About Flowmeters and Totalizers

Flowmeters measure the rate of flow for a liquid or a gas. Totalizers measure the cumulative flow volume. Flowmeter/totalizers display both the flow rate and the cumulative flow volume.

More

Flowmeters

Check the flow rate of liquids in your system. As your liquid flows through these flowmeters, it pushes an indicator up the scale, showing you the flow rate. Mount them vertically inline with your piping system, so liquid flows up from the bottom. They’re made from acrylic, so they’re completely clear to help you inspect your liquid’s color and clarity for any problems. They also have a white backing to help you read the scale clearly.

These flowmeters are calibrated with water but can be used with other liquids except for oil. If you’re using these with a liquid other than water, you’ll need to calculate the flow rate by multiplying the number shown on the scale by the specific-gravity conversion factor for your liquid.

Flowmeters with a rectangular body are made from a single block of acrylic, so they’re more durable and resist impact better than flowmeters with a cylindrical body. However, they’re not as durable as flowmeters with a protective case.

Flowmeters with a calibration certificate traceable to NIST states that the flowmeter has passed a test for accuracy.

Choose a fitting material that is compatible with the liquid you're running through your line. Polypropylene and PVC fittings work with a wide range of chemicals. However, they can crack from impact or when overtightened. Brass and 316 stainless steel fittings resist impact better than polypropylene and PVC fittings.

Body with

Female Fittings

Flowmeters | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Range | Replacement Fittings | Replacement Seal Kits | |||||||||||

| Gallons per Minute | Overall Ht. | Accuracy | Max. Pressure | Temp. Range, °F | Body Material | Seal Material | Mounting Orientation | Each | Each | Each | |||

PVC Plastic Fittings | |||||||||||||

3/8 NPT Female | |||||||||||||

| 0.1 to 1 gpm | 8 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | 00000000 | 0000000 | 00000000 | 000000 | 00000000 | 000000 |

| 0.2 to 2 gpm | 8 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.3 to 3.5 gpm | 8 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 00000 |

| 0.5 to 5 gpm | 8 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 00000 |

316 Stainless Steel Fittings | |||||||||||||

3/8 NPT Female | |||||||||||||

| 0.1 to 1 gpm | 8 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 00000 |

| 0.2 to 2 gpm | 8 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 00000 |

| 0.3 to 3.5 gpm | 8 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 00000 |

| 0.5 to 5 gpm | 8 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 00000 |

Body with

Male Fittings

Body with

Female Fittings

Flowmeters | Replacement Fittings | Replacement Seal Kits | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Range | Overall Ht. | Accuracy | Max. Pressure | Temp. Range, °F | Body Material | Seal Material | Mounting Orientation | Certification | Each | Each | Each | |||

PVC Plastic Fittings | ||||||||||||||

1/4 NPT Male | ||||||||||||||

| 0.7 to 7 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 1 to 12 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 00000 | 00000000 | 000000 | 0000000 | 000000 |

| 2.2 to 22 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 |

| 4.4 to 44 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 |

| 6 to 60 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 |

| 7.5 to 75 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 00000 | 000000 | 00 | 000000 | 00 |

1/2 NPT Female | ||||||||||||||

| 0.1 to 1 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.1 to 1 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.2 to 2 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.2 to 2 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.2 to 2 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | Calibration Certificate Traceable to NIST | 00000000 | 000000 | 00000000 | 00000 | 000000 | 00 |

| 0.35 to 3.5 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 000000 | 00 |

| 0.35 to 3.5 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | Calibration Certificate Traceable to NIST | 00000000 | 000000 | 00000000 | 00000 | 000000 | 00 |

| 0.35 to 3.6 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 00000 | 000000 | 00 | 000000 | 00 |

| 0.4 to 5 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.5 to 5 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.5 to 5 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | Calibration Certificate Traceable to NIST | 00000000 | 000000 | 00000000 | 00000 | 000000 | 00 |

3/4 NPT Female | ||||||||||||||

| 0.2 to 2 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.35 to 3.5 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.5 to 5 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.5 to 5 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | Calibration Certificate Traceable to NIST | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 1 to 10 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 1 to 10 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | Calibration Certificate Traceable to NIST | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

1 NPT Female | ||||||||||||||

| 1 to 10 gpm | 8 3/8" | ±4% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 1.5 to 15 gpm | 8 3/8" | ±4% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 2 to 20 gpm | 8 3/8" | ±4% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

Brass Fittings | ||||||||||||||

1/4 NPT Female | ||||||||||||||

| 0.7 to 7 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 00000 | 000000 | 00 | 000000 | 00 |

| 1 to 12 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 |

| 2.2 to 22 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 |

| 4.4 to 44 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 |

| 6 to 60 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 |

| 7.5 to 75 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 00000 | 000000 | 00 | 000000 | 00 |

