Filter by

Nozzle Type

Air Consumption @ Pressure

Overall Length

Maximum Temperature

Airflow Adjustability

Volume @ Pressure

Specifications Met

RoHS

DFARS Specialty Metals

REACH

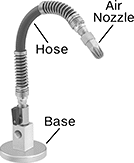

Create-Your-Own Bend-and-Stay Air Nozzles

|

|  |

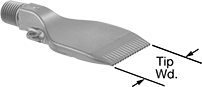

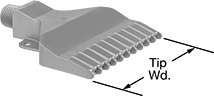

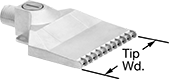

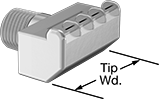

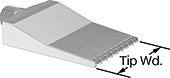

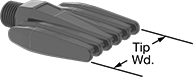

Wide-Airflow Air Nozzles Style A | Wide-Airflow Air Nozzles Style B |

|  |

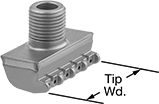

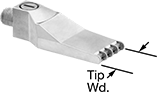

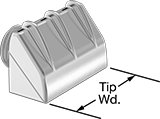

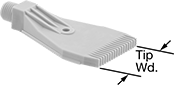

Wide-Airflow Air Nozzles Style C | Wide-Airflow Air Nozzles, Style D |

Wide-Airflow Air Nozzles

|  |

Style A | Style B |

|  |

Style C | Style D |

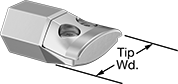

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Male Inlet—316L Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 ft³/min @ 100 psi | 750 | 84 dBA @ 80 psi | 15/16" | 3/16" | 2 1/4" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N17 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Inlet—316L Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 46 ft³/min @ 100 psi | 750 | 89 dBA @ 80 psi | 2 7/16" | 3/16" | 3 1/8" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

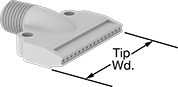

Style B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Inlet—Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 ft³/min @ 100 psi | 350 | 84 dBA @ 80 psi | 1 7/8" | 1/4" | 2 9/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N11 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58 ft³/min @ 100 psi | 350 | 90 dBA @ 80 psi | 2 3/4" | 1/4" | 2 9/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N15 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Inlet—ABS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 43 ft³/min @ 90 psi | 170 | 85 dBA @ 80 psi | 2" | 1/4" | 3 9/16" | 100 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N54 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 ft³/min @ 100 psi | 150 | 87 dBA @ 80 psi | 1 7/8" | 1/4" | 3 9/16" | 100 | — | 7343N63 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Inlet—316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 43 ft³/min @ 90 psi | 500 | 85 dBA @ 80 psi | 2" | 1/4" | 3 9/16" | 150 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N56 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 ft³/min @ 100 psi | 500 | 82 dBA @ 80 psi | 1 7/8" | 1/4" | 3 9/16" | 150 | OSHA Compliant 29 CFR 1910.95 | 7343N62 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Female Inlet—ABS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 ft³/min @ 90 psi | 170 | 85 dBA @ 80 psi | 2" | 1/4" | 3 9/16" | 100 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N52 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 43 ft³/min @ 90 psi | 170 | 85 dBA @ 80 psi | 2" | 1/4" | 3 9/16" | 100 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N55 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style D | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Female Inlet—Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37 ft³/min @ 80 psi | 250 | 83 dBA @ 80 psi | 2" | 7/16" | 2 1/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N38 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 ft³/min @ 100 psi | 250 | 75 dBA @ 80 psi | 2" | 7/16" | 2 1/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K65 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Female Inlet—316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 ft³/min @ 80 psi | 1,000 | 77 dBA @ 80 psi | 2" | 7/16" | 2 1/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N37 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37 ft³/min @ 80 psi | 1,000 | 83 dBA @ 80 psi | 2" | 7/16" | 2 1/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N39 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wide-Airflow Air Nozzles

