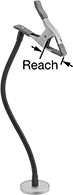

Any-Which-Way Positioning Arms

Bend these arms to hold small equipment such as lights and microphones in almost any position.

For technical drawings and 3-D models, click on a part number.

Use threaded stud and threadlocker to convert a threaded hole into a threaded stud.

| Max. Projection | Attaching End Mount. Thread Size | Base Mount. Thread Size | Max. Load Capacity, lbs. | Material | Color | Includes | Each | |

Threaded Hole/Threaded Stud Attaching End | ||||||||

|---|---|---|---|---|---|---|---|---|

| 6" | 1/4"-20 | 1/4"-20 | 4 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 000000 |

| 9" | 1/4"-20 | 1/4"-20 | 3.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 12" | 1/4"-20 | 1/4"-20 | 3 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 15" | 1/4"-20 | 1/4"-20 | 2.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 18" | 1/4"-20 | 1/4"-20 | 2.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 24" | 1/4"-20 | 1/4"-20 | 1.5 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 30" | 1/4"-20 | 1/4"-20 | 0.8 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| 36" | 1/4"-20 | 1/4"-20 | 0.6 | Vinyl-Coated Steel | Black | Two 1/4"-20 Threaded Studs, Threadlocker | 00000000 | 00000 |

| Max. Projection | Attaching End Mount. Thread Size | Attaching End Mount. Pipe Size | Base Mount. Thread Size | Base Mount. Pipe Size | Max. Load Capacity, lbs. | Material | Color | Each | |

Threaded Hole Attaching End | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 6" | 5/8"-27 | __ | 5/8"-27 | __ | 3 | Vinyl-Coated Steel | Black | 000000000 | 00000 |

| 13" | 5/8"-27 | __ | 5/8"-27 | __ | 1 | Vinyl-Coated Steel | Black | 000000000 | 00000 |

| 19" | 5/8"-27 | __ | 5/8"-27 | __ | 1 | Vinyl-Coated Steel | Black | 000000000 | 00000 |

Threaded Stud Attaching End | |||||||||

| 9" | __ | 1/8 | __ | 1/8 | 2 | Vinyl-Coated Steel | Black | 000000000 | 0000 |

| 15" | __ | 1/8 | __ | 1/8 | 1 | Vinyl-Coated Steel | Black | 000000000 | 0000 |

| 24" | __ | 1/8 | __ | 1/8 | 1 | Vinyl-Coated Steel | Black | 000000000 | 00000 |

Base with

Plate Attaching End

Attaching End | Base | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Projection | Plate Lg. | Plate Wd. | No. of Mount. Holes | Mount. Hole Dia. | Mount. Fasteners Included | No. of Mount. Holes | Mount. Hole Dia. | Lg. | Wd. | Max. Load Capacity, lbs. | Material | Color | Each | |

| 14" | 2" | 1 7/8" | 8 | 3/16" | No | 3 | 13/64" | 2" | 3" | 5 | Vinyl-Coated Steel | Black | 000000 | 000000 |

Hole/Threaded

Stud Attaching End

Use threaded stud and threadlocker to convert a threaded hole into a threaded stud.

Base | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Projection | Attaching End Mount. Thread Size | Mount. Fasteners Included | No. of Mount. Holes | Mount. Hole Dia. | Lg. | Wd. | Max. Load Capacity, lbs. | Material | Color | Includes | Each | |

| 9" | 1/4"-20 | No | 2 | 0.275" | 2" | 1" | 3.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 000000 |

| 9" | 3/8"-16 | Yes | 2 | 0.275" | 2" | 1" | 3 | Vinyl-Coated Steel | Black | One 3/8"-16 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 16" | 1/4"-20 | No | 2 | 0.275" | 2" | 1" | 2.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 16" | 3/8"-16 | No | 2 | 0.275" | 2" | 1" | 2.5 | Vinyl-Coated Steel | Black | One 3/8"-16 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 24" | 1/4"-20 | No | 2 | 0.275" | 2" | 1" | 1.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 24" | 3/8"-16 | No | 2 | 0.275" | 2" | 1" | 1.5 | Vinyl-Coated Steel | Black | One 3/8"-16 Threaded Stud, Threadlocker | 00000000 | 00000 |

Arms with padded base clamp have plastic pads that protect mounting surfaces from marring.

Where included, use threaded stud and threadlocker to convert a threaded hole into a threaded stud.

