How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Low-Pressure Stainless Steel Unthreaded Pipe Flanges

Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a

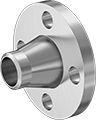

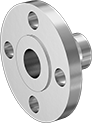

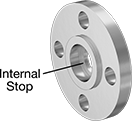

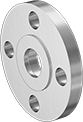

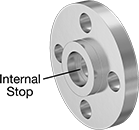

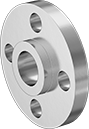

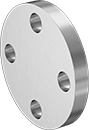

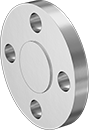

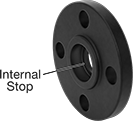

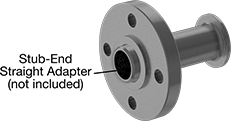

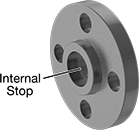

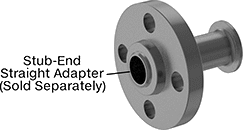

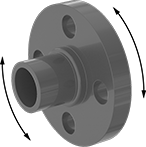

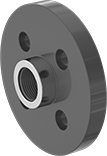

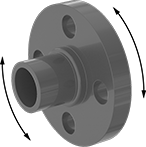

Butt-weld flanges are also known as weld-neck flanges; the flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld. Socket-connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through. Slip-on weld flanges have no internal stop; slide a pipe through the flange and weld on both sides. Stub-end flanges are also known as lap-joint flanges; use them with a stub-end straight adapter (not included). The stub-end straight adapter slides into the flange and welds to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily for frequent cleaning and inspecting. Cap flanges are also known as blind flanges.

Forged flanges have better strength than cast flanges. Cast flanges are also called MSS flanges.

304 stainless steel flanges offer very good corrosion resistance. 316 stainless steel flanges have excellent corrosion resistance.

- For Use With: Air, Water, Oil, Natural Gas

- Pressure Class: 150

- Specifications Met: ASTM A182, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- For Use With: Air, Water, Oil, Natural Gas

- Pressure Class: 150

- Specifications Met

4-8 pipe size: ASTM 182

All other pipe sizes: ASME B16.5, ASTM A182 - Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- For Use With: Air, Water, Oil, Natural Gas

- Pressure Class: 150

- Specifications Met: ASTM A182, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- For Use With: Air, Water, Oil, Natural Gas

- Pressure Class: 150

- Specifications Met: ASTM A182, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

Flanges | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bolt Hole | Thin-Wall Straight Adapters | Standard-Wall Straight Adapters | ||||||||||

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Each | Each | Each | |||

304/304L Stainless Steel | ||||||||||||

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 230 psi @ 72° F | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 |

316/316L Stainless Steel | ||||||||||||

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 230 psi @ 72° F | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 |

- For Use With: Air, Water, Oil, Natural Gas

- Pressure Class: 150

- Specifications Met: ASTM A182, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- For Use With: Air, Water, Natural Gas, Oil

- Pressure Class: 150

- Specifications Met: MSS SP-51, ASTM A351

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- For Use With: Air, Water, Natural Gas, Oil

- Pressure Class: 150

- Specifications Met: MSS SP-42, ASTM A351

- Fittings: Use schedule 40 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

High-Pressure Stainless Steel Unthreaded Pipe Flanges

Use these heavy duty forged flanges for high-pressure applications. Bolt two flat-surface flanges or two raised-surface flanges of same size together with a gasket (sold separately) to create an access point in a pipe line.

304 stainless steel flanges offer very good corrosion resistance. 316 stainless steel flanges have excellent corrosion resistance.

Butt-weld flanges are also known as weld-neck flanges; the flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld. Slip-on weld flanges have no internal stop; slide a pipe through the flange and weld on both sides. Socket-connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through.

