About Noise, Filtration, and Flow Ratings

More

Gas Chimney Vents and Fittings

For use with gas-fired equipment, such as boilers and furnaces, these vent pipes and fittings withstand temperatures up to 400° F. Also known as type B gas vents.

To join pipes and connectors, insert a male end into a female end and secure with the included locking band.

Galvanized Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Chimney Pipe Size | Female ID | Male OD | Lg. | Gauge | Construction | Inner Wall Material | Specifications Met | Each | |

| 4 | 4" | 4 1/2" | 18" | 28 | Double Wall | Aluminum | UL Listed | 0000000 | 000000 |

| 5 | 5" | 5 1/2" | 18" | 28 | Double Wall | Aluminum | UL Listed | 0000000 | 00000 |

| 6 | 6" | 6 1/2" | 18" | 28 | Double Wall | Aluminum | UL Listed | 0000000 | 00000 |

| 7 | 7" | 8" | 18" | 28 | Double Wall | Aluminum | UL Listed | 0000000 | 00000 |

| 8 | 8" | 9" | 18" | 28 | Double Wall | Aluminum | UL Listed | 0000000 | 00000 |

Adjustable-angle elbow connectors can be used at an angle or straight.

Galvanized Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| Chimney Pipe Size | Female ID | Male OD | Gauge | Construction | Inner Wall Material | Specifications Met | Each | |

Female × Female × Male | ||||||||

| 4 | 4" | 4 1/2" | 28 | Double Wall | Aluminum | UL Listed | 0000000 | 000000 |

| 5 | 5" | 5 1/2" | 28 | Double Wall | Aluminum | UL Listed | 0000000 | 00000 |

| 6 | 6" | 6 1/2" | 28 | Double Wall | Aluminum | UL Listed | 0000000 | 00000 |

| 8 | 8" | 9" | 28 | Double Wall | Aluminum | UL Listed | 0000000 | 000000 |

High-Temperature Chimney Vents and Fittings

Built to withstand temperatures up to 1000° F, these vent pipes and fittings are for use with boilers, furnaces, stoves, and other equipment that is fired by gas, oil, wood, or coal.

To join pipes and connectors, twist a male end into a female end and secure with the included locking band.

Weather-Resistant Breather Vents

Shield outdoor pipe and tank openings from the environment. Also known as vent caps, these breather vents have screens to allow air flow while blocking debris. Use them to prevent excess vacuum and pressure in your equipment.

Style C has a set screw to secure in place

Screen | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Pipe Size | Ht. | Dia. | For Use With | Material | Construction | Mesh Size | Opening Size | Removes Particle Size Down To, microns | Each | |

NPT Male | |||||||||||

Zinc-Plated Steel Body and Fitting | |||||||||||

| A | 3/8 | 1 1/4" | 1 1/4" | Air | 304 Stainless Steel | Wire Mesh | 100 | __ | 140 | 00000000 | 000000 |

| A | 1/2 | 1 7/16" | 1 1/4" | Air | 304 Stainless Steel | Wire Mesh | 100 | __ | 140 | 00000000 | 00000 |

Slip On Female | |||||||||||

Zinc-Plated Steel Body and Fitting | |||||||||||

| C | 1 | 1 1/2" | 2 1/2" | Air | Steel | Perforated Metal | __ | 1/8" | __ | 00000000 | 0000 |

| C | 1 1/2 | 1 3/4" | 2 3/4" | Air | Steel | Perforated Metal | __ | 1/8" | __ | 00000000 | 0000 |

| C | 1 1/4 | 1 1/2" | 2 1/2" | Air | Steel | Perforated Metal | __ | 1/8" | __ | 00000000 | 0000 |

| C | 2 | 2 3/4" | 4" | Air | Steel | Perforated Metal | __ | 1/8" | __ | 00000000 | 00000 |

Breather Vents

Protect against excess vacuum and pressure in cylinders, gear boxes, enclosures, manifolds, and tanks. You can also use these breather vents to block debris from entering equipment.

Breather vents with splash guard are good for containers that are often filled and drained; they have a guard that prevents oil from splashing out of the vent hole.

| Style | Pipe Size | Max. Flow Rate | Max. Pressure, psi | Max. Temp., °F | Ht. | For Use With | Removes Particle Size Down To, microns | Features | Each | |

NPT Male | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel Body and Fitting | ||||||||||

| A | 2 | 1,095 scfm @ 100 psi | 150 | 300° | 1 5/8" | Air, Inert Gas | 90 | __ | 0000000 | 000000 |