Base | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Projection | Attaching End Mount. Thread Size | Lg. | Wd. | For Max. Mount. Surface Thick. | Max. Load Capacity, lbs. | Material | Color | Includes | Features | Each | |

Threaded Hole Attaching End | |||||||||||

| 16" | 3/8"-16 | 2" | 2" | 2" | 2.5 | Vinyl-Coated Steel | Black | __ | Padded Base Clamp | 00000000 | 000000 |

| 24" | 3/8"-16 | 2" | 2" | 2" | 1.5 | Vinyl-Coated Steel | Black | __ | Padded Base Clamp | 00000000 | 00000 |

Threaded Hole/Threaded Stud Attaching End | |||||||||||

| 9" | 1/4"-20 | 2 7/8" | 2" | 2" | 3.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | __ | 00000000 | 00000 |

| 9" | 3/8"-16 | 2" | 1 5/8" | 2" | 3 | Vinyl-Coated Steel | Black | One 3/8"-16 Threaded Stud, Threadlocker | Padded Base Clamp | 00000000 | 00000 |

| 16" | 1/4"-20 | 2 7/8" | 2" | 2" | 2.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | __ | 00000000 | 00000 |

| 24" | 1/4"-20 | 2 7/8" | 2" | 2" | 1.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | __ | 00000000 | 00000 |

Where included, use threaded stud and threadlocker to convert a threaded hole into a threaded stud.

| Max. Projection | Attaching End Mount. Thread Size | Base Dia. | Max. Pull, lbs. | Max. Load Capacity, lbs. | Material | Color | Includes | Each | |

Threaded Hole Attaching End | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 16" | 3/8"-16 | 3" | 100 | 2.5 | Vinyl-Coated Steel | Black | __ | 00000000 | 000000 |

| 25" | 3/8"-16 | 3" | 100 | 1.5 | Vinyl-Coated Steel | Black | __ | 00000000 | 00000 |

Threaded Hole/Threaded Stud Attaching End | |||||||||

| 9" | 1/4"-20 | 3 1/4" | 100 | 3.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 9" | 3/8"-16 | 3" | 100 | 3 | Vinyl-Coated Steel | Black | One 3/8"-16 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 16" | 1/4"-20 | 3 1/4" | 100 | 2.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 00000 |

| 24" | 1/4"-20 | 3 1/4" | 100 | 1.5 | Vinyl-Coated Steel | Black | One 1/4"-20 Threaded Stud, Threadlocker | 00000000 | 00000 |

Bend-and-Stay Positioning Arms

Stronger and with greater load capacities than gooseneck-style positioning arms, these arms keep their shape even when moving or when exposed to vibration. They’re often used in robotics and conveyor applications when frequent repositioning isn’t required.

Base | Attaching End | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Projection | Dia. | Max. Load Cap., lbs. | Material | Color | Mount Type | Mounting Thread Size | Mounting Hole Thread Type | Mounting Fasteners Included | Mount Type | Mounting Thread Size | Mounting Thread Type | Mounting Fasteners Included | Each | |

| 6" | 5/8" | 20 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 000000 |

| 9" | 5/8" | 7 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

| 12" | 5/8" | 5 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

| 18" | 5/8" | 3 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

| 24" | 5/8" | 2.5 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

| 30" | 5/8" | 2 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

| 36" | 5/8" | 0.5 | Vinyl-Coated Copper | Black | Threaded Hole | 3/8"-24 | UNF | No | Threaded Hole | 3/8"-24 | UNF | No | 00000000 | 00000 |

Spring Clamps with Flexible Arm

Attached to an arm you can flex into position, these clamps hold objects such as a flashlight, tool, or instructions. Squeeze the handles to open the clamp; release and the spring holds it tightly in place.

Magnetic-mount clamp attaches to steel surfaces.

For technical drawings and 3-D models, click on a part number.

Economy Jointed-Arm Magnetic-Base Indicator Holders

Position the arm by adjusting joints at the top and middle. Use the fine adjustment knob for precise positioning.

Holders with a V-grooved base can be mounted on both curved and flat metal surfaces. They have an additional joint at the bottom.

Base | Arm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Mounting Stem Dia. | Type | Dia. | Lg. | Wd. | Ht. | Thread Size | Thread Pitch, mm | Material | Magnetic Pull, lbs. | Lg. | Dia. | Features | Each | |

Stem Mount | ||||||||||||||

| 1/8"-1/4" | Flat | 1 3/8" | __ | __ | 1 1/8" | M6 | 1 | Steel | 33 | 3 3/8" | 0.236" | Fine-Adjustment Arm, Fine-Adjustment Base | 0000000 | 000000 |

Dovetail and Stem Mount | ||||||||||||||

| 3/8" | V-Grooved | __ | 2 1/2" | 2" | 2 3/16" | M8 | 1.25 | Cast Iron | 132 | 13 1/2" | 0.464" | Fine-Adjustment Clamp, Magnetic-Release Switch | 000000 | 00000 |

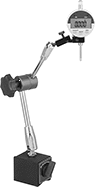

Jointed-Arm Magnetic-Base Indicator Holders

Position the arm by adjusting joints at the top, middle, and bottom. The magnetic base has a V-grooved bottom for mounting on curved and flat metal surfaces and a magnetic-release switch for easy setups. Holders have fine-adjustment knobs for precise positioning.

