About Sealant Flexibility

More

About Structural Adhesives

More

About Paint and Protective Coatings

More

Concrete Patching Compounds

Patch concrete floors and stairs with these compounds.

Epoxy compounds are three-part compounds consisting of a resin, a hardener, and aggregate in separate containers that can be mixed in the pail. The size listed is the combined total of the parts. They have excellent impact and chemical resistance. Paste compounds are ready for foot traffic in 8-12 hours. Thick liquid compounds are ready for traffic in two hours, and can withstand steel wheels and forklifts.

Container | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, gal. | Net Weight, lbs. | Type | Begins to Harden, min. | Reaches Full Strength | Consistency | Mix Ratio | Approximate Coverage @ Thick. | Max. Thick. | Application Temp. Range, °F | Finishing Method | For Use On | Choose a Color | Each | |

Epoxy | ||||||||||||||

| __ | 10 | Pail | 30 | 72 hrs. | Paste | 2:1 | 4 1/2 sq. ft. @ 1/4" | 2" | 35° to 90° | Drill, Sand | Concrete | 0000000 | 000000 | |

| __ | 10 | Pail | 30 | 72 hrs. | Paste | 2:1 | 4 1/2 sq. ft. @ 1/4" | 2" | 50° to 100° | Drill, Sand | Concrete | 0000000 | 00000 | |

| __ | 50 | Pail | 30 | 72 hrs. | Paste | 2:1 | 20 sq. ft. @ 1/4" | 2" | 35° to 90° | Drill, Sand | Concrete | 0000000 | 000000 | |

| __ | 50 | Pail | 30 | 72 hrs. | Paste | 2:1 | 20 sq. ft. @ 1/4" | 2" | 50° to 100° | Drill, Sand | Concrete | 0000000 | 000000 | |

| 2 | __ | Pail | 5 | 2 hrs. | Thick Liquid | 2:1 | 5 sq. ft. @ 1/4" | Not Rated | 50° to 90° | Drill | Concrete | 0000000 | 00000 | |

| 5 | __ | Pail | 5 | 2 hrs. | Thick Liquid | 2:1 | 15 sq. ft. @ 1/4" | Not Rated | 50° to 90° | Drill | Concrete | 0000000 | 000000 | |

Low-Temperature Concrete Patching Compounds

Use these two-part compounds to patch concrete floors and stairs in cold environments, such as freezers. At room temperature, they cure faster than any of our other concrete patching compounds. Once cured, they withstand impact, abrasion, and chemicals. The size listed is the combined total of the two parts.

Polyurea compounds are ready for foot traffic in ten minutes and vehicle traffic in 30 minutes. They are self-leveling, but can be mixed with sand (not included) and applied with a trowel.

Epoxy compounds are ready for foot traffic in ten minutes and vehicle traffic in two hours. Urethane compounds are ready for foot traffic in five minutes and vehicle traffic in ten minutes. Both can be applied with a trowel when mixed with the included aggregate or used as a self-leveling compound when used alone. Mix in the included pail.

Container | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Type | Begins to Harden, min. | Reaches Full Strength | Consistency | Mix Ratio | Approximate Coverage @ Thick. | Max. Thick. | For Use Outdoors | Application Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Polyurea | ||||||||||||||

| 1 gal. | Jug | 5 | 30 min. | Thin Liquid | 1:1 | 4 1/2 sq. ft. @ 1/4" | 1" | Yes | -5° to 90° | Gray | Drill, Sand | Concrete, Stone | 00000000 | 0000000 |

| 1 gal. | Jug | 5 | 30 min. | Thin Liquid | 1:1 | 4 1/2 sq. ft. @ 1/4" | 1" | Yes | -5° to 90° | Red | Drill, Sand | Concrete, Stone | 0000000 | 000000 |

Epoxy | ||||||||||||||

| 2 gal. | Pail | 10 | 2 hrs. | Thick Liquid | 2:1 | 7 1/2 sq. ft. @ 1/4" | Not Rated | No | -20° to 40° | Beige | Drill | Concrete | 0000000 | 000000 |

Heavy-Traffic Concrete Leveling Compounds

Not only do these leveling compounds withstand severe abrasion, wear, and impact, they stand up to heavy steel-wheel traffic and heavy blows without cracking. Apply with a trowel. They're ready for foot traffic in 12 hours. The resin and hardener are in separate containers that can be mixed in the pail. The size listed is the combined total of the two parts.

