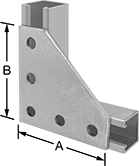

Surface Strut Channel Brackets

Zinc-plated steel brackets are more corrosion resistant in wet environments than powder-coated and painted steel.

Galvanized steel brackets have better corrosion resistance in wet environments than zinc-plated steel and can be used outdoors.

304 stainless steel brackets are more corrosion resistant than galvanized steel. They also have good chemical resistance.

316 stainless steel brackets have excellent resistance to chemicals and salt water.

Aluminum brackets are about half the weight of steel and resist corrosion in wet environments.

Fiberglass brackets are nonconductive with good resistance to chemicals and salt water. They're about half the weight of aluminum.

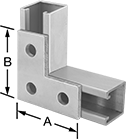

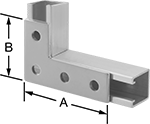

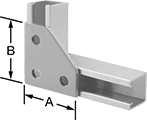

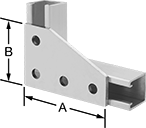

Lg. | |||||||

|---|---|---|---|---|---|---|---|

| Style | (A) | (B) | Thick. | Hole Dia. | Fasteners Included | Each | |

For 1 5/8" Channel Wd. | |||||||

Zinc-Plated Steel | |||||||

| 6 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

| 7 | 5 3/8" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 0000 |

| 8 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 0000 |

| 9 | 5 3/8" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 0000 |

| 10 | 5 3/8" | 5 3/8" | 1/4" | 9/16" | No | 00000000 | 00000 |

Green Powder-Coated Steel | |||||||

| 6 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 0000 |

| 7 | 5 3/8" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 0000 |

| 8 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

| 9 | 5 3/8" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

| 10 | 5 3/8" | 5 3/8" | 1/4" | 9/16" | No | 00000000 | 00000 |

Black Powder-Coated Steel | |||||||

| 6 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 0000 |

White Powder-Coated Steel | |||||||

| 6 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 0000 |

Yellow Powder-Coated Steel | |||||||

| 6 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 0000 |

Galvanized Steel | |||||||

| 6 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 0000 |

| 7 | 5 3/8" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 0000 |

| 8 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

| 9 | 5 3/8" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

| 10 | 5 3/8" | 5 3/8" | 1/4" | 9/16" | No | 000000000 | 00000 |

304 Stainless Steel | |||||||

| 6 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

| 10 | 5 3/8" | 5 3/8" | 1/4" | 9/16" | No | 00000000 | 000000 |

316 Stainless Steel | |||||||

| 7 | 5 3/8" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

| 9 | 5 3/8" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

Aluminum | |||||||

| 6 | 3 1/2" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

| 7 | 5 3/8" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

| 9 | 5 3/8" | 3 1/2" | 1/4" | 9/16" | No | 000000000 | 00000 |

Gray Fiberglass | |||||||

| 6 | 3 1/4" | 3 1/4" | 3/8" | 7/16" | No | 000000000 | 00000 |

| 10 | 4 7/8" | 4 7/8" | 3/8" | 7/16" | No | 000000000 | 00000 |

For 13/16" Channel Wd. | |||||||

Zinc-Plated Steel | |||||||

| 6 | 1 7/8" | 1 7/8" | 1/8" | 9/32" | No | 000000000 | 00000 |

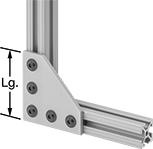

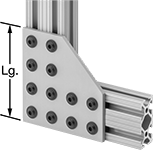

T-Slotted Framing Structural Brackets

Connect T-slotted rails and reinforce joints for structural stability. Fasteners are included.

Surface brackets create strong connection points because they secure to the surface of rails.

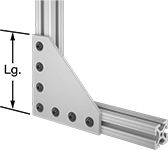

Extended brackets have more connection points for stronger connections than standard-length brackets.

90° angle brackets make a corner or create another 90° connection along your rail.

Flush tee and flush 90° angle brackets create a finished appearance. However, they are not as strong as standard tee or 90° angle brackets.

| For Rail Ht. | Lg. | Rail Machining | Mounting Fasteners Included | Material | Each | |

Silver | ||||||

|---|---|---|---|---|---|---|

90° Angle | ||||||

| 1" | 3" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 000000 |

| 1 1/2" | 4 1/2" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 00000 |

| 20mm | 2 3/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 30mm | 3 1/2" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 40mm | 4 5/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 45mm | 5 1/4" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Extended 90° Angle | ||||||

| 1" | 4" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 1 1/2" | 6" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 40mm | 6 5/16" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Flush 90° Angle | ||||||

| 1" | 3" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 1 1/2" | 4 1/2" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 20mm | 2 3/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 30mm | 3 9/16" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 40mm | 4 3/4" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 45mm | 5 5/16" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Black | ||||||

90° Angle | ||||||

| 1" | 3" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 00000 |

| 1 1/2" | 4 1/2" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 00000 |

| 20mm | 2 3/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

| 30mm | 3 1/2" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

| 40mm | 4 5/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

| 45mm | 5 1/4" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Extended 90° Angle | ||||||

| 1" | 4" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 00000 |

| 1 1/2" | 6" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 00000 |

Flush 90° Angle | ||||||

| 1" | 3" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 00000 |

| 1 1/2" | 4 1/2" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 00000 |

Yellow | ||||||

90° Angle | ||||||

| 1" | 3" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 1 1/2" | 4 1/2" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

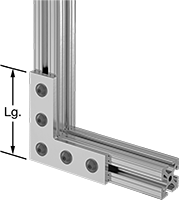

Surface brackets create strong connection points because they secure to the surface of rails.

