About Torque Tools

More

High-Accuracy Torque Tool Testers

Accurate to within ±1%, these torque testers are often used to check the accuracy of torque wrenches and screwdrivers on assembly lines. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. To test, place your torque wrench or screwdriver onto the tester with the included square drive connection and turn. These testers display torque as it's measured and the maximum torque reached. For accuracy when testing click-style wrenches, they also show the first torque peak reached. They’re not for use with impact or pulse tools.

Note: For the most accurate readings, the maximum torque you're applying should fall near the middle of the tester's torque range.

Portable testers are lightweight and easy to move around your facility. Their touch-screen display makes it easier to navigate through different menus than testers with a digital-screen display. To view data in a CSV file, pop out the tester’s SD card and plug it into your computer. You can also transfer data by connecting the tester directly to your computer with the USB cord. To use these testers with nonimpact power tools, they include at least one socket screw adapter. These testers meet ISO 17025, so they’ve been checked in a laboratory that was evaluated for accuracy.

Accuracy | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Drive Size | Hex Drive Size | Torque Range | Graduations | Torque-Measuring Direction | Clockwise | Counterclockwise | For Tool Type | Ht. | Wd. | Dp. | Includes | Each | |

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration | |||||||||||||

in.-lbs., kgf-cm, cNm | |||||||||||||

| 1/4" | __ | 0.1 to 1 in.-lbs. 0.1 to 1.2 kgf-cm 1.1 to 11.3 cNm | 0.001 in.-lbs. 0.001 kgf-cm 0.001 cNm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools and Nonimpact Power Tools | 2 1/8" | 8" | 4 1/4" | 3-ft Long USB Cable, 8 GB SD Card, AC Adapter, Carrying Case, Socket Screw Adapter (1.5 mm Hex) | 00000000 | 000000000 |

| 1/4" | __ | 0.3 to 3 in.-lbs. 0.3 to 3.5 kgf-cm 3.4 to 33.9 cNm | 0.001 in.-lbs. 0.001 kgf-cm 0.001 cNm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools and Nonimpact Power Tools | 2 1/8" | 8" | 4 1/4" | 3-ft Long USB Cable, 8 GB SD Card, AC Adapter, Carrying Case, Two Socket Screw Adapters (1.5 mm Hex) | 00000000 | 00000000 |

| 1/4" | __ | 0.5 to 5 in.-lbs. 0.6 to 5.8 kgf-cm 5.6 to 56.5 cNm | 0.001 in.-lbs. 0.001 kgf-cm 0.001 cNm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools and Nonimpact Power Tools | 2 1/8" | 8" | 4 1/4" | 3-ft Long USB Cable, 8 GB SD Card, AC Adapter, Carrying Case, Two Socket Screw Adapters (2.5 mm Hex) | 00000000 | 00000000 |

| __ | 17 mm | 1 to 10 in.-lbs. 1.2 to 11.5 kgf-cm 11.3 to 113 cNm | 0.001 in.-lbs. 0.001 kgf-cm 0.001 cNm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools and Nonimpact Power Tools | 2 1/8" | 8" | 4 1/4" | 1/4" Square Drive Adapter, 3-ft Long USB Cable, 8 GB SD Card, AC Adapter, Carrying Case, Socket Screw Adapter (1.5 mm Hex), Socket Screw Adapter (2.5 mm Hex) | 00000000 | 00000000 |

| __ | 17 mm | 5 to 50 in.-lbs. 5.8 to 57.6 kgf-cm 56.5 to 565 cNm | 0.001 in.-lbs. 0.001 kgf-cm 0.001 cNm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools and Nonimpact Power Tools | 2 1/8" | 8" | 4 1/4" | 1/4" Square Drive Adapter, 3-ft Long USB Cable, 8 GB SD Card, AC Adapter, Carrying Case, Socket Screw Adapter (2.5 mm Hex), Socket Screw Adapter (3 mm Hex) | 00000000 | 00000000 |

