About Moment Loads

More

Ball Bearing Carriages and Guide Rails

Operating with less friction than sleeve and roller bearing carriages, ball bearing carriages provide accurate movement and positioning in high-speed, high-load applications. However, they don’t hold up to dusty and wet environments as well as sleeve bearing carriages. Mount in any orientation without affecting load capacity. End seals keep lubricant in and dirt out. Add optional guide rail bellows to protect the rails from contaminants as carriages move across them.

Standard carriages are narrower than flanged carriages, making them better for confined spaces.

Flanged carriages have threaded mounting holes on the flanges rather than the carriage body, so you can fasten loads from both the top and bottom. When fastening from the bottom, use the mounting hole as a through-hole.

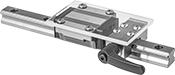

Add a hand brake to lock carriages in position. To install, fasten the brake to the same mounting surface as your carriage.

Mounting hole plugs protect mounting fasteners from corrosion. Carriage and guide rail systems for 5 mm-12 mm wide rails include mounting hole plugs with the guide rails.

Note: Each carriage can only be used with its corresponding guide rail.

For technical drawings and 3-D models, click on a part number.

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments). The mounting holes will be centered along the rail.

Carriages | Guide Rails | Made-to-Order Guide Rails | Hand Brakes | Mounting Hole Plugs | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

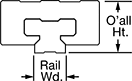

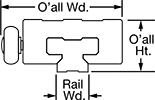

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Carriage Material | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | Each | |||||

Load Fastening From Top | |||||||||||||||||

| 20 | 4,450 | 30 | 44 | 74 | Steel | 0000000 | 0000000 | 0000000 | 00000 | 160-2,200 | 0000000 | 00000 | 000000 | 0000000 | 000000 | 00000 | |

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments). The mounting holes will be centered along the rail.

Carriages | Guide Rails | Made-to-Order Guide Rails | Hand Brakes | Mounting Hole Plugs | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Carriage Material | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | Each | |||||

Load Fastening From Top and From Bottom | |||||||||||||||||

| 20 | 4,400 | 30 | 63 | 74 | Steel | 0000000 | 0000000 | 0000000 | 00000 | 160-2,200 | 0000000 | 00000 | 000000 | 0000000 | 000000 | 00000 | |

Corrosion-Resistant Ball Bearing Carriages and Guide Rails

Made of stainless steel, these carriages and guide rails are more corrosion resistant than steel carriages and guide rails. Ball bearings provide accurate movement and positioning at high speeds under heavy loads. Mount in any orientation without affecting load capacity. End seals keep lubricant in and dirt out. Add guide rail bellows to protect rails from contaminants as carriages move across them.

Standard carriages are narrower than flanged carriages, making them better for confined spaces.

Flanged carriages have threaded mounting holes on the flanges rather than the carriage body, so you can fasten loads from both the top and bottom. When fastening from the bottom, use the mounting hole as a through-hole.

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments).

Mounting hole plugs protect mounting fasteners from corrosion.

Note: Each carriage can only be used with its corresponding guide rail.

For technical drawings and 3-D models, click on a part number.

440 Stainless Steel Carriages | 440 Stainless Steel Guide Rails | Made-to-Order 440 Stainless Steel Guide Rails | Mounting Hole Plugs | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | ||||

Load Fastening From Top | ||||||||||||||

| 20 | 2,300 | 28 | 42 | 76 | 0000000 | 0000000 | 0000000 | 00000 | 140-3,600 | 00000000 | 00000 | 00000000 | 00000 | |

Anti-Reflective Ultra-Corrosion-Resistant Ball Bearing Carriages and Guide Rails

A black chrome plating diffuses light, preventing reflecting light from causing equipment to malfunction. They're great for precision positioning systems that use photosensors or cameras, which are sensitive to light. The finish also resists rust two times better than 440 stainless steel alone. They have ball bearings, so they operate with less friction than sleeve and roller bearing carriages for accurate movement in high-speed, high-load applications. However, they don’t hold up to dusty and wet environments as well as sleeve bearings. These carriages have a standard profile that’s narrower than flanged carriages, making them better for confined spaces.