Container | Application | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Type | Begins to Harden, hrs. | Reaches Full Strength, hrs. | Consistency | Mix Ratio | Approximate Coverage @ Thick. | Max. Thick. | For Use Outdoors | Temp. Range, °F | Time After Mixing, min. | Finishing Method | For Use On | Choose a Color | Each | |

Epoxy | |||||||||||||||

| 2 gal. | Pail | 12 | 24 | Thick Liquid | 2:1 | 10 sq. ft. @ 1/8" | 1/8" | Yes | 50° to 90° | 30 | Drill | Concrete | 0000000 | 0000000 | |

| 5 gal. | Pail | 12 | 24 | Thick Liquid | 2:1 | 50 sq. ft. @ 1/8" | 1/8" | Yes | 50° to 90° | 30 | Drill | Concrete | 0000000 | 000000 | |

Chemical-Resistant Heavy-Traffic Concrete Leveling Compounds

These leveling compounds stand up to acid and chemical spills, making them a good choice for corrosive environments. They also withstand steel-wheel traffic and heavy impact. Apply with a trowel. They're ready for foot traffic in 12 hours. The resin and hardener are in separate containers that can be mixed in the pail. The size listed is the combined total of the two parts.

Container | Application | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Type | Begins to Harden, hrs. | Reaches Full Strength, hrs. | Consistency | Mix Ratio | Approximate Coverage @ Thick. | Max. Thick. | For Use Outdoors | Temp. Range, °F | Time After Mixing, min. | Finishing Method | For Use On | Choose a Color | Each | |

Epoxy | |||||||||||||||

| 2 gal. | Pail | 12 | 24 | Thick Liquid | 2:1 | 10 sq. ft. @ 1/8" | 1/8" | Yes | 50° to 70° | 15-20 | Drill | Concrete | 000000 | 0000000 | |

| 5 gal. | Pail | 12 | 24 | Thick Liquid | 2:1 | 50 sq. ft. @ 1/8" | 1/8" | Yes | 50° to 70° | 15-20 | Drill | Concrete | 0000000 | 000000 | |

Concrete Leveling Compounds

Give new life to damaged and worn concrete floors. These leveling compounds also fill minor depressions and cracks. Apply with a trowel.

Epoxy compounds resist abrasion for use in high-traffic areas. They’re ready for foot traffic in 8 hours. The resin and hardener are in separate containers that can be mixed in the pail. The size listed is the combined total of the two parts.

Container | Application | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, gal. | Type | Begins to Harden | Reaches Full Strength | Consistency | Mix Ratio | Approximate Coverage @ Thick. | Max. Thick. | For Use Outdoors | Temp. Range, °F | Time After Mixing, min. | Finishing Method | For Use On | Choose a Color | Each | |

Epoxy | |||||||||||||||

| 2 | Pail | 8 hrs. | 72 hrs. | Thick Liquid | 2:1 | 10 sq. ft. @ 1/8" | 2" | Yes | 50° to 100° | 30 | Drill, Sand | Concrete | 00000000 | 000000 | |

| 5 | Pail | 8 hrs. | 72 hrs. | Thick Liquid | 2:1 | 50 sq. ft. @ 1/8" | 2" | Yes | 50° to 100° | 30 | Drill, Sand | Concrete | 0000000 | 000000 | |

Self-Leveling Deep-Crack Concrete Fillers

Fill cracks up to 4" deep on horizontal surfaces such as floors and sidewalks. These epoxies are shrink, impact, and chemical resistant, and can also be used on wood, fiberglass, and metal surfaces. Use the cartridges with a standard caulk gun (sold separately) for dispensing.