Indicator Holders | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Base | Arm | Replacement Arms | Replacement Clamps | ||||||||||||||

| For Mounting Stem Dia. | Lg. | Wd. | Ht. | Thread Size | Thread Pitch, mm | Material | Magnetic Pull, lbs. | Lg. | Dia. | Features | Includes | Each | Each | Each | |||

Dovetail and Stem Mount | |||||||||||||||||

| 6mm, 8mm, 3/8" | 1 1/2" | 1 1/4" | 1 3/8" | M5 | 0.8 | Cast Iron | 70 | 4 1/4" | 3/8" | Fine-Adjustment Base, Fine-Adjustment Clamp, Magnetic-Release Switch | Swivel Clamp | 00000000 | 0000000 | 00000000 | 000000 | 00000000 | 000000 |

| 6mm, 8mm, 3/8" | 2 3/8" | 1 15/16" | 2 5/32" | M8 | 1.25 | Cast Iron | 176 | 11" | 1/2" | Fine-Adjustment Base, Fine-Adjustment Clamp, Magnetic-Release Switch | Swivel Clamp | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 00000 |

| 6mm, 8mm, 3/8" | 4 3/4" | 1 15/16" | 2 5/32" | M10 | 1.25 | Cast Iron | 290 | 20" | 3/4" | Fine-Adjustment Clamp, Magnetic-Release Switch | Swivel Clamp | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 00000 |

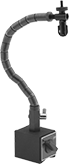

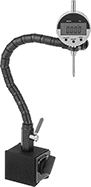

Flexible-Arm Magnetic-Base Indicator Holders

and Fine-Adjustment

Clamp

Adjust the flexible arm to nearly any position. These holders have a ball-and-socket segmented arm that locks in place with a lever. The magnetic base has a release switch for easy setups.

Holders with V-grooved base can be mounted on both curved and flat surfaces.

Holders with fine-adjustment base or clamp give you more precise control over positioning.

Indicator Holders | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Base | Arm | Replacement Arms | ||||||||||||

| For Mounting Stem Dia. | Type | Lg. | Wd. | Ht. | Thread Size | Thread Pitch, mm | Material | Magnetic Pull, lbs. | Lg. | Dia. | Each | Each | ||

Dovetail and Stem Mount | ||||||||||||||

Magnetic-Release Switch | ||||||||||||||

| 3/8" | V-Grooved | 2 1/2" | 2" | 2 1/8" | M8 | 1.25 | Steel | 125 | 12" | 0.625" | 00000000 | 000000 | 00000000 | 000000 |

Fine-Adjustment Clamp, Magnetic-Release Switch | ||||||||||||||

| 3/8" | V-Grooved | 2" | 2 1/2" | 2 5/8" | 5/16''-18 | __ | Steel | 90 | 15 1/4" | 0.625" | 00000000 | 000000 | 00000000 | 00000 |

Stem Mount | ||||||||||||||

Magnetic-Release Switch | ||||||||||||||

| 5/32"-1/2" | V-Grooved | 2 1/2" | 2" | 2 1/4" | M8 | 1.25 | Steel | 180 | 12 1/2" | 0.63" | 0000000 | 00000 | 0000000 | 00000 |

Fine-Adjustment Base, Magnetic-Release Switch | ||||||||||||||

| 1/8"-1/2" | Flat | 2" | 1 5/8" | 2" | __ | __ | Steel | 65 | 14" | 0.625" | 00000000 | 000000 | 00000000 | 000000 |

Flexible-Arm Magnetic-Base Indicator Holders for Uneven Surfaces

A flexible ball-and-socket segmented arm adjusts to nearly any position and locks in place with a lever. The base is comprised of adjustable magnetic pins which allow it to conform to any shape and grip most metal surfaces. It has a magnetic-release switch for easy setups.

Base | Arm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Mounting Stem Dia. | Lg. | Wd. | Ht. | Thread Size | Thread Pitch, mm | Material | Magnetic Pull, lbs. | Lg. | Dia. | Material | Features | Each | |

Stem Mount | |||||||||||||

| 5/64"-1/2" | 1 15/16" | 1 5/8" | 2 7/8" | M8 | 1.25 | Cast Aluminum | 120 | 12 1/2" | 0.47" | Steel | Magnetic-Release Switch | 0000000 | 0000000 |

Economy Flexible-Arm Weighted-Base Indicator Holders

Adjust the flexible ball-and-socket segmented arm to nearly any position and lock in place. A heavy base adds stability.

