Filter by

Hazardous Location Protection Type

Hazardous Location Rating

Certification

Current

Overall Width

Airflow @ Static Pressure

Power Source

Overall Height

Housing Material

Electrical Connection Type

Overall Depth

Export Control Classification Number (ECCN)

DFARS Specialty Metals

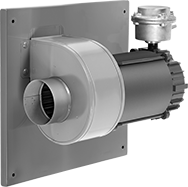

Wall-Mount Hazardous Location Fume Exhausters

Overall | Mounting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Airflow @ SP | Volume (Sound) @ Distance | Power, hp | Inlet Dia. | Outlet Dia. | Ht. | Wd. | Dp. | Housing Material | Base Material | Wheel Material | Fasteners Included | For Screw Size | Hole Dia. | No. of Holes | Hazardous Location Rating | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 ft³/min @ 1/2 in. H₂O | 61 dBC @ 15 ft. | 1/4 | 4" | 4" | 16" | 17 5/8" | 8 7/8" | Galvanized Steel | Steel | Aluminum | No | 1/4" | 9/32" | 4 | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups E, F, G | 000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

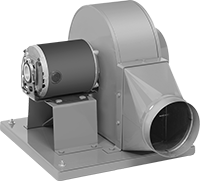

Floor-Mount Hazardous Location Fume Exhausters

Overall | Mounting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Airflow @ SP | Volume (Sound) @ Distance | Power, hp | Inlet Dia. | Outlet Dia. | Ht. | Wd. | Dp. | Housing Material | Base Material | Wheel Material | Fasteners Included | For Screw Size | Hole Dia. | No. of Holes | Hazardous Location Rating | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 800 ft³/min @ 1/2 in. H₂O | 65 dBC @ 15 ft. | 1/3 | 6" | 6" | 15 1/8" | 18 1/4" | 20 3/8" | Galvanized Steel | Steel | Aluminum | No | 1/4" | 9/32" | 4 | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups E, F, G | 000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Suspended-Hood Hazardous Location Fume Exhausters

Fume Exhausters | Fume Exhauster Mounting Brackets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hood Dia. | Airflow @ SP | Volume (Sound) @ Distance | Power, hp | ID | Lg., ft. | Includes | Hazardous Location Rating | Enclosure Rating | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC/230V AC—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 27" | 450 ft³/min @ 0 in. H₂O | 69 dB @ 5 ft. | 1/2 | 6" | 10 | Blower, Outside Vent Kit | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | IP54 | 00000000 | 000000000 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32" | 450 ft³/min @ 0 in. H₂O | 69 dB @ 5 ft. | 1/2 | 6" | 10 | Blower, Outside Vent Kit | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | IP54 | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 37" | 450 ft³/min @ 0 in. H₂O | 69 dB @ 5 ft. | 1/2 | 6" | 10 | Blower, Outside Vent Kit | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | IP54 | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 44" | 450 ft³/min @ 0 in. H₂O | 69 dB @ 5 ft. | 1/2 | 6" | 10 | Blower, Outside Vent Kit | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | IP54 | 00000000 | 00000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hazardous Location Spark-Resistant Blowers

With Round Outlet and Round Inlet

Overall | Mounting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Airflow @ SP | Volume (Sound) @ Distance | Motor Speed, rpm | Power, hp | Outlet Dia. | Inlet Dia. | Wheel Dia. | Ht. | Wd. | Dp. | Current | Temp. Range, ° F | Housing Material | Hazardous Location Rating | Enclosure Rating | Fasteners Included | Hole Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC/230V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 295 ft³/min @ 1 in. H₂O 505 ft³/min @ 1/4 in. H₂O | 55 dBA @ 15 ft. | 1,750 | 1/3 | 6" | 6" | 6 1/4" | 14 1/8" | 12 1/4" | 13 1/4" | 6.0 amp/3.0 amp | 0 to 150 | Aluminum | NEC Class I Divisions 1, 2 Group D NEC Class II Divisions 1, 2 Groups F, G | IP44 | No | 7/16" | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 320 ft³/min @ 1 in. H₂O 375 ft³/min @ 1/4 in. H₂O | 60 dBA @ 15 ft. | 3,450 | 1/3 | 4" | 5" | 4 3/4" | 12 5/8" | 9 7/8" | 12 1/4" | 7.0 amp/3.5 amp | 0 to 150 | Aluminum | NEC Class I Divisions 1, 2 Group D NEC Class II Divisions 1, 2 Groups F, G | IP44 | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 995 ft³/min @ 1 in. H₂O 1,070 ft³/min @ 1/4 in. H₂O | 70 dBA @ 15 ft. | 3,450 | 1 1/2 | 6" | 6" | 6 1/4" | 14 1/8" | 12 1/4" | 13 1/4" | 15.4 amp/8.4 amp | 0 to 150 | Aluminum | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | IP54 | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,045 ft³/min @ 1/4 in. H₂O | 55 dBA @ 15 ft. | 1,150 | 1/3 | 8" | 8" | 8 1/4" | 18 3/4" | 14 3/4" | 15 3/8" | 6.8 amp/3.4 amp | 0 to 150 | Aluminum | NEC Class I Divisions 1, 2 Group D NEC Class II Divisions 1, 2 Groups F, G | IP44 | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