Note: Each carriage can only be used with its corresponding guide rail. Load capacity is diminished when carriages are mounted upside down or on a vertical surface.

For technical drawings and 3-D models, click on a part number.

Black Chrome-Plated 440 Stainless Steel Carriages and 440 Stainless Steel Bearings | Black Chrome-Plated 440 Stainless Steel Guide Rails | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Each | Rail Lengths, mm | Per mm | ||

Standard Carriages—Load Fastening From Top | |||||||||

| 20 | 1,450 | 20 | 40 | 50 | 0000000 | 0000000 | 0000000 | 00000 | |

Horizontal-Mount Ball Bearing Carriages and Guide Rails

Designed for use on horizontal surfaces, the contact angle of the ball bearings on the rail allows these carriages to last longer than other carriages. The ball bearings provide accurate movement and positioning at high speeds under heavy loads. End seals keep lubricant in and dirt out. Add guide rail bellows to protect rails from contaminants as carriages move across them.

Standard carriages are narrower than flanged carriages, making them better for confined spaces.

Flanged carriages have through-holes for access when fastening loads.

Add a hand brake to lock carriages in position. To install, fasten the brake to the same mounting surface as your carriage.

Mounting hole plugs protect mounting fasteners from corrosion.

For technical drawings and 3-D models, click on a part number.

For made-to-order guide rails, please specify the length (in 1 mm increments). The mounting holes will be centered along the rail.

Steel Carriages | Steel Guide Rails | Made-to-Order Steel Guide Rails | Hand Brakes | Mounting Hole Plugs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | Each | |||||

Load Fastening From Top | ||||||||||||||||

| 20 | 4,300 | 28 | 42 | 66 | 0000000 | 0000000 | 000000 | 00000 | 220-2,500 | 0000000 | 00000 | 000000 | 0000000 | 000000 | 00000 | |

For made-to-order guide rails, please specify the length (in 1 mm increments). The mounting holes will be centered along the rail.

Steel Carriages | Steel Guide Rails | Made-to-Order Steel Guide Rails | Hand Brakes | Mounting Hole Plugs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | Each | |||||

Load Fastening From Bottom | ||||||||||||||||

| 20 | 4,300 | 28 | 59 | 66 | 0000000 | 0000000 | 000000 | 00000 | 220-2,500 | 0000000 | 00000 | 000000 | 0000000 | 000000 | 00000 | |

Maintenance-Free Ball Bearing Carriages and Guide Rails

With an internal reservoir that continuously supplies grease, these carriages and guide rails are good for use in hard-to-reach places. Ball bearings provide accurate movement and positioning at high speeds under heavy loads. Mount in any orientation without affecting load capacity.

Standard carriages are narrower than flanged carriages, making them better for confined spaces.

Flanged carriages have threaded mounting holes on the flanges rather than the carriage body, so you can fasten loads from both the top and bottom. When fastening from the bottom, use the mounting hole as a through-hole.

Add a hand brake to lock carriages in position. To install, fasten the brake to the same mounting surface as your carriage.

Mounting hole plugs protect mounting fasteners from corrosion.

For technical drawings and 3-D models, click on a part number.

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments). The mounting holes will be centered along the rail.

Steel Carriages | Steel Guide Rails | Made-to-Order Steel Guide Rails | Hand Brakes | Mounting Hole Plugs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | Each | |||||

Load Fastening From Top | ||||||||||||||||

| 20 | 3,450 | 30 | 44 | 57 | 00000000 | 0000000 | 0000000 | 00000 | 230-2,500 | 0000000 | 00000 | 0000000 | 0000000 | 0000000 | 00000 | |

| 20 | 4,200 | 30 | 44 | 75 | 0000000 | 000000 | 0000000 | 000 | 230-2,500 | 0000000 | 000 | 0000000 | 000000 | 0000000 | 000 | |

| 20 | 6,650 | 30 | 44 | 91 | 00000000 | 000000 | 0000000 | 000 | 230-2,500 | 0000000 | 000 | 0000000 | 000000 | 0000000 | 000 | |

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments). The mounting holes will be centered along the rail.

