About Dock Levelers and Dock Plates

More

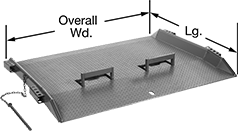

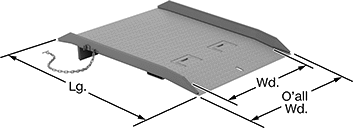

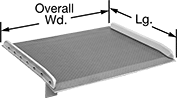

Portable Dock Plates with Forklift Loops

The heaviest dock plates we offer, these are built to endure high-traffic use. Forklift loops on the top flip up for easy maneuvering with a forklift and fold down when not in use. Use plates to bridge the gap between a truck and the dock when loading and unloading with forklifts, battery-operated hand trucks, and other powered equipment. They have a diamond surface texture for positive traction and lips on the sides lessen the chance of vehicle runoff. Plates have anchoring pins that you drop into any of the eight holes along their edges—this secures the plate in the space between the dock and the truck.

Dock Plates | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Lip | Replacement Anchoring Pins | |||||||||

| Max. Ht. Differential | Capacity, lbs. | Lg. | Overall Wd. | Material | Material | Color | Each | Each | ||

| ±5" | 15,000 | 48" | 60" | Steel | Painted Steel | Blue | 0000000 | 000000000 | 0000000 | 000000 |

| ±5" | 15,000 | 48" | 72" | Steel | Painted Steel | Blue | 0000000 | 00000000 | 0000000 | 00000 |

| ±7" | 15,000 | 60" | 60" | Steel | Painted Steel | Blue | 0000000 | 00000000 | 0000000 | 00000 |

| ±7" | 15,000 | 60" | 72" | Steel | Painted Steel | Blue | 0000000 | 00000000 | 0000000 | 00000 |

| ±7" | 15,000 | 60" | 84" | Steel | Painted Steel | Blue | 0000000 | 00000000 | 0000000 | 00000 |

| ±8 1/2" | 15,000 | 72" | 60" | Steel | Painted Steel | Blue | 0000000 | 00000000 | 0000000 | 00000 |

| ±8 1/2" | 15,000 | 72" | 72" | Steel | Painted Steel | Blue | 0000000 | 00000000 | 0000000 | 00000 |

| ±8 1/2" | 20,000 | 72" | 72" | Steel | Painted Steel | Blue | 0000000 | 00000000 | 0000000 | 00000 |

| ±10" | 15,000 | 84" | 72" | Steel | Painted Steel | Blue | 0000000 | 00000000 | 0000000 | 00000 |

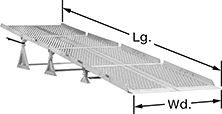

Vehicle Ramps

Drive a fully loaded forklift into a truck, trailer, or dock door from ground level. When you’re done, these ramps break down to the size of a double-wide pallet for storage. They’re often referred to as yard ramps because they’re common in shipping yards. Made entirely of aluminum, these ramps stand up to the weather. The perforated surface gives your vehicle traction in all conditions and allows rain, snow, and dirt to pass through. These ramps have two included ratchet straps to secure them to a vehicle and prevent them from pulling away. Plates on either end facilitate smooth transitions from ground to ramp and ramp to truck.

No tools are needed for setup. Assembly can be completed in as little as 15 minutes with two people and a forklift.

Note: Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

| Max. Ht. Differential | Ht. | Capacity, lbs. | Lg., ft. | Wd. | Overall Wd. | Material | Lip Material | Includes | Specifications Met | Each | |

| ±60" | 15"-60" | 30,000 | 8-30 | 99" | 101" | Aluminum | Aluminum | Three Adjustable-Height Support Stands, Six Stand Pins with Clips, Eight Ramp Sections, Six Steel Rods with Hooks, Two Ratchet Straps | OSHA Compliant 29 CFR 1910 Subpart D, OSHA Compliant 29 CFR 1926.451 | 00000000 | 0000000000 |

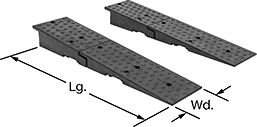

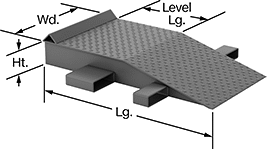

Low-Height Vehicle Ramps

Create a smooth transition for driving forklifts over curbs and into shipping containers. Often used for loading or unloading, these vehicle ramps have a diamond texture on the surface to give wheels traction.

Rubber ramps are best for occasional use, since fully loaded forklifts will erode their surface over time. Lock them together with the built-in connectors to make a solid ramp, or separate them to use as wheel tracks.

Steel ramps are strong enough to hold up to frequent use. A lip on each side keeps wheels from running off the edge. To keep them from shifting, lock them to your container with the included chains. These ramps have loops built into the top, so you can pick them up and move them with your forklift. The loops fold flat when they’re not in use.

Note: Ramps that have OSHA specifications listed meet dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

Lip | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Ramps Included | Max. Ht. Differential | Capacity, lbs. | Lg., ft. | Wd. | Overall Wd. | Plate Thick. | Material | Color | Features | Includes | Specifications Met | Each | |

| 1 | ±11" | 20,000 | 6 | 66" | 72" | 3/8" | Painted Steel | Blue | Forklift Loops | Locking Chains | ANSI MH 30.2, OSHA Compliant 29 CFR 1910.26 | 00000000 | 000000000 |

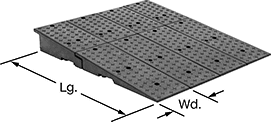

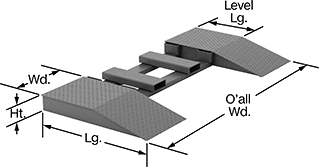

Wheel Risers with Forklift Pockets

Pockets make it easy to move these risers with a forklift. Use them to raise vehicles up for maintenance jobs or bring vehicles up to dock height for loading and unloading. The diamond surface texture creates good traction, so tires won't slip or spin.

