Filter by

Mount Type

Projection

Width

Handle Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Maximum Temperature

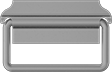

Weld-On-Mount Pull Handles

Grip | Mounting Plate | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Dia. | Ht. | Thk. | Projection | Pull Cap. | Ht. | Wd. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 1—Round Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

300 Series Stainless Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 1/2" | — | — | 2 1/16" | Not Rated | — | — | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | 1/2" | — | — | 2 1/16" | Not Rated | — | — | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 1/2" | — | — | 2 1/16" | Not Rated | — | — | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 1/2" | — | — | 2 15/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 1/2" | — | — | 4 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | 1/2" | — | — | 2 15/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | 1/2" | — | — | 4 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | 5/8" | — | — | 3 3/8" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | 5/8" | — | — | 4 15/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 1/2" | — | — | 2 15/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 1/2" | — | — | 4 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 5/8" | — | — | 3 3/8" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 5/8" | — | — | 4 15/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 13/16" | 5/8" | — | — | 3 3/8" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 13/16" | 5/8" | — | — | 4 15/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 5/16" | — | — | 1 3/8" | Not Rated | — | — | 000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 7/16" | 5/16" | — | — | 1 3/8" | Not Rated | — | — | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 15/16" | 5/16" | — | — | 1 3/8" | Not Rated | — | — | 000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 15/16" | 3/8" | — | — | 1 11/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 3/8" | — | — | 1 11/16" | Not Rated | — | — | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 5/8" | — | — | 2 5/16" | Not Rated | — | — | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | 3/8" | — | — | 1 11/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | 5/8" | — | — | 2 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 5/8" | — | — | 2 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 13/16" | — | — | 2 11/16" | Not Rated | — | — | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 7/8" | 13/16" | — | — | 2 11/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 5/16" | — | — | 1 3/8" | Not Rated | — | — | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 7/16" | 5/16" | — | — | 1 3/8" | Not Rated | — | — | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 15/16" | 5/16" | — | — | 1 3/8" | Not Rated | — | — | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 15/16" | 3/8" | — | — | 1 11/16" | Not Rated | — | — | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 3/8" | — | — | 1 11/16" | Not Rated | — | — | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 1/2" | — | — | 2" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 5/8" | — | — | 2 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | 3/8" | — | — | 1 11/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | 1/2" | — | — | 2" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | 5/8" | — | — | 2 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 1/2" | — | — | 2" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 5/8" | — | — | 2 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 13/16" | — | — | 2 11/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 1" | — | — | 4 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 7/8" | 13/16" | — | — | 2 11/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 7/8" | 1" | — | — | 4 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 13/16" | 13/16" | — | — | 3 9/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 13/16" | 1" | — | — | 4 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 13/16" | 1 3/16" | — | — | 5 1/8" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 13/16" | 1 3/16" | — | — | 5 1/8" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 3/4" | 13/16" | — | — | 3 9/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 3/4" | 1" | — | — | 4 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 3/4" | 1 3/16" | — | — | 5 1/8" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 11/16" | 1" | — | — | 4 5/16" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 11/16" | 1 3/16" | — | — | 5 1/8" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 23 5/8" | 1 3/16" | — | — | 5 1/8" | Not Rated | — | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 2—Round Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13" | 1/2" | — | — | 2 1/16" | Not Rated | 11/16" | 1 3/4" | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel—Polished | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 1/2" | 5/8" | — | — | 2 5/8" | Not Rated | 1" | 2 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 13/16" | 1/2" | — | — | 2 1/8" | Not Rated | 3/4" | 1 7/8" | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1010-1018 Low-Carbon Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13" | 1/2" | — | — | 2 1/16" | Not Rated | 11/16" | 1 3/4" | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1010-1018 Low-Carbon Steel—Polished | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 1/2" | 5/8" | — | — | 2 5/8" | Not Rated | 1" | 2 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 1/2" | 5/8" | — | — | 2 5/8" | Not Rated | 1" | 2 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 1/2" | 5/8" | — | — | 2 5/8" | Not Rated | 1" | 2 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 1/2" | 5/8" | — | — | 2 5/8" | Not Rated | 1" | 2 1/4" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 3—Oval Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 3 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 3/4" | — | 5/8" | 7/16" | 1 1/4" | Not Rated | 1 9/16" | 7/8" | 000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | — | 13/16" | 1/2" | 1 1/2" | Not Rated | 1 5/8" | 15/16" | 000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1010-1018 Low-Carbon Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 3/4" | — | 5/8" | 7/16" | 1 1/4" | Not Rated | 1 1/2" | 7/8" | 000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1020 Low-Carbon Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/16" | — | 13/16" | 1/2" | 1 1/2" | Not Rated | 1 5/8" | 15/16" | 000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

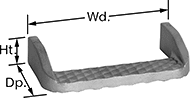

Weld-On-Mount Folding Pull Handles with Mounting Plate

Mounting Plate | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Folding Angle | Grip Dia. | Handle Wd. | Projection | Pull Cap., lbf | Ht. | Wd. | Thk. | 1-49 | 50-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 1—Round Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90° | 5/16" | 3 1/2" | 2 1/4" | 325 | 1 3/4" | 3 3/8" | 1/16" | 0000000 | 000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1008 Low-Carbon Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90° | 5/16" | 3 7/8" | 3" | 325 | 2 7/8" | 3 3/8" | 1/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90° | 5/16" | 4" | 2 1/2" | 325 | 1 3/4" | 3 3/8" | 1/16" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90° | 5/16" | 4" | 2 1/2" | 325 | 2 7/8" | 3 3/8" | 1/32" | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90° | 3/8" | 5 1/8" | 3 1/4" | 350 | 2 5/8" | 4" | 1/16" | 00000000 | 00000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 2—Round Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120° | 1/4" | 2 15/16" | 1 13/16" | Not Rated | 1 3/8" | 3 1/2" | 1/16" | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

