Filter by

Length

Electrical Connection

Heat Cable Type

Watt Density

Maximum Temperature

Temperature Control Type

Cable Cover Material

Current

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Self-Regulating Heating Tape for Pipes and Tubes

Watt Density, W/ft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., ft. | Wattage, W | @40°F | @80°F | @100°F | Current, amp | Wd. | Thk. | Environment Temp. Range, ° F | NEMA Type | Cord Lg., ft. | Cable Cover Material | For Surface Material | For Use Outdoors | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 36 | 6 | 3 | 1.5 | 0.15 | 7/16" | 1/4" | -40 to 150 | — | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 72 | 6 | 3 | 1.5 | 0.3 | 7/16" | 1/4" | -40 to 150 | — | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 108 | 6 | 3 | 1.5 | 0.45 | 7/16" | 1/4" | -40 to 150 | — | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 144 | 6 | 3 | 1.5 | 0.6 | 7/16" | 1/4" | -40 to 150 | — | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plug In—Straight Blade | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 36 | 6 | 3 | 1.5 | 0.3 | 7/16" | 1/4" | -40 to 150 | 5-15 | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 72 | 6 | 3 | 1.5 | 0.6 | 7/16" | 1/4" | -40 to 150 | 5-15 | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 108 | 6 | 3 | 1.5 | 0.9 | 7/16" | 1/4" | -40 to 150 | 5-15 | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 144 | 6 | 3 | 1.5 | 1.2 | 7/16" | 1/4" | -40 to 150 | 5-15 | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 300 | 6 | 3 | 1.5 | 2.5 | 7/16" | 1/4" | -40 to 150 | 5-15 | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75 | 450 | 6 | 3 | 1.5 | 3.75 | 7/16" | 1/4" | -40 to 150 | 5-15 | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 600 | 6 | 3 | 1.5 | 5 | 7/16" | 1/4" | -40 to 150 | 5-15 | 6 | Rubber | Metal, Plastic | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

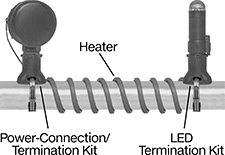

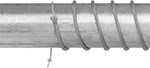

Cut-to-Length Self-Regulating Heating Tape for Pipes and Tubes

Heating Tape

Watt Density, W/ft | Per Ft. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

@50°F | @100°F | @150°F | Wd. | Thk. | Max. Lg., ft. | Environment Temp. Range, ° F | Electrical Connection Type | For Surface Material | For Use Outdoors | 1-99 | 100-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150° F Maximum Heat Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1 | 0.5 | 1/2" | 3/16" | 500 | -60 to 185 | Hardwire | Metal, Plastic | No | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 2.5 | 1 | 1/2" | 3/16" | 500 | -60 to 185 | Hardwire | Metal, Plastic | No | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 4.5 | 1.7 | 1/2" | 3/16" | 500 | -60 to 185 | Hardwire | Metal, Plastic | No | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 5.5 | 2 | 1/2" | 3/16" | 500 | -60 to 185 | Hardwire | Metal, Plastic | No | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1 | 0.5 | 1/2" | 3/16" | 500 | -60 to 185 | Hardwire | Metal, Plastic | No | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 2.5 | 1 | 1/2" | 3/16" | 500 | -60 to 185 | Hardwire | Metal, Plastic | No | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 4.5 | 1.7 | 1/2" | 3/16" | 500 | -60 to 185 | Hardwire | Metal, Plastic | No | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 5.5 | 2 | 1/2" | 3/16" | 500 | -60 to 185 | Hardwire | Metal, Plastic | No | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Cable Cover

Watt Density, W/ft | Per Ft. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

@50°F | @100°F | @150°F | Wd. | Thk. | Max. Lg., ft. | Environment Temp. Range, ° F | Electrical Connection Type | For Surface Material | Hazardous Location Rating | For Use Outdoors | 1-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150° F Maximum Heat Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1.5 | 0.2 | 9/16" | 1/4" | 500 | -60 to 185 | Hardwire | Metal, Plastic | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 0000000 | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 2.5 | 1 | 9/16" | 1/4" | 500 | -60 to 185 | Hardwire | Metal, Plastic | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 0000000 | 00000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 4.5 | 1.8 | 9/16" | 1/4" | 500 | -60 to 185 | Hardwire | Metal, Plastic | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 0000000 | 00000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 5.7 | 2.1 | 9/16" | 1/4" | 500 | -60 to 185 | Hardwire | Metal, Plastic | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 0000000 | 00000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 4.5 | 1.8 | 9/16" | 1/4" | 500 | -60 to 185 | Hardwire | Metal, Plastic | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 0000000 | 00000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 5.7 | 2.1 | 9/16" | 1/4" | 500 | -60 to 185 | Hardwire | Metal, Plastic | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 0000000 | 00000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

