How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

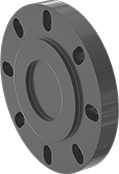

Low-Pressure Steel Unthreaded Pipe Flanges for Low Temperatures

Even in temperatures as low as -46°, these A350 LF2 steel flanges won’t become brittle, so they absorb impact better than other low-pressure steel flanges. Also known as Pressure Class 150 flanges, they’re used in low-pressure lines. Bolt two flanges together with a gasket (not included) to create an access point within a line. All are impact tested to verify their strength.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met: ASME B16.5, ASTM A350

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 ASTM A333 carbon steel

- Fittings: Use Schedule 40 ASTM A420 carbon steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | Material | Each | |

| 1 | 4 1/2" | 1/2" | 5/8" | 4 | 3 1/8" | 285 psi @ 72° F | 230 psi @ 300° F | -46° to 800° | A350 LF2 Steel | 0000000 | 000000 |

UV-Resistant Polypropylene Pipe Flanges for Chemicals

- For Use With: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water

- Temperature Range: See Table

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Fittings: Use Schedule 80 Polypropylene Plastic

Use these polypropylene flanges in outdoor environments—they resist the damaging effects of ultraviolet light. Flanges have the chemical resistance to stand up to a wide variety of acids, solvents, and other harsh substances. Also known as Pressure Class 150 flanges, they have thick, strong walls for heavy duty chemical processing applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. When connecting to pipe, apply a non-hardening, plastic-compatible sealant to the male pipe threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the flange, then wrench-tighten one to two turns.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

| Pipe Size | Flanged Connection Surface | Flange OD | For Bolt Dia. | Bolt Hole Dia. | Number of Bolt Holes | Bolt Circle Dia. | Material | Color | Max. Pressure | Temperature Range, °F | Each | |

NPT Threads | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/4 | Flat | 4 1/2" | 1/2" | 5/8" | 4 | 3 1/2" | Polypropylene Plastic | Black | Not Rated | 0° to 180° | 000000000 | 0000000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

Cap flanges are also known as blind flanges.

| Pipe Size | Flanged Connection Surface | Flange OD | For Bolt Dia. | Bolt Hole Dia. | Number of Bolt Holes | Bolt Circle Dia. | Material | Color | Max. Pressure | Temperature Range, °F | Each | |

| 1 1/4 | Raised | 4 1/2" | 1/2" | 5/8" | 4 | 3 1/2" | Polypropylene Plastic | Black | Not Rated | 0° to 180° | 000000000 | 0000000 |

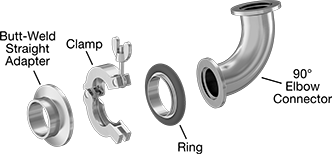

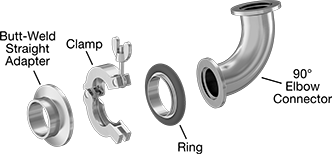

Quick-Clamp High-Vacuum Fittings for Stainless Steel Tubing

- For Use With:

Fittings with Gasket End: Air, Argon, Helium, Nitrogen

All Other Fittings: Air - Specifications Met: ISO 2861

Instead of a gasket, these fittings have a metal-reinforced O-ring that is designed for high-vacuum applications, such as vacuum coating and heat treating, leak testing, and analyzing gases. Also known as KF, QF, and NW fittings, they are the most common type of connection in high-vacuum systems. Connect with a clamp and another quick-clamp fitting for fast, easy access to your line. To use fittings in pressure applications, use a pressure-rated ring (sold separately). Made of 304 stainless steel, these fittings have very good corrosion resistance.

Note: To complete a connection, you’ll need two quick-clamp fittings, a ring, and a clamp (all sold separately).

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Fittings with flanged end connect to pumps, valves or gauges that have flanged connections. Also known as conflat, CF, or UHV fittings, they have a higher vacuum rating than quick-clamp fittings, so these adapters allow you to connect between different levels of vacuum within a system. A copper gasket (sold separately) creates a tight seal between the two flanges.

Quick-Clamp Tube Connection | Flanged Tube Connection | Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | For Bolt Dia. | Bolts Included | Max. Vacuum | Max. Pressure | Each | |

| 1 1/2" | 2.16" | 40 | ISO-KF | 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | 5/16" | No | 10 -8 torr @ 72° F | 5 psi @ 72° F | 00000000 | 0000000 |

| Copper Gasket for 4 1/2" Flange OD (Flanged End) | 0000000 | Each | 00000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Clamps tighten by hand.

Lever clamps are also known as toggle clamps.

Clamps with lanyard let you secure the clamp to equipment.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Lanyard Lg. | Each | |

Wing Nut | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 000000 |

Lever | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

Lever with Lanyard | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

- Temperature Range:

Fittings with Viton® Fluoroelastomer Rubber O-Ring: 0° to 300° F

Fittings with Silicone Rubber O-Ring: -50° to 390°F - Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

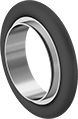

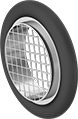

Use these rings with quick-clamp high-vacuum fittings. They consist of a stainless steel inner ring covered by an O-ring.