90° angle brackets make a corner or create another 90° connection along your rail.

| For Rail Ht. | Lg. | Rail Machining | Mounting Fasteners Included | Material | Each | |

Silver | ||||||

|---|---|---|---|---|---|---|

90° Angle | ||||||

| 2" | 4" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 000000 |

| 3" | 6" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 00000 |

| 40mm | 3 1/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 60mm | 4 5/8" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 80mm | 6 1/4" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

| 90mm | 7" | Not Required | Yes | Anodized 6063 Aluminum | 00000000 | 00000 |

Black | ||||||

90° Angle | ||||||

| 2" | 4" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 00000 |

| 3" | 6" | Not Required | Yes | Anodized 6063 Aluminum | 000000000 | 00000 |

| 40mm | 3 1/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

| 60mm | 4 5/8" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

| 80mm | 6 1/4" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

| 90mm | 7" | Not Required | Yes | Powder-Coated 6063 Aluminum | 00000000 | 00000 |

Miniature T-Slotted Framing and Fittings

Build test fixtures, prototypes, and other small structures with this miniature version of T-slotted framing and fittings. The framing has continuous T-slots for attaching fittings with the included mounting fasteners.

Corner brackets are also known as angle brackets.

Silver | |||||||

|---|---|---|---|---|---|---|---|

| Corner Bracket Style | For Rail Ht., mm | Lg. | Rail Machining | Mounting Fasteners Included | Includes | Each | |

| Corner | 10 | 31/64" | Not Required | Yes | 2 Nuts, 2 Screws | 0000000 | 00000 |

Surface brackets connect rails without machining.

Flush 90° angle brackets create a more finished appearance than standard 90° angle brackets. However, they are not as strong.

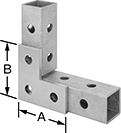

Steel Bolt-Together Framing and Fittings

Rails are drilled with consistently spaced holes for multiple mounting options that do not require machining. Use this bolt-together framing to build guards, tables, and racks.

Surface and corner brackets connect rails.

Zinc-plated steel brackets resist corrosion better in wet environments than plain steel brackets.

Lg. | Mounting Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bracket Style | For Rail Ht. | (A) | (B) | Thick. | Material | No. of | Ctr.-to-Ctr. | Mounting Fasteners Included | For Screw Size | Each | |

| Flush 90° Angle | 1 1/2", 1 3/4", 2", 2 1/4", 2 1/2" | 4 3/4" | 4 3/4" | 3/16" | Zinc-Plated Steel | 3 | 1" | No | 7/16" | 00000000 | 00000 |

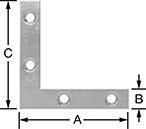

Flat-Surface Brackets

Lg. | Mounting | Each | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Appearance | (A) | (B) | (C) | Thick. | Capacity | Fasteners Included | Number of Holes | Hole Style | For Screw Size | 1-49 | 50-Up | ||

| 1 | Zinc-Plated Steel | Dull | 1 1/2" | 3/8" | 1 1/2" | 0.06" | Not Rated | No | 4 | Countersunk | No. 5 | 0000000 | 00000 | 00000 |

| 1 | Zinc-Plated Steel | Dull | 2" | 3/8" | 2" | 0.07" | Not Rated | No | 4 | Countersunk | No. 5 | 0000000 | 0000 | 0000 |

| 1 | Zinc-Plated Steel | Dull | 2 1/2" | 1/2" | 2 1/2" | 0.06" | Not Rated | No | 4 | Countersunk | No. 6 | 0000000 | 0000 | 0000 |

| 1 | Zinc-Plated Steel | Dull | 3 1/2" | 5/8" | 3 1/2" | 0.07" | Not Rated | No | 4 | Countersunk | No. 8 | 0000000 | 0000 | 0000 |

| 1 | Zinc-Plated Steel | Dull | 6" | 1" | 6" | 0.08" | Not Rated | No | 6 | Countersunk | No. 9 | 0000000 | 0000 | 0000 |

Fixturing for Parts Inspection

From towers and brackets to standoffs and supports, these components are the building blocks for your custom fixturing setup. They elevate parts so you can access a variety of angles for measuring and inspecting while protecting your measuring device from hitting the inspection table. You’ll often see them used with coordinate measuring machines (CMMs). They’re not for use in machining applications.

Corner plates act as a repeatable stop, making it easy for your CMM and vision system to find your workpiece. When using them with a vision system, fasten them to an acrylic plate. They have threaded holes for standoffs and other fixturing components.