Steel Carriages | Steel Guide Rails | Made-to-Order Steel Guide Rails | Hand Brakes | Mounting Hole Plugs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | Each | |||||

Load Fastening From Top and From Bottom | ||||||||||||||||

| 20 | 3,450 | 30 | 63 | 57 | 00000000 | 0000000 | 0000000 | 00000 | 230-2,500 | 0000000 | 00000 | 0000000 | 0000000 | 0000000 | 00000 | |

| 20 | 4,200 | 30 | 63 | 75 | 0000000 | 000000 | 0000000 | 000 | 230-2,500 | 0000000 | 000 | 0000000 | 000000 | 0000000 | 000 | |

| 20 | 6,650 | 30 | 63 | 91 | 00000000 | 000000 | 0000000 | 000 | 230-2,500 | 0000000 | 000 | 0000000 | 000000 | 0000000 | 000 | |

Corrosion-Resistant Maintenance-Free Ball Bearing Carriages and Guide Rails

Made of stainless steel, these carriages and guide rails are more corrosion resistant than steel carriages and guide rails. An internal reservoir continuously supplies grease for maintenance-free operation, making them great for hard-to-reach places. Ball bearings provide accurate movement and positioning at high speeds under heavy loads. Mount in any orientation without affecting load capacity. End seals keep lubricant in and dirt out.

Mounting hole plugs protect mounting fasteners from corrosion.

For technical drawings and 3-D models, click on a part number.

High-Cycle Ball Bearing Carriages and Guide Rails

A plastic cage surrounds the ball bearings and keeps them from colliding, so these carriages run for many cycles without needing maintenance. They also run quietly, since the bearings aren’t colliding. End seals keep dust from entering, and the cage traps lubricant around the bearings, reducing friction and heat buildup. Ball bearings provide accurate movement and positioning at high speeds under heavy loads. Mount in any orientation without affecting load capacity.

Standard carriages are narrower than flanged carriages, making them better for confined spaces.

Flanged carriages have threaded mounting holes on the flanges rather than the carriage body, so you can fasten loads from both the top and bottom. When fastening from the bottom, use the mounting hole as a through-hole.

Add a hand brake to lock carriages in position. To install, fasten the brake to the same mounting surface as your carriage.

Mounting hole plugs protect mounting fasteners from corrosion.

For technical drawings and 3-D models, click on a part number.

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments). The mounting holes will be centered along the rail.

Carriages | Steel Guide Rails | Made-to-Order Steel Guide Rails | Hand Brakes | Mounting Hole Plugs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | Each | |||||

Load Fastening From Top | ||||||||||||||||

| 20 | 5,000 | 30 | 44 | 79 | 0000000 | 0000000 | 0000000 | 00000 | 160-2,500 | 0000000 | 00000 | 0000000 | 0000000 | 000000 | 00000 | |

| 20 | 6,300 | 30 | 44 | 98 | 00000000 | 000000 | 0000000 | 000 | 160-2,500 | 0000000 | 000 | 0000000 | 000000 | 000000 | 000 | |

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments). The mounting holes will be centered along the rail.

Carriages | Steel Guide Rails | Made-to-Order Steel Guide Rails | Hand Brakes | Mounting Hole Plugs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | Each | |||||

Load Fastening From Top and From Bottom | ||||||||||||||||

| 20 | 5,000 | 30 | 63 | 79 | 0000000 | 0000000 | 0000000 | 00000 | 160-2,500 | 0000000 | 00000 | 0000000 | 0000000 | 000000 | 00000 | |

| 20 | 6,300 | 30 | 63 | 98 | 00000000 | 000000 | 0000000 | 000 | 160-2,500 | 0000000 | 000 | 0000000 | 000000 | 000000 | 000 | |

Clean Room Ball Bearing Carriages and Guide Rails

Suitable for clean room use, these carriages and guide rails are made entirely of stainless steel. Ball bearings provide accurate movement and positioning at high speeds under heavy loads. Mount in any orientation without affecting load capacity. End seals keep lubricant in and dirt out.

