About Glove Sizing

More

Neoprene Chemical-Resistant Gloves

From acids to alkalis, these neoprene gloves protect your hands from chemicals. They resist tears, have good dexterity, and stay flexible across a wide range of temperatures. They're often used when cleaning and maintaining equipment.

High-temperature gloves are best for jobs that require contact with moderate heat, such as boiler room maintenance. Neoprene-coated neoprene gloves have two layers of coating for extra abrasion resistance.

Textured gloves give you extra grip on wet or oily objects. Gloves with a wear indicator have a colored inner layer that shows through as the coating wears down.

Gloves that meet ANSI/ISEA 105 or EN 388 standards are rated for various forms of protection, such as cuts, abrasions, or punctures.

Gloves that meet EN 374 Type A or Type B standards protect against chemical permeation for at least 30 minutes. Each letter in the rating represents a chemical that these gloves were tested against.

Temp., °F | Pair | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thick., mil | Lg. | Texture | Cuff Style | Color | Min. | Max. | For Use With | Features | Specifications Met | Choose a Size (Glove Size) | 1-11 | 12-Up | |

High-Temperature Gloves | |||||||||||||

Neoprene Rubber-Coated Neoprene Rubber | |||||||||||||

| 22 | 14" | Textured | Open | Black | -20° | 345° | Hydrochloric Acid, Hydrofluoric Acid, Hydrogen Peroxide, Isopropyl Alcohol, Nitric Acid, Sodium Hydroxide, Sulfuric Acid | Wear Indicator | EN 374 Type A (ABCJKL), EN 388 (3112) | 0000000 | 00000 | 00000 | |

| 22 | 18" | Textured | Open | Black | -20° | 345° | Hydrochloric Acid, Hydrofluoric Acid, Hydrogen Peroxide, Isopropyl Alcohol, Nitric Acid, Sodium Hydroxide, Sulfuric Acid | Wear Indicator | EN 374 Type A (ABCJKL), EN 388 (3112) | 0000000 | 00000 | 00000 | |

| 40 | 14" | Textured | Open | Black | -20° | 300° | Hydrochloric Acid, Hydrofluoric Acid, Isopropyl Alcohol, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Sulfuric Acid, Turpentine | Wear Indicator | FDA Compliant 21 CFR 177.2600, EN 374 Type A (ABCJLMNS), EN 388 (2111X) | 000000 | 00000 | 00000 | |

PVA Chemical-Resistant Gloves

Protect your hands against strong organic chemicals, oil-based degreasing solvents, and lacquer thinner. These gloves are often used when maintaining lab equipment, or cleaning pumps or furnaces. However, they’re not designed for use with water-based or alkali-based degreasing products. Their cotton liner absorbs perspiration to keep your hands dry. They’ve been tested according to EN 374 against different classes of chemicals. A Type A rating means they resist permeation for at least 30 minutes.

Available Sizes | |

|---|---|

| Size | Glove Size |

| XL | 10 |

| Texture | Lining Material | Thick., mil | Lg. | Color | For Use With | Specifications Met | Size | Pair | |

PVA Plastic | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Smooth | Cotton Fabric | 40 | 14" | Red | Hydraulic Fluid, Lacquer Thinner, Methylene Chloride, Mineral Spirits, Turpentine, Xylene | EN 374 Type A (BCDFIJ) | XL | 0000000 | 000000 |

Heat-Protection Gloves

Designed for intermittent handling of hot pipes, engine parts, and castings, these gloves protect your hands from moderate heat and some abrasion. Holding heavy objects may decrease the temperature rating.

Gloves with a nitrile grip are textured to help you grasp slippery plastics or oily machine parts.

Gloves that meet ANSI/ISEA 105 standards are rated for various forms of protection, such as cut, abrasion, or heat resistance.

Coated Cut-Protection Gloves

The coating on these gloves provides extra protection and wear resistance. All meet the ANSI/ISEA 105 standard, which designates levels of cut resistance based on the force needed to cut through the material of the glove using a razor blade.

Kevlar aramid gloves absorb moisture. Fully coated gloves provide the same protection for the front and back of the hand.

Nitrile-coated gloves are oil resistant and have better abrasion resistance than other coated gloves.

Style C are suitable for working with oily heavy metal parts with sharp, rough edges. They have a smooth surface. Open cuffs make them convenient to put on and take off.

High-Dexterity Cut- and Puncture-Protection Gloves

These flexible gloves combine cut resistance with a design that conforms to your hand for improved dexterity. All have reinforced palms to reduce the risk of cuts when handling sharp and pointed objects. They meet the ANSI/ISEA 105 standard, which designates levels of cut resistance based on the force needed to cut through the material of the glove using a razor blade.

Silicone-grip gloves are textured providing a secure grip even when handling slippery objects. They also have bumpers on the back of the gloves to protect your hands from impact when working in confined spaces.

Gloves with open cuffs are more convenient to put on and take off than other gloves.