Holders with a granite base have an extremely tight flatness tolerance. Their flatness gives you an accurate reference for inspection work and lets you move workpieces in and out smoothly. These holders have a fine-adjustment clamp to position indicators at precise angles.

Base | Upright Post | Arm | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Mounting Stem Dia. | Dia. | Lg. | Wd. | Ht. | Thread Size | Material | Dia. | Ht. | Lg. | Dia. | Features | Each | |

Dovetail and Stem Mount | |||||||||||||

| 5/8" | __ | 9" | 12" | 2" | 5/16''-24 | Granite | 5/8" | 12" | 12" | 0.625" | Fine-Adjustment Clamp | 0000000 | 0000000 |

| 5/8" | __ | 12" | 18" | 3" | 5/16''-24 | Granite | 5/8" | 12" | 15" | 0.625" | Fine-Adjustment Clamp | 0000000 | 000000 |

Stem Mount | |||||||||||||

| 1/8"-1/2" | 6" | __ | __ | 15/16" | 5/16''-18 | Cast Iron | __ | __ | 13" | 0.625" | __ | 0000000 | 000000 |

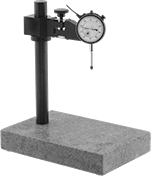

Economy Jointed-Arm Weighted-Base Indicator Holders

Stabilize and precisely position your indicator with these weighted bases. Attached to the base, these holders have a jointed arm for moving your indicator up and down and in and out. Tighten the knob on the arm to lock it in place and use the fine-adjustment clamp for angling your indicator just right. Made of granite, the base has an extremely tight flatness tolerance, so it creates an accurate reference point for inspection work. It also means you can easily slide your workpiece in and out.

Base | Arm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Mounting Stem Dia. | Lg. | Wd. | Ht. | Thread Size | Material | Lg. | Dia. | Granite Base Flatness Tolerance | Features | Each | |

Dovetail and Stem Mount | |||||||||||

| 8mm, 3/8" | 12" | 9" | 2" | 5/16''-18 | Granite | 12 1/2" | 0.495" | ±0.00015" | Fine-Adjustment Arm, Fine-Adjustment Clamp | 0000000 | 0000000 |

| 8mm, 3/8" | 18" | 12" | 3" | 5/16''-18 | Granite | 14" | 0.495" | ±0.00015" | Fine-Adjustment Arm, Fine-Adjustment Clamp | 0000000 | 000000 |

Precision Weighted-Base Indicator Holders

These holders come with a certificate of accuracy traceable to NIST stating that the granite base has passed a test for surface accuracy. The extremely tight flatness tolerances of the granite allow for nearly frictionless workpiece movement and provide an accurate reference plane for inspection work.

Holders with jointed arm have a fine-adjustment knob for precise positioning.

For technical drawings and 3-D models, click on a part number.

Base | Upright Post | Arm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Mounting Stem Dia. | Surface Accuracy | Throat Dp. | Lg. | Wd. | Ht. | Thread Size | Material | Dia. | Ht. | Material | Lg. | Flexibility | Features | Each | |

| 3/8" | ±0.0001" | 5" | 8" | 12" | 2" | 1/2"-13 | Granite | 1 1/4" | 12" | Steel | 7 5/16" | Jointed | Fine-Adjustment Arm | 0000000 | 0000000 |

| 3/8" | ±0.0001" | 5" | 12" | 18" | 4" | 1/2"-13 | Granite | 1 1/4" | 12" | Steel | 7 5/16" | Jointed | Fine-Adjustment Arm | 0000000 | 000000 |

Base | Upright Post | Arm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Mounting Lug Hole Dia. | Surface Accuracy | Throat Dp. | Lg. | Wd. | Ht. | Thread Size | Material | Dia. | Ht. | Material | Lg. | Flexibility | Features | Each | |

| 1/4" | ±0.0001" | 5" | 8" | 12" | 2" | 1/2"-13 | Granite | 1 1/4" | 12" | Steel | 7 5/16" | Jointed | Fine-Adjustment Arm | 0000000 | 0000000 |

| 1/4" | ±0.0001" | 5" | 12" | 18" | 4" | 1/2"-13 | Granite | 1 1/4" | 12" | Steel | 7 5/16" | Jointed | Fine-Adjustment Arm | 0000000 | 000000 |

Workpiece-Centering Indicator Holders

Mount this holder into your machine spindle and use for centering workpieces. The clamp has a fine-adjustment knob for precise positioning.

