Filter by

Speed @ Continuous Operating Torque

Starting Torque

Continuous Operating Torque

Voltage Type

Maximum Rotation Speed

Shaft Orientation

Mounting Position

Shaft Type

Full Load Current

Motor Type

Motor Enclosure Type

Direction of Operation

Radial Load Capacity

Power Source

REACH

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

DC Gearmotors

Gearmotors | Replacement Motor Brushes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

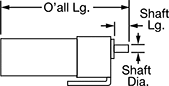

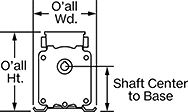

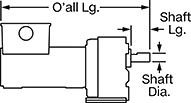

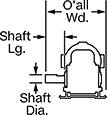

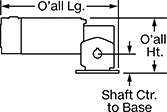

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

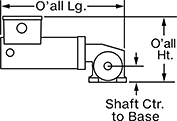

Max. Rotation Speed, rpm | Power, hp | Speed @ Continuous Operating Torque | Radial Load Cap., lb. | Full Load Current, amp | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Certification | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/20 | 0.9 rpm @ 711 in·lbf | 900 | 0.23 | Totally Enclosed Fan-Cooled (TEFC) | 12" | 5" | 6 1/4" | 3/4" | 2" | 4 1/2" | F | 311 | UL Recognized Component | 0000000 | 000000000 | 2 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1/20 | 8.7 rpm @ 293 in·lbf | 400 | 0.6 | Totally Enclosed Nonventilated (TENV) | 10 1/2" | 4" | 5 1/4" | 5/8" | 1 3/8" | 3 1/2" | F | 311 | UL Recognized Component | 0000000 | 000000 | 2 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 1/2 | 17 rpm @ 1,112 in·lbf | 700 | 5 | Totally Enclosed Fan-Cooled (TEFC) | 16 1/2" | 8 1/4" | 6 1/2" | 3/4" | 1 1/2" | 3" | F | 311 | UL Recognized Component | 0000000 | 00000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 1/8 | 22 rpm @ 300 in·lbf | 322 | 1.16 | Totally Enclosed Nonventilated (TENV) | 12 1/4" | 4" | 5 1/4" | 5/8" | 1 3/8" | 3 1/2" | F | 311 | UL Recognized Component | 0000000 | 000000 | 2 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 31 | 1/8 | 31 rpm @ 220 in·lbf | 327 | 1.3 | Totally Enclosed Nonventilated (TENV) | 11 1/2" | 5" | 5 1/4" | 5/8" | 1 1/2" | 3 1/2" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33 | 1/2 | 30 rpm @ 822 in·lbf | 650 | 5 | Totally Enclosed Fan-Cooled (TEFC) | 16 1/2" | 8 1/4" | 6 1/2" | 3/4" | 1 1/2" | 3" | F | 311 | UL Recognized Component | 0000000 | 00000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 1/17 | 30 rpm @ 100 in·lbf | 171 | 0.8 | Totally Enclosed Nonventilated (TENV) | 8 3/4" | 4 1/2" | 5 1/2" | 1/2" | 1" | 3" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 | 1/2 | 39 rpm @ 705 in·lbf | 650 | 5 | Totally Enclosed Fan-Cooled (TEFC) | 16 1/2" | 8 1/4" | 6 1/2" | 3/4" | 1 1/2" | 3" | F | 311 | UL Recognized Component | 0000000 | 00000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 44 | 1/4 | 42 rpm @ 280 in·lbf | 327 | 2.3 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 51 | 1/8 | 51 rpm @ 130 in·lbf | 277 | 1.3 | Totally Enclosed Nonventilated (TENV) | 11 1/2" | 5" | 6 1/4" | 5/8" | 1 1/2" | 3 1/2" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 1/20 | 49 rpm @ 55 in·lbf | 160 | 0.62 | Totally Enclosed Nonventilated (TENV) | 8 3/4" | 3 3/4" | 3 3/4" | 1/2" | 1" | 2.55" | F | 311 | UL Recognized Component | 0000000 | 000000 | 2 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 1/2 | 57 rpm @ 476 in·lbf | 625 | 5 | Totally Enclosed Fan-Cooled (TEFC) | 16 1/2" | 8 1/4" | 6 1/2" | 3/4" | 1 1/2" | 3" | F | 311 | UL Recognized Component | 0000000 | 00000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 61 | 1/8 | 61 rpm @ 113 in·lbf | 267 | 1.3 | Totally Enclosed Nonventilated (TENV) | 11 1/2" | 5" | 5 1/4" | 5/8" | 1 1/2" | 3 1/2" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62 | 1/4 | 62 rpm @ 220 in·lbf | 303 | 2.3 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 1/17 | 60 rpm @ 56 in·lbf | 171 | 0.8 | Totally Enclosed Nonventilated (TENV) | 8 3/4" | 4 1/2" | 5 1/2" | 1/2" | 1" | 3" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 1/4 | 83 rpm @ 155 in·lbf | 267 | 2.3 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 92 | 1/2 | 84 rpm @ 320 in·lbf | 575 | 5 | Totally Enclosed Fan-Cooled (TEFC) | 16 1/2" | 8 1/4" | 6 1/2" | 3/4" | 1 1/2" | 3" | F | 311 | UL Recognized Component | 0000000 | 00000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 94 | 1/8 | 94 rpm @ 77 in·lbf | 236 | 1.3 | Totally Enclosed Nonventilated (TENV) | 11 1/2" | 5" | 5 1/4" | 5/8" | 1 1/2" | 3 1/2" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 1/17 | 100 rpm @ 36 in·lbf | 177 | 0.8 | Totally Enclosed Nonventilated (TENV) | 8 3/4" | 4 1/2" | 5 1/2" | 1/2" | 1" | 3" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 125 | 1/4 | 110 rpm @ 100 in·lbf | 256 | 2 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 | 1/17 | 150 rpm @ 24 in·lbf | 180 | 0.8 | Totally Enclosed Nonventilated (TENV) | 8 1/2" | 4 1/2" | 5 1/2" | 1/2" | 1" | 3" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 167 | 1/8 | 167 rpm @ 43 in·lbf | 197 | 1.3 | Totally Enclosed Nonventilated (TENV) | 11 1/2" | 5" | 5 1/4" | 5/8" | 1 1/2" | 3 1/2" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 173 | 1/4 | 165 rpm @ 70 in·lbf | 232 | 2 | Totally Enclosed Nonventilated (TENV) | 13 1/4" | 6" | 5 1/2" | 3/4" | 1 5/8" | 4" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 | 1/17 | 300 rpm @ 10 in·lbf | 180 | 0.8 | Totally Enclosed Nonventilated (TENV) | 8 1/2" | 4 1/2" | 5 1/2" | 1/2" | 1" | 3" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 393 | 1/4 | 360 rpm @ 40 in·lbf | 170 | 2.51 | Totally Enclosed Nonventilated (TENV) | 14 1/4" | 4" | 5 1/4" | 5/8" | 1 3/8" | 3 1/2" | F | 311 | UL Recognized Component | 0000000 | 000000 | 2 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 404 | 1/8 | 360 rpm @ 17 in·lbf | 200 | 1.1 | Totally Enclosed Nonventilated (TENV) | 9 3/4" | 3 3/4" | 3 3/4" | 1/2" | 1" | 2.55" | F | 311 | UL Recognized Component | 0000000 | 000000 | 2 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,800 | 1/20 | 20 rpm @ 100 in·lbf | 155 | 0.54 | Totally Enclosed Nonventilated (TENV) | 9 1/4" | 3 3/4" | 3 3/4" | 1/2" | 1" | 2 3/4" | F | 311 | UL Recognized Component | 0000000 | 000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,800 | 1/2 | 210 rpm @ 210 in·lbf | 525 | 5 | Totally Enclosed Fan-Cooled (TEFC) | 16 1/4" | 8 1/4" | 6 3/4" | 3/4" | 1 1/2" | 3" | F | 311 | UL Recognized Component | 0000000 | 00000000 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