A roll-off lip stops tires from going too far and accidentally falling off the riser.

For Maximum Fork | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Risers | Height | Capacity, lbs. | Width | Height | Level Length | Length | Width | Overall Width | Material | Features | Specifications Met | Each | |

| 1 | 6 1/4" | 40,000 | 7 1/2" | 2 1/2" | 24" | 48" | 24" | __ | Painted Steel | Forklift Pockets, Roll Off Lip | ANSI B56.1 | 0000000 | 0000000 |

| 2 | 6 1/4" | 40,000 | 7 1/2" | 2 1/2" | 24" | 48" | 24" | 101 1/8" | Painted Steel | Forklift Pockets | ANSI B56.1 | 0000000 | 00000000 |

Portable Dock Plates

These plates allow forklift access so you can move them easily to bridge the gap between a truck and the dock. Use them when loading and unloading with forklifts, battery-operated hand trucks, and other powered equipment. Plates have a diamond surface texture for positive traction and lips on the sides lessen the chance of vehicle runoff.

Lip | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max. Ht. Differential | Capacity, lbs. | Lg. | Overall Wd. | Material | Material | Color | Features | Each | |

| ±5" | 15,000 | 36" | 60" | Aluminum | Painted Steel | Fluorescent Yellow | Anchoring Legs | 00000000 | 0000000 |

| ±5" | 20,000 | 36" | 60" | Aluminum | Painted Steel | Fluorescent Yellow | Anchoring Legs | 00000000 | 000000 |

| ±7" | 10,000 | 48" | 60" | Aluminum | Painted Steel | Fluorescent Yellow | Anchoring Legs | 00000000 | 000000 |

| ±7" | 15,000 | 48" | 60" | Aluminum | Painted Steel | Fluorescent Yellow | Anchoring Legs | 00000000 | 00000000 |

| ±10" | 10,000 | 60" | 60" | Aluminum | Painted Steel | Fluorescent Yellow | Anchoring Legs | 00000000 | 00000000 |

| ±10" | 15,000 | 60" | 60" | Aluminum | Painted Steel | Fluorescent Yellow | Anchoring Legs | 00000000 | 00000000 |

| ±12" | 10,000 | 72" | 60" | Aluminum | Painted Steel | Fluorescent Yellow | Anchoring Legs | 00000000 | 00000000 |

| ±12" | 15,000 | 72" | 60" | Aluminum | Painted Steel | Fluorescent Yellow | Anchoring Legs | 00000000 | 00000000 |

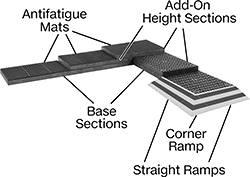

Modular Work Platforms

Stack platforms vertically and connect them horizontally to create various sizes and configurations. They have an open-grid design that allows liquids to drain and debris to fall through.

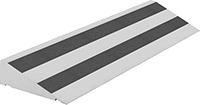

Ramps create a smooth transition for hand trucks and carts to roll onto the platform. They connect to base sections and add-on height sections with two horizontal connectors (sold separately). Use straight ramps along the sides and ends of the platform. Use corner ramps to connect two straight ramps and wrap around the entire platform edge.

Note: Work platforms and ramps meet OSHA and Cal/OSHA dimensional and construction standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe setup and operating practices.

| No. of Levels | Lg. | Wd. | Ht. | Cap., lbs. | Color | Assembled or Unassembled | Specifications Met | Each | |

Grit-Coated Wood | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Straight | |||||||||

| 1 | 2 ft. | 10" | 2 7/8" | 250 | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 000000 |

| 1 | 3 ft. | 10" | 2 7/8" | 500 | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 00000 |

| 1 | 5 1/2 ft. | 10" | 2 7/8" | 250 | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 000000 |

| 2 | 2 ft. | 1 1/2 ft. | 5 1/2" | 750 | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 00000 |

| 2 | 3 ft. | 1 1/2 ft. | 5 1/2" | 250 | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 000000 |

| 2 | 5 1/2 ft. | 1 1/2 ft. | 5 1/2" | 750 | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 000000 |

| 3 | 2 ft. | 2 1/2 ft. | 8 1/8" | 750 | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 000000 |

| 3 | 3 ft. | 2 1/2 ft. | 8 1/8" | 750 | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 000000 |

| 3 | 5 1/2 ft. | 2 1/2 ft. | 8 1/8" | 750 | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 000000 |

Corner | |||||||||

| 1 | 10" | 10" | 2 7/8" | Not Rated | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 00000 |

| 2 | 1 1/2 ft. | 1 1/2 ft. | 5 1/2" | Not Rated | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 00000 |

| 3 | 2 1/2 ft. | 2 1/2 ft. | 8 1/8" | Not Rated | Black/Yellow | Assembled | Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 000000000 | 000000 |

| Horizontal Connectors (Pkg. of 4) | 00000000 | Pkg. | 000000 |