1/2 NPT Female | ||||||||||||||

| 0.1 to 1 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.1 to 1 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.2 to 2 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.2 to 2 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 000000 | 00 |

| 0.35 to 3.5 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 000000 | 00 |

| 0.35 to 3.6 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.4 to 5 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.5 to 5 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 000000 | 00 |

3/4 NPT Female | ||||||||||||||

| 0.2 to 2 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.35 to 3.5 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.5 to 5 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 00000 |

| 1 to 10 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 00000 |

1 NPT Female | ||||||||||||||

| 1 to 10 gpm | 8 3/8" | ±4% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 00000 |

| 1.5 to 15 gpm | 8 3/8" | ±4% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 00000 |

| 2 to 20 gpm | 8 3/8" | ±4% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 00000 |

316 Stainless Steel Fittings | ||||||||||||||

1/4 NPT Female | ||||||||||||||

| 0.7 to 7 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 1 to 12 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 2.2 to 22 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 4.4 to 44 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 6 to 60 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 7.5 to 75 gph | 4 3/4" | ±6% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

1/2 NPT Female | ||||||||||||||

| 0.1 to 1 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.1 to 1 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.2 to 2 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.2 to 2 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.35 to 3.5 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.35 to 3.6 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.5 to 5 gpm | 6 1/2" | ±5% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 |

| 0.5 to 5 gpm | 9 1/4" | ±3% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 00000 | 000000 | 00 |

3/4 NPT Female | ||||||||||||||

| 0.2 to 2 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.35 to 3.5 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 000000 | 00 | 000000 | 00 |

| 0.5 to 5 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 00000 |

| 1 to 10 gpm | 14 13/16" | ±2% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 00000 |

1 NPT Female | ||||||||||||||

| 1 to 10 gpm | 8 3/8" | ±4% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 00000 |

| 1.5 to 15 gpm | 8 3/8" | ±4% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 00000 |

| 2 to 20 gpm | 8 3/8" | ±4% | 125 psi @ 70° F | 33° to 130° | Acrylic Plastic | EPR Rubber | Vertical | __ | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 00000 |

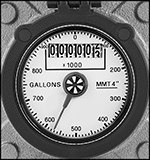

Totalizers

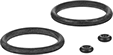

Measure the total amount of liquid flowing through these totalizers. They total the volume by counting how many times their turbine turns as liquid flows through. To avoid clogging the turbine and other damage to the sensor, use them only with clean, low-viscosity liquids. Their total cannot be reset.

These totalizers are calibrated with water. You can use them with other liquids, but they may not measure accurately if the liquid’s viscosity differs from water.

Optional magnetically actuated switches send flow rate data. They create a pulse each time the switch closes. One pulse is equivalent to one gallon measured.

Totalizers | Replacement Couplings | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Connections | Flow Range, gpm | Max. Total Volume, gallons | Inlet ID | End-to-End Lg. | Accuracy | Max. Pressure | Temp. Range, °F | Seal Material | Mounting Orientation | Display Type | Each | Pair | ||

Nylon Plastic Body with 304 Stainless Steel/ Nylon Plastic Fittings | ||||||||||||||

| 1/2 NPT Male | 0.25 to 13 | 9,999,999 | 5/8" | 10" | ±1.5% | 100 psi @ 70° F | 35° to 120° | Buna-N Rubber | Horizontal | Analog | 0000000 | 0000000 | 0000000 | 000000 |

| 3/4 NPT Male | 0.25 to 22 | 9,999,999 | 5/8" | 11 1/2" | ±1.5% | 100 psi @ 70° F | 35° to 120° | Buna-N Rubber | Horizontal | Analog | 0000000 | 000000 | 0000000 | 00000 |

| Wire Connection Type | No. of Wire Leads | Wire Lead Lg. | Output Type | Digital Output Type | No. of Circuits Controlled | Switch Starting Position | Industry Designation | Max. Switching Current | Each | |

| Wire Lead | 2 | 60" | Digital | Pulse | 1 | 1 Off (Normally Open) | SPST | 10 mA @ 24 V AC/DC | 0000000 | 000000 |

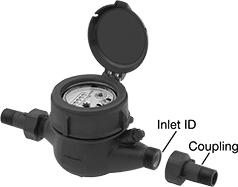

Flanged Totalizers for Drinking Water

Flanged ends let you securely integrate these totalizers into large drinking water pipelines to measure the cumulative amount of water flowing through them. They meet NSF/ANSI 61, so they're safe to use with drinking water. They measure flow volume by counting how many times their turbine turns as liquid flows through. To avoid clogging the turbine and other damage to the sensor, use them only with clean, low-viscosity liquids. Their total cannot be reset.