For technical drawings and 3-D models, click on a part number.

Arm | Shank | |||||||

|---|---|---|---|---|---|---|---|---|

| For Mounting Stem Dia. | Lg. | Dia. | Lg. | Dia. | Material | Features | Each | |

Dovetail and Stem Mount | ||||||||

| 6mm, 8mm, 3/8" | 7 " | 3/8 " | 1 9/16" | 5/16" | Steel | Fine-Adjustment Clamp | 0000000 | 000000 |

Flexible-Arm Vacuum-Base Indicator Holders

Position the flexible ball-and-socket segmented arm around obstructions and lock in place with a lever. The vacuum base provides stability on granite plates and other nonmagnetic surfaces.

Base | Arm | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Mounting Stem Dia. | Dia. | Ht. | Thread Size | Thread Pitch, mm | Material | Lg. | Dia. | Each | |

Stem Mount | |||||||||

| 1/8"-1/2" | 3.465" | 1.063" | M8 | 1.25 | Aluminum | 13" | 0.625" | 0000000 | 0000000 |

Flexible-Arm Clamp-On Indicator Holders

Vise-grip locking pliers clamp this holder to most thin, flat surfaces, and the flexible arm lets you position your indicator around obstructions. Lock the arm in place with a lever.

Jointed-Arm Vacuum-Base Indicator Holders

Position the arm by adjusting joints at the top, middle, and bottom. A vacuum base provides stability on granite plates and other nonmagnetic surfaces. Use the fine-adjustment knob on the clamp for precise positioning

For technical drawings and 3-D models, click on a part number.

Base | Arm | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Mounting Stem Dia. | Dia. | Ht. | Thread Size | Thread Pitch, mm | Material | Lg. | Dia. | Features | Each | |

Dovetail and Stem Mount | ||||||||||

| 6mm, 8mm, 3/8" | 3 7/16" | 13/16" | M8 | 1.25 | Cast Aluminum | 11 1/8" | 0.705" | Fine-Adjustment Clamp | 0000000 | 0000000 |

Economy Electronic Plunger-Style Variance

Indicators with Jointed-Arm Magnetic-Base Holder

Adjust joints at the top, middle, and bottom of the base to position the indicator in place. Use the knob on the fine-adjustment clamp to precisely angle the indicator. The base is magnetic and has a V-groove on the bottom for a solid mount on flat and curved metal surfaces. Flip a switch to release the magnet.

A spring-loaded plunger extends and retracts from the indicator to take measurements. The measurements display on an easy-to-read LCD display. Start measuring at any point by pressing the zero-set button. They have zero-position memory, also known as absolute (ABS) positioning, which retains the measuring position when the indicator is off.

All can send data to your computer using a USB cord (sold separately). Indicators with Bluetooth Connection can transfer your measurement data wirelessly to your device with the push of a button. You'll need a data transmitter/receiver set (sold separately). .

IP67-rated indicators seal out coolant, water, and dust, so you can take measurements in dirty machining environments.

Tolerance checking indicators inform you when an item falls outside your set measurements.

Contact Point | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Measuring Increments | Accuracy | Counting Direction | Industry Designation | Dial Dia. | Head Dia. | Lg. | Mount. Thread Size | Base Magnetic Pull, lbs. | Arm Lg. | Batteries Included | Features | Each | |

Lug and Stem Mount | ||||||||||||||

With SPC Data Output | ||||||||||||||

| 0"-1" 0mm-25mm | 0.0005" 0.01mm | ±0.0015" ±0.03 mm | Forward | AGD Group 2 | 2 3/16" | 0.197" | 0.354" | 4-48 | 125 | 15" | Yes | Fine-Adjustment Clamp, Magnetic Release Switch, Zero-Position Memory (ABS), Zero-Set Button | 0000000 | 000000 |

Lug and Stem Mount—IP67 | ||||||||||||||

With SPC Data Output, Bluetooth Connection, and Charging Cord | ||||||||||||||

| 0"-1" 0mm-25mm | 0.00005" 0.001mm | ±0.00035" ±0.008 mm | Forward, Backward | AGD Group 2 | 2 3/16" | 0.197" | 0.315" | 4-48 | 125 | 15" | Yes | Fine-Adjustment Clamp, Magnetic Release Switch, Tolerance-Checking Go/No-Go Operation, Zero-Position Memory (ABS), Zero-Set Button | 0000000 | 000000 |

Economy Electronic Plunger-Style Variance Indicators

with Magnetic-Base Holder for Uneven Surfaces

With adjustable magnetic pins that conform to any shape, the base on these variance indicators mounts securely to uneven surfaces. The ball-and-socket arm is highly adjustable and locks in place with a lever, so it holds the indicator in almost any position. For quick dismounting, the base has a magnetic release switch.