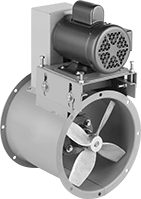

Belt-Drive Hazardous Location Duct Fans

Overall | Mounting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Duct Dia. | No. of Speeds | Airflow @ SP | Volume (Sound) @ Distance | Motor Speed, rpm | Power, hp | Dia. | Ht. | Dp. | Max. Temp., ° F | Housing Material | Blade Material | Certification | Fasteners Included | Hole Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, 230V AC, Single Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IP44 Enclosure Rating | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1 | 1,400 ft³/min @ 3/8 in. H₂O 1,600 ft³/min @ 1/8 in. H₂O | 65 dBA @ 15 ft. | 3,025 | 1/2 | 14 1/16" | 23 7/16" | 12" | 175 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 1 | 2,800 ft³/min @ 3/8 in. H₂O 3,200 ft³/min @ 1/8 in. H₂O | 65 dBA @ 15 ft. | 2,275 | 3/4 | 17 1/16" | 26 15/16" | 12" | 175 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 1 | 2,500 ft³/min @ 3/8 in. H₂O 3,400 ft³/min @ 1/8 in. H₂O | 60 dBA @ 15 ft. | 1,600 | 1/2 | 20 1/16" | 30 3/16" | 12" | 175 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

230V AC, 460V AC, Three Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IP44 Enclosure Rating | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 1 | 4,400 ft³/min @ 3/8 in. H₂O 4,800 ft³/min @ 1/8 in. H₂O | 65 dBA @ 15 ft. | 2,150 | 1 | 20 1/16" | 30 3/16" | 12" | 175 | Steel | Aluminum | UL Recognized Component, CSA Energy Verified, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 1 | 13,300 ft³/min @ 3/8 in. H₂O 15,200 ft³/min @ 1/8 in. H₂O | 65 dBA @ 15 ft. | 1,000 | 2 | 39 1/4" | 49 1/4" | 16" | 175 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Energy Verified, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

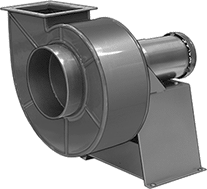

Hazardous Location Chemical-Resistant Blowers

With Round Outlet and Round Inlet

|  |

Replacement Wheels |

Blowers | Replacement Wheels | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Mounting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Airflow @ SP | Volume (Sound) @ Distance | Motor Speed, rpm | Power, hp | Outlet Dia. | Inlet Dia. | Wheel Dia. | Ht. | Wd. | Dp. | Current | Housing Material | Hazardous Location Rating | Fasteners Included | Hole Dia. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 185 ft³/min @ 1/2 in. H₂O | Not Rated | 1,725 | 1/6 | 5" | 6" | 5 11/16" | 12 1/4" | 11" | 15 1/2" | 1.9 amp | PVC | NEC Class I Divisions 1, 2 Group D NEC Class II Divisions 1, 2 Groups F, G | No | 3/8" | 0000000 | 000000000 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC/230V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 810 ft³/min @ 1 in. H₂O 960 ft³/min @ 1/2 in. H₂O | Not Rated | 1,725 | 1/3 | 8" | 8" | 7" | 16 3/4" | 15 1/8" | 21 1/2" | 6.0 amp/3.0 amp | Fiberglass | NEC Class I Divisions 1, 2 Group D NEC Class II Divisions 1, 2 Groups F, G | No | 3/8" | 0000000 | 00000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Rectangular Outlet and Round Inlet

