Filter by

Environment

Food Industry Standard

System of Measurement

U-Joint Type

Shaft Type

For Shaft Misalignment Type

Set Screw Material

Maximum Torque

Shaft Mount Type

Maximum Operating Angle

Torque @ Motor Speed

Joint Type

Bearing Material

Bellows Material

DFARS Specialty Metals

Drive Style

Export Control Classification Number (ECCN)

Maximum Rotation Speed

Number of Set Screws Required

REACH

RoHS

Sanitary Sealed Single U-Joints

U-Joints | Replacement Covers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft | Keyway | Torque | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

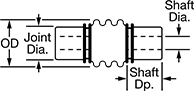

Dia. | Dp. | Joint Dia. | Overall Lg. | OD | Wd. | Dp. | Max. Operating Angle | Max. Rotation Speed, rpm | Max. Torque, in·lbf | 3° Operating Angle | 10° Operating Angle | Bellows Material | Joint Type | For Shaft Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel with Steel Bearings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FDA Compliant 21 CFR 177.2600 U-Joints | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 15/16" | 3/4" | 2 11/16" | 1 3/8" | 3/32" | 3/64" | 35° | 6,000 | 95 | 28 in·lbf @ 1,000 rpm | 19 in·lbf @ 1,000 rpm | Silicone Rubber | Needle Bearing | Keyed | 0000000 | 0000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 3/16" | 1" | 3 3/8" | 1 1/2" | 1/8" | 1/16" | 35° | 6,000 | 215 | 110 in·lbf @ 1,000 rpm | 77 in·lbf @ 1,000 rpm | Silicone Rubber | Needle Bearing | Keyed | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 1/4" | 1 1/4" | 3 3/4" | 1 7/8" | 3/16" | 3/32" | 35° | 6,000 | 700 | 275 in·lbf @ 1,000 rpm | 185 in·lbf @ 1,000 rpm | Silicone Rubber | Needle Bearing | Keyed | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

U-Joints | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 3/8" | 1 1/2" | 4 1/4" | 2 1/4" | 3/16" | 3/32" | 35° | 6,000 | 1,780 | 545 in·lbf @ 1,000 rpm | 370 in·lbf @ 1,000 rpm | Silicone Rubber | Needle Bearing | Keyed | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 11/16" | 2" | 5 1/2" | 2 11/16" | 1/4" | 1/8" | 35° | 6,000 | 4,300 | 1,050 in·lbf @ 1,000 rpm | 705 in·lbf @ 1,000 rpm | Silicone Rubber | Needle Bearing | Keyed | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||