| __ | 17 mm | 10 to 100 in.-lbs. 11.5 to 115 kgf-cm 113.0 to 1,130 cNm | 0.01 in.-lbs. 0.01 kgf-cm 0.01 cNm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools and Nonimpact Power Tools | 2 1/8" | 8" | 4 1/4" | 1/4" Square Drive Adapter, 3-ft Long USB Cable, 8 GB SD Card, AC Adapter, Carrying Case, Socket Screw Adapter (3 mm Hex), Socket Screw Adapter (5 mm Hex) | 00000000 | 00000000 |

| __ | 17 mm | 15 to 150 in.-lbs. 17.3 to 173 kgf-cm 169.5 to 1,695 cNm | 0.01 in.-lbs. 0.01 kgf-cm 0.01 cNm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools and Nonimpact Power Tools | 2 1/8" | 8" | 4 1/4" | 1/4" Square Drive Adapter, 3-ft Long USB Cable, 8 GB SD Card, AC Adapter, Carrying Case, Socket Screw Adapter (3 mm Hex), Socket Screw Adapter (6 mm Hex) | 00000000 | 00000000 |

| __ | 17 mm | 30 to 300 in.-lbs. 34.5 to 345 kgf-cm 339 to 3,390 cNm | 0.01 in.-lbs. 0.01 kgf-cm 0.01 cNm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools and Nonimpact Power Tools | 2 1/8" | 8" | 4 1/4" | 1/4" Square Drive Adapter, 3-ft Long USB Cable, 8 GB SD Card, AC Adapter, Carrying Case, Socket Screw Adapter (10 mm Hex), Socket Screw Adapter (6 mm Hex) | 00000000 | 00000000 |

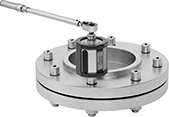

Rotary Torque Testers

Monitor torque as you apply it—these testers mount between your torque tool and your fastener. Engage the fastener to track both torque and the angle of rotation for each crank of your tool (snug torque) before you've reached the final torque. This gives you a better idea if fasteners are consistently tightened than measuring torque alone. These testers are often used with nutrunners and click-style torque wrenches in the automotive and aerospace industries. Store up to 999 maximum torque (peak) and rotation values, including the date and time of each test, or transfer to your computer to view in an Excel file. CE marked, they meet European safety standards.

For the most accurate readings, the maximum torque you're applying should fall near the middle of the tester's torque range. They are not for use with impact tools.

Testers with a USB connection transfer data directly to your computer with the included cord. These testers last up to 10 hours on a single charge.

Testers with a Bluetooth connection wirelessly transmit data to a computer as you measure. You can also remotely set snug torque, or when these testers starting measuring the torque applied with each rotation. They last up to 8 hours on a single charge with Bluetooth on and 10 hours with it off.

Accuracy | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Drive Size | Torque Range | Graduations | Clockwise | Counterclockwise | Lg. | OD | Features | Battery Type | Battery Charger Included | Includes | Each | |

USB-B Data Connection | ||||||||||||

| 1/4" | 280 to 1,400 in.-oz. 17.6 to 88 in.-lbs. 1.5 to 7.3 ft.-lbs. 20 to 100 kgf-cm 0.2 to 1 kgf-m 200 to 1,000 cNm 2 to 10 Nm | 1 in.-oz. 0.1 in.-lbs. 0.01 ft.-lbs. 0.1 kgf-cm 0.001 kgf-m 1 cNm 0.01 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 000000000 |

| 3/8" | 560 to 2,800 in.-oz. 35 to 175 in.-lbs. 3 to 14.5 ft.-lbs. 40 to 200 kgf-cm 0.4 to 2 kgf-m 400 to 2,000 cNm 4 to 20 Nm | 2 in.-oz. 0.2 in.-lbs. 0.02 ft.-lbs. 0.2 kgf-cm 0.002 kgf-m 2 cNm 0.02 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 00000000 |

| 3/8" | 1,400 to 7,000 in.-oz. 88 to 440 in.-lbs. 7.5 to 36.5 ft.-lbs. 100 to 500 kgf-cm 1 to 5 kgf-m 1,000 to 5,000 cNm 10 to 50 Nm | 5 in.-oz. 0.5 in.-lbs. 0.05 ft.-lbs. 0.5 kgf-cm 0.005 kgf-m 5 cNm 0.05 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 00000000 |

| 1/2" | 176 to 880 in.-lbs. 15 to 73 ft.-lbs. 200 to 1,000 kgf-cm 2 to 10 kgf-m 20 to 100 Nm | 1 in.-lbs. 0.1 ft.-lbs. 1 kgf-cm 0.01 kgf-m 0.1 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 00000000 |

| 1/2" | 350 to 1,750 in.-lbs. 30 to 145 ft.-lbs. 400 to 2,000 kgf-cm 4 to 20 kgf-m 40 to 200 Nm | 2 in.-lbs. 0.2 ft.-lbs. 2 kgf-cm 0.02 kgf-m 0.2 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 00000000 |

