Filter by

System of Measurement

Readout Type

Measurement Unit

Maximum Pressure

Schrader Valve Connection Type

Connects To

Fitting Connection

Connection Material

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Color

Maximum Temperature

Maximum Short-Term Pressure

Tire Pressure and Inflator Test Gauges

Head Type | No. of Heads | Pressure Range | Pressure Numeric Increments, psi | Accuracy | Overall Lg. | Dial Dia. | Material | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dial Readout | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Angled | 2 | 10 psi to 120 psi 100 kPa to 900 kPa | 2 | ±1 psi | 11 1/2" | 3/4" | Chrome-Plated Brass | Bleed Valve | 7554N11 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tire Gauges with Dial

Style | Head Type | No. of Heads | Pressure Range | Pressure Numeric Increments, psi | Accuracy | Overall Lg. | Dial Dia. | Material | Case Material | Features | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | Angled | 1 | 0 psi to 120 psi, 0 kPa to 800 kPa | 2 | ±3% | 4 3/4" | 2 1/2" | Nickel-Plated Brass | Rubber | Rubber Sleeve, Tread Depth Gauge | 6654A101 | 000000 |

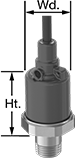

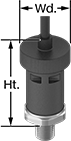

Pressure Transmitters

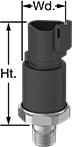

4 mA to 20 mA Output Current—Wire Lead Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | 1 15/16" | 15/16" | IP67, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K562 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

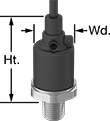

4 mA to 20 mA Output Current—4-Pole M12 Plug Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | 1 11/16" | 15/16" | IP67, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K123 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

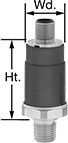

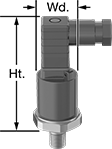

4 mA to 20 mA Output Current—DIN A Wire Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Electrical Connection Thread Size | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | PG-9 | 3 7/16" | 1 5/16" | IP65, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K602 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

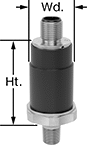

4 mA to 20 mA Output Current—DIN C Wire Connection

Pressure Transmitters | Pressure Transmitters with Calibration Certificate Traceable to NIST | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Electrical Connection Thread Size | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | PG-7 | 2 5/8" | 1 3/8" | IP65, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K379 | 0000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | PG-7 | 2 5/8" | 1 3/8" | IP65, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K54 | 000000 | 3196K74 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

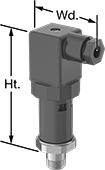

4 mA to 20 mA Output Current—Aptiv MP 150 Plug Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | 2 1/16" | 1 1/16" | IP67, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K443 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mA to 20 mA Output Current—3-Pole DT Deutsch Style Plug Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | 2 1/16" | 1 1/16" | IP67, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K456 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0V DC to 5V DC Output Voltage—4-Pole Wire Lead Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | 1 15/16" | 15/16" | IP67, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K518 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1V DC to 5V DC Output Voltage—Wire Lead Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | 1 15/16" | 15/16" | IP67, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K533 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1V DC to 5V DC Output Voltage—4-Pole M12 Plug Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | 1 11/16" | 7/8" | IP67, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K504 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1V DC to 5V DC Output Voltage—DIN A Wire Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Electrical Connection Thread Size | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | PG-9 | 3 7/16" | 1 5/16" | IP65, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K575 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1V DC to 5V DC Output Voltage—DIN C Wire Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Electrical Connection Thread Size | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 9 to 36 | PG-7 | 2 5/8" | 1 3/8" | IP65, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K339 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0V DC to 10V DC Output Voltage—Wire Lead Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 14 to 36 | 1 15/16" | 15/16" | IP67, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K547 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0V DC to 10V DC Output Voltage—4-Pole M12 Plug Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 14 to 36 | 1 11/16" | 15/16" | IP67, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K326 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0V DC to 10V DC Output Voltage—DIN A Wire Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Electrical Connection Thread Size | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 14 to 36 | PG-9 | 3 7/16" | 1 5/16" | IP65, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K588 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0V DC to 10V DC Output Voltage—DIN C Wire Connection

Pressure Transmitters | Pressure Transmitters with Calibration Certificate Traceable to NIST | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Electrical Connection Thread Size | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 14 to 36 | PG-7 | 2 5/8" | 1 3/8" | IP65, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Air Argon Diesel Fuel Gasoline Hydraulic Fluid Nitrogen Water | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3196K204 | 0000000 | 3196K94 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure and Vacuum Transmitters