Stub-end flanges are also known as lap-joint flanges; use them with a stub-end straight adapter (not included). The stub-end straight adapter slides into the flange and welds to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily for frequent cleaning and inspecting. Cap flanges are also known as blind flanges.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met:

Pressure Class 300: ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6

Pressure Class 600: ASME B16.5, ASTM A182 - Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Fittings: Use Schedule 40 stainless steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Each | |

304/304L Stainless Steel | ||||||||||

Pressure Class 300 | ||||||||||

| 3/4 | 12 | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 600 psi @ 72° F | 415 psi @ 360° F | 00000000 | 000000 |

316/316L Stainless Steel | ||||||||||

Pressure Class 300 | ||||||||||

| 3/4 | 12 | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 600 psi @ 72° F | 415 psi @ 360° F | 00000000 | 00000 |

- For Use With:

4 and 6 Pipe Sizes: Air, Hydraulic Fluid, Natural Gas, Oil, Water

All other sizes: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water - Pressure Class: See table

- Specifications Met: See table

- Certification:: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Fittings: Use Schedule 40 stainless steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Specifications Met | Each | |

304/304L Stainless Steel | |||||||||||

Pressure Class 300 | |||||||||||

| 3/4 | 12 | 600 psi @ 72° F | 300 psi @ 360° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 000000 |

316/316L Stainless Steel | |||||||||||

Pressure Class 300 | |||||||||||

| 3/4 | 12 | 600 psi @ 72° F | 300 psi @ 360° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6 | 00000000 | 00000 |

Pressure Class 600 | |||||||||||

| 3/4 | 12 | 1,200 psi @ 72° F | 840 psi @ 400° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | ASME B16.5, ASTM A182 | 0000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met:

Pressure Class 300: ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6

Pressure Class 600: ASME B16.5, ASTM A182 - Certification:: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Fittings: Use Schedule 40 stainless steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Each | |

304/304L Stainless Steel | ||||||||||

Pressure Class 300 | ||||||||||

| 3/4 | 12 | 600 psi @ 72° F | 300 psi @ 360° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 00000000 | 000000 |

316/316L Stainless Steel | ||||||||||

Pressure Class 300 | ||||||||||

| 3/4 | 12 | 600 psi @ 72° F | 300 psi @ 360° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 00000000 | 00000 |

Pressure Class 600 | ||||||||||

| 3/4 | 12 | 1,200 psi @ 72° F | 840 psi @ 400° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 0000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met:

Pressure Class 300: ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6

Pressure Class 600: ASME B16.5, ASTM A182 - Certification:: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Fittings: Use Schedule 40 stainless steel

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met:

Pressure Class 300: ASME B16.5, ASTM A182, MSS SP-25, MSS SP-6

Pressure Class 600: ASME B16.5, ASTM A182 - Certification:: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Fittings: Use Schedule 40 stainless steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Each | |

304/304L Stainless Steel | ||||||||||

Pressure Class 300 | ||||||||||

| 3/4 | 12 | 600 psi @ 72° F | 300 psi @ 360° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 00000000 | 000000 |

Pressure Class 600 | ||||||||||

| 3/4 | 12 | 1,200 psi @ 72° F | 840 psi @ 400° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 0000000 | 00000 |

316/316L Stainless Steel | ||||||||||

Pressure Class 300 | ||||||||||

| 3/4 | 12 | 600 psi @ 72° F | 300 psi @ 360° F | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 00000000 | 00000 |

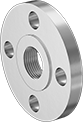

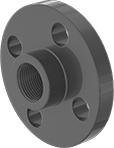

Low-Pressure Stainless Steel Threaded Pipe Flanges

Also known as Pressure Class 150 flanges, these are designed for low-pressure pipe applications. Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a gasket (sold separately) to create an access point within a line.

304 stainless steel flanges have very good corrosion resistance. 316 stainless steel flanges have excellent corrosion resistance.

Forged flanges have better strength than cast flanges. They are also called ANSI flanges. Cast flanges are also called MSS flanges.