A spring-loaded plunger extends and retracts to measure objects. The measurements are displayed on an LCD screen. Start measuring at any point by pressing the zero-set button. They have zero-position memory, also known as absolute (ABS) positioning, which retains the measuring position when the indicator is off.

All can send data to your computer using a USB cord (sold separately). They have SPC data output to wirelessly transfer your measurement data to your device with the push of a button. You'll need a data transmitter/receiver set (sold separately). Indicators with Bluetooth send measurement data to your device wire-free and without an additional device.

IP67-rated indicators seal out coolant, water, and dust, so you can take measurements in dirty machining environments.

Tolerance checking indicators inform you when an item falls outside your set measurements.

Contact Point | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Measuring Increments | Accuracy | Counting Direction | Industry Designation | Dial Dia. | Head Dia. | Lg. | Mount. Thread Size | Base Magnetic Pull, lbs. | Arm Lg. | Batteries Included | Features | Each | |

Lug and Stem Mount | ||||||||||||||

With SPC Data Output | ||||||||||||||

| 0"-1" 0mm-25mm | 0.0005" 0.01mm | ±0.0015" ±0.03 mm | Forward | AGD Group 2 | 2 3/16" | 0.197" | 0.354" | 4-48 | 125 | 12" | Yes | Magnetic Release Switch, Zero-Position Memory (ABS), Zero-Set Button | 0000000 | 0000000 |

Lug and Stem Mount—IP67 | ||||||||||||||

With SPC Data Output, Bluetooth Connection, and Charging Cord | ||||||||||||||

| 0"-1" 0mm-25mm | 0.00005" 0.001mm | ±0.00035" ±0.008 mm | Forward, Backward | AGD Group 2 | 2 3/16" | 0.197" | 0.315" | 4-48 | 125 | 12" | Yes | Magnetic Release Switch, Tolerance-Checking Go/No-Go Operation, Zero-Position Memory (ABS), Zero-Set Button | 0000000 | 000000 |

Economy Electronic Plunger-Style Variance

Indicators with Flexible-Arm Magnetic-Base Holder

Bend and flex the arm of the base to position your indicator—these holders have ball-and-socket segments that lock in place with a lever. The base is magnetic and has a V-groove on the bottom for a solid mount on flat and curved metal surfaces. Flip a switch to release the magnet.

A spring-loaded plunger extends and retracts from the indicator to take measurements. The measurements display on an easy-to-read LCD screen. Press the zero-set button to start measuring at any point. They have zero-position memory, also known as absolute (ABS) positioning, which retains the measuring position when the indicator is off.

All can send data to your computer using a USB cord (sold separately). They have SPC data output to wirelessly transfer your measurement data to your device with the push of a button. You'll need a data transmitter/receiver set (sold separately). Indicators with Bluetooth send measurement data to your device wire-free and without an additional device.

IP67-rated indicators seal out coolant, water, and dust, so you can take measurements in dirty machining environments.

Tolerance checking indicators inform you when an item falls outside your set measurements.

Contact Point | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Measuring Increments | Accuracy | Counting Direction | Industry Designation | Dial Dia. | Head Dia. | Lg. | Mount. Thread Size | Base Magnetic Pull, lbs. | Arm Lg. | Batteries Included | Features | Each | |

Lug and Stem Mount | ||||||||||||||

With SPC Data Output | ||||||||||||||

| 0"-1" 0mm-25mm | 0.0005" 0.01mm | ±0.0015" ±0.03 mm | Forward | AGD Group 2 | 2 3/16" | 0.197" | 0.354" | 4-48 | 125 | 12" | Yes | Magnetic Release Switch, Zero-Position Memory (ABS), Zero-Set Button | 0000000 | 000000 |

Lug and Stem Mount—IP67 | ||||||||||||||

With SPC Data Output, Bluetooth Connection, and Charging Cord | ||||||||||||||

| 0"-1" 0mm-25mm | 0.00005" 0.001mm | ±0.00035" ±0.008 mm | Forward, Backward | AGD Group 2 | 2 3/16" | 0.197" | 0.315" | 4-48 | 125 | 12" | Yes | Magnetic Release Switch, Tolerance-Checking Go/No-Go Operation, Zero-Position Memory (ABS), Zero-Set Button | 0000000 | 000000 |

Dial Plunger-Style Variance Indicators with Precision Weighted-Base Holder

Mount

Side View

Mount

Side View

A granite base stabilizes these indicators. The extremely tight flatness tolerances of the granite allow for nearly frictionless workpiece movement and provide an accurate reference plane for inspection work.

