About Moment Loads

More

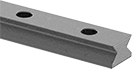

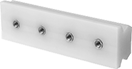

Sleeve Bearing Carriages and Guide Rails

With fewer moving parts and no need for lubrication, sleeve bearing carriages perform better in dusty and wet environments than ball and roller bearing carriages. They're also better at handling impact and vibration.

Carriages with polyethylene bearing have high impact strength and are more abrasion resistant than carriages with a PTFE bearing.

Note: Each carriage can only be used with its corresponding guide rail. Load capacity is diminished when carriages are mounted upside down or on a vertical surface.

Polyethylene Plastic Carriages and Bearings | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting | Ceramic-Coated Aluminum Guide Rails | ||||||||||||||

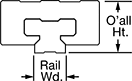

| For Rail Wd. | Static Load Cap., lbs. | O'all Ht. | Carriage Wd. | Carriage Lg. | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Dp. | Fasteners Included | Each | Rail Lengths | Per Inch | ||

| 1/2" | 100 | 9/16" | 1" | 1 1/4" | 180° | 4 | M3 | 0.5 | 5/16" | No | 9728K31 | 000000 | 9728K6 | 00000 | |

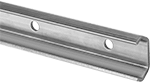

Side-Mount Sleeve Bearing Carriages and Guide Rails

C-shaped guide rails grip the carriage around the outside to support linear motion along walls and other vertical surfaces. Sleeve bearings allow them to outperform ball bearings in wet, dirty, and high-vibration environments.