|  |  |

Style A | Style B | Style C |

|  |  |

Style D | Style E | Style F |

Style A

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 ft³/min @ 100 psi | 158 | 80 dBA @ 80 psi | 15/16" | 1/8" | 2 3/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 31875K19 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Female Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 ft³/min @ 100 psi | 158 | 85 dBA @ 80 psi | 1 13/16" | 3/16" | 3 1/8" | 145 | OSHA Compliant 29 CFR 1910.242 | 31875K29 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 BSPP Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 ft³/min @ 85 psi | 155 | 82 dBA @ 80 psi | 15/16" | 3/16" | 2 3/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N22 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 ft³/min @ 100 psi | 158 | 83 dBA @ 80 psi | 1 3/16" | 1/8" | 3 1/8" | 145 | OSHA Compliant 29 CFR 1910.242 | 31875K14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 BSPP Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 ft³/min @ 85 psi | 155 | 85 dBA @ 80 psi | 1 13/16" | 3/16" | 3 1/8" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N23 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style B

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 BSPP Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 52 ft³/min @ 85 psi | 355 | 90 dBA @ 80 psi | 2 3/4" | 1/4" | 2 9/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N29 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2 NPT Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 165 ft³/min @ 100 psi | 350 | 96 dBA @ 80 psi | 5 9/16" | 1/4" | 3 13/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N16 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2 BSPP Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 156 ft³/min @ 85 psi | 355 | 96 dBA @ 80 psi | 5 9/16" | 1/4" | 3 13/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N31 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ABS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33 ft³/min @ 100 psi | 170 | 85 dBA @ 80 psi | 1 7/8" | 1/4" | 3 9/16" | 100 | OSHA Compliant 29 CFR 1910.95 | 5329K51 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33 ft³/min @ 100 psi | 500 | 85 dBA @ 80 psi | 1 7/8" | 1/4" | 3 9/16" | 150 | OSHA Compliant 29 CFR 1910.95 | 5329K68 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style D

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 ft³/min @ 100 psi | 400 | 90 dBA @ 80 psi | 2" | 1/8" | 3 7/16" | 120 | OSHA Compliant 29 CFR 1910.95 | 5329K65 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style E

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 BSPT Female Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37 ft³/min @ 80 psi | 250 | 83 dBA @ 80 psi | 2" | 7/16" | 2 1/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N47 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37 ft³/min @ 80 psi | 1,000 | 83 dBA @ 80 psi | 2" | 7/16" | 2 1/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N48 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style F

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Barbed Male Inlet for 5/16" Hose ID | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 ft³/min @ 75 psi | 120 | 83 dBA @ 80 psi | 1 7/8" | 1/8" | 8" | 75 | OSHA Compliant 29 CFR 1910.95 | 5329K64 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Food and Beverage Wide-Airflow Air Nozzles