Bluetooth Data Connection | ||||||||||||

| 1/4" | 280 to 1,400 in.-oz. 17.6 to 88 in.-lbs. 1.5 to 7.3 ft.-lbs. 20 to 100 kgf-cm 0.2 to 1 kgf-m 200 to 1,000 cNm 2 to 10 Nm | 1 in.-oz. 0.1 in.-lbs. 0.01 ft.-lbs. 0.1 kgf-cm 0.001 kgf-m 1 cNm 0.01 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

| 3/8" | 560 to 2,800 in.-oz. 35 to 175 in.-lbs. 3 to 14.5 ft.-lbs. 40 to 200 kgf-cm 0.4 to 2 kgf-m 400 to 2,000 cNm 4 to 20 Nm | 2 in.-oz. 0.2 in.-lbs. 0.02 ft.-lbs. 0.2 kgf-cm 0.002 kgf-m 2 cNm 0.02 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

| 3/8" | 1,400 to 7,000 in.-oz. 88 to 440 in.-lbs. 7.5 to 36.5 ft.-lbs. 100 to 500 kgf-cm 1 to 5 kgf-m 1,000 to 5,000 cNm 10 to 50 Nm | 5 in.-oz. 0.5 in.-lbs. 0.05 ft.-lbs. 0.5 kgf-cm 0.005 kgf-m 5 cNm 0.05 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

| 1/2" | 176 to 880 in.-lbs. 15 to 73 ft.-lbs. 200 to 1,000 kgf-cm 2 to 10 kgf-m 20 to 100 Nm | 1 in.-lbs. 0.1 ft.-lbs. 1 kgf-cm 0.01 kgf-m 0.1 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

| 1/2" | 350 to 1,750 in.-lbs. 30 to 145 ft.-lbs. 400 to 2,000 kgf-cm 4 to 20 kgf-m 40 to 200 Nm | 2 in.-lbs. 0.2 ft.-lbs. 2 kgf-cm 0.02 kgf-m 0.2 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

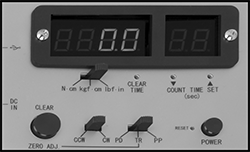

Torque Testers for Torque-Limiting Power Tools

Calibrate torque-limiting power tools such as air-powered and impact drivers. These testers check clockwise and counterclockwise torque, so fasteners do not fail because they were too loose or over-tightened and deformed. They record the first time your maximum torque is reached (peak down), the maximum torque (peak), and torque as it's measured (real-time). Use the flexible or rigid joints to connect your tools to these testers to simulate your fastening application.

These testers have a calibration certificate with test data traceable to NIST, so they meet standards for accuracy. For the most accurate performance, the maximum torque you're applying should fall near the middle of the tester's torque range.

Torque Testers cannot be sold to the listed areas due to energy efficiency regulations.

Testers that meet ISO 17025 have been checked in a laboratory that was evaluated for accuracy.

Connect to computers, laptops, or tablets that run on Microsoft Windows with a USB cable and analyze results with data acquisition software (both sold separately).