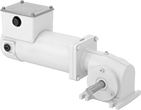

Right-Angle DC Gearmotors

Electric Gearmotors

|

|

|

Gearmotors | Conduit Bodies | Replacement Motor Brushes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

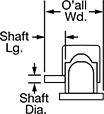

Power, hp | Speed @ Continuous Operating Torque | Radial Load Cap., lb. | Full Load Current, amp | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/17 | 42 rpm @ 22 in·lbf | 185 | 0.9 | 8 3/4" | 4" | 3 3/4" | 1/2" | 1.3" | 1.3" | H | 356 | 00000000 | 0000000 | 00000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/17 | 62 rpm @ 19 in·lbf | 185 | 0.9 | 8 3/4" | 4" | 3 3/4" | 1/2" | 1.3" | 1.3" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/17 | 116 rpm @ 16 in·lbf | 185 | 0.9 | 8 3/4" | 4" | 3 3/4" | 1/2" | 1.3" | 1.3" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/17 | 222 rpm @ 10 in·lbf | 185 | 1 | 8 3/4" | 4" | 3 3/4" | 1/2" | 1.3" | 1.3" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/17 | 445 rpm @ 5 in·lbf | 185 | 1 | 8 3/4" | 4" | 3 3/4" | 1/2" | 1.3" | 1.3" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 42 rpm @ 80 in·lbf | 235 | 1.4 | 10 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 62 rpm @ 70 in·lbf | 235 | 1.4 | 10 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 122 rpm @ 45 in·lbf | 235 | 1.4 | 10 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 237 rpm @ 25 in·lbf | 235 | 1.4 | 10 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 475 rpm @ 13 in·lbf | 235 | 1.4 | 10 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 60 rpm @ 135 in·lbf | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 79 rpm @ 125 in·lbf | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 120 rpm @ 90 in·lbf | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 233 rpm @ 50 in·lbf | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 465 rpm @ 30 in·lbf | 235 | 2.3 | 12 3/4" | 5 1/4" | 4 3/4" | 5/8" | 1.8" | 1.67" | H | 356 | 00000000 | 000000 | 00000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