4 mA to 20 mA Output Current Range—Wire Leads

Max. Pressure, psi | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Range, psi | Vacuum Range, in. Hg | Continuous | Short-Term | Input Voltage, V DC | Pipe Size | Ht. | Wd. | Enclosure Rating | For Use With | Accuracy | Temp. Range, ° F | Connection Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 0 to 30 | 120 | 120 | 9 to 36 | 1/4 NPT Male | 1 15/16" | 15/16" | IP67, NEMA 4X | Air, Argon, Diesel Fuel, Gasoline, Hydraulic Fluid, Nitrogen, Water | ±1.0% | -40 to 255 | 304 Stainless Steel | 2957N13 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mA to 20 mA Output Current Range— 4 Pole M12 Plug In Connection

Max. Pressure, psi | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Range, psi | Vacuum Range, in. Hg | Continuous | Short-Term | Input Voltage, V DC | Pipe Size | Ht. | Wd. | Enclosure Rating | For Use With | Accuracy | Temp. Range, ° F | Connection Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 0 to 30 | 120 | 120 | 9 to 36 | 1/4 NPT Male | 1 11/16" | 7/8" | IP67, NEMA 4X | Air, Argon, Diesel Fuel, Gasoline, Hydraulic Fluid, Nitrogen, Water | ±1.0% | -40 to 255 | 304 Stainless Steel | 4674N2 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mA to 20 mA Output Current Range—DIN C Connection

Max. Pressure, psi | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Range, psi | Vacuum Range, in. Hg | Continuous | Short-Term | Input Voltage, V DC | Pipe Size | Electrical Connection Thread Size | Ht. | Wd. | Enclosure Rating | For Use With | Accuracy | Temp. Range, ° F | Connection Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 0 to 30 | 120 | 120 | 9 to 36 | 1/4 NPT Male | PG-7 | 2 1/2" | 15/16" | IP65, NEMA 4X | Air, Argon, Diesel Fuel, Gasoline, Hydraulic Fluid, Nitrogen, Water | ±1.0% | -40 to 255 | 304 Stainless Steel | 4674N152 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1V DC to 5V DC Output Voltage Range—Wire Leads

Max. Pressure, psi | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Range, psi | Vacuum Range, in. Hg | Continuous | Short-Term | Input Voltage, V DC | Pipe Size | Ht. | Wd. | Enclosure Rating | For Use With | Accuracy | Temp. Range, ° F | Connection Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 0 to 30 | 120 | 120 | 9 to 36 | 1/4 NPT Male | 1 15/16" | 15/16" | IP67, NEMA 4X | Air, Argon, Diesel Fuel, Gasoline, Hydraulic Fluid, Nitrogen, Water | ±1.0% | -40 to 255 | 304 Stainless Steel | 4674N357 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0V DC to 10V DC Output Voltage Range—Wire Leads

Max. Pressure, psi | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Range, psi | Vacuum Range, in. Hg | Continuous | Short-Term | Input Voltage, V DC | Pipe Size | Ht. | Wd. | Enclosure Rating | For Use With | Accuracy | Temp. Range, ° F | Connection Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 0 to 30 | 120 | 120 | 14 to 36 | 1/4 NPT Male | 1 15/16" | 15/16" | IP67, NEMA 4X | Air, Argon, Diesel Fuel, Gasoline, Hydraulic Fluid, Nitrogen, Water | ±1.0% | -40 to 255 | 304 Stainless Steel | 4674N347 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0V DC to 10V DC Output Voltage Range—DIN C Connection

Max. Pressure, psi | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Range, psi | Vacuum Range, in. Hg | Continuous | Short-Term | Input Voltage, V DC | Pipe Size | Electrical Connection Thread Size | Ht. | Wd. | Enclosure Rating | For Use With | Accuracy | Temp. Range, ° F | Connection Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Nylon Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 0 to 30 | 120 | 120 | 14 to 36 | 1/4 NPT Male | PG-7 | 2 1/2" | 15/16" | IP65, NEMA 4X | Air, Argon, Diesel Fuel, Gasoline, Hydraulic Fluid, Nitrogen, Water | ±1.0% | -40 to 255 | 304 Stainless Steel | 4674N144 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure Transmitters for Oxygen