250° F Maximum Heat Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | — | 6 | 7/16" | 1/4" | 500 | -75 to 400 | Hardwire | Metal, Plastic | Ex Eb IIC Ex Tb IIIC NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA AEx Eb IIC Gb AEx Tb IIIC Db | No | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | — | 8.5 | 7/16" | 1/4" | 500 | -75 to 400 | Hardwire | Metal, Plastic | Ex Eb IIC Ex Tb IIIC NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA AEx Eb IIC Gb AEx Tb IIIC Db | No | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | — | 11 | 7/16" | 1/4" | 500 | -75 to 400 | Hardwire | Metal, Plastic | Ex Eb IIC Ex Tb IIIC NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA AEx Eb IIC Gb AEx Tb IIIC Db | No | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | — | 15 | 7/16" | 1/4" | 500 | -75 to 400 | Hardwire | Metal, Plastic | Ex Eb IIC Ex Tb IIIC NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA AEx Eb IIC Gb AEx Tb IIIC Db | No | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | — | 8.5 | 7/16" | 1/4" | 500 | -75 to 400 | Hardwire | Metal, Plastic | Ex Eb IIC Ex Tb IIIC NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA AEx Eb IIC Gb AEx Tb IIIC Db | No | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | — | 15 | 7/16" | 1/4" | 500 | -75 to 400 | Hardwire | Metal, Plastic | Ex Eb IIC Ex Tb IIIC NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA AEx Eb IIC Gb AEx Tb IIIC Db | No | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Constant-Wattage Heating Tape with Adjustable Temperature Control for Pipes and Tubes

Hardwire—240V AC, Single Phase | Plug In—120V AC, Single Phase | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., ft. | Wattage, W | Watt Density, W/ft | Thk. | Environment Temp. Range, ° F | Cord Lg., ft. | Cable Cover Material | For Surface Material | For Use Outdoors | Current, amp | Each | Current, amp | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Wide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 72 | 36 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 0.3 | 0000000 | 0000000 | 0.6 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 144 | 36 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 0.6 | 0000000 | 000000 | 1.2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 216 | 36 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 0.9 | 0000000 | 000000 | 1.8 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 288 | 36 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 1.2 | 0000000 | 000000 | 2.4 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 360 | 36 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 1.5 | 0000000 | 000000 | 3 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 432 | 36 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 1.8 | 00000000 | 000000 | 3.6 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 504 | 36 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 4.2 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 576 | 36 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 4.8 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 648 | 36 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 5.4 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 720 | 36 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 3 | 00000000 | 000000 | 6 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" Wide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 144 | 72 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 0.6 | 0000000 | 000000 | 1.2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 288 | 72 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 1.2 | 0000000 | 000000 | 2.4 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 432 | 72 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 1.8 | 0000000 | 000000 | 3.6 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 576 | 72 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 2.4 | 0000000 | 000000 | 4.8 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 720 | 72 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 3 | 0000000 | 000000 | 6 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 864 | 72 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 3.6 | 00000000 | 000000 | 7.2 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 1,008 | 72 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 8.4 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 1,152 | 72 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 9.6 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 1,296 | 72 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 10.8 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 1,440 | 72 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 6 | 0000000 | 000000 | 12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2" Wide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 288 | 144 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 2.4 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 576 | 144 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 4.8 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 864 | 144 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 7.2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 1,152 | 144 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 9.6 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1,440 | 144 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 6 | 0000000 | 000000 | 12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3" Wide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 432 | 216 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 3.6 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 864 | 216 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 7.2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 1,296 | 216 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 10.8 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 1,440 | 180 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1,440 | 144 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | — | ——— | 0 | 12 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1,800 | 180 | 3/16" | -30 to 450 | 6 | Rubber | Metal | No | 7.5 | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-High Temperature Constant-Wattage Heating Tape for Pipes and Tubes

