How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Socket-Connect Fittings for Plastic Tubing—Air and Water

- Temperature Range: 0° to 140° F

- Tubing: Use with PVC plastic

Made of soft PVC, these fittings flex to withstand high-vibration applications. Use them in place of rigid fittings to create a more flexible system. To connect, slide fittings onto tubing and secure with a clamp.

| For Tube OD | Socket Depth | Material | Color | Max. Pressure | Each | |

| 3/8" | 47/64" | PVC Plastic | Clear | 60 psi @ 72° F | 0000000 | 000000 |

| 1/2" | 21/32" | PVC Plastic | Clear | 45 psi @ 72° F | 0000000 | 00000 |

| 3/4" | 1 3/32" | PVC Plastic | Clear | 60 psi @ 72° F | 0000000 | 00000 |

| 1" | 1 29/64" | PVC Plastic | Clear | 45 psi @ 72° F | 0000000 | 00000 |

| 1 1/4" | 1 11/16" | PVC Plastic | Clear | 20 psi @ 72° F | 0000000 | 00000 |

| 2" | 2 21/32" | PVC Plastic | Clear | 45 psi @ 72° F | 0000000 | 00000 |

| For Tube OD | Socket Depth | Material | Color | Max. Pressure | Each | |

| 1 1/4" | 1 1/16" | PVC Plastic | Blue | 45 psi @ 72° F | 0000000 | 000000 |

Underground Snap-Lock Polyethylene Pipe for Drain, Waste, and Vent

- For Use With: Water

- Specifications Met: ASTM F667

Pipe has a snap-together design that allows you to quickly connect to fittings with no cement required. It is typically used in gravity-flow drainage applications. Made of high-density polyethylene (HDPE), it stands up to freeze/thaw cycles and resists corrosion and stress cracking. Pipe is corrugated inside and out for flexibility. It meets ASTM F667 specifications and testing requirements for material quality as well as soil conservation service (SCS) standards for use in underground drain lines.

Nonperforated pipe allows you to flow drainage to one area. Perforated pipe has slits along the entire length that allow drainage to be dispersed.

Female/male ends connect to female or male snap-lock fittings. Male ends allow you to join two lengths of pipe without the need for a fitting.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas. Do not expose pipe to direct sunlight.

Clear-View Standard-Wall Plastic Pipe for Water

See inside your line with this clear pipe, which works in a variety of residential and commercial low-pressure plumbing and water supply applications. It connects to standard-wall plastic pipe fittings. Made of PVC, it has good corrosion resistance. Join this pipe to unthreaded female socket-connect fittings using a PVC primer and cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Water

- Maximum Temperature: 140° F

- Fittings: Use Schedule 40 PVC Plastic

- Flanges: Use Schedule 40 PVC Plastic

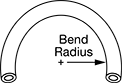

Semi-flexible pipe isn’t as bendable as soft tubing, but it can still bend around objects, resulting in fewer connection points in your line. Fewer connection points both reduces installation time and allows for smoother flow through your line.

Bend radius is the point to which you can bend pipe or tubing without damaging it. The smaller the measurement, the better the bend.

5 ft. | 10 ft. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Schedule | OD | ID | Wall Thick. | Bend Radius | Max. Pressure | Each | Each | ||

| 1/2 | 40 | 27/32" | 0.622" | 0.109" | 2 1/2" | 65 psi @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 3/4 | 40 | 1 3/64" | 0.824" | 0.113" | 3" | 55 psi @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 1 | 40 | 1 5/16" | 1.049" | 0.133" | 4" | 50 psi @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 1 1/2 | 40 | 1 29/32" | 1.61" | 0.145" | 7" | 45 psi @ 72° F | 0000000 | 00000 | 0000000 | 000000 |

| 2 | 40 | 2 3/8" | 2.067" | 0.154" | 9" | 40 psi @ 72° F | 0000000 | 00000 | 0000000 | 000000 |

| Pipe Cement | 000000000 | Each | 00000 |