Filter by

Body Material

Maximum Flow Rate

Wetted Parts Material

Fitting Connection

Flow Measurement Type

Maximum Temperature

Fitting Material

Maximum Switching Current @ Voltage

Connects To

Maximum Pressure @ Temperature

Maximum Flow

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Insertion-Mount Flow Switches

For Pipe Size | Flow Set Point Range, gpm | Max. Flow Rate, gpm | Paddle Material | Max. Pressure @ Temp. | Temp. Range, ° F | Max. Switching Current @ Voltage | Body Ht. | Enclosure Rating | Specs. Met | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Noryl Body with 3/4 Socket-Connect Noryl Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Set-Point-Adjustment Trimmable Paddles | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 2 3 | 7.7 to 19.3 10.3 to 21 16.5 to 52 | 110; 150; 390 | Noryl | 160 psi @ 70° F | -13 to 212 | 1 amp @ 230V AC 1 amp @ 48V DC | 2 1/2" | IP65 | UL 508 | — | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 2 3 | 7.9 to 15 10 to 22 18 to 50 | 144; 240; 650 | 301 Stainless Steel | 160 psi @ 70° F | -13 to 212 | 1 amp @ 230V AC 1 amp @ 48V DC | 2 1/2" | IP65 | UL 508 | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Noryl Body with 1/2 NPT Male Threaded Brass Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Set-Point-Adjustment Trimmable Paddles | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 2 3 4 8 | 7.7 to 19.3 10.3 to 21 16.5 to 52 25.5 to 68 126 to 240 | 110; 150; 390; 420; 1,100 | Noryl | 160 psi @ 70° F | -13 to 212 | 1 amp @ 230V AC 1 amp @ 48V DC | 2 1/2" | IP65 | UL 508 | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 2 3 4 8 | 7.9 to 15 10 to 22 18 to 50 25 to 66 114 to 176 | 144; 240; 650; 800; 1,900 | 301 Stainless Steel | 160 psi @ 70° F | -13 to 212 | 1 amp @ 230V AC 1 amp @ 48V DC | 2 1/2" | IP65 | UL 508 | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body with 1 NPT Male Threaded Brass Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Set-Point-Adjustment Removable Layered Paddles, Set-Point-Adjustment Trimmable Paddles | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 2 4 6 | 4.9 to 17.6 13.7 to 56.4 35.3 to 118 60.3 to 245 | 27; 105; 397; 900 | 304 Stainless Steel | 160 psi @ 70° F | 33 to 225 | 3.7 amp @ 240V AC 7.4 amp @ 120V AC | 5" | NEMA 4X | — | C-UL Listed UL Recognized Component | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 2 4 6 | 6 to 10.2 18.8 to 32.8 39.7 to 73.5 79.2 to 166 | 27; 105; 397; 900 | 304 Stainless Steel | 160 psi @ 70° F | 33 to 300 | 3.7 amp @ 240V AC 7.4 amp @ 120V AC | 5" | — | — | C-UL Listed UL Listed | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body with 1 NPT Male Threaded 316 Stainless Steel Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Set-Point-Adjustment Removable Layered Paddles, Set-Point-Adjustment Trimmable Paddles | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 2 4 6 | 6 to 10.2 18.8 to 32.8 39.7 to 73.5 79.2 to 166 | 27; 105; 397; 900 | 304 Stainless Steel | 160 psi @ 70° F | 33 to 300 | 3.7 amp @ 240V AC 7.4 amp @ 120V AC | 5" | — | — | C-UL Listed UL Listed | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

