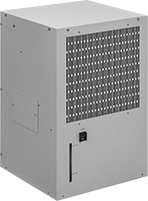

Heat Sinks with Internal Pump for Water

To provide a more consistent flow of cooled water than other heat sinks for water, these have a built-in pump and reservoir. The internal fan-cooled heat exchanger dissipates heat. Btu/hr. cooling capacity is based on water with an initial temperature difference of 77° F.

Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Pipe Size | Thread Type | Gender | Ht. | Wd. | Dp. | Heat Sink Material | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | Voltage (Electrical Phase) | Current | NEMA Style | Cord Lg., ft. | Each | |

For Use with Water, Noncorrosive Liquids | ||||||||||||||||

| 12,000 | 1/2 | NPT | Female | 24" | 15" | 15" | Copper | 60 | 1.8 | 130° | 120V AC (Single) | 5.8A | 5-15 | 8 | 00000000 | 000000000 |

Heat Sinks for Oil

Dozens of fins and coolant tubes quickly dissipate excess heat. Also known as oil coolers, these heat sinks cool hydraulic fluid and lubricating oil in cylinders and compressors. Cooling and flow capacities are based on 50 SSU oil, 1,000 feet per minute of air, a 50° F initial temperature difference, and a 10 psi pressure drop.

Heat sinks with a bypass prevent damage to the cooling fins by diverting pressurized oil. They’re often used in machines that are started up while cold. Once the oil heats up and the pressure drops, flow through the cooling tubes resumes.

Mounting kits (sold separately) are required for installation.

Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Cap., Btu/hr. | Pipe Size | Thread Type | Gender | Ht. | Wd. | Dp. | Heat Sink Material | Max. Pressure, psi | Max. Flow Rate, gpm | Max. Temp., °F | No. of Mount. Kits Required | Each | |

Copper Tube—For Use with Oil | |||||||||||||

| 3,300 | 1/2 | NPT | Female | 4 1/2" | 15" | 1 1/2" | Aluminum | 300 | 7 | 350° | 2 | 0000000 | 0000000 |

| 6,100 | 1/2 | NPT | Female | 6 1/2" | 18" | 1 1/2" | Aluminum | 300 | 9 | 350° | 4 | 0000000 | 000000 |

| 8,100 | 1/2 | NPT | Female | 6 1/2" | 24" | 1 1/2" | Aluminum | 300 | 7 | 350° | 4 | 0000000 | 000000 |

| 9,600 | 1/2 | NPT | Female | 8 1/2" | 21" | 1 1/2" | Aluminum | 300 | 11 | 350° | 4 | 0000000 | 000000 |

Copper Tube with Bypass—For Use with Oil | |||||||||||||

| 3,400 | 1/2 | NPT | Female | 4 1/2" | 15" | 1 1/2" | Aluminum | 300 | 7 | 350° | 2 | 00000000 | 000000 |

| 6,300 | 1/2 | NPT | Female | 6 1/2" | 18 1/4" | 1 1/2" | Aluminum | 300 | 9 | 350° | 4 | 00000000 | 000000 |

| 10,000 | 1/2 | NPT | Female | 8 1/2" | 21" | 1 1/2" | Aluminum | 300 | 11 | 350° | 4 | 00000000 | 000000 |

| Includes | Each | |

| Two Carriage Bolts, Two Flat Washers, Two Lock Washers, Two Nuts, Two Rubber Blocks | 0000000 | 000000 |

Heat Exchangers for Sampling

Often used to monitor boiler water quality without shutting down the system, these heat exchangers cool hot liquid samples to safe temperatures for testing. Sample liquid flows through the tubes, and cold water from an external water supply flows around the tubes to cool the liquid in the tubes. Cooled sample water then flows out of the heat exchanger for analysis.

304 stainless steel tubes are more corrosion resistant than copper tubes.

Heat exchangers with 1.3 or 1.64 sq. ft. surface area are often used for sampling liquid from a boiler.

Shell-Side | Tube-Side | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Surface Area, sq. ft. | Pipe Size | Thread Type | Gender | Flow Cap., gpm | Max. Pressure, psi | Max. Temp., °F | Pipe Size | Thread Type | Gender | Flow Cap., gpm | Max. Pressure, psi | Max. Temp., °F | Lg. | Head Dia. | Each | |

Steel Shell and Copper Tube | ||||||||||||||||

| 1.64 | 1/2 | NPT | Female | Not Rated | 250 | 650° | 1/4 | NPT | Male | Not Rated | 300 | 400° | 19" | 7" | 0000000 | 0000000 |

Steel Shell and 304 Stainless Steel Tube | ||||||||||||||||

| 1.64 | 1/2 | NPT | Female | Not Rated | 250 | 650° | 1/4 | NPT | Male | Not Rated | 900 | 750° | 19" | 7" | 0000000 | 000000 |