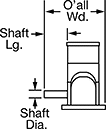

Gearmotors with Hollow Body/Removable Shaft

|  |

Side View of Gearmotor with Hollow Body and Shaft Removed | Gearmotor Shown with Hollow Body and Shaft Installed |

|

|

Gearmotors | Conduit Bodies | Replacement Motor Brushes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Power, hp | Speed @ Continuous Operating Torque | Radial Load Cap., lb. | Full Load Current, amp | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Each | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 30 rpm @ 94 in·lbf | 300 | 1.28 | 10 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 00000000 | 0000000 | 00000000 | 000000 | 2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 40 rpm @ 82 in·lbf | 300 | 1.28 | 10 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 00000000 | 000000 | 00000000 | 00000 | 2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 60 rpm @ 64 in·lbf | 300 | 1.28 | 10 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 00000000 | 000000 | 00000000 | 00000 | 2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 180 rpm @ 27 in·lbf | 300 | 1.28 | 10 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 00000000 | 000000 | 00000000 | 00000 | 2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 60 rpm @ 120 in·lbf | 300 | 2.33 | 12 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 00000000 | 000000 | 00000000 | 00000 | 2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 90 rpm @ 100 in·lbf | 300 | 2.33 | 12 1/4" | 5 1/4" | 4 3/4" | 5/8" | 1.6" | 1.45" | F | 311 | 00000000 | 000000 | 00000000 | 00000 | 2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Washdown DC Gearmotors

Gearmotors | Replacement Motor Brushes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

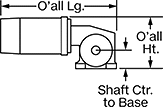

Max. Rotation Speed, rpm | Power, hp | Speed @ Continuous Operating Torque | Full Load Current, amp | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Enclosure Rating | Certification | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 1/8 | 14 rpm @ 341 in·lbf | 1.5 | Totally Enclosed Nonventilated (TENV) | 11 3/4" | 6" | 6 3/4" | 3/4" | 1 5/8" | 4" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 0000000 | 0000000 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 31 | 1/8 | 31 rpm @ 220 in·lbf | 1.6 | Totally Enclosed Nonventilated (TENV) | 12" | 5" | 6 3/8" | 5/8" | 1 1/2" | 3.13" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 0000000 | 00000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 | 1/4 | 42 rpm @ 280 in·lbf | 2.6 | Totally Enclosed Nonventilated (TENV) | 13 3/4" | 6" | 6 3/4" | 3/4" | 1 5/8" | 4" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 0000000 | 00000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 94 | 1/8 | 61 rpm @ 113 in·lbf | 1.6 | Totally Enclosed Nonventilated (TENV) | 12" | 5" | 6 3/8" | 5/8" | 1 1/2" | 3.13" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 0000000 | 00000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 167 | 1/8 | 167 rpm @ 43 in·lbf | 1.6 | Totally Enclosed Nonventilated (TENV) | 12" | 5" | 6 3/8" | 5/8" | 1 1/2" | 3.13" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 0000000 | 00000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 | 1/4 | 500 rpm @ 25 in·lbf | 2.4 | Totally Enclosed Nonventilated (TENV) | 13 3/4" | 6" | 6 3/4" | 3/4" | 1 5/8" | 4" | F | 311 | IP55 | UL Recognized Component, CSA Certified, CE Marked | 00000000 | 00000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Washdown Right-Angle DC Gearmotors

Gearmotors | Replacement Motor Brushes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Shaft | Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Rotation Speed, rpm | Power, hp | Speed @ Continuous Operating Torque | Full Load Current, amp | Motor Enclosure Type | Lg. | Wd. | Ht. | Dia. | Lg. | Ctr.-to-Base Lg. | Class | Max. Temp., ° F | Enclosure Rating | Certification | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

90V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 | 1/8 | 42 rpm @ 80 in·lbf | 2.2 | Totally Enclosed Nonventilated (TENV) | 10 3/4" | 5 1/4" | 6 1/2" | 5/8" | 1 3/4" | 1.67" | F | 311 | IP55 | UL Recognized Component, CSA Certified | 0000000 | 0000000 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62 | 1/4 | 62 rpm @ 135 in·lbf | 3.7 | Totally Enclosed Nonventilated (TENV) | 12 3/4" | 5 1/4" | 6 5/8" | 5/8" | 1 3/4" | 1.67" | F | 311 | IP55 | UL Recognized Component, CSA Certified | 0000000 | 00000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 125 | 1/4 | 125 rpm @ 90 in·lbf | 3.8 | Totally Enclosed Nonventilated (TENV) | 12 3/4" | 5 1/4" | 6 5/8" | 5/8" | 1 3/4" | 1.67" | F | 311 | IP55 | UL Recognized Component, CSA Certified | 0000000 | 00000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 250 | 1/4 | 250 rpm @ 50 in·lbf | 3.7 | Totally Enclosed Nonventilated (TENV) | 12 3/4" | 5 1/4" | 6 5/8" | 5/8" | 1 3/4" | 1.67" | F | 311 | IP55 | UL Recognized Component, CSA Certified | 0000000 | 00000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||