Standard carriages are narrower than flanged carriages, making them better for confined spaces.

Flanged carriages have threaded mounting holes on the flanges rather than the carriage body, so you can fasten loads from both the top and bottom. When fastening from the bottom, use the mounting hole as a through-hole.

Add mounting hole plugs to protect mounting fasteners from corrosion.

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments). The mounting holes will be centered along the rail.

For technical drawings and 3-D models, click on a part number.

440 Stainless Steel Carriages | 440 Stainless Steel Guide Rails | Made-to-Order 440 Stainless Steel Guide Rails | Mounting Hole Plugs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Environmental Rating | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | ||||

Load Fastening From Top | |||||||||||||||

| 20 | 1,000 | 20 | 40 | 38 | Fed. Std. Class 1,000; ISO Class 6 | 00000000 | 0000000 | 0000000 | 00000 | 120-900 | 0000000 | 00000 | 00000000 | 00000 | |

| 20 | 1,450 | 20 | 40 | 50 | Fed. Std. Class 1,000; ISO Class 6 | 000000 | 000000 | 0000000 | 000 | 120-900 | 0000000 | 000 | 00000000 | 0000 | |

| 20 | 1,900 | 20 | 40 | 68 | Fed. Std. Class 1,000; ISO Class 6 | 00000000 | 000000 | 0000000 | 000 | 120-900 | 0000000 | 000 | 00000000 | 0000 | |

440 Stainless Steel Carriages | 440 Stainless Steel Guide Rails | Mounting Hole Plugs | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Environmental Rating | Each | Rail Lengths, mm | Per mm | Each | |||

Load Fastening From Top and From Bottom | ||||||||||||

| 20 | 5,000 | 30 | 63 | 79 | Fed. Std. Class 10,000; ISO Class 7 | 00000000 | 0000000 | 0000000 | 00000 | 000000 | 00000 | |

Horizontal-Mount Quiet-Ride Ball Bearing Carriages and Guide Rails

Designed for use on horizontal surfaces, the contact angle of the ball bearings on the rail allows these carriages to last longer than other carriages. The ball bearings operate with less friction than sleeve and roller bearing carriages to provide accurate movement and positioning at high speeds under heavy loads. However, they’re worse than sleeve bearings in dusty and wet environments. A plastic cage separates the ball bearings to minimize noise, reduce heat buildup, and eliminate ball collisions. End seals keep lubricant in and dirt out.

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments). The mounting holes will be centered along the rail.

Add a hand brake to lock carriages in position. To install, fasten the brake to the same mounting surface as your carriage.

Mounting hole plugs protect mounting fasteners from corrosion.

For technical drawings and 3-D models, click on a part number.

Steel Carriages | Steel Guide Rails | Made-to-Order Steel Guide Rails | Hand Brakes | Mounting Hole Plugs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Each | Rail Lengths, mm | Per mm | Rail Lengths, mm | Per mm | Each | Each | |||||

Load Fastening From Top | ||||||||||||||||

| 20 | 4,400 | 28 | 42 | 67 | 0000000 | 0000000 | 000000 | 00000 | 220-2,500 | 0000000 | 00000 | 000000 | 0000000 | 000000 | 00000 | |

Sleeve Bearing Carriages and Guide Rails

With fewer moving parts and no need for lubrication, sleeve bearing carriages perform better in dusty and wet environments than ball and roller bearing carriages. They're also better at handling impact and vibration.

Carriages with PTFE bearing operate with less friction than carriages with a polyethylene bearing.

Note: Each carriage can only be used with its corresponding guide rail. Load capacity is diminished when carriages are mounted upside down or on a vertical surface.

For technical drawings and 3-D models, click on a part number.

