How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

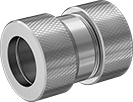

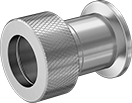

Quick-Connect High-Vacuum Fittings for Stainless Steel Tubing

Twist these fittings onto high-vacuum tubing to quickly make sealed, high-vacuum connections without the need for clamping, welding, or tools. To connect, insert your tubing into the fitting and twist the collar on the end of the fitting; an O-ring on the inside of the fitting compresses to form the seal. Also known as quick-disconnects, they're as easy to twist off as they are to twist on. Not for use in pressure applications.

Connectors have quick-connect fittings on both sides. Use them to connect two lengths of tubing: stainless steel to stainless steel, glass to glass, or go from one material to the other.

Adapters have a quick-connect fitting on one side and a quick-clamp fitting on the other. Use them to attach and remove components for one-off uses or to adapt your quick-clamp system to connect to glass tubing. Quick-clamp fittings are also known as KF, QF, and NW fittings; they require a clamp and ring (sold separately) to complete the connection.

Connectors | Replacement O-Rings | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Wall Thick. | Max. Vacuum | Material | O-Ring Material | Temp. Range, °F | Each | Each | ||

| 1/4" | 0.118" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | 0000000 | 0000000 | 0000000 | 00000 |

| 1/2" | 0.078" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | 0000000 | 000000 | 0000000 | 0000 |

| 3/4" | 0.212" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | 0000000 | 000000 | 0000000 | 0000 |

| 1" | 0.18" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | 0000000 | 000000 | 0000000 | 0000 |

| 1 1/2" | 0.242" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | 0000000 | 000000 | 0000000 | 0000 |

| 2" | 0.242" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | 0000000 | 000000 | 0000000 | 0000 |

Adapters | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Quick Clamp Tube Connection | Replacement O-Rings | |||||||||||||

| For Tube OD (Quick Connect) | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Wall Thick. | Max. Vacuum | Material | O-Ring Material | Temp. Range, °F | Specifications Met | Each | Each | ||

| 1/4" | 3/4" | 1.18" | 16 | ISO-KF | 0.118" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | ISO 2861 | 0000000 | 000000 | 0000000 | 00000 |

| 1/2" | 1" | 1.57" | 25 | ISO-KF | 0.118" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | ISO 2861 | 0000000 | 000000 | 0000000 | 0000 |

| 3/4" | 1" | 1.57" | 25 | ISO-KF | 0.055" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | ISO 2861 | 0000000 | 000000 | 0000000 | 0000 |

| 1" | 1" | 1.57" | 25 | ISO-KF | 0.055" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | ISO 2861 | 0000000 | 000000 | 0000000 | 0000 |

| 1 1/2" | 1 1/2" | 2.16" | 40 | ISO-KF | 0.055" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | ISO 2861 | 0000000 | 000000 | 0000000 | 0000 |

| 2" | 2" | 2.95" | 50 | ISO-KF | 0.118" | 10 -8 torr @ 72° F | 304 Stainless Steel | Buna-N Rubber | -40° to 250° | ISO 2861 | 0000000 | 000000 | 0000000 | 0000 |

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Nut Material | Max. Vacuum | Temp. Range, °F | Specifications Met | Each | |

with Wing Nut | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2"; 3/4" | 1.18" | 10; 16 | ISO-KF | Aluminum | Zinc Alloy | 10 -8 torr @ 72° F | 0° to 300° | ISO 2861 | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Aluminum | Zinc Alloy | 10 -8 torr @ 72° F | 0° to 300° | ISO 2861 | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | Zinc Alloy | 10 -8 torr @ 72° F | 0° to 300° | ISO 2861 | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | Zinc Alloy | 10 -8 torr @ 72° F | 0° to 300° | ISO 2861 | 0000000 | 00000 |

Material | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | O-Ring | Inner Ring | Max. Vacuum | Temp. Range, °F | Specifications Met | Each | |

| 3/4" | 1.18" | 16 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 0° to 300° | ISO 2861 | 00000000 | 00000 |

| 1" | 1.57" | 25 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 0° to 300° | ISO 2861 | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 0° to 300° | ISO 2861 | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 0° to 300° | ISO 2861 | 0000000 | 00000 |