Container | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden, min. | Reaches Full Strength, hrs. | Temp. to Begin to Harden, °F | Consistency | Mix Ratio | For Max. Crack Wd. | Approx. Coverage @ Thick. | For Use Outdoors | Application Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

| 10 | Cartridge | 15 | 24 | 77° | Thin Liquid | 1:1 | 1/16" | 24 ft. @ 4" | Yes | 50° to 90° | Light Amber | Sand, Tap | Concrete | 00000000 | 000000 |

| 10 | Cartridge | 15 | 24 | 77° | Thick Liquid | 1:1 | 1/4" | 6 ft. @ 4" | Yes | 50° to 90° | Light Amber | Sand, Tap | Concrete | 00000000 | 00000 |

Deep-Crack Concrete Fillers

Fill cracks up to 10" deep on vertical and overhead surfaces. To use this filler, secure the included injection ports to the crack with the two-part epoxy sealer, then spread sealer over the entire crack. Allow sealer 24 hours to cure. Application time for sealer, after mixing, is 40 minutes. To fill the rest of the void, use the cartridge with a standard caulk gun (sold separately) to dispense the two-part epoxy filler into the injection ports.

Sealant | Filler | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, fl. oz. | Container Type | Container Size, fl. oz. | Container Type | Begins to Harden, min. | Reaches Full Strength, hrs. | Consistency | Mix Ratio | Color | For Max. Crack Wd. | Approx. Coverage @ Thick. | Application Temp. Range, °F | Finishing Method | For Use On | Each | |

| 34 | Jar | 10 | Cartridge | 15 | 24 | Thin Liquid | 1:1 | Light Amber | 1/4" | 8 ft. @ 10" | 50° to 90° | Sand, Tap | Concrete | 00000000 | 0000000 |

Concrete Crack Fillers

Fill cracks in horizontal, vertical, and overhead concrete surfaces. Surface fillers that have a mix ratio are multi-part fillers. Size listed is the combined total of the parts.

Knead surface fillers in a stick to a uniform color to mix and press them into cracks in concrete floors, stairs, and walls. They can also be used to anchor bolts.

Container | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Net Weight | Type | Begins to Harden | Reaches Full Strength | Consistency | For Max. Crack Wd. | Approx. Coverage @ Thick. | Max. Thick. | For Use Outdoors | Application Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Epoxy Formulation | ||||||||||||||

| 4 oz. | Stick | 2 min. | 60 min. | Putty | 1/4" | 21 ft. @ 1/4" | 1/4" | Yes | 40° to 110° | Gray | Drill, Sand, Saw, Tap | Concrete, Masonry | 0000000 | 000000 |

Concrete Surface Fillers

Fill in and shape horizontal, vertical, and overhead concrete surfaces, such as steps and columns.

Epoxy surface fillers are nonsagging. They resist oil, grease, water, alkalies, and chemicals. Application time, after mixing, is 1 hour. The size listed is the combined total of the two parts.

Container | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Type | Begins to Harden, min. | Reaches Full Strength, hrs. | Formulation | Consistency | Mix Ratio | Approximate Coverage @ Thick. | Max. Thick. | For Use Outdoors | Application Temp. Range, °F | Color | Finishing Method | For Use On | Each | |

Epoxy | |||||||||||||||

| 12 fl. oz. | Can | 60 | 6 | Epoxy | Paste | 1:1 | 1/2 sq. ft. @ 1/4" | 1/4" | Yes | 50° to 90° | Gray | Drill, Sand | Concrete, Ceramic, Porcelain, Masonry, Stone | 0000000 | 000000 |

| 2 qt. | Can | 60 | 6 | Epoxy | Paste | 1:1 | 3 sq. ft. @ 1/4" | 1/4" | Yes | 50° to 90° | Gray | Drill, Sand | Concrete, Ceramic, Porcelain, Masonry, Stone | 000000 | 000000 |

| 2 qt. | Can | 60 | 6 | Epoxy | Paste | 1:1 | 3 sq. ft. @ 1/4" | 1/4" | Yes | 50° to 90° | White | Drill, Sand | Concrete, Ceramic, Porcelain, Masonry, Stone | 000000 | 000000 |

| 2 gal. | Can | 60 | 6 | Epoxy | Paste | 1:1 | 12 sq. ft. @ 1/4" | 1/4" | Yes | 50° to 90° | Gray | Drill, Sand | Concrete, Ceramic, Porcelain, Masonry, Stone | 000000 | 000000 |

Surface Filler Patches

Knead the epoxy-coated patch and resin together to make repairs to pipes, tanks, drums, and containers in the field.