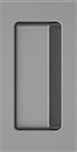

Weld-On-Mount Recessed Pull Handles

|

For Panel Cutout, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht., mm | Wd., mm | Back Projection, mm | Ht. | Wd. | Pull Cap. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 122 | 62 | 16 | 90 | 40 | Not Rated | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spring Handles

Style 1 |

Style 2 |

Style | For Rod Dia. | Lg. | Max. Dia. | Mount Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3/8" | 2 1/2" | 1" | Slide On, Weld On | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3/8" | 2 1/2" | 1 1/4" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/2" | 3 3/8" | 1 1/2" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/2" | 3 1/2" | 1 3/4" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/2" | 4 1/4" | 1 1/2" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2" | 4 1/4" | 1 1/4" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2" | 4 1/2" | 1 1/2" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2" | 5 3/4" | 1 1/2" | Slide On, Weld On | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3/8" | 2 1/2" | 1 1/8" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3/8" | 2 1/2" | 1 1/4" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/2" | 3 3/8" | 1 1/2" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/2" | 3 1/2" | 1 3/4" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/2" | 4 1/4" | 1 1/4" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/2" | 4 1/4" | 1 1/2" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2" | 4 1/2" | 1 1/2" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2" | 5 3/4" | 1 1/2" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3/8" | 2 1/2" | 1" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/2" | 3 1/2" | 1 3/4" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/2" | 4 1/4" | 1 1/2" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2" | 4 1/2" | 1 1/2" | Slide On, Weld On | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2" | 5 3/4" | 1 1/2" | Slide On, Weld On | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Curved Weld-On-Mount Folding Pull Handles with Mounting Plate

Mounting Plate | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Folding Angle | For Drum Dia. | Grip Dia. | Handle Wd. | Projection | Pull Cap. | Ht. | Wd. | Thk. | Mounting Fasteners Included | Min. | Max. | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel with Nylon Grip—Dull | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90° | 23 1/2" | 13/16" | 5 1/2" | 5/8" | Not Rated | 2 1/8" | 4" | 1/16" | No | 20 | 390 | 0000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90° | 23 1/2" | 13/16" | 5 1/2" | 11/16" | Not Rated | 2 1/8" | 4" | 1/16" | No | 20 | 390 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90° | 23 1/2" | 13/16" | 5 1/2" | 3/4" | Not Rated | 2 1/8" | 4" | 1/16" | No | 20 | 390 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

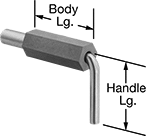

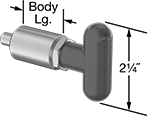

T-Handle Weld-On Retractable Spring Plungers

|

Spring Plungers | Replacement Barrel Sleeves | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Body | Handle | Nonlocking | Twist-to-Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Lg. | Dia. | Material | Wd. | Lg. | Material | Lg. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.25" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 2.25" | Plastic | 2 1/4" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 4.5" | Plastic | 2 1/4" | 000000000 | 00000 | ——— | 0 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | Steel | 1" | 2.25" | Plastic | 2 1/4" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.375" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 000000000 | 00000 | ——— | 0 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.5" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 000000000 | 00000 | ——— | 0 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.5" | Steel | 1" | 3" | Plastic | 2 1/4" | 000000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.685" | 0.5" | Steel | 1" | 1.5" | Plastic | 2 1/4" | ——— | 0 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.688" | 0.5" | Steel | 1" | 1.5" | Plastic | 2 1/4" | 000000000 | 00000 | ——— | 0 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 2 1/4" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 2 1/4" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 2 1/4" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 2 1/4" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Step Handles

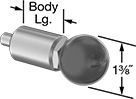

Ball-Grip Weld-On Retractable Spring Plungers

|

Spring Plungers | Replacement Barrel Sleeves | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Body | Handle | Nonlocking | Twist-to-Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Lg. | Dia. | Material | Wd. | Lg. | Material | Lg. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.25" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 2.25" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 4.5" | Plastic | 1 3/8" | 000000000 | 00000 | ——— | 0 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | Steel | 1" | 2.25" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.375" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | ——— | 0 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.375" | Steel | 1" | 3" | Plastic | 1 3/8" | 000000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.625" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | ——— | 0 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.688" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 1 3/8" | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

L-Handle Weld-On Retractable Spring Plungers

Spring Plungers | Weld-On Catches | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Nose Force, lbf | Body | Handle | Nonlocking | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Lg. | Dia. | Extended | Compressed | Material | Wd. | Lg. | Material | Lg. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.38" | 0.16" | 0.5 | 2.5 | Steel | 0.25" | 0.88" | Steel | 3/4" | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.56" | 0.24" | 0.8 | 3.8 | Steel | 0.375" | 1.47" | Steel | 1" | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.75" | 0.32" | 1 | 5 | Steel | 0.5" | 1.42" | Steel | 1 3/8" | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.38" | 1 | 5 | Steel | 0.625" | 2.11" | Steel | 1 3/8" | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.38" | 0.16" | 0.5 | 2.5 | 18-8 Stainless Steel | 0.25" | 0.88" | 18-8 Stainless Steel | 3/4" | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.56" | 0.24" | 3.8 | 3.8 | 18-8 Stainless Steel | 0.375" | 1.47" | 18-8 Stainless Steel | 1" | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.75" | 0.32" | 1 | 5 | 18-8 Stainless Steel | 0.5" | 1.42" | 18-8 Stainless Steel | 1 3/8" | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.38" | 1 | 5 | 18-8 Stainless Steel | 0.625" | 2.11" | 18-8 Stainless Steel | 1 3/8" | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||