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Performance | Specs. Met | Food Industry Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 13 ft³/min @ 75 psi | 120 | 80 dBA @ 80 psi | 1" | 1/16" | 3 9/16" | 85 | — | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297 | 5329K91 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 18 ft³/min @ 75 psi | 120 | 86 dBA @ 80 psi | 1 7/8" | 1/4" | 3 1/2" | 85 | — | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297 | 5329K83 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 20 ft³/min @ 75 psi | 120 | 83 dBA @ 80 psi | 1 7/8" | 1/8" | 3 9/16" | 85 | — | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297 | 5329K63 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 11 ft³/min @ 75 psi | 120 | 83 dBA @ 80 psi | 1 7/8" | 1/8" | 3 9/16" | 85 | — | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 177.1520 | 5329K52 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVDF | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 17 ft³/min @ 75 psi | 200 | 82 dBA @ 80 psi | 1 13/16" | 1/4" | 3 9/16" | 100 | Metal Detectable | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 177.2510 | 5329K31 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 24 ft³/min @ 75 psi | 200 | 85 dBA @ 80 psi | 1 13/16" | 1/4" | 3 9/16" | 100 | Metal Detectable | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 177.2510 | 5329K32 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 36 ft³/min @ 75 psi | 200 | 93 dBA @ 80 psi | 1 13/16" | 1/4" | 3 9/16" | 100 | Metal Detectable | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 177.2510 | 5329K33 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 16 ft³/min @ 75 psi | 1,000 | 83 dBA @ 80 psi | 1 5/8" | 1/16" | 3 3/16" | 145 | — | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 5329K85 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 38 ft³/min @ 75 psi | 1,000 | 90 dBA @ 80 psi | 2 3/4" | 3/16" | 3 1/8" | 435 | — | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 5329K89 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 BSPP Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 13 ft³/min @ 75 psi | 120 | 80 dBA @ 80 psi | 1" | 1/16" | 3 9/16" | 85 | — | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297 | 5329K92 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 18 ft³/min @ 75 psi | 120 | 84 dBA @ 80 psi | 1 7/8" | 1/4" | 3 5/8" | 85 | — | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 177.2470, FDA Compliant 21 CFR 178.3297 | 5329K84 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 16 ft³/min @ 75 psi | 1,000 | 83 dBA @ 80 psi | 1 5/8" | 1/16" | 3 3/16" | 145 | — | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 5329K86 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 38 ft³/min @ 75 psi | 1,000 | 90 dBA @ 80 psi | 2 3/4" | 3/16" | 3 1/8" | 435 | — | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 5329K9 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Profile Wide-Airflow Air Nozzles

|  |  |

Style A | Style B | Style C |

Style A

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316L Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 ft³/min @ 100 psi | 750 | 81 dBA @ 80 psi | 15/16" | 3/16" | 15/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N21 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style B

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 ft³/min @ 80 psi | 250 | 75 dBA @ 80 psi | 1" | 3/8" | 1 5/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N35 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 ft³/min @ 80 psi | 250 | 82 dBA @ 80 psi | 1" | 3/8" | 1 5/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N41 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 ft³/min @ 80 psi | 1,000 | 75 dBA @ 80 psi | 1" | 3/8" | 1 5/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N36 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 ft³/min @ 80 psi | 1,000 | 82 dBA @ 80 psi | 1" | 3/8" | 1 5/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N42 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 BSPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 ft³/min @ 80 psi | 250 | 82 dBA @ 80 psi | 1" | 3/8" | 1 5/16" | 250 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N49 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ABS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 ft³/min @ 90 psi | 170 | 85 dBA @ 80 psi | 1 11/16" | 5/16" | 1 5/8" | 100 | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 7343N53 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 31 ft³/min @ 100 psi | 500 | 91 dBA @ 80 psi | 1 11/16" | 5/16" | 1 5/8" | 150 | OSHA Compliant 29 CFR 1910.95 | 7343N57 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Right-Angle Food and Beverage Wide-Airflow Air Nozzles

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Food Industry Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 ft³/min @ 75 psi | 1,000 | 84 dBA @ 80 psi | 1" | 1/8" | 3/4" | 435 | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 5329K87 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 BSPP Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 ft³/min @ 75 psi | 1,000 | 84 dBA @ 80 psi | 1" | 1/8" | 3/4" | 435 | OSHA Compliant 29 CFR 1910.95 | FDA Compliant 21 CFR 110.40 | 5329K88 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wide-Airflow Bend-and-Stay Air Nozzles