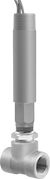

Fixed-Set-Point Flow Switches

Straight

Conduit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Pipe Size | Thread Type | Gender | Set Point, gpm | Approx. Difference Between Set Point and Reset Point, gpm | Max. Pressure @ Temp. | Temp. Range, ° F | Max. Switching Current @ Voltage | Trade Size | Thread Type | Gender | End-to-End Lg. | Mounting Position | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body with Bronze Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SPDT | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 2 | NPT | Female | 2 | 0.3 | 400 psi @ 70° F | -20 to 300 | 400 mA @ 30V AC 170 mA @ 120V AC 80 mA @ 240V AC 300 mA @ 30V DC 130 mA @ 120V DC 60 mA @ 240V DC | 1/2 | NPT | Male | 5 3/8" | Any Angle | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 2 | NPT | Female | 5 | 0.75 | 400 psi @ 70° F | -20 to 300 | 400 mA @ 30V AC 170 mA @ 120V AC 80 mA @ 240V AC 300 mA @ 30V DC 130 mA @ 120V DC 60 mA @ 240V DC | 1/2 | NPT | Male | 5 3/8" | Any Angle | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 2 | NPT | Female | 50 | 7.5 | 400 psi @ 70° F | -20 to 300 | 400 mA @ 30V AC 170 mA @ 120V AC 80 mA @ 240V AC 300 mA @ 30V DC 130 mA @ 120V DC 60 mA @ 240V DC | 1/2 | NPT | Male | 5 3/8" | Any Angle | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body with 316 Stainless Steel Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SPDT | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 2 | NPT | Female | 2 | 0.3 | 400 psi @ 70° F | -20 to 300 | 400 mA @ 30V AC 170 mA @ 120V AC 80 mA @ 240V AC 300 mA @ 30V DC 130 mA @ 120V DC 60 mA @ 240V DC | 1/2 | NPT | Male | 5 3/8" | Any Angle | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 2 | NPT | Female | 5 | 0.75 | 400 psi @ 70° F | -20 to 300 | 400 mA @ 30V AC 170 mA @ 120V AC 80 mA @ 240V AC 300 mA @ 30V DC 130 mA @ 120V DC 60 mA @ 240V DC | 1/2 | NPT | Male | 5 3/8" | Any Angle | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 2 | NPT | Female | 50 | 7.5 | 400 psi @ 70° F | -20 to 300 | 400 mA @ 30V AC 170 mA @ 120V AC 80 mA @ 240V AC 300 mA @ 30V DC 130 mA @ 120V DC 60 mA @ 240V DC | 1/2 | NPT | Male | 5 3/8" | Any Angle | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hazardous-Location Insertion-Mount Flow Switches

Flow Set Point Range | Max. Flow Rate | Conduit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Thread Type | Gender | For Pipe Size | For Water and Oil | For Air and Inert Gas | For Water and Oil | For Air and Inert Gas | Max. Pressure @ Temp. | Temp. Range, ° F | Max. Switching Current @ Voltage | Trade Size | Thread Type | Gender | Body Ht. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SPDT | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | NPT | Male | 1 1/2 2 4 12 20 | 3 gpm to 7 gpm 4 gpm to 15 gpm 12 gpm to 95 gpm 140 gpm to 900 gpm 400 gpm to 2,400 gpm | 17 scfm to 32 scfm 13 scfm to 65 scfm 50 scfm to 400 scfm 800 scfm to 3,450 scfm 2,850 scfm to 10,000 scfm | 55 gpm 97 gpm 391 gpm 3,525 gpm 9,792 gpm | Not Rated | 1,000 psi @ 70° F | -4 to 275 | 5 amp @ 125V AC 5 amp @ 250V AC | 3/4 | NPT | Female | 8" | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | NPT | Male | 1 1/2 2 4 12 20 | 3 gpm to 7 gpm 4 gpm to 15 gpm 12 gpm to 95 gpm 140 gpm to 900 gpm 400 gpm to 2,400 gpm | 17 scfm to 32 scfm 13 scfm to 65 scfm 50 scfm to 400 scfm 800 scfm to 3,450 scfm 2,850 scfm to 10,000 scfm | 55 gpm 97 gpm 391 gpm 3,525 gpm 9,792 gpm | Not Rated | 2,000 psi @ 70° F | -4 to 275 | 5 amp @ 125V AC 5 amp @ 250V AC | 3/4 | NPT | Female | 8" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DPDT | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | NPT | Male | 1 1/2 2 4 12 20 | 3 gpm to 7 gpm 4 gpm to 15 gpm 12 gpm to 95 gpm 140 gpm to 900 gpm 400 gpm to 2,400 gpm | 17 scfm to 32 scfm 13 scfm to 65 scfm 50 scfm to 400 scfm 800 scfm to 3,450 scfm 2,850 scfm to 10,000 scfm | 55 gpm 97 gpm 391 gpm 3,525 gpm 9,792 gpm | Not Rated | 1,000 psi @ 70° F | -4 to 275 | 5 amp @ 125V AC 5 amp @ 250V AC | 3/4 | NPT | Female | 8" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | NPT | Male | 1 1/2 2 4 12 20 | 3 gpm to 7 gpm 4 gpm to 15 gpm 12 gpm to 95 gpm 140 gpm to 900 gpm 400 gpm to 2,400 gpm | 17 scfm to 32 scfm 13 scfm to 65 scfm 50 scfm to 400 scfm 800 scfm to 3,450 scfm 2,850 scfm to 10,000 scfm | 55 gpm 97 gpm 391 gpm 3,525 gpm 9,792 gpm | Not Rated | 2,000 psi @ 70° F | -4 to 275 | 5 amp @ 125V AC 5 amp @ 250V AC | 3/4 | NPT | Female | 8" | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