4 mA to 20 mA Output Current—Wire Lead Connection

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Ht. | Wd. | Enclosure Rating | Certification | For Use With | Accuracy | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 NPT Male Pipe Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 120 | 120 | 9 to 36 | 2 3/8" | 1 5/16" | IP65, NEMA 4X | UL Recognized Component, C-UL Recognized Component, CE Marked | Oxygen | ±1.0% | Glass-Filled Nylon | 304 Stainless Steel | -40 to 255 | 3914A12 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

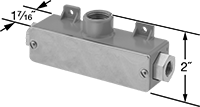

Differential Pressure Transmitters for Liquids

316 Stainless Steel Housing%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential, psi | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | For No. of Wires | Mounting Hardware Included | Dia. | No. of | Ht. | Wd. | Certification | Enclosure Rating | For Use With | Accuracy | Pipe | Fitting | Material | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 to 20 mA Output Signal—Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 25 | 120 | 10 to 35 | 1/4 | 2 | No | 1/4" | 2 | 2" | 1 7/16" | CE Marked | IP66, NEMA 4X | Diesel Fuel, Gasoline, Hydraulic Fluid, Water | ±0.5% | NPT Female | Threaded | 316 Stainless Steel | 0 to 200 | 3257N13 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

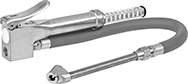

Inflator Tire Gauges

Indicator Bar Readout

|  |  |

Angled Head 1 Head | Angled Head 2 Heads | With One Straight Head |

Tire Gauges | Replacement Hose | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hose | Air Inlet | Air Outlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Head Type | No. of Heads | Pressure Range | Pressure Numeric Increments, psi | Indicator Bar Material | Lg. | Material | Connection Port | Pipe Size | Thread Type | Thread Size | Thread Type | Schrader Valve Connection Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Angled | 1 | 10 psi to 120 psi, 80 kPa to 840 kPa | 2 | Plastic | 12" | Rubber | Pipe | 1/4 | NPT | 0.305"-32 | Schrader | Press-and-Hold | 6113A11 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Angled | 2 | 10 psi to 120 psi, 80 kPa to 840 kPa | 2 | Plastic | 12" | Rubber | Pipe | 1/4 | NPT | 0.305"-32 | Schrader | Press-and-Hold | 6113A12 | 00000 | 6647A13 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Straight | 1 | 10 psi to 120 psi, 80 kPa to 840 kPa | 2 | Plastic | 12" | Rubber | Pipe | 1/4 | NPT | 0.305"-32 | Schrader | Press-and-Hold | 6647A14 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tire Gauges with Indicator Bar

1 Angled Head

Pressure Range | Pressure Numeric Increments, psi | Accuracy | Overall Lg. | Indicator Bar Material | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nickel-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 psi to 120 psi, 120 kPa to 820 kPa | 2 | ±2 psi | 6" | Plastic | Pocket Clip | 6637A22 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Angled Head

| |

Gauge with Quick-Connect Tip |

Pressure Range, psi | Pressure Numeric Increments, psi | Accuracy | Overall Lg. | Indicator Bar Material | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Chrome-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 to 120 | 2.5 | ±2 psi | 9" | Plastic | Pocket Clip, Quick-Connect Tip | 6637A102 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Angled Head and 1 Straight Head

Pressure Range | Pressure Numeric Increments, psi | Accuracy | Overall Lg. | Indicator Bar Material | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nickel-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 psi to 120 psi, 120 kPa to 820 kPa | 2 | ±2 psi | 6 1/2" | Plastic | Pocket Clip | 6637A23 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable-Range Pressure Transmitters

|

±1% Accuracy | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Range, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Input Voltage, V DC | Pipe Size | Ht. | Wd. | Enclosure Rating | For Use With | Pipe Connection | Housing Material | Connection Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 mA to 20 mA Output Current—Wire Lead Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 10 to 36 | 1/4 | 3" | 7/8" | NEMA 4X | Air Diesel Fuel Gasoline Hydraulic Fluid Water | NPT Male | 304 Stainless Steel | 304 Stainless Steel | -20 to 180 | 31685K624 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1V DC to 5V DC Output Voltage—Wire Lead Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 60 | 60 | 120 | 10 to 36 | 1/4 | 3" | 7/8" | NEMA 4X | Air Diesel Fuel Gasoline Hydraulic Fluid Water | NPT Male | 304 Stainless Steel | 304 Stainless Steel | -20 to 180 | 31685K612 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||