Accuracy | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Joint Hex Head Wd., mm | Torque Range | Graduations | Torque-Measuring Direction | Clockwise | Counterclockwise | Ht. | Wd. | Dp. | Material | Battery Type | Charger Plug Type | Includes | Cannot Be Sold To | Each | |

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration | |||||||||||||||

lbf-in., kgf-cm, N-cm | |||||||||||||||

| 14 | 3 to 220 lbf-in. 3 to 250 kgf-cm 30 to 2,500 N-cm | 0.001 kgf-cm 0.1 lbf-in. 1 N-cm | Clockwise and Counterclockwise | ±0.5% | ±0.5% | 3" | 6" | 8 1/2" | Steel | Rechargeable | Two Prong | 1 Drive Adapter (3/8" Hex Shank), 2 Joints (Flexible and Rigid), Carrying Case | CA, OR | 000000 | 000000000 |

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration—ISO 17025 | |||||||||||||||

lbf-in., kgf-cm, N-cm | |||||||||||||||

| 14 | 3 to 220 lbf-in. 3 to 250 kgf-cm 30 to 2,500 N-cm | 0.001 kgf-cm 0.1 lbf-in. 1 N-cm | Clockwise and Counterclockwise | ±0.5% | ±0.5% | 3" | 6" | 8 1/2" | Steel | Rechargeable | Two Prong | 1 Drive Adapter (3/8" Hex Shank), 2 Joints (Flexible and Rigid), Carrying Case | CA, OR | 000000 | 00000000 |

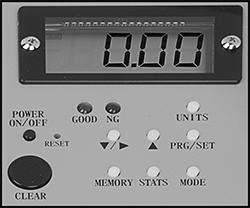

Torque Tool Testers for Torque Screwdrivers

Measure the force of hand and non-impact electric torque screwdrivers to keep fasteners from failing due to under or overtightening. A chuck-like adapter simulates your fastener joint during testing. These testers record the first time you reach the maximum torque (peak down), the maximum torque (peak), and torque as it's measured (real-time). For the most accurate performance, the maximum torque you're applying should fall near the middle of the tester's torque range. A track mode lets you monitor fluctuating torque. For quick pass/fail testing, these testers have programmable high/low set points with lights and an alarm. They include a calibration certificate with test data traceable to NIST that states they have passed tests for accuracy.

Testers that meet ISO 17025 have been checked in a laboratory that was evaluated for accuracy.

Testers with automatic screw release reduce time between tests by returning the test screw to its starting position once torque is removed.

Use data acquisition software and a USB cable (each sold separately) to analyze results and connect to computers, laptops, or tablets that run on Microsoft Windows.

Testers cannot be sold to the listed areas due to energy efficiency regulations.

Testers | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Accuracy | USB Output Cables | ||||||||||||

| Screw Drive Size | Square Drive Size | Torque Range | Graduations | Clockwise | Counterclockwise | Features | Battery Type | Includes | Cannot Be Sold To | Each | Each | ||

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration | |||||||||||||

lbf-in., kgf-cm, N-cm | |||||||||||||

| No. 2 | 3/8" | 0.02 to 6.97 lbf-in. 0.02 to 8 kgf-cm 0.2 to 78.6 N-cm | 0.001 lbf-in. 0.001 kgf-cm 0.01 N-cm | ±0.5% | ±0.5% | Automatic Screw Release | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 000000 | 000000000 | 000000 | 000000 |

lbf-in., kgf-cm, N-cm, Nm | |||||||||||||

| No. 2, No. 3 | 3/8" | 0.2 to 69.70 lbf-in. 0.2 to 80.00 kgf-cm 2 to 786.00 N-cm 0.02 to 7.86 Nm | 0.01 lbf-in. 0.01 kgf-cm 0.1 N-cm 0.001 Nm | ±0.5% | ±0.5% | Automatic Screw Release | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 000000 | 00000000 | 000000 | 00000 |

lbf-in., kgf-cm, Nm | |||||||||||||

| No. 4 | 3/8" | 1.8 to 221.2 lbf-in. 2 to 255 kgf-cm 0.2 to 25 Nm | 0.01 lbf-in. 0.1 kgf-cm 0.01 Nm | ±0.5% | ±0.5% | __ | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 00000000 | 00000000 | 000000 | 00000 |