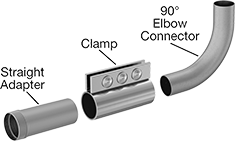

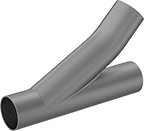

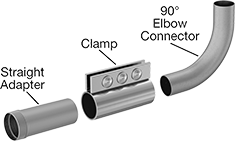

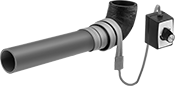

Vacuum Fittings for Steel Tubing

- For Use With: Air, Glass, Plastic Pellets, Resins, Wood Chips

- Temperature Range: -10° to 180° F

- Tubing: Galvanized Steel: Use with steel, galvanized steel

Steel: Use with steel

Use these fittings to create an air vacuum system without the hassle of brazing and welding. Insert two fittings into a clamp (sold separately) and tighten to form a secure seal.

Galvanized steel fittings have fair corrosion resistance. Fittings without a finish should only be used in noncorrosive environments.

Galvanized Steel | Steel | ||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Max. Pressure | Max. Vacuum | Each | Each | ||

NPT Threads | |||||||

| 2 1/8" | 2 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 000000 | 0000000 | 000000 |

| 2 1/2" | 2 1/2 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 3" | 3 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 3 1/2" | 3 1/2 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 4" | 4 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 5" | 5 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 000000 | 0000000 | 00000 |

| 6" | 6 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 000000 | 0000000 | 000000 |

Galvanized Steel | Steel | ||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Max. Pressure | Max. Vacuum | Each | Each | ||

NPT Threads | |||||||

| 2 1/8" | 2 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 000000 | 0000000 | 000000 |

| 2 1/2" | 2 1/2 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 3" | 3 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 3 1/2" | 3 1/2 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 000000 | 0000000 | 000000 |

| 4" | 4 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 000000 | 0000000 | 00000 |

| 5" | 5 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 000000 | 0000000 | 000000 |

| 6" | 6 | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 000000 | 0000000 | 000000 |

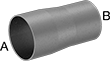

Galvanized Steel | Steel | ||||||

|---|---|---|---|---|---|---|---|

| For Tube OD (A) | For Tube OD (B) | Max. Pressure | Max. Vacuum | Each | Each | ||

| 2 1/2" | 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 3" | 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3 1/2" | 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3 1/2" | 2 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 4" | 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 00000 | 0000000 | 00000 |

| 5" | 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 000000 | 0000000 | 000000 |

| 6" | 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 00000000 | 000000 | 0000000 | 000000 |

Galvanized Steel | Steel | |||||

|---|---|---|---|---|---|---|

| For Tube OD | Max. Pressure | Max. Vacuum | Each | Each | ||

| 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 2 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 4" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 5" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 00000 |

| 6" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

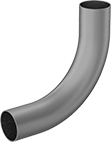

Galvanized Steel | Steel | |||||

|---|---|---|---|---|---|---|

| For Tube OD | Max. Pressure | Max. Vacuum | Each | Each | ||

| 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 2 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 4" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 5" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 6" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 00000 |

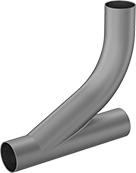

Galvanized Steel | Steel | |||||

|---|---|---|---|---|---|---|

| For Tube OD | Max. Pressure | Max. Vacuum | Each | Each | ||

| 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 2 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 00000 |

| 4" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 5" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 6" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

Galvanized Steel | Steel | |||||

|---|---|---|---|---|---|---|

| For Tube OD | Max. Pressure | Max. Vacuum | Each | Each | ||

| 2 1/8" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 2 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3 1/2" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 000000 |

| 4" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 00000 |

| 5" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 6" | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

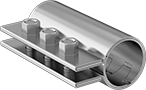

Clamps for Vacuum Fittings for Steel Tubing

Use these clamps to connect vacuum tube fittings. Insert two fittings into a clamp and tighten to form a secure seal.

- For Use With: Air, Glass, Plastic Pellets, Resins, Wood Chips

- Temperature Range: Neoprene Rubber Gaskets: -20° to 190° F

Silicone Rubber Gaskets: -100° to 500° F - Tubing: Use with steel

Bolt clamps have a stainless steel strip that provides an escape route for electrostatic buildup when used in a fully-grounded system. They have fair corrosion resistance.

