About Gas Regulators

More

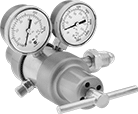

Tank-Mount Pressure-Regulating Valves for Fuel Gases

- For Use With: See Table

- Temperature Range: -20° to 120° F

Attach these valves to acetylene, hydrogen, methane, propane, or propylene tanks to reduce a high inlet pressure to a lower, stable outlet pressure. They have Compressed Gas Association (CGA) numbered inlet fittings for secure connections to compressed gas tanks. Choose a valve with the same CGA number as your tank and other system components. Valves come with a gauge to monitor outlet pressure and a gauge to monitor inlet pressure from the tank.

Choose a valve with a maximum outlet pressure that’s approximately twice your application’s normal operating pressure. Your operating pressure should never exceed 75% of the valve’s maximum outlet pressure.

Single-stage valves reduce pressure in one step, which causes the outlet pressure to fluctuate slightly as you empty the tank. They’re best for applications where a constant outlet pressure isn’t critical.

Two-stage valves progressively reduce pressure over two steps for more consistent outlet pressure at all times. They’re often used in applications that require a constant outlet pressure regardless of the tank level.

Valves with a brass body have a longer service life than valves with a brass and steel body.

Inlet | Outlet | Material | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Location | Thread Direction | Pressure Gauge Range, psi | Thread Size | Location | Thread Direction | Pressure Range, psi | Pressure Adjustment Method | Body | Seal | Diaphragm | Each | |

For Use With Propane and Propylene | |||||||||||||

UNF Male Outlet × NGO Male Inlet | |||||||||||||

| CGA 510 | Side | Left Hand | 0 to 400 | 9/16"-18 | Side | Left Hand | 0 to 50 | T-Handle | Brass | PTFE | Rubber | 0000000 | 0000000 |

| CGA 510 | Side | Left Hand | 0 to 400 | 9/16"-18 | Side | Left Hand | 5 to 50 | Knob | Brass/Steel | PTFE | Rubber | 0000000 | 000000 |

Inlet | Outlet | Material | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | Location | Thread Direction | Pressure Gauge Range, psi | Thread Size | Location | Thread Direction | Pressure Range, psi | Pressure Adjustment Method | Body | Seal | Diaphragm | Each | |

For Use With Propane and Propylene | |||||||||||||

UNF Male Outlet × NGO Male Inlet | |||||||||||||

| CGA 510 | Side | Left Hand | 0 to 400 | 9/16"-18 | Side | Left Hand | 0 to 50 | T-Handle | Brass/Steel | PTFE | Rubber | 0000000 | 0000000 |

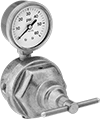

Pressure-Regulating Valves for Fuel Gases

- For Use With: See Table

- Temperature Range: See Table

Install these valves directly in gas distribution pipelines for acetylene, hydrogen, or propane. They automatically reduce a high inlet pressure to a lower, stable outlet pressure. Valves have two outlets to fit various pipe configurations and come with a plug to close the unused outlet. The gauge monitors outlet pressure. All valves are single stage and reduce pressure in one step, which causes the outlet pressure to fluctuate.

Choose a valve with a maximum outlet pressure that’s approximately twice your application’s normal operating pressure. Your operating pressure should never exceed 75% of the valve’s maximum outlet pressure.

Inlet | Outlet | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Use With | Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | Pressure Gauge Range, psi | Temperature Range, ° F | End-to-End Lg. | Port-to-Port Lg. | Each | |

NPT Female | ||||||||||||

Brass Body—Stainless Steel Diaphragm and Neoprene Seal | ||||||||||||

| Hydrogen, Propane | 1/4 | Side | 500 | 1/4 | Bottom, Side | T-Handle | 0 to 60 | 0° to 120° | 2.40" | 1.01" | 0000000 | 0000000 |

| Hydrogen, Propane | 1/4 | Side | 500 | 1/4 | Bottom, Side | T-Handle | 0 to 200 | 0° to 120° | 2.40" | 1.01" | 0000000 | 000000 |

Propane Tank Refill Indicator Gauges

Know at a glance if your propane gas supply is running low. These gauges work with tanks manufactured after 1995.

Inlet | Internal Outlet Connection | External Outlet Connection | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Type | Gender | For Valve Type | CGA Number | Gender | Thread Size | Thread Type | Gender | Cable Lg. | Each | |

| 1 5/16"-5 | Acme | Female | POL/Acme (Type 1) | CGA 510 | Female | 1 5/16"-5 | Acme | Male | 30" | 0000000 | 000000 |