| Mfr. Model No. | Lg. | Wd. | Begins to Harden, min. | Reaches Full Strength | Mix Ratio | For Use Outdoors | Temp. Range, ° F | Color | Finishing Method | For Use On | Each | |

Devcon Zip Patch™ | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 11500 | 4" | 9" | 5 | 4 hrs. | __ | Yes | -40° to 200° | Brown | Machine, Drill, Sand, Saw, Tap | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, Polystyrene Plastic, Polycarbonate Plastic, Polyurethane Rubber, ABS Plastic, PVC Plastic, CPVC Plastic, PETG Plastic, PVDF Plastic, Polyimide Plastic, Fiberglass, Ceramic, Wood | 0000000 | 0000000 |

Surface Fillers | ||||||||||||

| __ | 4" | 6" | 1 | 30 min. | 1:1 | Yes | Not Rated to 425° | Clear | Sand | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Cast Iron, Titanium, Polystyrene Plastic, Polycarbonate Plastic, Polyurethane Rubber, ABS Plastic, PVC Plastic, CPVC Plastic, PETG Plastic, PVDF Plastic, Polyimide Plastic, Vinyl Plastic, EPDM Rubber, SBR Rubber, Fiberglass, Wood | 00000000 | 00000 |

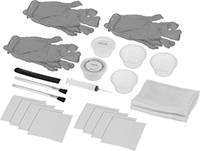

Water-Resistant Surface Filler Kits

Everything you need to repair cracked, worn, and damaged surfaces—even underwater.

| Includes | Formulation | Consistency | For Use Outdoors | Temp. Range, °F | Finishing Method | For Use On | Each | |

| 8 One-Time-Use Packets of 101-TS Two-Part Epoxy Filler 0.1-oz. 406 Collodial Silica Filler 0.1-oz. 410 Low-Density Filler Two Brushes Reusable Mixing Stick Three Mixing Cups 15" × 15" Fiberglass Cloth Syringe Dispenser Three Pairs of Disposable Gloves | Epoxy | Thin Liquid | Yes | 35° to 130° | Machine, Drill, Sand, Saw, Tap | Aluminum, Steel, Stainless Steel, ABS Plastic, PVC Plastic, Fiberglass, Wood | 0000000 | 000000 |

Container | ||||||||

|---|---|---|---|---|---|---|---|---|

| Component | No. of Pieces | Mfr. Model No. | Size | Type | Lg. | Wd. | Each | |

| Two-Part Epoxy | 6 | 101-TS | 0.6 fl. oz. | One-Time-Use Packet | __ | __ | 0000000 | 000000 |

| Resin | 1 | 105 | 1 qt. | Can | __ | __ | 0000000 | 00000 |

| Fast Hardener | 1 | 205 | 7 fl. oz. | Can | __ | __ | 0000000 | 00000 |

| Slow Hardener | 1 | 206 | 7 fl. oz. | Can | __ | __ | 0000000 | 00000 |

| Colloidal Silica Filler | 1 | 406 | 1.7 fl. oz. | Canister | __ | __ | 0000000 | 00000 |

| Colloidal Silica Filler | 1 | 406 | 5.5 fl. oz. | Canister | __ | __ | 0000000 | 00000 |

| Low-Density Filler | 1 | 410 | 5 fl. oz. | Canister | __ | __ | 0000000 | 00000 |

| Mini Dispensing Pump | 3 | 300 | __ | __ | __ | __ | 0000000 | 00000 |

| Fiberglass Cloth | 1 | 745 | __ | __ | 30" | 30" | 0000000 | 00000 |

Heavy Duty Epoxy Coatings for Concrete Floors

These coatings are more durable than our standard coatings for concrete floors. They provide a stain-resistant finish that protects your floors from moisture, chemicals, foot traffic, and hand carts. Repair cracks and holes prior to application. Apply with a squeegee, roller, or sprayer. The size listed is the combined total of the two parts.