Nickel-Plated Steel Body and Fitting | ||||||||||

| A | 1/8 | 2 scfm @ 100 psi | 150 | 300° | 7/16" | Air, Inert Gas | 40 | __ | 0000000 | 0000 |

| A | 1/4 | 3 scfm @ 100 psi | 150 | 300° | 5/8" | Air, Inert Gas | 40 | __ | 0000000 | 0000 |

| A | 3/8 | 7 scfm @ 100 psi | 150 | 300° | 3/4" | Air, Inert Gas | 40 | __ | 0000000 | 0000 |

| A | 1/2 | 17 scfm @ 100 psi | 150 | 300° | 7/8" | Air, Inert Gas | 40 | __ | 0000000 | 0000 |

| A | 3/4 | 20 scfm @ 100 psi | 150 | 300° | 1" | Air, Inert Gas | 40 | __ | 0000000 | 0000 |

| A | 1 | 28 scfm @ 100 psi | 150 | 300° | 1 5/16" | Air, Inert Gas | 40 | __ | 0000000 | 0000 |

| A | 1 1/4 | 50 scfm @ 100 psi | 150 | 300° | 1 7/16" | Air, Inert Gas | 40 | __ | 0000000 | 00000 |

| A | 1 1/2 | 73 scfm @ 100 psi | 150 | 300° | 1 1/2" | Air, Inert Gas | 40 | __ | 0000000 | 00000 |

Steel Body and Fitting | ||||||||||

| D | 1/8 | Not Rated | Not Rated | 225° | 1" | Air, Inert Gas, Oil, Water | 40 | __ | 0000000 | 00000 |

| D | 1/4 | Not Rated | Not Rated | 225° | 1" | Air, Inert Gas, Oil, Water | 40 | __ | 0000000 | 00000 |

| D | 3/8 | Not Rated | Not Rated | 225° | 1 1/16" | Air, Inert Gas, Oil, Water | 40 | __ | 0000000 | 00000 |

| D | 1/2 | Not Rated | Not Rated | 225° | 1 3/16" | Air, Inert Gas, Oil, Water | 40 | __ | 0000000 | 00000 |

| D | 3/4 | Not Rated | Not Rated | 225° | 1 1/4" | Air, Inert Gas, Oil, Water | 40 | __ | 0000000 | 00000 |

| E | 1/8 | Not Rated | Not Rated | 225° | 1 3/16" | Air, Inert Gas, Oil, Water | 40 | Splash Guard | 0000000 | 00000 |

| E | 1/4 | Not Rated | Not Rated | 225° | 1 3/16" | Air, Inert Gas, Oil, Water | 40 | Splash Guard | 0000000 | 00000 |

| E | 3/8 | Not Rated | Not Rated | 225° | 1 1/4" | Air, Inert Gas, Oil, Water | 40 | Splash Guard | 0000000 | 00000 |

| E | 1/2 | Not Rated | Not Rated | 225° | 1 5/16" | Air, Inert Gas, Oil, Water | 40 | Splash Guard | 0000000 | 00000 |

| E | 3/4 | Not Rated | Not Rated | 225° | 1 3/8" | Air, Inert Gas, Oil, Water | 40 | Splash Guard | 0000000 | 00000 |

BSPT Male | ||||||||||

Zinc-Plated Steel Body and Fitting | ||||||||||

| A | 1/8 | 26 scfm @ 100 psi | 150 | 300° | 7/16" | Air, Inert Gas | 90 | __ | 0000000 | 0000 |

| A | 1/4 | 35 scfm @ 100 psi | 150 | 300° | 11/16" | Air, Inert Gas | 90 | __ | 0000000 | 0000 |

| A | 3/8 | 87 scfm @ 100 psi | 150 | 300° | 13/16" | Air, Inert Gas | 90 | __ | 0000000 | 0000 |

| A | 1/2 | 131 scfm @ 100 psi | 150 | 300° | 1" | Air, Inert Gas | 90 | __ | 0000000 | 0000 |

| A | 3/4 | 219 scfm @ 100 psi | 150 | 300° | 1 1/16" | Air, Inert Gas | 90 | __ | 0000000 | 0000 |

NPSM Female | ||||||||||

Zinc-Plated Steel Body and Fitting | ||||||||||

| F | 1/8 | 26 scfm @ 100 psi | 150 | 300° | 5/8" | Air, Inert Gas | 90 | __ | 0000000 | 0000 |

| F | 1/4 | 35 scfm @ 100 psi | 150 | 300° | 3/4" | Air, Inert Gas | 90 | __ | 0000000 | 0000 |

| F | 3/8 | 87 scfm @ 100 psi | 150 | 300° | 15/16" | Air, Inert Gas | 90 | __ | 0000000 | 0000 |

| F | 1/2 | 131 scfm @ 100 psi | 150 | 300° | 1" | Air, Inert Gas | 90 | __ | 0000000 | 0000 |

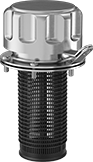

Lockable Breather Vents with Cap

Secure access to vented openings in pipe and tanks—the cap can be locked to prevent tampering. These breather vents allow you to add a filling port to your hydraulic tank while protecting against excess pressure and vacuum. Use them to stop debris from entering your tank. Breather vents mount on top of standard tank openings with included hardware. Padlock is not included.