Lg., ft. | Wattage, W | Watt Density, W/ft | Current, amp | Wd. | Thk. | Environment Temp. Range, ° F | Cord Lg., ft. | Cable Cover Material | For Surface Material | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 39 | 19.5 | 0.3 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 104 | 52 | 0.9 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 156 | 78 | 1.3 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 78 | 19.5 | 0.7 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 208 | 52 | 1.7 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 312 | 78 | 2.6 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 117 | 19.5 | 1 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 312 | 52 | 2.6 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 468 | 78 | 3.9 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 156 | 19.5 | 1.3 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 416 | 52 | 3.5 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 624 | 78 | 5.2 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 195 | 19.5 | 1.6 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 520 | 52 | 4.3 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 234 | 19.5 | 2 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 312 | 19.5 | 2.6 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 39 | 19.5 | 0.2 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 104 | 52 | 0.4 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 156 | 78 | 0.7 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 78 | 19.5 | 0.3 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 208 | 52 | 0.9 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 312 | 78 | 1.3 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 117 | 19.5 | 0.5 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 312 | 52 | 1.3 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 468 | 78 | 2 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 156 | 19.5 | 0.7 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 416 | 52 | 1.7 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 624 | 78 | 2.6 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 195 | 19.5 | 0.8 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 520 | 52 | 2.2 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 234 | 19.5 | 1 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 312 | 19.5 | 1.3 | 1/2" | 1/8" | -60 to 1,400 | — | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plug In—Straight Blade | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 39 | 19.5 | 0.3 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 104 | 52 | 0.9 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 156 | 78 | 1.3 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 78 | 19.5 | 0.7 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 208 | 52 | 1.7 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 312 | 78 | 2.6 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 117 | 19.5 | 1 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 312 | 52 | 2.6 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 468 | 78 | 3.9 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 156 | 19.5 | 1.3 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 416 | 52 | 3.5 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 624 | 78 | 5.2 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 195 | 19.5 | 1.6 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 520 | 52 | 4.3 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 234 | 19.5 | 2 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 312 | 19.5 | 2.6 | 1/2" | 1/8" | -60 to 1,400 | 2 | Fiberglass | Ceramic, Glass, Metal | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Constant-Wattage Heating Tape with Temperature Control for Pipes and Tubes

Lg., ft. | Wattage, W | Watt Density, W/ft | Current, amp | Wd. | Thk. | Environment Temp. Range, ° F | For Pipe Dia. | NEMA Type | Cord Lg., ft. | Cable Cover Material | For Surface Material | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Plug In—Straight Blade | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 21 | 7 | 0.2 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 42 | 7 | 0.4 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 63 | 7 | 0.5 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 84 | 7 | 0.7 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 105 | 7 | 0.9 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 126 | 7 | 1.1 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 168 | 7 | 1.4 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 210 | 7 | 1.8 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 280 | 7 | 2.3 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 420 | 7 | 3.5 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 560 | 7 | 4.7 | 1/2" | 3/8" | -40 to 155 | 3/4" to 1 1/2" | 5-15 | 2 | Plastic | Metal, Plastic | Yes | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cut-to-Length Constant-Wattage Heating Tape for Pipes and Tubes

Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Watt Density, W/ft | Wd. | Thk. | Max. Lg., ft. | Environment Temp. Range, ° F | Electrical Connection Type | Cable Cover Material | For Surface Material | Hazardous Location Rating | For Use Outdoors | 1-99 | 100-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

150° F Maximum Heat Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | 1/2" | 11/32" | 500 | -40 to 400 | Hardwire | Plastic | Metal | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 00000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 1/2" | 11/32" | 500 | -40 to 400 | Hardwire | Plastic | Metal | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 1/2" | 11/32" | 500 | -40 to 400 | Hardwire | Plastic | Metal | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1/2" | 11/32" | 500 | -40 to 400 | Hardwire | Plastic | Metal | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 1/2" | 11/32" | 500 | -40 to 400 | Hardwire | Plastic | Metal | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

480V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1/2" | 11/32" | 500 | -40 to 400 | Hardwire | Plastic | Metal | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

300° F Maximum Heat Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1/2" | 11/32" | 500 | -60 to 500 | Hardwire | Plastic | Metal | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 1/2" | 11/32" | 500 | -60 to 500 | Hardwire | Plastic | Metal | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1/2" | 11/32" | 500 | -60 to 500 | Hardwire | Plastic | Metal | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 1/2" | 11/32" | 500 | -60 to 500 | Hardwire | Plastic | Metal | Ex E II NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 AEx E II | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

480V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1/2" | 11/32" | 500 | -60 to 500 | Hardwire | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 1/2" | 11/32" | 500 | -60 to 500 | Hardwire | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 1/2" | 11/32" | 500 | -60 to 500 | Hardwire | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA | No | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Constant-Wattage Heating Tape for Pipes and Tubes