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, gal. | Composition | Touch, hrs. | Overall, hrs. | Approx. Coverage @ Thick. | Mix Ratio | Application Time After Mixing, hrs. | Max. Temp., °F | Application Temp. Range, °F | For Use On | Choose a Color (Appearance) | Each | |

| 1 | Water Based | 24 | 72 | 160 sq. ft. @ 5 mil | 2:1 | 2 | 250° | 50° to 90° | Concrete | 000000 | 0000000 | |

Low-Odor Heavy Duty Epoxy Coatings for Concrete Floors

Use these solvent-free, high-gloss coatings to protect concrete floors in enclosed areas. Durable enough for forklift traffic, they resist stains, moisture, and chemicals. Apply with a brush, roller, or sprayer. The size listed is the combined total of the two parts.

Dry Time | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, gal. | Touch, hrs. | Overall, hrs. | Approx. Coverage @ Thick. | Mix Ratio | Application Time After Mixing, min. | Max. Temp., °F | Application Temp. Range, °F | For Use On | Choose a Color (Appearance) | Each | |

| 3/4 | 24 | 72-96 | 90 sq. ft. @ 10 mil | 2:1 | 20-30 | 250° | 50° to 100° | Concrete | 0000000 | 0000000 | |

Antislip Coatings

Longer-lasting than antislip tape, these coatings contain grit to provide traction. They’re good for areas with pedestrian traffic.

Water-based epoxy coatings are clear and can be applied over nearly any surface, even old coatings, without altering their appearance. These two-part coatings come with a mixer that attaches to a hand-held drill and a roller cover to apply them once mixed. The size listed is the combined total of the two parts.

Apply acrylic coatings with a roller or sprayer. Apply gallon-sized water-based coatings with a roller. Apply gallon-sized solvent-based coatings with a notched trowel, sprayer, or a roller cover for thick coatings (sold separately).

Coatings that comply with OSHA 29 CFR 1910.22 meet requirements for walking-working surfaces.

Container | Dry Time | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size, gal. | Net Weight, oz. | Composition | Touch | O'all | Approx. Coverage @ Thick. | Approx. Coverage, sq. ft. | Mix Ratio | Application Time After Mixing, min. | Specifications Met | For Use On | Primer Required For Use On | Includes | Choose a Color (Appearance) | Each | |

Epoxy—Aerosol Can | |||||||||||||||

| __ | 12 | Solvent Based | 20 min. | 24 hrs. | 15 sq. ft. @ 1 mil | __ | __ | __ | __ | Aluminum, Brass, Bronze, Copper, Steel, Stainless Steel, Iron, Galvanized Iron, Galvanized Steel, Fiberglass, Masonry, Concrete, Stone, Asphalt, Wood | __ | __ | 00000000 | 000000 | |

Epoxy—Can | |||||||||||||||

| 1 | __ | Water Based | 27 min. | 30 min. | 185 sq. ft. @ 38 mil | __ | 4:1 | 25 | OSHA Compliant 29 CFR 1910.22 | Aluminum, Brass, Copper, Steel, Stainless Steel, Galvanized Iron, Galvanized Steel, Plastic, Rubber, Ceramic, Glass, Masonry, Concrete, Stone, Asphalt, Drywall | __ | Mixer, Roller Cover | Clear (Gloss) | 0000000 | 000000 |

| 1 | __ | Solvent Based | 12 hrs. | 3 days | __ | 50 | __ | __ | ASTM F609 | Aluminum, Steel, Iron, Fiberglass, Concrete, Wood | Aluminum, Steel, Iron, Concrete, Wood | __ | 00000000 | 000000 | |

Acrylic—Can | |||||||||||||||

| 1 | __ | Water Based | 4 hrs. | 24 hrs. | __ | 70 | __ | __ | __ | Steel, Iron, Concrete, Wood | Steel, Iron, Concrete, Wood | __ | 0000000 | 000000 | |

| Roller Cover for Solvent-Based Coatings | 0000000 | Each | 00000 |

Low-Odor Vehicle-Grade Antislip Coatings

These high-traction antislip coatings have zero VOCs and are low odor. They contain grit to provide traction for pedestrian, cart, and hand-truck traffic. Apply with a roller. The size listed is the combined total of the two parts.

| Container Size, gal. | Composition | O'all Dry Time, hrs. | Approximate Coverage @ Thickness | Mix Ratio | Application Time After Mixing, min. | Max. Temp., °F | Application Temp. Range, °F | Specifications Met | For Use On | Choose a Color (Appearance) | Each | |