Reducing flanges allow you to transition your system to a smaller pipe size; attach to a flange with a larger pipe size but with the same flange dimensions.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met:

Alloy 20 flanges: ASME B16.5

All other flanges: ASME B16.5, ASTM A182 - Fittings: Use Class 150 stainless steel

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met: ASTM A182, ASME B16.5

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Fittings: Use Class 150 stainless steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Flange Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Each | |

304/304L Stainless Steel | ||||||||||

NPT | ||||||||||

| 1 | 1 1/4 | 4 5/8" | 1/2" | 0.62" | 4 | 3 1/2" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 0000000 |

316/316L Stainless Steel | ||||||||||

NPT | ||||||||||

| 1 | 1 1/4 | 4 5/8" | 1/2" | 0.62" | 4 | 3 1/2" | 230 psi @ 72° F | 150 psi @ 360° F | 000000000 | 000000 |

- For Use With: Natural Gas, Steam, Oil, Water, Air

- Pressure Class: 150

- Specifications Met: MSS SP-51, ASTM A351, MSS SP-42

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Fittings: Use Class 150 stainless steel

High-Pressure Stainless Steel Threaded Pipe Flanges

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A182, ASME B16.5

- Pipe Nipples and Pipe: Use Schedule 80 stainless steel

Forged for high strength, these heavy duty flanges can handle high-pressure applications. They are also known as ANSI flanges. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line.

304 stainless steel flanges provide very good corrosion resistance. 316 stainless steel flanges have excellent corrosion resistance.

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Each | |

304/304L Stainless Steel | ||||||||||

NPT | ||||||||||

Pressure Class 300 | ||||||||||

| 3/4 | 12 | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | 0000000 | 000000 |

Pressure Class 600 | ||||||||||

| 3/4 | 12 | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 1,200 psi @ 72° F | 840 psi @ 400° F | 0000000 | 00000 |

316/316L Stainless Steel | ||||||||||

NPT | ||||||||||

Pressure Class 300 | ||||||||||

| 3/4 | 12 | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | 0000000 | 00000 |

Pressure Class 600 | ||||||||||

| 3/4 | 12 | 4 5/8" | 5/8" | 0.75" | 4 | 3 1/4" | 1,200 psi @ 72° F | 840 psi @ 400° F | 0000000 | 000000 |

Low-Pressure Steel Unthreaded Pipe Flanges

Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a gasket (sold separately) to create an access point in a pipe line. Flanges are for use with low-pressure applications in noncorrosive environments.

Butt-weld flanges are also known as weld-neck flanges. The flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld.

Slip-on weld flanges have no internal stop. Slide a pipe through the flange and weld on both sides.

Socket-connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through.

Cap flanges are also known as blind flanges.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: See table

- Certification: See table

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Schedule 40 iron or steel

Bolt Hole | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Wall Thick. | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Pressure Class | Construction | Max. Pressure | Max. Steam Pressure | Certification | Specifications Met | Each | |

| 1 1/4 | 0.14" | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 150 | Seamless | 285 psi @ 72° F | 150 psi @ 300° F | Material Certificate with Traceable Lot Number and Test Report | ASME B16.5, ASTM A105, MSS SP-25 | 000000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: See table

- Certification: See table

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: See Table

Bolt Hole | For Fitting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Pressure Class | Max. Pressure | Max. Steam Pressure | Schedule | Material | Certification | Specifications Met | Each | |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 150 | 285 psi @ 72° F | 150 psi @ 300° F | 40 | Iron, Steel | Material Certificate with Traceable Lot Number and Test Report | ASME B16.5, ASTM A105, MSS SP-25 | 000000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met: See table

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Schedule 40 iron or steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Specifications Met | Each | |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 285 psi @ 72° F | 150 psi @ 300° F | ASME B16.5, ASTM A105, MSS SP-25 | 000000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met: MSS SP-25, ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Schedule 40 iron or steel

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: See table

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Schedule 40 iron or steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Pressure Class | Max. Pressure | Max. Steam Pressure | Specifications Met | Each | |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 150 | 285 psi @ 72° F | 150 psi @ 300° F | ASME B16.5, ASTM A105, MSS SP-25 | 000000000 | 000000 |

High-Pressure Steel Unthreaded Pipe Flanges

Forged for extra strength, these heavy duty flanges can withstand high-pressure applications. Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a gasket (sold separately) to create an access point in a pipe line.

