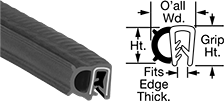

High-Temperature Chemical-Resistant Push-On Seals with Bulb on Side

Similar to standard silicone seals, fluorosilicone rubber seals can be used at high temperatures, but also withstand fuel and oil.

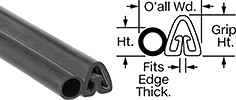

Oil-Resistant Food Industry Push-On Seals with Bulb on Side

FDA compliant, these seals can directly touch food. They’re made of Buna-N foam, so they resist oil, grease, salts, water, and most detergents. The foam resists absorption thanks to its closed-cell construction.

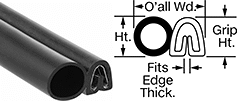

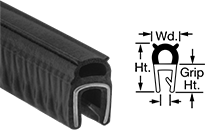

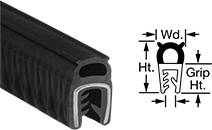

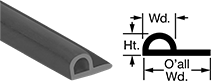

Oil-Resistant Push-On Seals with Bulb on Side

In addition to oil, these Buna-N seals resist grease, salts, water, steam, and most detergents. Push them onto a door’s edge to stop wind, dust, and water from entering. All have a hollow bulb for compressibility.

Buna-N foam seals have a closed-cell construction that resists absorption. They also have gripping edges with fingers for a strong hold.

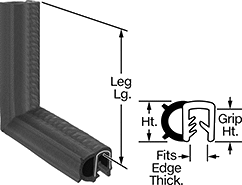

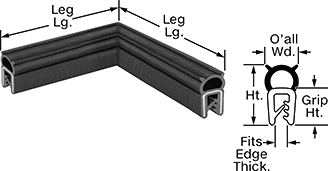

Oil-Resistant Push-On Seals for Corners with Bulb on Side

Save time covering corners—these seals come formed to a corner, so they don't require bending or cutting. Made of Buna-N foam, these seals resist oil, grease, salts, water, and most detergents. The foam has a closed-cell construction, so it resists absorption.

Use straight seals (sold separately) to fill in gaps along edges if the corner seal isn’t long enough for your application.

| Fits Edge Thick. | Leg Lg. | Ht. | Grip Ht. | Grip Material | Core Material | Temp. Range, °F | For Use Outdoors | Color | Each | |

Buna-N Foam | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3/64" to 1/8" | 6 1/4" | 1/2" | 27/64" | Buna-N Rubber | Metal | -20° to 210° | No | Black | 0000000 | 000000 |

| 3/64" to 1/8" | 9 7/8" | 1/2" | 27/64" | Buna-N Rubber | Metal | -20° to 210° | No | Black | 0000000 | 00000 |

| 3/64" to 1/8" | 15 3/4" | 1/2" | 27/64" | Buna-N Rubber | Metal | -20° to 210° | No | Black | 0000000 | 00000 |

| 3/64" to 1/8" | 24 3/4" | 1/2" | 27/64" | Buna-N Rubber | Metal | -20° to 210° | No | Black | 0000000 | 00000 |

Water- and Weather-Resistant Push-On Seals for Corners with Bulb on Side

Quickly seal corners without needing to bend, cut, or piece straight seals together. All of these seals are made of EPDM foam to resist water, sunlight, and ozone.

Use the straight seals (sold separately) to fill in gaps along edges if the corner seals aren't long enough for your application.

| Fits Edge Thick. | Leg Lg. | Ht. | Grip Ht. | Grip Material | Core Material | Temp. Range, °F | For Use Outdoors | Color | Each | |

EPDM Foam | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3/64" to 1/8" | 6 1/4" | 1/2" | 27/64" | EPDM Rubber | Metal | -40° to 210° | Yes | Black | 0000000 | 000000 |

| 3/64" to 1/8" | 9 7/8" | 1/2" | 27/64" | EPDM Rubber | Metal | -40° to 210° | Yes | Black | 0000000 | 00000 |

| 3/64" to 1/8" | 15 3/4" | 1/2" | 27/64" | EPDM Rubber | Metal | -40° to 210° | Yes | Black | 0000000 | 00000 |

| 3/64" to 1/8" | 24 3/4" | 1/2" | 27/64" | EPDM Rubber | Metal | -40° to 210° | Yes | Black | 0000000 | 00000 |