Epoxy | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | Water Based | 48 | 25 sq. ft. @ 30 mil | 3:1 | 45 | 300° | 50° to 100° | ADA Standards, ASTM D3960 | Aluminum, Steel, Iron, Concrete, Wood | 0000000 | 000000 | |

| 1 | Water Based | 48 | 50 sq. ft. @ 30 mil | 3:1 | 45 | 300° | 50° to 100° | ADA Standards, ASTM D3960 | Aluminum, Steel, Iron, Concrete, Wood | 0000000 | 000000 | |

Vehicle-Grade Antislip Coatings

Designed for use in areas with heavy vehicular traffic, these coatings are highly resistant to wear. They contain grit to provide traction to your surface. Apply with a notched trowel, roller, or sprayer. The size listed is the combined total of the two parts. They cannot be sold to the regions listed because they exceed local regulatory limits on VOCs (volatile organic compounds).

Coatings in a pail have a resin and a hardener in separate containers that can be mixed in the pail.

Dry Time | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, gal. | Composition | Touch, hrs. | O'all, days | Approximate Coverage @ Thickness | Application Time After Mixing, hrs. | Max. Temp., °F | Application Temp. Range, °F | Specifications Met | For Use On | Cannot Be Sold To | Choose a Color (Appearance) | Each | |

Epoxy—Can | |||||||||||||

| 1 | Solvent Based | 12 | 3 | 40 sq. ft. @ 2 mil | 4 | 160° | 50° to 130° | ADA Standards, ASTM F609 | Aluminum, Steel, Iron, Fiberglass, Concrete, Wood | Los Angeles County, CA, Orange County, CA, Riverside County, CA, San Bernardino County, CA | 0000000 | 0000000 | |

Epoxy—Pail | |||||||||||||

| 5 | Solvent Based | 12 | 3 | 40 sq. ft. @ 2 mil | 4 | 160° | 50° to 130° | ADA Standards, ASTM F609 | Aluminum, Steel, Iron, Fiberglass, Concrete, Wood | Los Angeles County, CA, Orange County, CA, Riverside County, CA, San Bernardino County, CA | 0000000 | 000000 | |

Heavy Duty Vehicle-Grade Antislip Coatings

These provide the highest traction and impact resistance of our antislip coatings. Longer-lasting than antislip tape, these coatings contain grit to provide traction. Apply with a roller. The resin and hardener come in separate containers that can be mixed in the pail. The size listed is the combined total of the two parts. They cannot be sold to the regions listed because they exceed local regulatory limits on VOCs (volatile organic compounds).

Coatings that meet MIL-PRF 24667 Type 1 are our most wear and impact resistant. They can also be applied with a notched trowel.

Dry Time | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, gal. | Composition | Touch, hrs. | O'all, days | Approximate Coverage @ Thickness | Application Time After Mixing, hrs. | Max. Temp., °F | Application Temp. Range, °F | Specifications Met | For Use On | Primer Required For Use On | Color (Appearance) | Cannot Be Sold To | Each | |

Epoxy—Can | ||||||||||||||

| 1 | Solvent Based | 24 | 4 | 25 sq. ft. @ 2 mil | 8 | 160° | 40° to 100° | MIL-PRF-24667 Type 2 Composition G, MIL-PRF-24667 Type 4 Composition G | Aluminum, Steel, Iron, Concrete, Wood | Aluminum, Steel, Iron, Concrete, Wood | Dark Gray (Flat) | Los Angeles County, CA, Orange County, CA, Riverside County, CA, San Bernardino County, CA | 0000000 | 0000000 |

Epoxy—Pail | ||||||||||||||

| 5 | Solvent Based | 24 | 4 | 125 sq. ft. @ 2 mil | 4 | 160° | 40° to 100° | MIL-PRF-24667 Type 1 Composition G, MIL-PRF-24667 Type 2 Composition G | Aluminum, Steel, Iron, Concrete, Wood | Aluminum, Steel, Iron, Concrete, Wood | Dark Gray (Flat) | Los Angeles County, CA, Orange County, CA, Riverside County, CA, San Bernardino County, CA | 0000000 | 000000 |

| 5 | Solvent Based | 24 | 4 | 125 sq. ft. @ 2 mil | 8 | 160° | 40° to 100° | MIL-PRF-24667 Type 2 Composition G, MIL-PRF-24667 Type 4 Composition G | Aluminum, Steel, Iron, Concrete, Wood | Aluminum, Steel, Iron, Concrete, Wood | Dark Gray (Flat) | Los Angeles County, CA, Orange County, CA, Riverside County, CA, San Bernardino County, CA | 0000000 | 000000 |

