainless Steel | 000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.001" | 2 1/4" | 1 9/16" | 1.5625" to 1.5630" | Yes | 1.765" | No | 600 lb. @ 100 fpm | 11,000 | -400 | 375 | Aluminum, Stainless Steel | 000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 0.001" | 2 5/8" | 2" | 2.0000" to 2.0010" | Yes | 2.055" | No | 900 lb. @ 100 fpm | 16,000 | -400 | 375 | Aluminum, Stainless Steel | 000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.0015" | 3" | 2 3/8" | 2.3750" to 2.3760" | Yes | 2.43" | No | 1,000 lb. @ 100 fpm | 22,000 | -400 | 375 | Aluminum, Stainless Steel | 000000 | 000000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.0015" | 4" | 3" | 3.0000" to 3.0010" | Yes | 3.21" | No | 2,000 lb. @ 100 fpm | 40,000 | -400 | 375 | Aluminum, Stainless Steel | 000000 | 000000 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 0.001" | 25 mm | 16 mm | 16.000 mm to 16.018 mm | Yes | 16.2 mm | No | 90 lb. @ 100 fpm | 1,100 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 0.001" | 32 mm | 22 mm | 22.000 mm to 22.021 mm | Yes | 22.6 mm | No | 150 lb. @ 100 fpm | 2,200 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 0.001" | 36 mm | 26 mm | 26.000 mm to 26.021 mm | Yes | 24.6 mm | No | 250 lb. @ 100 fpm | 3,300 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 0.001" | 45 mm | 32 mm | 32.000 mm to 32.025 mm | Yes | 31.2 mm | No | 350 lb. @ 100 fpm | 5,200 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 0.001" | 58 mm | 40 mm | 40.000 mm to 40.025 mm | Yes | 43.7 mm | No | 600 lb. @ 100 fpm | 8,400 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 0.001" | 68 mm | 47 mm | 47.000 mm to 47.025 mm | Yes | 51.7 mm | No | 900 lb. @ 100 fpm | 11,800 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Alignment

Bearings | Retaining Rings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Shaft Dia., mm | Shaft Clearance | Overall Lg., mm | OD, mm | For Housing ID | With Retaining Ring Grooves | Retaining Ring Groove End-to-End Lg., mm | With End Seals | Dynamic Linear Load Cap. @ Speed | Static Load Cap., lb. | Min. | Max. | For Shaft Material | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE-Lined 6061 Aluminum Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 0.001" | 25 | 16 | 16.000 mm to 16.018 mm | Yes | 16.2 | No | 90 lb. @ 100 fpm | 1,100 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 000000 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 0.001" | 32 | 22 | 22.000 mm to 22.021 mm | Yes | 22.6 | No | 150 lb. @ 100 fpm | 2,200 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 0.001" | 36 | 26 | 26.000 mm to 26.021 mm | Yes | 24.6 | No | 250 lb. @ 100 fpm | 3,300 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 0.001" | 45 | 32 | 32.000 mm to 32.025 mm | Yes | 31.2 | No | 350 lb. @ 100 fpm | 5,200 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

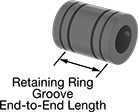

High-Speed Linear Sleeve Bearings

Fixed Alignment

Bearings | Retaining Rings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Shaft Dia. | Shaft Clearance | Overall Lg. | OD | For Housing ID | With Retaining Ring Grooves | Retaining Ring Groove End-to-End Lg. | With End Seals | Dynamic Linear Load Cap. @ Speed | Static Load Cap., lb. | Min. | Max. | For Shaft Material | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic-Lined 6061 Aluminum Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.0005" | 3/4" | 1/2" | 0.5000" to 0.5005" | Yes | 0.517" | No | 70 lb. @ 100 fpm | 935 | -200 | 400 | Aluminum, Stainless Steel, Steel | 0000000 | 000000 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.0005" | 7/8" | 5/8" | 0.6250" to 0.6255" | Yes | 0.642" | No | 100 lb. @ 100 fpm | 1,600 | -200 | 400 | Aluminum, Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.0005" | 1 1/4" | 7/8" | 0.8750" to 0.8755" | Yes | 0.969" | No | 250 lb. @ 100 fpm | 3,100 | -200 | 400 | Aluminum, Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.0005" | 1 1/2" | 1 1/8" | 1.1250" to 1.1255" | Yes | 1.116" | No | 350 lb. @ 100 fpm | 4,600 | -200 | 400 | Aluminum, Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.0008" | 1 5/8" | 1 1/4" | 1.2500" to 1.2505" | Yes | 1.178" | No | 450 lb. @ 100 fpm | 6,100 | -200 | 400 | Aluminum, Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.0008" | 1 5/8" | 1 1/4" | 1.2500" to 1.2505" | Yes | 1.178" | No | 600 lb. @ 100 fpm | 8,100 | -200 | 400 | Aluminum, Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 0.0127 mm to 0.0381 mm | 25 mm | 16 mm | 16 mm | Yes | 14 mm | No | 100 lb. @ 100 fpm | 1,550 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 0.0127 mm to 0.0381 mm | 32 mm | 22 mm | 22 mm | Yes | 20 mm | No | 150 lb. @ 100 fpm | 2,950 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 0.0127 mm to 0.0381 mm | 36 mm | 26 mm | 26 mm | Yes | 22 mm | No | 200 lb. @ 100 fpm | 4,450 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 0.0127 mm to 0.0381 mm | 45 mm | 32 mm | 32 mm | Yes | 28 mm | No | 300 lb. @ 100 fpm | 6,950 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 0.0127 mm to 0.0381 mm | 58 mm | 40 mm | 40 mm | Yes | 40 mm | No | 500 lb. @ 100 fpm | 11,250 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 0.013 mm to 0.05 mm | 68 mm | 47 mm | 47 mm | Yes | 48 mm | No | 900 lb. @ 100 fpm | 15,800 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 mm | 0.013 mm to 0.05 mm | 100 mm | 75 mm | 75 mm | Yes | 72 mm | No | 2,000 lb. @ 100 fpm | 38,750 | -200 | 400 | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Linear Sleeve Bearings for Support Rail Shafts