Butt-weld flanges are also known as weld-neck flanges; the flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld.

Slip-on weld flanges have no internal stop; slide a pipe through the flange and weld on both sides.

Socket-connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through.

Stub-end flanges are also known as lap-joint flanges; use them with a stub-end straight adapter (not included). The stub-end straight adapter slides into the flange and welds to pipe (not the flange). Since the flange isn’t welded to the pipe, it can be disconnected easily for frequent cleaning and inspecting.

Cap flanges are also known as blind flanges.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 3000 and Schedule 80 steel

Bolt Hole | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Wall Thick. | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

Pressure Class 300 | ||||||||||||

| 3/4 | 12 | 0.154" | 4 5/8" | 5/8" | 3/4" | 4 | 3 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | Steel | 00000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 3000 and Schedule 80 steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

Pressure Class 300 | |||||||||||

| 3/4 | 12 | 4 5/8" | 5/8" | 3/4" | 4 | 3 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | Steel | 00000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: See table

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 3000 and Schedule 80 steel

Bolt Hole | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Specifications Met | Each | |

Pressure Class 300 | ||||||||||||

| 3/4 | 12 | 4 5/8" | 5/8" | 3/4" | 4 | 3 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | Steel | ASME B16.5, ASTM A105 | 00000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 3000 and Schedule 80 steel

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A105, ASME B16.5

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 3000 and Schedule 80 steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

Pressure Class 300 | |||||||||||

| 3/4 | 12 | 4 5/8" | 5/8" | 3/4" | 4 | 3 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | Steel | 00000000 | 000000 |

Low-Pressure Steel Threaded Pipe Flanges

Use these flanges for low-pressure applications in noncorrosive environments. Bolt two flanges of the same size together with a gasket (sold separately) to create an access point within a line.

Reducing flanges allow you to transition your system to a smaller pipe size; attach to a flange with a larger pipe size but with the same flange dimensions.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met:

NPT: ASME B16.5, ASTM A105, MSS SP-25

BSPT: ASTM A105 - Fittings: Use Class 125 or 150 iron and steel

- Pipe Nipples and Pipe: Use Schedule 40 steel

- For Use With:

1/4 Pipe Size: Air, Natural Gas, Oil, Water

All other sizes: Air, Natural Gas, Oil, Steam, Water - Specifications Met:

1/4 Pipe Size: ASTM A105, MSS SP-6

All other sizes: ASME B16.5, ASTM A105, MSS SP-25, MSS SP-6 - Fittings: Use Class 125 or 150 iron and steel

- Pipe Nipples and Pipe: Use Schedule 40 Steel

Bolt Hole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Flange Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | |||||||||||

| 1 | 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 285 psi @ 72° F | 230 psi @ 300° F | Steel | 0000000 | 0000000 |

Low-Pressure Steel Threaded Pipe Flanges for Low Temperatures

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Temperature Range: -40° to 800° F

- Specifications Met: ASME B16.5, ASTM A350, MSS SP-25

- Certification: Material Certificate with Traceable Lot Number and Test Report

- Fittings: Use Schedule 40 ASTM A420 carbon steel

- Pipe Nipples and Pipe: Use Schedule 40 ASTM A333 carbon steel

Use these Pressure Class 150 pipe flanges in low-pressure lines where temperatures drop down to -40° F. Even as temperatures drop, these flanges won't become brittle, so they absorb impact better than our other low-pressure steel flanges. All have been impact tested to verify their toughness. Bolt two flanges together with a gasket to create an access point within a line. With threaded connections, you can take them apart for maintenance and repairs.