Air Inlet | Tip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Hose Material | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 12 ft³/min @ 100 psi | 140 | 75 dBA @ 80 psi | 1" | 3/8" | 25" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K913 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 14 ft³/min @ 100 psi | 140 | 75 dBA @ 80 psi | 1" | 3/8" | 13 11/16" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K43 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 21 ft³/min @ 100 psi | 140 | 85 dBA @ 80 psi | 1" | 3/8" | 25" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K939 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 26 ft³/min @ 100 psi | 140 | 80 dBA @ 80 psi | 2" | 3/8" | 7 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K916 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 26 ft³/min @ 100 psi | 140 | 80 dBA @ 80 psi | 2" | 3/8" | 13 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K917 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 26 ft³/min @ 100 psi | 140 | 80 dBA @ 80 psi | 2" | 3/8" | 19 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K918 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 26 ft³/min @ 100 psi | 140 | 80 dBA @ 80 psi | 2" | 3/8" | 25 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K919 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 45 ft³/min @ 100 psi | 140 | 85 dBA @ 80 psi | 2" | 3/8" | 7 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K943 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 45 ft³/min @ 100 psi | 140 | 85 dBA @ 80 psi | 2" | 3/8" | 13 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K944 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 45 ft³/min @ 100 psi | 140 | 85 dBA @ 80 psi | 2" | 3/8" | 19 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K945 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 45 ft³/min @ 100 psi | 140 | 85 dBA @ 80 psi | 2" | 3/8" | 37 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K948 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 12 ft³/min @ 100 psi | 140 | 75 dBA @ 80 psi | 1" | 3/8" | 6 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K923 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 26 ft³/min @ 100 psi | 140 | 80 dBA @ 80 psi | 2" | 3/8" | 7 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K929 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 26 ft³/min @ 100 psi | 140 | 80 dBA @ 80 psi | 2" | 3/8" | 13 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K931 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 26 ft³/min @ 100 psi | 140 | 80 dBA @ 80 psi | 2" | 3/8" | 19 3/4" | 250 | PVC | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 31875K932 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable Wide-Airflow Air Nozzles

Tip | Air Inlet | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Thk. | Pipe Size | Thread Type | Gender | Connection Port | Connection | Air Consumption Range @ Pressure | Max. Temp., ° F | Volume @ Pressure | Overall Lg. | Max. Inlet Pressure, psi | Material | Specs. Met | Each | ||

| 15/16" | 3/16" | 1/8 | NPT | Male | Pipe | Threaded | 0.3 ft³/min to 17 ft³/min @ 100 psi | 750 | 82 dBA @ 80 psi | 2 3/4" | 145 | 316 Stainless Steel | OSHA Compliant 29 CFR 1910.242 | 31875K22 | 0000000 | |

| 2 7/16" | 3/16" | 1/4 | NPT | Male | Pipe | Threaded | 1 ft³/min to 46 ft³/min @ 100 psi | 750 | 87 dBA @ 80 psi | 3 1/8" | 145 | 316 Stainless Steel | OSHA Compliant 29 CFR 1910.242 | 31875K23 | 000000 | |

Right-Angle Wide-Airflow Air Nozzles

Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 ft³/min @ 100 psi | 155 | 84 dBA @ 80 psi | 15/16" | 3/16" | 15/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N18 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316L Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 ft³/min @ 100 psi | 750 | 81 dBA @ 80 psi | 15/16" | 3/16" | 11/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N19 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 BSPP Male | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 ft³/min @ 85 psi | 155 | 84 dBA @ 80 psi | 15/16" | 3/16" | 15/16" | 145 | OSHA Compliant 29 CFR 1910.242 | 7343N32 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

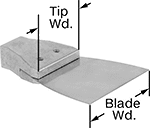

Scraper Air Nozzles

Nozzles | Replacement Blades | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Blade | Tip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lg. | Wd. | Thk. | Material | Air Consumption @ Pressure | Max. Temp., ° F | Volume @ Pressure | Wd. | Thk. | Overall Lg. | Max. Inlet Pressure, psi | Material | Specs. Met | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/16" | 3" | 0.03" | Steel | 26 ft³/min @ 100 psi | 250 | 75 dBA @ 80 psi | 2" | 1/2" | 4 3/8" | 250 | Aluminum | OSHA Compliant 29 CFR 1910.242, OSHA Compliant 29 CFR 1910.95 | 4653N11 | 0000000 | 4653N12 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||