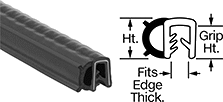

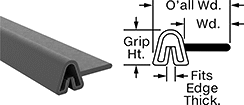

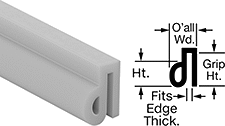

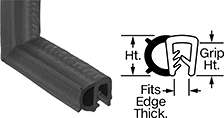

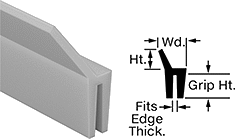

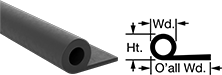

Oil-Resistant Rubber Push-On Seals with Bulb on Top

The Buna-N foam rubber bulb on these seals resists oil, grease, salts, water, steam, and most detergents. The bulb is hollow for compressibility and the foam has closed-cell construction, which resists absorption. Push seals onto a door’s edge to stop wind, dust, and water from entering. The gripping edges have fingers for a strong hold.

Per Ft. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fits Edge Thick. | Wd. | Ht. | Grip Ht. | Grip Material | Core Material | Bend Radius | Temp. Range, °F | For Use Outdoors | Color | Lengths, ft. | 1-99 | 100-Up | |

Buna-N Foam | |||||||||||||

| 3/64" to 9/64" | 7/16" | 53/64" | 33/64" | Buna-N Rubber | Metal | 3 3/4" | -40° to 212° | No | Black | 00000000 | 00000 | 00000 | |

| 1/8" to 13/64" | 29/64" | 53/64" | 33/64" | Buna-N Rubber | Metal | 6" | -40° to 212° | No | Black | 00000000 | 0000 | 0000 | |

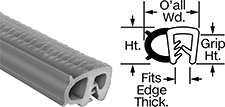

Oil-Resistant Push-On Seals for Corners with Bulb on Top

Already formed to 90°, these seals save you time and effort because you don’t have to cut and adhere straight pieces together to cover a corner. They’re made of Buna-N foam, so they resist oil, grease, salts, water, and most detergents.

Use the straight seals to fill in gaps along edges if the corner seals aren't long enough for your application.

| Fits Edge Thick. | Leg Lg. | O'all Wd. | Ht. | Grip Ht. | Grip Material | Core Material | Temp. Range, °F | For Use Outdoors | Color | Each | |

Buna-N Foam | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/64" to 1/8" | 6 1/4" | 27/64" | 51/64" | 13/32" | Buna-N Rubber | Metal | -20° to 210° | No | Black | 0000000 | 000000 |

| 3/64" to 1/8" | 9 7/8" | 27/64" | 51/64" | 13/32" | Buna-N Rubber | Metal | -20° to 210° | No | Black | 0000000 | 00000 |

| 3/64" to 1/8" | 15 3/4" | 27/64" | 51/64" | 13/32" | Buna-N Rubber | Metal | -20° to 210° | No | Black | 0000000 | 00000 |

| 3/64" to 1/8" | 24 3/4" | 27/64" | 51/64" | 13/32" | Buna-N Rubber | Metal | -20° to 210° | No | Black | 0000000 | 00000 |

High-Temperature Chemical-Resistant Push-On Seals with Wiper

Made of fluorosilicone rubber, these seals withstand high temperatures like standard silicone without breaking down when exposed to fuel and oil.

Oil-Resistant Push-On Seals with Wiper

In addition to oil, these seals resist grease, salts, water, steam, and most detergents.

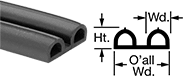

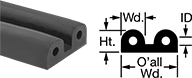

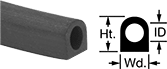

Chemical-Resistant Surface-Mount Seals

Use these Viton® fluoroelastomer rubber seals with fuels and aggressive chemicals, such as petroleum oil, hydrofluoric acid, and propyl alcohol. They have hollow construction for compressibility. Attach them directly to a door’s surface to shield against dust, noise, and vibration.

Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Ht. | ID | Hardness | Hardness Rating | Temp. Range, °F | For Use Outdoors | Specifications Met | Color | Lengths, ft. | 1-99 | 100-Up | |

Viton® Fluoroelastomer Rubber—Plain Back | ||||||||||||

| 3/8" | 3/8" | 1/4" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248, Type II, Class 1 | Black | 0000000 | 000000 | 00000 | |

| 1/2" | 1/2" | 9/32" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248 | Black | 0000000 | 00000 | 00000 | |

Per Ft. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Ht. | Hardness | Hardness Rating | Temp. Range, °F | For Use Outdoors | Specifications Met | Color | Lengths, ft. | 1-99 | 100-Up | |

Viton® Fluoroelastomer Rubber—Plain Back | |||||||||||

| 3/8" | 1/4" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248, Type II, Class 1 | Black | 0000000 | 00000 | 00000 | |

| 5/8" | 3/8" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248 | Black | 0000000 | 00000 | 00000 | |

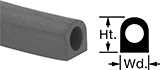

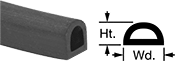

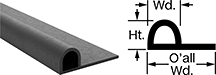

Oil-Resistant Surface-Mount Seals

To stand up to oil, grease, salts, water, and most detergents, these seals are made of Buna-N rubber. They have a hollow construction, so they’re more compressible than solid seals.

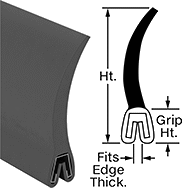

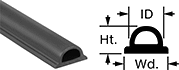

Chemical-Resistant Flange-Mount Seals

Made of Viton® fluoroelastomer rubber, these seals stand up to fuels and aggressive chemicals, such as petroleum oil, hydrofluoric acid, and propyl alcohol. They have hollow construction for compressibility and a flange that can be positioned along a door’s edge to cover gaps and block dust, noise, and vibration.

Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all Wd. | Wd. | Ht. | Hardness | Hardness Rating | Temp. Range, °F | For Use Outdoors | Specifications Met | Color | Lengths, ft. | 1-99 | 100-Up | |

Viton® Fluoroelastomer Rubber—Plain Back | ||||||||||||

| 1/2" | 3/16" | 3/16" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248; Type II; Class 1 | Black | 0000000 | 00000 | 00000 | |

| 3/4" | 1/4" | 1/4" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248; Type II; Class 1 | Black | 0000000 | 0000 | 0000 | |

| 1 1/4" | 3/4" | 5/8" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248 | Black | 0000000 | 00000 | 00000 | |

Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O'all Wd. | Wd. | Ht. | Hardness | Hardness Rating | Temp. Range, °F | For Use Outdoors | Specifications Met | Color | Lengths, ft. | 1-99 | 100-Up | |

Viton® Fluoroelastomer Rubber—Plain Back | ||||||||||||

| 1/2" | 1/4" | 1/4" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248 | Black | 0000000 | 00000 | 00000 | |

| 7/8" | 0.35" | 3/8" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248 | Black | 0000000 | 00000 | 0000 | |

| 2" | 1/2" | 1/2" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248 | Black | 0000000 | 00000 | 00000 | |

| 2" | 1" | 1" | Durometer 75A | Hard | -20° to 500° | Yes | MIL-R-83248 | Black | 0000000 | 00000 | 00000 | |

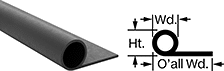

Oil-Resistant Flange-Mount Seals

Made of Buna-N rubber, these seals resist oil, grease, salts, water, steam, and most detergents. They have a hollow construction, so they’re more compressible than solid seals.