These totalizers are calibrated with water. You can use them with other liquids, but they may not measure accurately if the liquid’s viscosity differs from water.

Optional elliptical flange kit lets you convert elliptical flanges to NPT female connections.

Flange | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | Type | Flow Range, gpm | Max. Total Volume, gallons | End-to-End Lg. | Accuracy | Max. Pressure | Temp. Range, °F | Seal Material | Mounting Orientation | Display Type | Bolt Hole Dia. | Bolt Circle Dia. | Number of Bolt Holes | Each | |

Bronze Body and Brass Fittings | ||||||||||||||||

| 2 | 5 7/8" | Elliptical | 4 to 350 | 99,999,000 | 10" | ±1.5% | 175 psi @ 70° F | 33° to 150° | Buna-N Rubber | Horizontal | Analog | 5/8" | 4" | 2 | 0000000 | 000000000 |

| Optional Elliptical Flange Kit | 0000000 | Each | 0000000 |

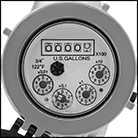

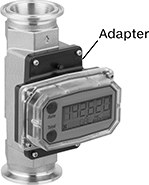

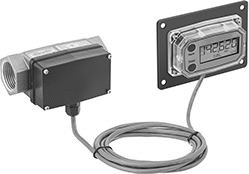

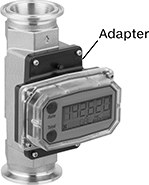

Flowmeter/Totalizers

Determine the flow rate and total volume of liquid flowing through your system with the same meter. To measure flow, these flowmeter/totalizers count how many times their turbine turns as liquid passes through. Use them only with clean, low-viscosity liquids to avoid clogging the turbine and other damage to these flowmeter/totalizers. You can reset the batch total, but you can’t reset the cumulative total. Mount them inline with your pipe system. They’re accurate in any mounting orientation.

These flowmeter/totalizers are either calibrated with water or solvent. You can recalibrate them in the field to other liquids, pipe, and operating conditions.

Choose a fitting material that is compatible with the liquid you're running through your line. 316 stainless steel fittings resist impact better than plastic fittings.

IP rated, all seal out dust and can be lightly rinsed. FM-approved flowmeter/totalizers are safe for use in hazardous location.

90° display adapter kits let you rotate the meter’s display 90°, so you can read it easier when mounted vertically.

Output modules allow you to transmit flow data from flowmeter/totalizers to an external device such as a programmable logic controller (PLC), data recorder, logger, and remote display (not included). 4-20 mA output modules have an analog output. As flow increases, the output signal from the transmitter increases. For your receiving device to interpret the signal from the transmitter, you will need to calibrate it for the measurement range and output signal of the transmitter. They only give accurate readings within the rated measurement range. Pulse output modules have a digital output. They transmit flow data using spikes of voltage that match the input voltage of the transmitter. The higher the flow, the more pulses they send.

Remote panel-mounting kits let you mount the meter’s display up to 10 feet away.

Flowmeter/Totalizers | Replacement Displays | 90° Display Adapter Kits | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Connections | Flow Range, gpm | End-to-End Lg. | Accuracy | Max. Total Volume, gallons | Max. Batch Volume, gallons | Max. Pressure | Temp. Range, °F | Batteries Included | Environmental Rating | Specifications Met | Each | Each | Each | |||

| 1/2 NPT Female | 1 to 10 | 4 1/4" | ±1.5% | 999,999 | 999,999 | 1500 psi @ 70 ° F | 14° to 140° | Yes | NEC Class I Divisions 1, 2 Groups A, B, C, D; NEC Class II Divisions 1, 2 Groups E, F, G; NEC Class III Divisions 1, 2; IP65 | FM Approved, CE Marked, ATEX II 1 G Ex ia IIC T4 Ga, C-FM Approved, IECEx Ex ia IIC T4 Ga | 00000000 | 0000000 | 00000000 | 0000000 | 00000000 | 000000 |

| Component | Number of Wire Leads | Wire Lead Lg., ft. | Input Voltage Range | Includes | Pkg. Qty. | For Flow Measurement Type | Each | |

| 4-20 mA Output Module | 4 | 10 | 8V DC to 26V DC | __ | __ | Turbine | 00000000 | 0000000 |

| Remote Panel-Mounting Kit | __ | __ | __ | __ | __ | Turbine | 00000000 | 000000 |

| 90° Display Adapter Kits | __ | __ | __ | 12 Screws, 90° Display Adapter, Nitrile Rubber O-Ring | __ | Turbine | 00000000 | 00000 |

| Pkg. | ||||||||

|---|---|---|---|---|---|---|---|---|

| Disposable Batteries | __ | __ | __ | __ | 4 | __ | 00000000 | 0000 |