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | ||||||||||

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 285 psi @ 72° F | 230 psi @ 300° F | A350 LF2 Steel | 0000000 | 000000 |

FM-Approved Low-Pressure Cast Iron Threaded Pipe Flanges

Suitable for use in fire-protection applications, these flanges are brittle and can be quickly opened with the strike of a sledge hammer. Bolt two flanges of the same size together with a gasket (sold separately) to create an access point within a line. Use in noncorrosive environments.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met:

3/4 Pipe Size: ASME B1.20.1, ASME B16.1, ASTM A126, FM Approved

All other sizes: ASME B1.20.1, ASME B16.1, ASTM A126, FM Approved, UL Listed - Pipe Nipples and Pipe: Use Schedule 40 steel

- Fittings: Use Class 125 iron and steel

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | ||||||||||

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 000000 |

Low-Pressure Galvanized Steel Threaded Pipe Flanges

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met: ASTM A123, ASTM A105, ASME B16.5

- Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

- Fittings: Use Class 125 or 150 galvanized iron and galvanized steel

The galvanized finish on these flanges provides fair corrosion resistance. Also known as Pressure Class 150 flanges, they are for use in low-pressure applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line.

Bolt Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Each | |

NPT | |||||||||

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 285 psi @ 72° F | 150 psi @ 300° F | 00000000 | 000000 |

Medium-Pressure Steel Threaded Pipe Flanges

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: See table

- Specifications Met: ASTM A105, ASME B16.5

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 300 or Schedule 80 iron and steel

With better strength than our low-pressure steel flanges, these are for use in medium-pressure applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. Flanges are also known as Pressure Class 300 or Pressure Class 600 flanges. Use in noncorrosive environments.

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT | ||||||||||

Pressure Class 300 | ||||||||||

| 3/4 | 4 5/8" | 5/8" | 3/4" | 4 | 3 1/4" | 600 psi @ 72° F | 300 psi @ 300° F | Steel | 00000000 | 000000 |

Medium-Pressure Galvanized Steel Threaded Pipe Flanges

- For Use With: Air, Natural Gas, Steam, Water

- Pressure Class : 300

- Specifications Met: ASTM A123, ASTM A105, ASME B16.5

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Fittings: Use Class 300 iron or steel

A galvanized finish gives these flanges fair corrosion resistance. Also known as Pressure Class 300 flanges, they can withstand medium-pressure applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line.

Bolt Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Each | |

NPT | ||||||||

| 3/4 | 4 5/8" | 3/4" | 3/4" | 4 | 3 1/4" | 600 psi @ 72° F | 0000000 | 0000000 |

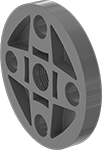

Aluminum Unthreaded Pipe Flanges

Also known as Pressure Class 125 flanges, these are for use in low-pressure applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. Flanges are aluminum, which is lightweight with good corrosion resistance. Slip-on weld flanges have no internal stop; slide a pipe through the flange and weld on both sides. Cap flanges are also known as blind flanges.

- For Use With: Air, Oil, Water

- Pressure Class: 125

- Specifications Met: ASME B16.1

- Fittings: Use Schedule 40 aluminum

- Pipe: Use Schedule 40 aluminum

Bolt Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Each | |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 150 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Oil, Water

- Pressure Class: 125

- Specifications Met: ASME B16.1

- Fittings: Use Schedule 40 aluminum

- Pipe: Use Schedule 40 aluminum

Bolt Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Each | |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 150 psi @ 72° F | 000000000 | 000000 |

Low-Pressure Aluminum Threaded Pipe Flanges

Also known as Pressure Class 125 flanges, these are for use in low-pressure applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. Flanges are aluminum, which is lightweight with good corrosion resistance.

Reducing flanges allow you to transition your system to a smaller pipe size; attach to a flange with a larger pipe size but with the same flange dimensions.