Material | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Opening Dia. | Ht. | For Use With | Cap | Screen | Mount Type | Bolts Included | Removes Particle Size Down To, microns | For Max. Padlock Shackle Dia. | Each | |

| 2 1/8" | 5 1/8" | Air, Oil | Steel | 304 Stainless Steel | Flange | Yes | 10 | 3/8" | 0000000 | 000000 |

| 2 1/8" | 5 1/8" | Air, Oil | Steel | 304 Stainless Steel | Flange | Yes | 40 | 3/8" | 0000000 | 00000 |

| 2 1/8" | 6 1/8" | Air, Oil | Steel | Nylon Plastic | Flange | Yes | 10 | 3/8" | 0000000 | 00000 |

| 2 1/8" | 6 1/8" | Air, Oil | Steel | Nylon Plastic | Flange | Yes | 40 | 3/8" | 0000000 | 00000 |

Moisture-Eliminating Breather Vents

Keep moisture, dirt, and debris from entering your oil reservoirs. The silica gel inside these breather vents absorbs moisture from the air, preventing rust from forming inside your tanks. The gel changes from blue to pink as it becomes saturated, letting you know it needs to be replaced. A second filter blocks dust and other particles from getting inside. These breather vents allow air to flow in and out of your lubrication system, keeping excess vacuum or pressure from building up in cylinders, gear boxes, and tanks.

For an extended service life, use breather vents with a steel body. They are stronger than breather vents with plastic bodies and hold up better when exposed to chemicals. A window lets you check the color of the gel. No need to replace the entire unit when the gel is saturated—use rebuild kits to add fresh gel and to replace the window, filters, and gaskets.

Breather Vents | Rebuild Kits | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Tank Capacity, gal. | Max. Flow Rate | Max. Temp., °F | Ht. | Dia. | For Use With | Removes Particle Size Down To, microns | Each | Each | ||

Steel Body and Fitting | |||||||||||

| 2 | 1-800 | 85 scfm @ 1 psi | 220° | 11 1/2" | 10 1/8" | Air | 1 | 0000000 | 000000000 | 00000000 | 0000000 |

| 2 | 1-1,300 | 85 scfm @ 1 psi | 220° | 13 3/4" | 10 1/8" | Air | 1 | 0000000 | 00000000 | 00000000 | 000000 |

| 2 | 1-2,400 | 80 scfm @ 1 psi | 220° | 18 1/4" | 10 1/8" | Air | 1 | 0000000 | 00000000 | 00000000 | 000000 |

| 3 | 1-4,000 | 205 scfm @ 1 psi | 220° | 19 1/4" | 15 1/2" | Air | 1 | 0000000 | 00000000 | 00000000 | 000000 |

Breather Vents with Cap

Add a filling port to your hydraulic tank while protecting against excess pressure and vacuum. Breather vents stop debris from entering your tank. Mount them on top of standard tank openings with included hardware.

Vents | Replacement Screens | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Opening Dia. | Max. Flow Rate, gpm | Max. Temp., °F | Ht. | For Use With | Screen Material | Mount Type | Number of Bolt Holes | Bolts Included | Removes Particle Size Down To, microns | Each | Each | ||

Steel Body | |||||||||||||

304 Stainless Steel Cap | |||||||||||||

| 2 1/8" | 20 | 220° | 5" | Air, Oil | 304 Stainless Steel | Flange | 6 | Yes | 40 | 0000000 | 000000 | 0000000 | 000000 |

Steel Cap | |||||||||||||

| 2 1/8" | 192 | 250° | 5 1/8" | Air, Oil | 304 Stainless Steel | Flange | 6 | Yes | 40 | 0000000 | 00000 | 0000000 | 0000 |

Vents | Replacement Screens | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Opening Dia. | Max. Flow Rate, gpm | Max. Temp., °F | Ht. | For Use With | Screen Material | Mount Type | Number of Bolt Holes | Bolts Included | Removes Particle Size Down To, microns | Each | Each | ||

Steel Body | |||||||||||||

304 Stainless Steel Cap | |||||||||||||

| 2 1/8" | 20 | 220° | 5 3/4" | Air, Oil | Nylon Plastic | Flange | 6 | Yes | 40 | 0000000 | 000000 | 0000000 | 000000 |

Steel Cap | |||||||||||||

| 2 1/8" | 115 | Not Rated | 5 1/8" | Air, Oil | 304 Stainless Steel | Flange | 6 | Yes | 10 | 00000000 | 00000 | 0000000 | 0000 |

| 2 1/8" | 115 | Not Rated | 6 1/8" | Air, Oil | Nylon Plastic | Flange | 6 | Yes | 10 | 00000000 | 00000 | 00000000 | 0000 |

| 2 1/8" | 190 | 150° | 6 1/8" | Air, Oil | Nylon Plastic | Flange | 6 | Yes | 40 | 0000000 | 00000 | 00000000 | 0000 |