About Hammers

More

About Plastic Hammer Faces

More

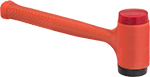

High-Visibility Replaceable-Face Dead Blow Mallets

Change the faces out when worn rather than replacing the entire tool. A fluorescent orange color makes these mallets easy to see. All have a head loaded with metal shot for added weight and a controlled impact with minimal rebound. Use them to drive chisels and strike work without damaging its surface. Often used on plastic, wood, and sheet metal, the polyurethane rubber faces resist oils and solvents and won't crack under high impact. The medium-hard face has a hardness similar to that of a plastic cutting board; the extra-hard face has a hardness similar to that of a hard hat. Use a face that's softer than your workpiece to avoid marring. Lighter weight mallets are good for tapping work into place and driving a chisel to make small cuts. Choose heavier weight mallets for assembling joints, dislodging stuck parts, and making aggressive cuts with a chisel. Longer mallets allow for more powerful swings. A textured grip provides slip resistance.

Face | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Head Wt. | Face Dia. | Face Hardness Rating (Face Color) | Pipe Size | Thread Type | Overall Lg. | Handle Material | Grip Style | Handle Replaceable | Each | |

Polyurethane Rubber Face | ||||||||||

| 7 lbs. | 2 7/8" | Medium Hard (Red) × Extra Hard (Black) | 1 1/2 | NPT | 19 1/4" | Polyurethane Rubber with Steel Core | Textured | Nonreplaceable | 0000000 | 0000000 |

Extra-soft faces have a hardness similar to that of a pencil eraser.

Soft faces have a hardness similar to that of a tire tread.

Medium faces have a hardness that's suitable for most general purpose applications.

Medium-hard faces have a hardness similar to that of a plastic cutting board.

Hard faces have a hardness similar to that of a bowling ball.

Extra-hard faces have a hardness similar to that of a hard hat.

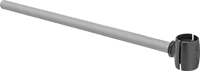

Create-Your-Own Sledge Hammers

Swing these long, heavy hammers with both hands to demolish material, form metal, and drive punches, chisels, and masonry drills. Mix faces of different materials or hardnesses to create the perfect striking tool. For demolition work, choose faces that are harder than your workpiece. The head has two pieces that clamp together to grip faces tightly.

Bodies consist of a head, nut, and handle. To assemble, loosen the nut under the head, insert the faces, and tighten the nut.

Rubber faces are softer than metal faces, so they're good for sheet metal work. All have a face hardness rating for comparing their hardness with other rubber and plastic faces.

Hard faces have a hardness similar to that of a bowling ball.

| Face Dia. | Face Hardness Rating | Face Color | Each | |

| 2 3/4" | Hard | Off-White | 0000000 | 000000 |

Plastic faces are softer than metal faces, so they're good for sheet metal work. All have a face hardness rating for comparing their hardness with other rubber and plastic faces.

Extra-hard faces have a hardness similar to that of a hard hat.

| Face Dia. | Face Hardness Rating | Face Color | Each | |

| 2 3/4" | Extra Hard | Yellow | 0000000 | 000000 |

Rawhide faces are more durable than plastic and won't distort the surface of soft sheet metal, such as brass, aluminum, and copper.

| Face Dia. | Each | |

| 2 3/4" | 0000000 | 000000 |