- For Use With: Air, Oil, Water

- Pressure Class: 125

- Specifications Met:

Pipe Size 1-6: ASME B16.1 - Fittings: Use Class 150 aluminum

- Pipe Nipples and Pipe: Use Schedule 40 aluminum

Bolt Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Each | |

NPT | ||||||||

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 150 psi @ 72° F | 000000000 | 000000 |

- For Use With: Air, Oil, Water

- Pressure Class: 125

- Specifications Met: ASME B16.1

- Fittings: Use Class 150 aluminum

- Pipe Nipples and Pipe: Use Schedule 40 aluminum

Bolt Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Flange Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Each | |

NPT | |||||||||

| 1 | 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 150 psi @ 72° F | 000000000 | 000000 |

Low-Pressure Brass and Bronze Threaded Pipe Flanges

- For Use With: Air, Drinking Water, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met:

NPT: ASME B1.20.1, ASME B16.24, ASTM B584, NSF/ANSI 61

BSPT: ASTM B584, BS21 - Pipe Nipples and Pipe: Use Schedule 40 brass

- Fittings:

NPT: Use Class 125 brass

BSPT: Use Class 125 bronze

Also known as Pressure Class 150 flanges, these are designed for low-pressure applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. Flanges have good corrosion resistance. To adhere to safety standards for drinking water systems, use flanges that meet NSF/ANSI 61.

Bolt Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Max. Pressure | Material | Each | |

NPT | |||||||||

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | 225 psi @ 72° F | Brass | 00000000 | 0000000 |

Thick-Wall Plastic Pipe Flanges for Water

- For Use With: Drinking Water, Water

- Pressure Class: 150

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Fittings: Use Schedule 80 PVC Plastic

Also known as Pressure Class 150 flanges, these flanges have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing, waste water treatment, and irrigation. They meet NSF/ANSI 61 for drinking water. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. All are PVC, which has good corrosion resistance. They meet ASTM D1784 specifications and testing requirements for material quality.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

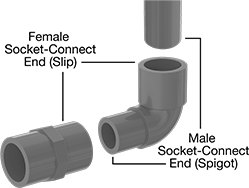

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

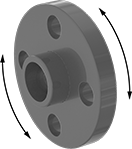

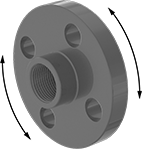

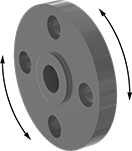

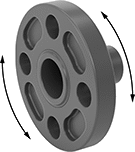

Rotating flanges are also known as Van Stone flanges; they swivel for easy bolt hole alignment.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Rotating flanges are also known as Van Stone flanges; they swivel for easy bolt hole alignment.

To prevent leaks in threaded connections, apply a sealant to the male threads. For plastic threads, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections.

To prevent leaks in threaded connections, apply a sealant to the male threads. For metal threads, use PTFE tape. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the flange, then wrench-tighten one to two turns.

Flanges with stainless steel collar have a reinforcement on the female threads to prevent the threads from cracking.

To prevent leaks in threaded connections, apply a sealant to the male threads. For plastic threads, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections.

Rotating flanges are also known as Van Stone flanges; they swivel for easy bolt hole alignment.

Cap flanges are also known as blind flanges.

Bolt Hole | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. | Bolt Circle Dia. | Material | Color | Each | |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | PVC Plastic | Dark Gray | 00000000 | 000000 |

CPVC Pipe Flanges for Hot Water

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water,

Fixed Cap Flanges: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water - Pressure Class: 150

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Fittings: Use Schedule 80 CPVC Plastic

Made of CPVC, these flanges can handle high temperatures up to 200° F. They meet NSF/ANSI Standard 61 for drinking water. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. Also known as Pressure Class 150 flanges, they have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. Flanges have good corrosion resistance. They meet ASTM D1784 specifications and testing requirements for material quality. They are comparable to Corzan.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local regulatory limits on VOCs (Volatile Organic Compounds).

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

Rotating flanges are also known as Van Stone flanges; they swivel for easy bolt hole alignment.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

Rotating flanges are also known as Van Stone flanges; they swivel for easy bolt hole alignment.

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the flange, then wrench-tighten one to two turns.

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the flange, then wrench-tighten one to two turns.

Rotating flanges are also known as Van Stone flanges; they swivel for easy bolt hole alignment.