Indicators have a continuous dial numbered clockwise around the face for taking direct measurements. Rotate the dial face for viewing at multiple angles. All come with calibration certificates traceable to NIST that state the indicator and the granite base have passed a test for accuracy. They have jeweled bearings that are highly sensitive and wear resistant for a long service life.

Holders with jointed arm have a fine-adjustment knob for precise positioning of the indicator.

Dial | Contact Point | Upright Post | Arm | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Measuring Increments | Accuracy | Industry Designation | Indicator Mount. Stem Dia. | Mount. Lug Hole Dia. | Dia. | Reading | Head Dia. | Lg. | Mount. Thread Size | Dia. | Ht. | Lg. | Flexibility | Throat Dp. | Granite Base Flatness Tolerance | Each | |

| 0"-1.000" | 0.001" | ±0.001" | AGD Group 2 | 3/8" | __ | 2 1/4" | 0-100 | 3/16" | 1/4" | 4-48 | 1 1/4" | 12" | 7 5/16" | Jointed | 5" | ±0.0001" | 0000000 | 0000000 |

| 0"-1.000" | 0.001" | ±0.001" | AGD Group 2 | 3/8" | 1/4" | 2 1/4" | 0-100 | 3/16" | 1/4" | 4-48 | 1 1/4" | 12" | 7 5/16" | Jointed | 5" | ±0.0001" | 0000000 | 000000 |

Economy Dial Plunger-Style Variance Indicators with Clamp-On Holder

Often used where space is tight or there’s not much of a surface for mounting, the clamp on these indicators fits where a weighted or magnetic base can’t. The clamp also gives you the option to directly mount these indicators to a machine or the piece you’re measuring. With the ball-and-socket segmented arm, you can adjust the indicator to nearly any position to keep it from obstructing what you're measuring. Pull the lever to lock the arm in place when you're done. To measure objects, these indicators have a spring-loaded plunger that retracts and extends as the surface varies. It’s easy to see how much a measurement increases, since the dial is continuous and numbered clockwise around the face. Adjust the tolerance pointers to mark measurements that fall outside your limits.

Indicators with a plier clamp work on most thin, flat surfaces.

Indicators with a C-clamp apply less pressure than indicators with a plier clamp, so there’s less risk of damaging a workpiece.

Dial | Contact Point | Arm | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Measuring Increments | Accuracy | Industry Designation | Indicator Mount. Stem Dia. | Mount. Lug Hole Dia. | Dia. | Reading | Head Dia. | Lg. | Mount. Thread Size | Clamping Range | Dia. | Lg. | Flexibility | Each | |

Lug and Stem Mount | ||||||||||||||||

Plier Clamp | ||||||||||||||||

| 0.000"-1.000" | 0.001" | ±0.001" | AGD Group 1 | 3/8" | 1/4" | 2" | 0-100 | 0.197" | 0.236" | 4-48 | 0"-1 3/4" | 0.625" | 12" | Flexible | 0000000 | 000000 |

C-Clamp | ||||||||||||||||

| 0.000"-1.000" | 0.001" | ±0.001" | AGD Group 1 | 3/8" | 1/4" | 2" | 0-100 | 0.197" | 0.236" | 4-48 | 0"-6" | 0.625" | 12" | Flexible | 0000000 | 00000 |

Economy Dial Plunger-Style Variance Indicators

with Jointed-Arm Magnetic-Base Holder

Jointed at the top, middle, and bottom, the arm holding these variance indicators adjusts to various angles. Turn the knob on the fine-adjustment clamp to angle them precisely. With a magnetic V-grooved base, they mount securely to both flat and curved metal surfaces. A spring-loaded plunger retracts and extends to measure objects. These indicators have a continuous dial numbered clockwise around the face, so it’s easy to see how much a dimension increases. Adjust the tolerance pointers to mark measurements that fall outside your limits. For quick dismounting, the base has a magnetic release switch.