Available Sizes | |

|---|---|

| Size | Glove Size |

| S | 7 |

| M | 8 |

| L | 9 |

| XL | 10 |

| 2XL | 11 |

Grip | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cut Resistance | Texture | Coverage | Pattern | Lg. | Cuff Style | Color | Features | Specifications Met | Choose a Size | Pair | |

Impact-Resistant Gloves | |||||||||||

Silicone-Rubber-Grip Synthetic Leather | |||||||||||

| ANSI Level A5 | Textured | Palm | Criss Cross | 9" | Open | Red/Yellow | Reinforced Palm, Spandex Backing, Knuckle Guard | ANSI/ISEA 105 | 000000 | 000000 | |

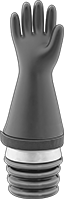

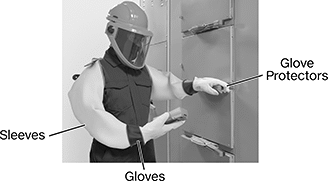

Electrical-Protection Gloves

Rated to ASTM D120 standards for handling live electrical equipment, these gloves come tested and marked with the test date. You have one year from the test date to put gloves into service before they must be retested. Once in use, gloves should be tested every six months. To comply with ASTM safety standards, protectors (sold separately) must be worn over gloves when working with live electrical equipment.

ASTM defines voltage classes for rubber insulating gloves. Make sure the gloves you use are rated for the voltage class of your equipment.

Use an inspection pump (sold separately) to check Class 1-4 gloves for damage. Purchase an adapter (sold separately) to use the inspection pump with Class 00 and 0 gloves.

Available Sizes | |

|---|---|

| Size | Glove Size |

| M | 8 |

| L | 9 |

| XL | 10 |

| 2XL | 11 |

| 3XL | 12 |

Protectors should be the same size as the gloves they will be worn over. To comply with ASTM standards, the cuff of the glove should extend past the end of the protector. For Class 00 and Class 0 ratings, the gloves must be at least 1/2" longer than the protector. For all other classes, the number of inches that the glove extends past the protector should match the class number. For example, Class 1 gloves should be 1" longer than their protector.

Those that cannot be sold to Canada are restricted due to import regulations.

| Lg. | Material | Lining Material | Arc Rating, cal/cm2 | Arc Rated PPE Category | ANSI Cut Rating | ANSI Puncture Rating | Color | Specifications Met | Cannot Be Sold To | Choose a Size | Pair | |

For Class 00, Class 0 Straight Cuff Gloves | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Adjustable Strap | ||||||||||||

| 10" | Goatskin Leather | __ | 25 | 3 | __ | 3 | Yellow | ANSI/ISEA 105, ASTM F696, NFPA 70E | Canada | 0000000 | 000000 | |

| 10" | Goatskin Leather | Kevlar Fabric | 36 | 3 | A3 | 4 | Yellow | ANSI/ISEA 105, ASTM F696, NFPA 70E | Canada | 0000000 | 00000 | |

Strap your glove to the pump and inflate to reveal cracks, pinholes, and other signs of wear.

| For ASTM Voltage Rating | Each | |

| Class 1, Class 2, Class 3, Class 4 | 0000000 | 0000000 |

| For ASTM Voltage Rating | Each | |

| Class 00, Class 0 | 0000000 | 0000000 |

| For Max. Glove Lg. | Ht. | Wd. | Dp. | Color | Each | |

Cotton Duck Fabric | ||||||

|---|---|---|---|---|---|---|

| 14" | 15" | 8" | 4" | Off-White | 0000000 | 000000 |

Electrical-Protection Sleeves

Pair these sleeves with electrical-protection gloves for full arm coverage when working near equipment running at 17,000V AC or higher. Rated to ASTM D1051 standards for handling live electrical equipment, these sleeves come tested and marked with the test date. You have one year from the test date to put sleeves into service before they must be retested. Once in use, sleeves should be tested every six months. All have a colored inner layer that shows through as the coating wears down, helping you spot cracks, pinholes, and other signs of damage.

ASTM defines voltage classes for rubber insulating sleeves. Make sure the sleeves and gloves you use are rated for the voltage class of your equipment.

Available Sizes | |

|---|---|

| Size | Upper Arm Circumference |

| S | 24 1/2" |

| M | 24 1/2" |

| L | 25 3/4" |

| XL | 25 3/4" |

| 2XL | 25 3/4" |

Sleeves | Replacement Straps | Replacement Buttons | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ASTM Voltage Rating | Max. Use Voltage | Lg. | Cuff Style | Color | Includes | Features | Specifications Met | Choose a Size | Pair | Each | Each | |||

Dielectric Rubber | ||||||||||||||

| Class 2 | 17,000V AC | 27" | Open | Yellow | Two Straps, Four Buttons | Wear Indicator | ASTM D1051 | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 00000 | |

| Class 3 | 26,500V AC | 27" | Open | Yellow | Two Straps, Four Buttons | Wear Indicator | ASTM D1051 | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 0000 | |

| Class 4 | 36,000V AC | 27" | Open | Yellow | Two Straps, Four Buttons | Wear Indicator | ASTM D1051 | 0000000 | 00000000 | 0000000 | 00000 | 0000000 | 0000 | |

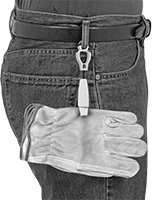

Glove Clips

Keep your gloves close at hand. These clips have a safety breakaway feature to prevent wearers from getting snagged by equipment.

Attach clip-on glove clips around belt loops or directly to clothing. Those with a ball-and-socket safety breakaway rotate as you move, allowing the clip and gloves to stay in place. They also have large jaws, which can hold large gloves.

Slip slide-on glove clips over belts, waistbands, and pockets. They hold gloves in a higher position than the clip-on clips, which helps keep them from moving around.