Antislip Coating Primers for Metal

Use these primers on your surface before antislip coatings to maximize longevity. They do not contain grit. Apply with a brush, roller, or sprayer. The size listed is the combined total of the two parts. They cannot be sold to the regions listed because they exceed local regulatory limits on VOCs (volatile organic compounds).

Dry Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container Size, gal. | Composition | Touch, min. | Overall, hrs. | Approx. Coverage @ Thick. | Application Time After Mixing, hrs. | Max. Temp., °F | For Topcoat Composition | For Use On | Color | Cannot Be Sold To | Each | |

| 1 | Solvent Based | 60 | 12 | 270 sq. ft. @ 4 mil | 4 | 160° | Solvent Based | Aluminum, Steel, Iron | Gray | Los Angeles County, CA, Orange County, CA, Riverside County, CA, San Bernardino County, CA | 0000000 | 0000000 |

Antislip Coating Primers for Concrete Floors

Use these primers on concrete floors before antislip coatings to maximize longevity. They do not contain grit. Apply with a brush or roller. The size listed is the combined total of the two parts.

| Container Size, fl. oz. | Composition | Approx. Coverage @ Thick. | Application Time After Mixing, hrs. | Color | Each | |

| 96 | Solvent Based | 200 sq. in. @ 2 mil | 1 | Amber | 0000000 | 0000000 |

Self-Leveling Concrete Joint Sealants

Thinner than non-sagging sealants, these flow easily into cracks and have a smooth finish.

Elongation indicates flexibility—the higher the value is, the more joint movement a sealant can sustain. For high-wear applications, choose a harder sealant for the most abrasion resistance.

Container | For Max. Crack | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Type | Begins to Harden | Reaches Full Strength | Mix Ratio | Elongation | Hardness | Wd. | Dp. | Application Temp. Range, °F | Temp. Range, °F | For Joining | Color | Each | |

Epoxy | ||||||||||||||

| 1 gal. | Can | 6 hrs. | 24 hrs. | 1:1 | Not Rated | Extra Hard (Durometer 60D) | 3/4" | 2" | 35° to 100° | -40° to 250° | Masonry | Gray | 0000000 | 0000000 |

| 1 gal. | Can | 6 hrs. | 24 hrs. | 1:1 | Not Rated | Extra Hard (Durometer 60D) | 3/4" | 2" | 50° to 100° | -40° to 250° | Masonry | Gray | 0000000 | 000000 |

| 2 gal. | Can | 6 hrs. | 24 hrs. | 1:1 | Not Rated | Extra Hard (Durometer 60D) | 3/4" | 2" | 35° to 100° | -40° to 250° | Masonry | Gray | 0000000 | 000000 |

| 2 gal. | Can | 6 hrs. | 24 hrs. | 1:1 | Not Rated | Extra Hard (Durometer 60D) | 3/4" | 2" | 50° to 100° | -40° to 250° | Masonry | Gray | 0000000 | 000000 |

Concrete Bonding Adhesives

Bond new concrete to old concrete, or use this epoxy as a primer for epoxy coatings on concrete surfaces. Mix the amount you need; the size listed is the combined total of the two parts.

Container | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size, gal. | Type | Begins to Harden | Reaches Full Strength | Mix Ratio | Consistency | Temp. Range, °F | Color | Each | |

| 0.75 | Can | 30 min. | 12 hrs. | 2:1 | Thick Liquid | 50° to 100° | Amber | 0000000 | 000000 |

Epoxy Adhesives for Floor Tiles

Use this two-part, solvent-free epoxy to install floor tiles.

Container | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size, gal. | Type | Approximate Coverage, sq. ft. | Mixing Required | Begins to Harden, min. | Reaches Full Strength, hrs. | For Use Outdoors | Each | |

| 1 | Can | 125-150 | Yes | 40 | 72 | No | 0000000 | 0000000 |