Aluminum Carriages and PTFE Plastic Bearings | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting | Anodized Aluminum Guide Rails | ||||||||||||||

| For Rail Wd., mm | Static Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Dp., mm | Fasteners Included | Each | Rail Lengths, mm | Per mm | ||

| 20 | 1,650 | 30 | 63 | 81 | 190° | 4 | M6 | 1 | 19.8 | No | 000000 | 000000 | 0000000 | 00000 | |

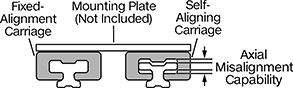

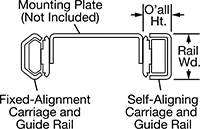

Self-Aligning Sleeve Bearing Carriages and Guide Rails

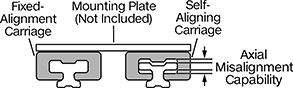

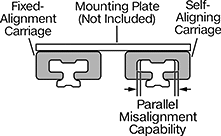

A floating bearing in these self-aligning carriages adjusts to compensate for misalignment between rails, so your carriages still move in tandem. For a complete system, you’ll need a self-aligning carriage and rail on one side and a fixed-alignment carriage and rail on the other (all sold separately).

Carriages for axial rail misalignment compensate when the rails aren’t installed at the same exact height.

Carriages for parallel rail misalignment compensate when one rail is straight and the other is installed at a slight angle.

Note: Each carriage can only be used with its corresponding guide rail. Load capacity is diminished when carriages are mounted upside down or on a vertical surface.

For technical drawings and 3-D models, click on a part number.

Aluminum Carriages and PTFE Plastic Bearings | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting | Anodized Aluminum Guide Rails | |||||||||||||||

| For Rail Wd., mm | Static Load Cap., lbs. | Axial Misalignment Capability, mm | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Dp., mm | Fasteners Included | Each | Rail Lengths, mm | Per mm | ||

| 20 | 1,650 | 0.5 | 30 | 63 | 81 | 190° | 4 | M6 | 1 | 19.8 | No | 0000000 | 000000 | 0000000 | 00000 | |

Aluminum Carriages and PTFE Plastic Bearings | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting | Anodized Aluminum Guide Rails | |||||||||||||||

| For Rail Wd., mm | Static Load Cap., lbs. | Parallel Misalignment Capability, mm | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Dp., mm | Fasteners Included | Each | Rail Lengths, mm | Per mm | ||

| 20 | 1,650 | 0.5 | 30 | 63 | 81 | 190° | 4 | M6 | 1 | 19.8 | No | 0000000 | 000000 | 0000000 | 00000 | |

Aluminum Carriages and PTFE Plastic Bearings | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting | Anodized Aluminum Guide Rails | ||||||||||||||

| For Rail Wd., mm | Static Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Dp., mm | Fasteners Included | Each | Rail Lengths, mm | Per mm | ||

| 20 | 1,650 | 30 | 63 | 81 | 190° | 4 | M6 | 1 | 19.8 | No | 000000 | 000000 | 0000000 | 00000 | |

Locking Sleeve Bearing Carriages and Guide Rails

A handle on the side of the carriage locks the carriage in place. With fewer moving parts and no need for lubrication, sleeve bearing carriages perform better in dusty and wet environments than ball and roller bearing carriages. They're also better at handling impact and vibration.

Note: Load capacity is diminished when carriages are mounted upside down or on a vertical surface.

For technical drawings and 3-D models, click on a part number.

Aluminum Carriages and PTFE Plastic Bearings | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting | Anodized Aluminum Guide Rails | ||||||||||||||||

| For Rail Wd., mm | Static Load Cap., lbs. | O'all Wd., mm | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Handle Dia., mm | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Dp., mm | Fasteners Included | Each | Rail Lengths, mm | Per mm | ||

| 20 | 1,650 | 80 | 30 | 63 | 81 | 28 | 190° | 4 | M6 | 1 | 19.8 | No | 000000 | 000000 | 0000000 | 00000 | |

Self-Aligning Locking Sleeve Bearing Carriages and Guide Rails

Create a self-aligning system that can be locked in place with these carriages and guide rails. The floating bearing in these self-aligning carriages compensates for misalignment, so carriages will still move in tandem even if the rails aren’t installed at the same exact height. A complete system includes a self-aligning carriage and rail on one side and a fixed-alignment carriage and rail on the other (all sold separately).