Self-Aligning with 2° Misalignment Capability

Bearings | Retaining Rings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Shaft Dia. | Shaft Clearance | Overall Lg. | OD | Wd. | For Housing ID | With Retaining Ring Grooves | Retaining Ring Groove End-to-End Lg. | With End Seals | Dynamic Linear Load Cap. @ Speed | Static Load Cap., lb. | Min. | Max. | For Shaft Material | Each | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE-Lined 6061 Aluminum Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.001" | 3/4" | 1/2" | 1/8" | 0.5000" to 0.5005" | Yes | 0.517" | No | 50 lb. @ 100 fpm | 935 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 000000 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.001" | 7/8" | 5/8" | 3/16" | 0.6250" to 0.6255" | Yes | 0.642" | No | 90 lb. @ 100 fpm | 1,600 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.001" | 1 1/4" | 7/8" | 5/16" | 0.8750" to 0.8755" | Yes | 0.969" | No | 150 lb. @ 100 fpm | 3,100 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.001" | 1 1/2" | 1 1/8" | 3/8" | 1.1250" to 1.1255" | Yes | 1.116" | No | 250 lb. @ 100 fpm | 4,600 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.001" | 1 5/8" | 1 1/4" | 7/16" | 1.2500" to 1.2505" | Yes | 1.178" | No | 350 lb. @ 100 fpm | 6,100 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.001" | 2 1/4" | 1 9/16" | 9/16" | 1.5625" to 1.5630" | Yes | 1.765" | No | 600 lb. @ 100 fpm | 11,000 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.0015" | 3" | 2 3/8" | 3/4" | 2.3750" to 2.3760" | Yes | 2.43" | No | 1,000 lb. @ 100 fpm | 22,000 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 000000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.0015" | 4" | 3" | 1" | 3.0000" to 3.0010" | Yes | 3.21" | No | 2,000 lb. @ 100 fpm | 40,000 | -400 | 375 | Aluminum, Stainless Steel | 0000000 | 000000 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 0.001" | 36 mm | 26 mm | 10.4 mm | 26.000 mm to 26.021 mm | Yes | 24.6 mm | No | 250 lb. @ 100 fpm | 3,300 | -400 | 375 | Aluminum, Stainless Steel | 00000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 0.001" | 45 mm | 32 mm | 10.8 mm | 32.000 mm to 32.025 mm | Yes | 31.2 mm | No | 350 lb. @ 100 fpm | 5,200 | -400 | 375 | Aluminum, Stainless Steel | 00000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 0.001" | 58 mm | 40 mm | 13.2 mm | 40.000 mm to 40.025 mm | Yes | 43.8 mm | No | 600 lb. @ 100 fpm | 8,400 | -400 | 375 | Aluminum, Stainless Steel | 00000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 0.001" | 68 mm | 47 mm | 14.2 mm | 47.000 mm to 47.025 mm | Yes | 51.8 mm | No | 900 lb. @ 100 fpm | 11,800 | -400 | 375 | Aluminum, Stainless Steel | 00000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Linear Sleeve Bearings for Support Rail Shafts

Self-Aligning with 2° Misalignment Capability

Bearings | Retaining Rings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Shaft Dia., mm | Shaft Clearance | Overall Lg., mm | OD, mm | Wd., mm | For Housing ID | With Retaining Ring Grooves | Retaining Ring Groove End-to-End Lg., mm | With End Seals | Dynamic Linear Load Cap. @ Speed | Static Load Cap., lb. | Min. | Max. | For Shaft Material | Each | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic-Lined 6061 Aluminum Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 0.001" | 32 | 22 | 7.6 | 22.0000 mm to 22.0210 mm | Yes | 22.6 | No | 150 lb. @ 100 fpm | 2,200 | -400 | 400 | Stainless Steel, Steel | 0000000 | 000000 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 0.001" | 58 | 40 | 13.2 | 40.0000 mm to 40.0250 mm | Yes | 43.7 | No | 500 lb. @ 100 fpm | 8,400 | -400 | 400 | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Alignment

Bearings | Retaining Rings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Shaft Dia., mm | Shaft Clearance | Overall Lg., mm | OD, mm | Wd., mm | For Housing ID | With Retaining Ring Grooves | Retaining Ring Groove End-to-End Lg., mm | With End Seals | Dynamic Linear Load Cap. @ Speed | Static Load Cap., lb. | Min. | Max. | For Shaft Material | Each | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic-Lined 6061 Aluminum Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 0.001" | 32 | 22 | 7.6 | 22.0000 mm to 22.0210 mm | Yes | 22.6 | No | 150 lb. @ 100 fpm | 2,200 | -400 | 400 | Stainless Steel, Steel | 0000000 | 000000 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 0.001" | 58 | 40 | 13.2 | 40.0000 mm to 40.0250 mm | Yes | 43.7 | No | 500 lb. @ 100 fpm | 8,400 | -400 | 400 | Stainless Steel, Steel | 0000000 | 00000 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||