Blowers | Replacement Wheels | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Outlet | Overall | Mounting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Airflow @ SP | Volume (Sound) @ Distance | Motor Speed, rpm | Power, hp | Ht. | Wd. | Inlet Dia. | Wheel Dia. | Ht. | Wd. | Dp. | Current | Housing Material | Hazardous Location Rating | Fasteners Included | Hole Dia. | Cannot Be Sold To | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

230V AC/460V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,300 ft³/min @ 1/2 in. H₂O 2,300 ft³/min @ 1 in. H₂O | Not Rated | 1,725 | 1 1/2 | 9 3/8" | 6 11/16" | 10" | 12" | 24 1/4" | 23" | 24 1/4" | 4.4 amp/2.2 amp | PVC | NEC Class I Divisions 1, 2 Group D NEC Class II Divisions 1, 2 Groups F, G | No | 3/8" | California | 0000000 | 000000000 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wide-Flow Equipment-Cooling Blowers

Overall, mm | Outlet, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Ht. | Wd. | Airflow, ft³/min | Temp. Range, ° F | Volume (Sound), dBA | Motor Speed, rpm | Current, amp | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase, 60 Hz—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 108 | 279.4 | 88.9 | 22.23 | 190.5 | 120 | 30 to 140 | — | 2,600 | 0.9 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 108 | 355.6 | 88.9 | 22.23 | 266.7 | 160 | 30 to 140 | — | 2,600 | 1.2 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 108 | 447.68 | 88.9 | 22.23 | 342.9 | 220 | 30 to 140 | — | 2,600 | 1.3 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12V DC—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50.8 | 412.75 | 47.63 | 15.88 | 352.43 | 91 | -4 to 140 | 51 | 3,600 | 0.8 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24V DC—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50.8 | 257.18 | 47.63 | 15.88 | 196.85 | 58 | -4 to 140 | 51 | 4,250 | 0.3 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50.8 | 412.75 | 47.63 | 15.88 | 352.43 | 91 | -4 to 140 | 51 | 3,600 | 0.4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Direct-Drive Hazardous Location Duct Fans

Overall | Mounting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Duct Dia. | No. of Speeds | Airflow @ SP | Volume (Sound) @ Distance | Motor Speed, rpm | Power, hp | Dia. | Ht. | Dp. | Max. Temp., ° F | Housing Material | Blade Material | Certification | Fasteners Included | Hole Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, 230V AC, Single Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IP44 Enclosure Rating | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1 | 1,900 ft³/min @ 3/8 in. H₂O 2,000 ft³/min @ 1/8 in. H₂O | 70 dBA @ 15 ft. | 3,450 | 1/2 | 14 1/16" | 14 1/16" | 20" | 100 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 1 | 2,100 ft³/min @ 3/8 in. H₂O 2,700 ft³/min @ 1/8 in. H₂O | 60 dBA @ 15 ft. | 1,750 | 1/2 | 17 1/16" | 17 1/16" | 20" | 100 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 1 | 3,900 ft³/min @ 3/8 in. H₂O 4,500 ft³/min @ 1/8 in. H₂O | 65 dBA @ 15 ft. | 1,750 | 3/4 | 20 1/16" | 20 1/16" | 20" | 100 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1 | 4,900 ft³/min @ 3/8 in. H₂O 5,800 ft³/min @ 1/8 in. H₂O | 65 dBA @ 15 ft. | 1,750 | 3/4 | 26 11/16" | 26 11/16" | 21" | 100 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

230V AC, 460V AC, Three Phase—Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