Cap flanges are also known as blind flanges.

Bolt Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Color | Each | |

| 1 1/4 | 4 5/8" | 1/2" | 5/8" | 4 | 3 1/2" | Light Gray | 00000000 | 000000 |

Solder-Connect Fittings for Copper Tubing

- Temperature Range: 32° to 200° F

Solder these fittings to copper tubing or the tube end of another fitting for a permanent, leak-tight connection. They are also known as sweat fittings. Fittings have good corrosion resistance. To adhere to safety standards for drinking water systems, use fittings that meet NSF/ANSI 61 or EN 1057.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

- For Use With: Drinking Water

- Tubing: Use with K, M, L copper

- Specifications Met: See table

Fittings with flange end bolt to equipment or another same-size flange to create an access point within a line.

| Copper Tube Size | For Tube OD | Flange OD | Bolt Circle Dia. | Number of Bolt Holes | Bolt Hole Diameter | For Bolt Diameter | Bolts Included | Material | Max. Pressure | Specifications Met | Each | |

| 1 1/4 | 1 3/8" | 4 5/8" | 3 1/2" | 4 | 5/8" | 1/2" | No | Brass | 400 psi @ 72° F | ASME B16.18, NSF/ANSI 61 | 00000000 | 0000000 |

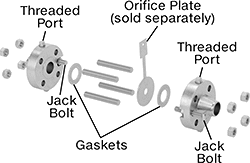

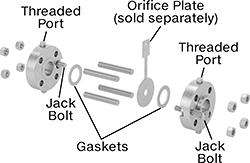

Flow-Control Flange Unions

Measure, throttle, and regulate the flow of liquids and gases in your line by adding an orifice plate to these unions. They consist of two flange halves, plus all of the components needed to connect them together. Tighten the jack bolts to separate the flange halves to inspect or replace the orifice plate.

To throttle flow, mount an orifice plate between the two flanges. The orifice plate restricts the flow in order to regulate it.

To measure flow, build the same assembly, except you’ll also connect a differential pressure gauge or transmitter to both flange halves using the threaded ports. Your gauge or transmitter will measure the difference between the pressure before and after the orifice plate. The pressure difference is proportional to flow rate, so you can use that measurement to calculate your line’s flow rate.

Butt-weld flanges are also known as weld-neck flanges; the flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld. Slip-on weld flanges have no internal stop; slide a pipe through the flange and weld on both sides.

316/316L stainless steel flanges have excellent corrosion resistance.

- For Use With: Air, Natural Gas, Oil, Water

- Temperature Range: Not Rated

- Specifications Met: See table

- Pressure Class: 300

- Fittings:

Carbon Steel: Use Schedule 40 steel

316/316L Stainless Steel: Use Schedule 40 stainless steel - Pipe Nipples and Pipe:

Carbon Steel: Use Schedule 40 steel

316/316L Stainless Steel: Use Schedule 40 stainless steel

Bolt Hole | Port | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Construction | Flange OD | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Pipe Size | No. of | Includes | Each | |

Carbon Steel | |||||||||||

| 3/4 | Seamless | 4 5/8" | 5/8" | 11/16" | 4 | 3 1/4" | 1/2 NPT | 2 | Gaskets, Jack Bolts, Nuts, Port Plugs, Threaded Rods | 0000000 | 0000000 |

316/316L Stainless Steel | |||||||||||

| 3/4 | Seamless | 4 5/8" | 5/8" | 11/16" | 4 | 3 1/4" | 1/2 NPT | 2 | Gaskets, Jack Bolts, Nuts, Port Plugs, Threaded Rods | 0000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Water

- Temperature Range: Not Rated

- Specifications Met: See table

- Pressure Class: 300

- Fittings:

Carbon Steel: Use Schedule 40 steel

316/316L Stainless Steel: Use Schedule 40 stainless steel - Pipe Nipples and Pipe:

Carbon Steel: Use Schedule 40 steel

316/316L Stainless Steel: Use Schedule 40 stainless steel