About Sizing Belts

More

Flat Belting

Weld the ends of this belting together for a firm hold. Resistant to chemicals and abrasion, it is often used for light to medium duty power transmission. To weld ends, use a welding kit.

For technical drawings and 3-D models, click on a part number.

| Wd. | Thick. | For Min. Pulley Dia. | Material | Color | Per Ft. | |

| 5/8" | 0.25" | 2" | Polyurethane Rubber | Orange | 0000000 | 000000 |

Rough-Top Belting for Slider-Bed Conveyors

The textured surface grips packages and cartons to prevent material from slipping when traveling on inclines and declines. A low-friction bottom surface allows belting to glide along the bed of the conveyor. Use belting with hammer-on hook-style lacing or quick-install hook-style lacing.

Note: The top surface of the belt ends should be removed with a conveyor belt shaver or skiver before installing lacing. Recommended lacing is based on the thickness of the belt after removing the top surface.

SBR has good impact resistance and an excellent grip.

For technical drawings and 3-D models, click on a part number.

For Lace No. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thick. | For Min. Pulley Dia. | Max. Belt Tension, PIW | Construction | Max. Temp., °F | Quick-Install Hook-Style | Hammer-On Hook-Style | 2" Wd. Per Ft. | 3" Wd. Per Ft. | 4" Wd. Per Ft. | 6" Wd. Per Ft. | 8" Wd. Per Ft. | 10" Wd. Per Ft. | 12" Wd. Per Ft. | 18" Wd. Per Ft. | 24" Wd. Per Ft. | |

Black SBR Rubber | ||||||||||||||||

| 0.250" | 2" | 150 | 2 Ply | 250° | 1 | 7 | 000000 | |||||||||

Cleated Belting for Slider-Bed Conveyors

Cleats keep material on the belt when traveling along inclines and declines. A low-friction bottom surface allows belting to glide along slider-bed conveyors.

Note: The cleats of the belt should be removed with a conveyor belt shaver or skiver before installing lacing.

White belting is appropriate for food applications when used with stainless steel lacing. It resists animal fats and oils.

For technical drawings and 3-D models, click on a part number.

Cleat | For Lace No. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thick. | For Min. Pulley Dia. | Max. Incline | Max. Belt Tension, PIW | Ht. | Spacing | Construction | Max. Temp., °F | Quick-Install Hook-Style | Hammer-On Hook-Style | 4" Wd. Per Ft. | 6" Wd. Per Ft. | 8" Wd. Per Ft. | 10" Wd. Per Ft. | 12" Wd. Per Ft. | 18" Wd. Per Ft. | 24" Wd. Per Ft. | |

| 0.250" | 2" | 30° | 150 | 1/8" | 1" | 3 Ply | 250° | 2 | 15S | 000000 | |||||||

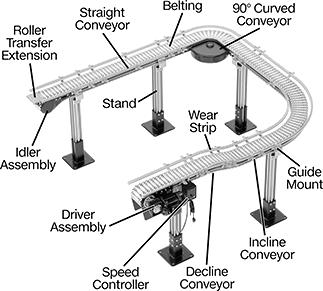

Modular Mini Chain Belt Conveyors

Build a mini conveyor in any shape you need. These conveyors have curved, straight, incline, and decline runs that you can quickly join together with the included brackets. They're often used in areas with limited floor space and applications that require frequent layout changes. To customize your conveyor, add on components, such as package stops and merge guides, with the built-in T-slots on the side. T-slot bolts are sold separately. These conveyors come with guides installed.

You'll need a drive assembly, an idler assembly, and a belt to complete your conveyor. To determine the belt length you need, multiply your conveyor’s length by 2.1. If you need a belt longer than what’s available, you can connect multiple together. Use a belt installation tool (sold separately) to pull out the pin, then line up two ends and push the pin in with the tool to connect them. You can also shorten a belt using the same tool.

Maximum run length is 70 ft. with two 90° curves. Adding more curved conveyors will reduce the run length.

For technical drawings and 3-D models, click on a part number.

Attach belting to your conveyor to transport material. It’s driven by the conveyor’s motor. Tabs on the bottom keep it from lifting off the conveyor in curved sections.

To determine the belt length you need, multiply your conveyor’s length by 2.1. Belting is not included with any other components.

Rough-surface belting has pads on its chain links to grip material. If you’re conveying material at an incline or decline of 10° or higher, this belting will keep it from slipping.