Dial | Contact Point | Arm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Measuring Increments | Accuracy | Industry Designation | Indicator Mounting Stem Dia. | Mounting Lug Hole Dia. | Dia. | Reading | Head Dia. | Lg. | Mounting Thread Size | Base Magnetic Pull, lbs. | Lg. | Dia. | Each | |

Lug and Stem Mount | |||||||||||||||

| 0"-1" | 0.001" | ±0.001" | AGD Group 2 | 3/8" | 1/4" | 2" | 0-100 | 0.197" | 0.275" | 4-48 | 125 | 15" | 0.375" | 0000000 | 000000 |

Economy Dial Plunger-Style Variance Indicators

with Magnetic-Base Holder for Uneven Surfaces

With adjustable magnetic pins that conform to any shape, the base on these variance indicators mounts securely to uneven surfaces. The ball-and-socket arm is highly adjustable and locks in place with a lever, so you can hold them in almost any position. A spring-loaded plunger retracts and extends to measure objects. These indicators have a continuous dial numbered clockwise around the face, so it’s easy to see how much a dimension increases. Adjust the tolerance pointers to mark measurements that fall outside your limits. For quick dismounting, the base has a magnetic release switch.

Dial | Contact Point | Arm | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Measuring Increments | Accuracy | Industry Designation | Indicator Mounting Stem Dia. | Mounting Lug Hole Dia. | Dia. | Reading | Head Dia. | Lg. | Mounting Thread Size | Base Magnetic Pull, lbs. | Lg. | Dia. | Flexibility | Each | |

Lug and Stem Mount | ||||||||||||||||

| 0"-1" | 0.001" | ±0.001" | AGD Group 2 | 3/8" | 1/4" | 2" | 0-100 | 0.197" | 0.275" | 4-48 | 125 | 12" | 0.625" | Flexible | 0000000 | 000000 |

Economy Dial Plunger-Style Variance Indicators

with Flexible-Arm Magnetic-Base Holder

Measure in almost any position—these variance indicators have an adjustable ball-and-socket arm that locks in place with a lever. With a magnetic V-grooved base, they mount securely to both flat and curved metal surfaces. A spring-loaded plunger retracts and extends to measure objects. These indicators have a continuous dial numbered clockwise around the face, so it’s easy to see how much a dimension increases. Adjust the tolerance pointers to mark measurements that fall outside your limits. For quick dismounting, the base has a magnetic release switch.

Dial | Contact Point | Arm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Measuring Increments | Accuracy | Industry Designation | Indicator Mounting Stem Dia. | Mounting Lug Hole Dia. | Dia. | Reading | Head Dia. | Lg. | Mounting Thread Size | Base Magnetic Pull, lbs. | Lg. | Dia. | Each | |

Lug and Stem Mount | |||||||||||||||

| 0"-1" | 0.001" | ±0.001" | AGD Group 2 | 3/8" | 1/4" | 2" | 0-100 | 0.197" | 0.275" | 4-48 | 80 | 12" | 0.375" | 0000000 | 000000 |

Economy Dial Lever-Style Variance Indicators

with Jointed-Arm Magnetic-Base Holder

Position the arm by adjusting joints at the top, middle, and bottom. The magnetic base has a V-grooved bottom for mounting on flat and curved metal surfaces and a magnetic release switch for easy setups. Use the fine-adjustment knob on the holder’s clamp for precise positioning of the indicator.

Also known as a test indicator, the indicator has a lever-style contact point that pivots as it comes into contact with a surface and a balanced dial with positive values on one side and negative values on the other side. It has jeweled bearings for high sensitivity, wear resistance, and a long service life. Rotate the dial face for viewing at multiple angles.

Dial | Contact Point | Base | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range | Measuring Increments | Accuracy | Reading | Dia. | Head Dia. | Lg. | Swivel Angle | Lg. | Wd. | Magnetic Pull, lbs. | Includes | Each | |

Horizontal Orientation | |||||||||||||

| 0"-0.03" | 0.0005" | ±0.0004" | 0-15-0 | 1 9/32" | 0.078" | 1/2" | 210° | 1 3/16" | 1 5/32" | 70 | 5/32" Dia. Dovetail-to-Stem Attachment 3/8" Dia. Dovetail-to-Stem Attachment | 0000000 | 000000 |

| 0"-0.03" | 0.0005" | ±0.0004" | 0-15-0 | 1 9/32" | 0.078" | 1/2" | 180° | 2 1/2" | 2" | 132 | 5/32" Dia. Dovetail-to-Stem Attachment 3/8" Dia. Dovetail-to-Stem Attachment | 0000000 | 000000 |

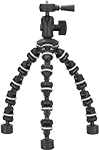

Flexible-Leg Positioning Stands

Bend and wrap the legs around almost anything while keeping a level mounting surface. Rubber rings around each section prevent slipping. These stands can also be used like a traditional tripod.

| Max. Load Capacity, lbs. | Ht. | Head Dia. | Leg Dia. | Material | Color | Mount Type | Thread Size | Each | |

| 1 | 4"-10 1/2" | 1 3/4" | 1" | Plastic | Black | Threaded Stud | 1/4"-20 | 0000000 | 000000 |