Note: Each carriage can only be used with its corresponding guide rail. Load capacity is diminished when carriages are mounted upside down or on a vertical surface.

For technical drawings and 3-D models, click on a part number.

Aluminum Carriages and PTFE Plastic Bearings | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting | Anodized Aluminum Guide Rails | ||||||||||||||||

| For Rail Wd., mm | Static Load Cap., lbs. | Axial Misalignment Capability, mm | O'all Wd., mm | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Dp., mm | Fasteners Included | Each | Rail Lengths, mm | Per mm | ||

| 20 | 1,650 | 1 | 80 | 30 | 63 | 81 | 190° | 4 | M6 | 1 | 19.8 | No | 0000000 | 0000000 | 0000000 | 00000 | |

Aluminum Carriages and PTFE Plastic Bearings | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting | Anodized Aluminum Guide Rails | |||||||||||||||

| For Rail Wd., mm | Static Load Cap., lbs. | O'all Wd., mm | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Dp., mm | Fasteners Included | Each | Rail Lengths, mm | Per mm | ||

| 20 | 1,650 | 80 | 30 | 63 | 81 | 190° | 4 | M6 | 1 | 19.8 | No | 000000 | 000000 | 0000000 | 00000 | |

High-Temperature Sleeve Bearing Carriages and Guide Rails

Use these carriages and guide rails in temperatures up to 300° F. The sleeve bearings allow them to outperform ball bearings carriages in wet, dirty, and high-vibration environments.

Note: Load capacity is diminished when carriages are mounted upside down or on a vertical surface.

For technical drawings and 3-D models, click on a part number.

Aluminum Carriages and Frelon Plastic Bearings | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting | Anodized Aluminum Guide Rails | ||||||||||||||

| For Rail Wd., mm | Static Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Dp., mm | Fasteners Included | Each | Rail Lengths, mm | Per mm | ||

| 20 | 1,350 | 25 | 46 | 62 | 300° | 4 | M4 | 0.7 | 12.5 | No | 000000 | 000000 | 0000000 | 00000 | |

Self-Aligning Side-Mount Track Roller Carriages and Guide Rails

Create a self-aligning carriage and guide rail system to compensate for mounting surfaces that aren't parallel. The floating bearing in these carriages adjusts to correct misalignment between rails, so your carriages still move in tandem. A complete system includes a fixed-alignment carriage and rail on one side and a self-aligning carriage and rail on the other. All components are sold separately.

Carriages can be adjusted for a snug or loose fit on the rail (also known as preload). They have permanently lubricated rollers to save maintenance time and effort.

Fixed-alignment rails have a C-shaped profile that ensures the system travels in a straight line.

Self-aligning rails have a rectangular profile that allows the carriage to move freely from side to side to compensate for misalignment.

For technical drawings and 3-D models, click on a part number.

Aluminum Carriages with Plastic Wipers and Adjustable Acetal Plastic Rollers | Aluminum Guide Rails | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Roller Dia., mm | Axial Misalignment Capability, mm | Max. Temp., °F | Each | Rail Lengths, mm | Per mm | ||

Fixed Alignment | ||||||||||

| 20 | 12 | 22 | 14.83 | __ | 245° | 00000000 | 0000000 | 0000000 | 00000 | |

Self Aligning | ||||||||||

| 20 | 12 | 23.09 | 14.83 | 1.09 | 245° | 00000000 | 000000 | 0000000 | 000 | |

Roller Bearing Carriages and Guide Rails

With a larger contact area than ball bearing carriages, roller bearing carriages provide better positioning accuracy and support heavier loads. Mount in any orientation without affecting load capacity.

Standard carriages are narrower than flanged carriages, making them better for confined spaces.

Flanged carriages have threaded mounting holes on the flanges rather than the carriage body, so you can fasten loads from both the top and bottom. When fastening from the bottom, use the mounting hole as a through-hole.

For technical drawings and 3-D models, click on a part number.

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments). The mounting holes will be centered along the rail.

For made-to-order guide rails, please specify the length of the rail (in 1 mm increments). The mounting holes will be centered along the rail.