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration—ISO 17025 | |||||||||||||

lbf-in., kgf-cm, N-cm | |||||||||||||

| No. 2 | 3/8" | 0.02 to 6.97 lbf-in. 0.02 to 8 kgf-cm 0.2 to 78.6 N-cm | 0.001 lbf-in. 0.001 kgf-cm 0.01 N-cm | ±0.5% | ±0.5% | Automatic Screw Release | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 000000 | 00000000 | 000000 | 00000 |

lbf-in., kgf-cm, N-cm, Nm | |||||||||||||

| No. 2, No. 3 | 3/8" | 0.2 to 69.70 lbf-in. 0.2 to 80.00 kgf-cm 2 to 786.00 N-cm 0.02 to 7.86 Nm | 0.01 lbf-in. 0.01 kgf-cm 0.1 N-cm 0.001 Nm | ±0.5% | ±0.5% | Automatic Screw Release | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 000000 | 00000000 | 000000 | 00000 |

lbf-in., kgf-cm, Nm | |||||||||||||

| No. 4 | 3/8" | 1.8 to 221.2 lbf-in. 2 to 255 kgf-cm 0.2 to 25 Nm | 0.01 lbf-in. 0.1 kgf-cm 0.01 Nm | ±0.5% | ±0.5% | __ | Rechargeable | 2 Joints (High- and Low-Torque), Carrying Case | CA, OR | 00000000 | 00000000 | 000000 | 00000 |

| Data Acquisition Software | 000000 | Each | 0000000 |

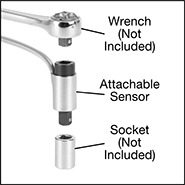

Data-Recording Torque Gauges

Use these gauges with changeable sensors and square-drive sockets (sold separately) to display, collect, and download torque readings. They display torque as it's measured and the maximum torque reached. Gauges can also be used to convert any hand-turned square drive tool into a precise torque-measuring tool. For the most accurate performance, the maximum torque you're applying should fall near the middle of the gauge's torque range.

Wrench-attachable sensors fit between your wrench and socket. Use with hand tools only.

Hand-turned sensors don't require a tool; place into your socket and turn them with your hand.

| Features | Lg. | Wd. | Ht. | Data Log Cap. | Batteries Included | Includes | Container Type | Each | |

in.-oz., in.-lbs., ft.-lbs., Nm, cNm, m-kg, cm.-kg | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Torque Measurement Memory, Programmable Torque Settings, Maximum Torque Display, Keypad, Headphone Jack, Audible Alarm | 6" | 3" | 2 1/2" | 3,500 | Yes | 3-ft Long USB Cable | Plastic Case | 0000000 | 000000000 |

Accuracy | |||||||

|---|---|---|---|---|---|---|---|

| Square Drive Size (Gender) | Torque Range | Torque-Measuring Direction | Clockwise | Counterclockwise | Cord Lg., ft. | Each | |

in.-oz., in.-lbs., ft.-lbs., Nm, cNm, m-kg, cm-kg | |||||||

| 1/4" (Female) × 1/4" (Male) | 80 to 800 in.-oz. 5 to 50 in.-lbs. 0.417 to 4.17 ft.-lbs. 0.565 to 5.65 Nm 56.5 to 565 cNm 0.058 to 0.576 m-kg 5.76 to 57.6 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 4 | 0000000 | 0000000 |

| 1/4" (Female) × 1/4" (Male) | 320 to 3,200 in.-oz. 20 to 200 in.-lbs. 1.67 to 16.7 ft.-lbs. 2.26 to 22.6 Nm 226 to 2,260 cNm 0.23 to 2.3 m-kg 23 to 230 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 4 | 0000000 | 000000 |

| 3/8" (Female) × 3/8" (Male) | 120 to 1,200 in.-lbs. 10 to 100 ft.-lbs. 13.6 to 136 Nm 1,356 to 13,560 cNm 1.38 to 13.8 m-kg 138 to 1,383 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 4 | 0000000 | 000000 |

| 1/2" (Female) × 1/2" (Male) | 300 to 3,000 in.-lbs. 25 to 250 ft.-lbs. 33.9 to 339 Nm 3,390 to 33,900 cNm 3.46 to 34.6 m-kg 346 to 3,456 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 4 | 0000000 | 000000 |

| 3/4" (Female) × 3/4" (Male) | 720 to 7,200 in.-lbs. 60 to 600 ft.-lbs. 81.3 to 813 Nm 8,135 to 81,350 cNm 8.3 to 83 m-kg 830 to 8,295 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 8 | 0000000 | 000000 |