IP44 Enclosure Rating | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 1 | 1,900 ft³/min @ 3/8 in. H₂O 2,000 ft³/min @ 1/8 in. H₂O | 70 dBA @ 15 ft. | 3,450 | 1/2 | 14 1/16" | 14 1/16" | 20" | 100 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 1 | 2,100 ft³/min @ 3/8 in. H₂O 2,700 ft³/min @ 1/8 in. H₂O | 60 dBA @ 15 ft. | 1,750 | 1/2 | 17 1/16" | 17 1/16" | 20" | 100 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 1 | 3,900 ft³/min @ 3/8 in. H₂O 4,500 ft³/min @ 1/8 in. H₂O | 60 dBA @ 15 ft. | 1,750 | 3/4 | 20 1/16" | 20 1/16" | 20" | 100 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 1 | 4,900 ft³/min @ 3/8 in. H₂O 5,800 ft³/min @ 1/8 in. H₂O | 65 dBA @ 15 ft. | 1,750 | 3/4 | 26 11/16" | 26 11/16" | 21" | 100 | Steel | Aluminum | UL Listed, UL Recognized Component, CSA Certified | No | 7/16" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Edge-Flow Equipment-Cooling Blowers

Square

Overall, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Temp. Range, ° F | Airflow, ft³/min | Volume (Sound), dBA | Motor Speed, rpm | Current, amp | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase, 60 Hz—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 180 | 180 | 40.64 | -20 to 155 | 55 | 60 | 2,750 | 0.2 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 220 | 220 | 55.88 | -20 to 155 | 130 | 62 | 3,050 | 0.4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12V DC—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 135 | 135 | 38.1 | -20 to 165 | 32 | 55 | 2,200 | 0.5 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 180 | 180 | 40.64 | -20 to 165 | 52 | 58 | 2,550 | 0.4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24V DC—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 135 | 135 | 38.1 | -20 to 165 | 32 | 55 | 2,200 | 0.2 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 180 | 180 | 40.64 | -20 to 165 | 52 | 58 | 2,550 | 0.2 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 220 | 220 | 55.88 | 0 to 140 | 120 | 66 | 2,850 | 0.8 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Flow Low-Pressure Compressed Air Blowers

Single Stage

Blowers | Air Intake Filters | Valves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Pipe Size | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Pressure | Max. Flow Rate @ Pressure | Vacuum Rating | Power, hp | Full Load Current @ Voltage | Volume (Sound), dBA | Lg. | Wd. | Ht. | Temp. Range, ° F | Inlet | Outlet | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Phase, 120/208/230V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 42 in. H₂O | 52 ft³/min @ 0 psi | 3 in. Hg 40 in. H₂O | 1/2 | 6 amp @ 115V AC 3.2 amp @ 208V AC 3 amp @ 230V AC | 68 | 13" | 10" | 10" | 32 to 100 | 1 1/4 | 1 1/4 | 0000000 | 000000000 | 00000000 | 0000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 52 in. H₂O | 92 ft³/min @ 0 psi | 3.5 in. Hg 48 in. H₂O | 1 | 9.8 amp @ 115V AC 5.2 amp @ 208V AC 4.9 amp @ 230V AC | 68 | 13" | 11" | 12" | 32 to 100 | 1 1/2 | 1 1/2 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Phase, 208/230/460V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 43 in. H₂O | 53 ft³/min @ 0 psi | 2.9 in. Hg 40 in. H₂O | 1/2 | 2 amp @ 208V AC 2 amp @ 230V AC 1 amp @ 460V AC | 68 | 11" | 10" | 10" | 32 to 100 | 1 1/4 | 1 1/4 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 psi 52 in. H₂O | 92 ft³/min @ 0 psi | 3.5 in. Hg 48 in. H₂O | 1 | 3.4 amp @ 208V AC 3.2 amp @ 230V AC 1.6 amp @ 460V AC | 68 | 13" | 11" | 12" | 32 to 100 | 1 1/2 | 1 1/2 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Phase, 208/230/460V AC (Inverter Rated) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 psi 110 in. H₂O | 265 ft³/min @ 0 psi | 6.6 in. Hg 90 in. H₂O | 6 | 16 amp @ 208V AC 15 amp @ 230V AC 7.5 amp @ 460V AC | 79 | 17" | 17" | 18" | 32 to 100 | 2 | 2 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Phase, 230/460V AC (Inverter Rated) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 psi 105 in. H₂O | 795 ft³/min @ 0 psi | 7 in. Hg 95 in. H₂O | 18 | 52 amp @ 230V AC 26 amp @ 460V AC | 79 | 29" | 18" | 20" | 32 to 100 | 2 1/2 | 4 | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||