High-Temperature Slotted Rope Edge Seals

Made of fiberglass, these seals are woven tighter than High-Temperature Ultra-Conformable Slotted Edge Seals for increased durability. Also known as drop-warp and bolt-hole tape, they have openings along the center to accommodate bolts and rivets. Use them on metal flanges, as well as on oven, furnace, and boiler doors. They resist grease, oil, hydraulic fluid, and solvents.

Adhesive-back seals will stay in place until you permanently secure them, making them the best choice when installing in confined spaces.

| Wd. | Thick. | Lg., ft. | Max. Temp., °F | Max. Adhesive Temp., °F | For Use Outdoors | Color | Each | |

Fiberglass Fabric—Plain Back | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1" | 1/16" | 25 | 1000° | __ | No | White | 000000 | 00000 |

| 1" | 1/8" | 25 | 1000° | __ | No | White | 0000000 | 00000 |

| 1 1/4" | 1/16" | 25 | 1000° | __ | No | White | 00000000 | 00000 |

| 1 1/4" | 1/8" | 25 | 1000° | __ | No | White | 00000000 | 00000 |

| 1 1/2" | 1/16" | 25 | 1000° | __ | No | White | 000000 | 0000 |

| 1 1/2" | 1/8" | 25 | 1000° | __ | No | White | 0000000 | 00000 |

| 2" | 1/16" | 25 | 1000° | __ | No | White | 000000 | 00000 |

| 2" | 1/8" | 25 | 1000° | __ | No | White | 0000000 | 00000 |

| 2 1/2" | 1/16" | 25 | 1000° | __ | No | White | 000000 | 00000 |

| 2 1/2" | 1/8" | 25 | 1000° | __ | No | White | 0000000 | 00000 |

| 3" | 1/16" | 25 | 1000° | __ | No | White | 000000 | 00000 |

| 3" | 1/8" | 25 | 1000° | __ | No | White | 0000000 | 00000 |

| 3 1/2" | 1/16" | 25 | 1000° | __ | No | White | 00000000 | 00000 |

| 3 1/2" | 1/8" | 25 | 1000° | __ | No | White | 00000000 | 00000 |

| 4" | 1/16" | 25 | 1000° | __ | No | White | 00000000 | 00000 |

| 4" | 1/8" | 25 | 1000° | __ | No | White | 00000000 | 00000 |

Fiberglass Fabric—Adhesive Back | ||||||||

| 1" | 1/16" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 1" | 1/8" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 1 1/2" | 1/16" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 1 1/2" | 1/8" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 2" | 1/16" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 2" | 1/8" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 2 1/2" | 1/16" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 2 1/2" | 1/8" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 3" | 1/16" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 3" | 1/8" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

High-Temperature Ultra-Conformable Slotted Rope Edge Seals

These loosely-knitted fiberglass seals are more flexible and conformable than High-Temperature Slotted Edge Seals. Also known as drop-warp and bolt-hole tape, they have openings along the center to accommodate bolts and rivets. Use them on metal flanges, as well as on oven, furnace, and boiler doors. They resist grease, oil, hydraulic fluid, and solvents.

Adhesive-back seals will stay in place until you permanently secure them, making them the best choice when installing in confined spaces.

| Wd. | Thick. | Lg., ft. | Max. Temp., °F | Max. Adhesive Temp., °F | For Use Outdoors | Color | Each | |

Fiberglass Fabric—Plain Back | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1" | 1/16" | 25 | 1000° | __ | No | White | 0000000 | 000000 |

| 1 1/2" | 1/16" | 25 | 1000° | __ | No | White | 0000000 | 00000 |

| 2" | 1/16" | 25 | 1000° | __ | No | White | 0000000 | 00000 |

| 2 1/2" | 1/16" | 25 | 1000° | __ | No | White | 0000000 | 00000 |

| 3" | 1/16" | 25 | 1000° | __ | No | White | 0000000 | 00000 |

Fiberglass Fabric—Adhesive Back | ||||||||

| 1" | 1/16" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 1 1/2" | 1/16" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 2" | 1/16" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 2 1/2" | 1/16" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |

| 3" | 1/16" | 25 | 1000° | 150° | No | White | 0000000 | 00000 |