Neoprene Rubber Gaskets | Silicone Rubber Gaskets | ||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Max. Pressure | Max. Vacuum | Each | Each | ||

| 1 1/2" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 000000 | 0000000 | 000000 |

| 1 3/4" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 2" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 2 1/8" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 2 1/4" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 2 1/2" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 3" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 5" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 6" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 00000 |

| 8" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 000000 |

| 10" | Galvanized Steel | 15 psi @ 72° F | 15 in. of Hg @ 72° F | 0000000 | 00000 | 0000000 | 000000 |

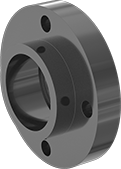

Fiberglass Pipe Flanges for Corrosive Chemicals

- For Use With: Acetic Acid (75%), Alcohol, Calcium Chloride, Chlorine, Fuel Oil, Gasoline, Hydrochloric Acid (37%), Nitric Acid (10%), Oil, Phosphoric Acid, Salt Water (30%), Sodium Hydroxide (50%), Solvents, Sulfuric Acid (70%), Water

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D4024

Flanges have excellent corrosion resistance to handle a wide range of acids and other highly-corrosive chemicals. Use in metal surface treating applications, plating solution lines, and other chemical process applications. They are reinforced with fiberglass layers for better strength and durability than any of our other pipe flanges for chemicals. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. Flanges meet ASTM D4024 specifications and testing requirements for product dimensions, performance, and material quality.

To connect flanges to pipe, first sand the inside of the flange and the end of the pipe to remove the surface finish. Next, mix the adhesive (sold separately) until the color is uniform with no streaks. Apply a thin layer of mixed adhesive to the sanded area of the pipe, approximately 1/8” thick. Repeat this process with the inside of the flange, applying a layer approximately 1/16” thick. After sealant has been applied, push the flange onto the pipe until it is fully engaged. Make sure you align the bolt holes prior to installing to minimize rotation after the flange is installed. Finally, use the adhesive-curing heat cable (sold separately) to cure the adhesive. Wrap the tape around the pipe and flange at the joint, taking care to not overlap the tape. Once you have waited the full cure time, the pipe and flange will be ready to use.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

| Pipe Size | Socket Dp. | Flange OD | For Bolt Dia. | Bolt Hole Dia. | Number of Bolt Holes | Bolt Circle Dia. | Material | Color | Max. Pressure | Each | |

| 1 1/2 | 1 3/8" | 5" | 1/2" | 5/8" | 4 | 3 7/8" | Fiberglass | Black | 300 psi @ 72° F | 0000000 | 0000000 |

| 2 | 1 3/4" | 6" | 5/8" | 3/4" | 4 | 4 3/4" | Fiberglass | Black | 250 psi @ 72° F | 0000000 | 000000 |

| 3 | 2" | 7 1/2" | 5/8" | 3/4" | 4 | 6" | Fiberglass | Black | 250 psi @ 72° F | 0000000 | 000000 |

| 4 | 2 1/2" | 9" | 5/8" | 3/4" | 8 | 7 1/2" | Fiberglass | Black | 150 psi @ 72° F | 0000000 | 000000 |

| Pipe Cement (11.8-fl. oz. Can) | 0000000 | Each | 000000 |

| Voltage | Max. Heat Output, °F | Lg. | Wd. | Thick. | Plug Type | Cord Lg. | Each | |

| 120V AC | 270° | 6 ft. | 1" | 1/8" | Two Prong | 6 ft. | 0000000 | 0000000 |

Gravity-Flow Polypropylene Pipe Fittings for Corrosive Chemical Waste

- For Use With: Deionized Water, Hydrochloric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Maximum Temperature: 220° F

- Specifications Met: ASTM D4101, ASTM D635, ASTM F1412, UL 94 V-2

- Compatible with Gravity-Flow Polypropylene Pipe for Corrosive Chemical Waste

Made of polypropylene, these gravity-flow fittings withstand organic solvents, such as acetone, that would dissolve CPVC pipe. They also stand up to highly corrosive acids, such as hydrochloric acid, and alkalies. All meet UL and ASTM standards for flame retardance and self-extinguishment in the case of fire. They also meet strict ASTM specifications and testing requirements for material quality and product dimensions. They’re compatible with Orion Blueline No-Hub and Orion Rionfuse chemical waste pipe and pipe fittings.

Adapters for glass pipe connect to older glass piping systems with a bead-to-bead clamp (not included).