Accuracy | |||||||

|---|---|---|---|---|---|---|---|

| Square Drive Size (Gender) | Torque Range | Torque-Measuring Direction | Clockwise | Counterclockwise | Cord Lg., ft. | Each | |

in.-oz., in.-lbs., ft.-lbs., Nm, cNm, m-kg, cm-kg | |||||||

| 1/4" (Male) | 2 to 20 in.-oz. 0.125 to 1.25 in.-lbs. 0.01 to 0.104 ft.-lbs. 0.014 to 0.141 Nm 1.41 to 14.1 cNm 0.001 to 0.014 m-kg 0.144 to 1.44 cm-kg | Clockwise and Counterclockwise | ±2% | ±2% | 4 | 0000000 | 0000000 |

| 1/4" (Male) | 16 to 160 in.-oz. 1 to 10 in.-lbs. 0.083 to 0.833 ft.-lbs. 0.113 to 1.13 Nm 11.3 to 113 cNm 0.012 to 0.115 m-kg 1.15 to 11.5 cm-kg | Clockwise and Counterclockwise | ±2% | ±2% | 4 | 0000000 | 000000 |

Digital Torque-Measuring Screwdrivers

A green light and a beep alert you when you've reached 90% of your set torque, and a steady tone sounds once you've hit your target. Set your torque in cNm, cm-Kg, or in.-lbs. and quickly check the LCD for real-time measurements along the way. A red light warns if you begin to overtighten. In addition to applying the correct torque to a fastener, these screwdrivers can help determine fastener torque specifications and identify the torque required to loosen tightened fasteners. They store up to nine torque settings to save time when working on multiple fasteners. They're compatible with any bit that has a 1/4" hex shank. All require one AAA battery (included). To save battery power, the display turns off after five minutes of idle time. You can also turn the display off manually.

Accurate to within 2% of the set torque in the clockwise direction, and 3% in the counterclockwise direction, these screwdrivers are more precise than standard torque screwdrivers. All screwdrivers come with a calibration certificate from the manufacturer. Screwdrivers with calibration certificate with test data traceable to NIST include the test measurements that confirm accuracy.

Accuracy | Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Torque Range | Graduations | For Bit Hex Shank Size | Clockwise | Counterclockwise | O'all Lg. | Shaft | Handle | Batteries Included | Each | |

Calibration Certificate | ||||||||||

in.-lbs., cNm, cm-kg | ||||||||||

| 0.45-4.4 in.-lbs. 5-50 cNm 0.5-5 cm-kg | 0.01 in.-lbs. 0.1 cNm 0.01 cm-kg | 1/4" | ±2% | ±3% | 8" | Steel | Plastic | Yes | 0000000 | 0000000 |

| 1.7-17.7 in.-lbs. 20-200 cNm 2-20 cm-kg | 0.01 in.-lbs. 0.1 cNm 0.01 cm-kg | 1/4" | ±2% | ±3% | 8" | Steel | Plastic | Yes | 0000000 | 000000 |

| 3.5-35 in.-lbs. 40-400 cNm 4-40 cm-kg | 0.01 in.-lbs. 0.1 cNm 0.01 cm-kg | 1/4" | ±2% | ±3% | 8" | Steel | Plastic | Yes | 0000000 | 000000 |

Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration | ||||||||||

in.-lbs., cNm, cm-kg | ||||||||||

| 0.45-4.4 in.-lbs. 5-50 cNm 0.5-5 cm-kg | 0.01 in.-lbs. 0.1 cNm 0.01 cm-kg | 1/4" | ±2% | ±3% | 8" | Steel | Plastic | Yes | 0000000 | 000000 |

| 1.7-17.7 in.-lbs. 20-200 cNm 2-20 cm-kg | 0.01 in.-lbs. 0.1 cNm 0.01 cm-kg | 1/4" | ±2% | ±3% | 8" | Steel | Plastic | Yes | 0000000 | 000000 |

| 3.5-35 in.-lbs. 40-400 cNm 4-40 cm-kg | 0.01 in.-lbs. 0.1 cNm 0.01 cm-kg | 1/4" | ±2% | ±3% | 8" | Steel | Plastic | Yes | 0000000 | 000000 |