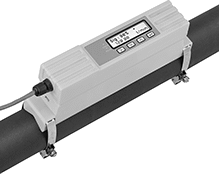

Contactless Flow Transmitters

Flow Range for Pipe Size, gpm | Input Voltage | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Measurement Type | For Pipe Size | 3/4 | 2 | 4 | End-to-End Lg. | Accuracy | Temp. Range, ° F | Min., V DC | Max. | Mounting Position | Field Recalibratable | Enclosure Rating | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

One Digital Pulse Output and One 4-20 mA Analog Transmitter Output—Wire Lead Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polycarbonate Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ultrasonic | 3/4 to 4 | 0 to 45 | 0 to 320 | 0 to 1,285 | 9 3/4" | ±3% | 32 to 185 | 12 | 24V AC/24V DC | Any Angle | Yes | IP54 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed-Set-Point Hazardous-Location Flow Switches

Set Point | Conduit | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Connections | For Liquids, gpm | For Gas, scfm | Max. Pressure @ Temp. | Temp. Range, ° F | Voltage, V AC | Max. Switching Current @ Voltage | Trade Size | Thread Type | Gender | End-to-End Lg. | Enclosure Rating | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Body with Threaded 304 Stainless Steel Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 NPT Female | 10 | 43 | 2,000 psi @ 70° F | -4 to 220 | 120/240 | 5 amp @ 120V AC | 3/4 | NPT | Male | 4 3/4" | NEMA 4 | UL Listed CE Marked | 00000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body with Threaded Brass Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 NPT Female | 10 | 43 | 250 psi @ 70° F | -4 to 220 | 120/240 | 5 amp @ 120V AC | 3/4 | NPT | Male | 3" | NEMA 4 | UL Listed CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Variable-Pressure Flow Switches

Flow Set Point, gpm | Max. Pressure @ Temp. | Temp. Range, ° F | Voltage | Max. Switching Current @ Voltage | Conduit Trade Size | End-to-End Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bronze Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 to 40 | 400 psi @ 70° F | -30 to 212 | 120V AC/175V DC | 180 mA @ 120V AC 250 mA @ 175V DC | 1/2 | 3 3/16" | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 to 100 | 400 psi @ 70° F | -30 to 212 | 120V AC/175V DC | 180 mA @ 120V AC 250 mA @ 175V DC | 1/2 | 3 3/16" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 to 200 | 400 psi @ 70° F | -30 to 212 | 120V AC/175V DC | 180 mA @ 120V AC 250 mA @ 175V DC | 1/2 | 3 3/16" | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

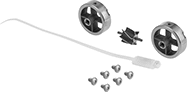

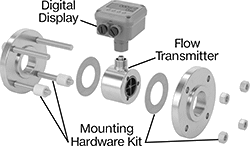

Build-Your-Own Flanged Pipe Flow Transmitters

|

Components Sold Separately (Pipe Flanges Not Included) |

Flow Transmitters

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Measurement Type | Pipe Size | Flow Range, gpm | Bore Size | OD | Type | For Flange ANSI Class | End-to-End Lg. | Accuracy | Max. Pressure @ Temp. | Temp. Range, ° F | Mounting Position | Field Recalibratable | Pulse Frequency per Volume, pulse per gal. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

One Digital Pulse Output—2-Pin BNC Connection Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316/316L Stainless Steel Body with 316/316L Stainless Steel Fitting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Turbine | 2 | 5 to 50 | 1" | 3 5/8" | Round | 150 | 2 1/2" | ±1.0% | 285 psi @ 70° F | -150 to 350 | Any Angle | No | 850 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Turbine | 2 | 15 to 180 | 1 1/2" | 3 5/8" | Round | 150 | 2 1/2" | ±1.0% | 285 psi @ 70° F | -150 to 350 | Any Angle | No | 325 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

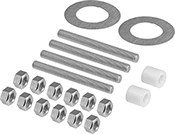

Mounting Hardware Kits

For Pipe Size | For Flange ANSI Class | Includes | Each | |||

|---|---|---|---|---|---|---|

| 2 | 150 | 4 Studs, 12 Nuts, 2 Gaskets, 2 Centering Rings | 0000000 | 0000000 | ||

High-Accuracy Flow and Temperature Transmitters

|

Flow Range | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Measurement Type | Pipe Connections | Gallons per Minute, gpm | Liters per Minute, L/min | End-to-End Lg. | Accuracy | Max. Pressure @ Temp. | Temp. Range, ° F | Input Voltage Range, V DC | Mounting Position | Field Recalibratable | Enclosure Rating | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two 4-20 mA Analog Transmitter Outputs—4-Pole Micro M12 Connection Plugs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel/Plastic/Polybutylene Body with 316 Stainless Steel Fitting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Magnetic Induction | 2 NPT Female | 1.3 to 158.5 | 5 to 600 | 7 1/16" | ±0.8% | 225 psi @ 70° F | 0 to 175 | 20 to 30 | Any Angle | No | IP65, IP67 | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||