Silicone rings withstand higher temperatures than fluoroelastomer ones.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Inner Ring Material | Max. Vacuum | Max. Pressure | Each | |

Viton® Fluoroelastomer Rubber O-Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

Rings | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 0000000 | 000000 |

Rings with Stainless Steel Screen | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

Rings with Aluminum Outer Ring | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 75 psi @ 72° F | 0000000 | 00000 |

Silicone Rubber O-Ring | ||||||||

Rings | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

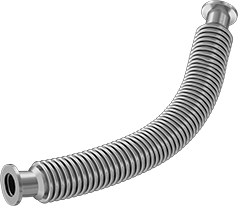

Hose absorbs moderate vibration

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Bend Radius | Flexibility | Each | |

4 3/16" Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | __ | Flexible | 0000000 | 0000000 |

12" Lg. | |||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

24" Lg. | |||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

39" Lg. | |||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

- Temperature Range: 0° to 190° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Valves are also known as vacuum isolation valves. They connect to a vacuum system so you can install gauges, release gases, and remove air. They operate manually and have a compact body that fits easily into tight spaces.

| Actuation | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Max. Vacuum | Body Material | Overall Ht. | Overall Lg. | Each | |

| Manual | 1 1/2" | 2 1/8" | 40 | ISO-KF | 10 -8 torr @ 72° F | 304 Stainless Steel | 6 3/8" | 3 7/8" | 00000000 | 0000000 |

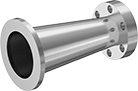

Flanged Ultra-High-Vacuum Fittings for Stainless Steel Tubing

- For Use With: Air

- Temperature Range:

Flanges: -300° to 800° F

Gaskets: Not Rated - Tubing: Use with 304/304L and 316/316L stainless steel

- Specifications Met:

Flanges: ASTM A240, ASTM E45, ASTM E12

Gaskets: ASTM B152-179, ASTM F68

Create access points in ultra-high-vacuum lines or chambers by bolting two same-size flanges together with a copper gasket (sold separately) between them. The flanges’ sharp edges dig into the copper gasket and form an extremely tight seal, which means they handle higher vacuum pressures than other high-vacuum fittings with rubber gaskets. Also known as CF, Conflat, and UHV fittings, use them in vacuum coating, heat treating, and drying applications, as well as for leak testing and analyzing gases. They’re stainless steel so they resist rusting.

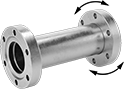

Fittings with a rotating flange turn so you can easily match up the bolt holes with another flange that may be misaligned.

Butt-weld flanges provide a flush connection for smooth flow through your line.

Socket-connect flanges are easier to weld than butt-weld flanges because they don’t need to align perfectly to tubing; insert the tubing into the socket end and weld together.

Caps are also known as blind flanges.

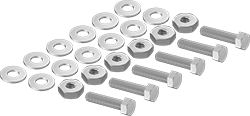

Bolt kits are required to make a complete connection.

Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Lg. | Max. Vacuum | Material | Appearance | Each | |

Fixed × Rotating | ||||||||||||||

| 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | No | 2 | 6 11/16" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 0000000 |

Bolt Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Max. Vacuum | Material | Appearance | Each | |

Rotating | |||||||||||||

| 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | No | 2 | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 0000000 |

Butt-Weld Tube Connection | Flanged Tube Connection | Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Wall Thick. | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Lg. | Max. Vacuum | Material | Appearance | Each | |

Fixed | ||||||||||||||||

| 2 1/2" | 0.065" | 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | No | 1 | 3 3/8" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 0000000 |

Socket-Connect Tube Connection | Flanged Tube Connection | Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Socket Dp. | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Lg. | Max. Vacuum | Material | Appearance | Each | |

Fixed | ||||||||||||||||

| 2 1/2" | 3/8" | 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | No | 1 | 11/16" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 000000 |

Rotating | ||||||||||||||||

| 2 1/2" | 3/8" | 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | No | 1 | 11/16" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 00000 |

Bolt Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Max. Vacuum | Material | Appearance | Each | |

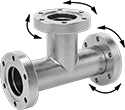

Fixed × Rotating × Rotating | |||||||||||||

| 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | No | 3 | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 0000000 |

Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Lg. | Max. Vacuum | Material | Appearance | Each | |

Fixed | ||||||||||||||

| 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | No | 1 | 11/16" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 000000 |

| For Tube OD | For Flange OD | Gasket Material | Specifications Met | Each | |

| 2 1/2" | 4 1/2" | Copper | ASTM F68 | 0000000 | 00000 |

| For Flange OD | For High-Vacuum Flange Size | Bolt Dia. | Thread Size | No. of Bolts Included | No. of Nuts Included | No. of Washers Included | Bolt Material | Each | |

| 4 1/2" | 63 | 5/16" | 5/16"-24 | 8 | 8 | 16 | 18-8 Stainless Steel | 0000000 | 000000 |