Hardwire | Plug In | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wattage, W | Watt Density, W/ft | Current, amp | Cable Cover Material | For Surface Material | For Use Outdoors | Thk. | Environment Temp. Range, ° F | Each | Thk. | Environment Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 25 | 50 | 0.2 | Fiberglass | Metal | No | 0.17" | -100 to 900 | 0000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 35 | 52.5 | 0.3 | Fiberglass | Metal | No | — | — | ——— | 0 | 0.3" | -50 to 900 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 50 | 50 | 0.4 | Fiberglass | Metal | No | 0.17" | -100 to 900 | 0000000 | 00000 | 0.3" | -50 to 900 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 100 | 50 | 0.8 | Fiberglass | Metal | No | 0.17" | -100 to 900 | 0000000 | 00000 | 0.3" | -50 to 900 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" | 125 | 41.5 | 1 | Fiberglass | Metal | No | 0.17" | -100 to 900 | 0000000 | 00000 | 0.3" | -50 to 900 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60" | 250 | 50 | 2.1 | Fiberglass | Metal | No | 0.17" | -100 to 900 | 0000000 | 00000 | 0.3" | -50 to 900 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96" | 400 | 50 | 3.3 | Fiberglass | Metal | No | 0.17" | -100 to 900 | 0000000 | 00000 | 0.3" | -50 to 900 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120" | 500 | 50 | 4.2 | Fiberglass | Metal | No | 0.17" | -100 to 900 | 0000000 | 000000 | 0.3" | -50 to 900 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Flexible Constant-Wattage Heating Tape for Pipes and Tubes

Tape | Adapters | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., ft. | Wattage, W | Watt Density | Current, amp | Wd. | Thk. | Environment Temp. Range, ° F | Cable Cover Material | For Surface Material | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2 | 36 | 2 W/in² | 0.3 | 0.5" | 0.06" | -75 to 250 | Silicone Rubber | Ceramic, Glass, Metal, Plastic | 00000000 | 0000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 48 | 2 W/in² | 0.4 | 0.5" | 0.06" | -75 to 250 | Silicone Rubber | Ceramic, Glass, Metal, Plastic | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 1/2 | 72 | 2 W/in² | 0.6 | 0.5" | 0.06" | -75 to 250 | Silicone Rubber | Ceramic, Glass, Metal, Plastic | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 92 | 2 W/in² | 0.77 | 0.5" | 0.06" | -75 to 250 | Silicone Rubber | Ceramic, Glass, Metal, Plastic | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2 | 36 | 2 W/in² | 0.15 | 0.5" | 0.06" | -75 to 250 | Silicone Rubber | Ceramic, Glass, Metal, Plastic | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 48 | 2 W/in² | 0.2 | 0.5" | 0.06" | -75 to 250 | Silicone Rubber | Ceramic, Glass, Metal, Plastic | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 1/2 | 72 | 2 W/in² | 0.3 | 0.5" | 0.06" | -75 to 250 | Silicone Rubber | Ceramic, Glass, Metal, Plastic | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 92 | 2 W/in² | 0.38 | 0.5" | 0.06" | -75 to 250 | Silicone Rubber | Ceramic, Glass, Metal, Plastic | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3 | 3 W/ft | 0.3 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 6 | 3 W/ft | 0.5 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 9 | 3 W/ft | 0.8 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 12 | 3 W/ft | 1 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 6 | 3 W/ft | 0.3 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 12 | 3 W/ft | 0.5 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 18 | 3 W/ft | 0.8 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 24 | 3 W/ft | 1 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

36V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 9 | 3 W/ft | 0.3 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 18 | 3 W/ft | 0.5 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 27 | 3 W/ft | 0.8 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 36 | 3 W/ft | 1 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plug In—2.1 mm Barrel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3 | 3 W/ft | 0.3 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 6 | 3 W/ft | 0.5 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 9 | 3 W/ft | 0.8 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 12 | 3 W/ft | 1 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 6 | 3 W/ft | 0.3 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 12 | 3 W/ft | 0.5 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 18 | 3 W/ft | 0.8 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 24 | 3 W/ft | 1 | 0.12" | 0.06" | -30 to 220 | Polymer Fiber | Metal, Plastic | 0000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

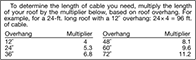

Roof and Gutter Heat Cables

|  |  |

No. Included | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., ft. | Wattage, W | Watt Density, W/ft | Current, amp | Roof Clips | Downspout Spacers | Connection | No. of Blades | Cord Lg., ft. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 150 | 5 | 1.3 | 19 | 16 | Straight Blade | 3 | 6 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 300 | 5 | 2.5 | 38 | 32 | Straight Blade | 3 | 6 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 400 | 5 | 3.3 | 57 | 48 | Straight Blade | 3 | 6 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 500 | 5 | 4.2 | 76 | 64 | Straight Blade | 3 | 6 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | 600 | 5 | 5 | 76 | 64 | Straight Blade | 3 | 6 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 160 | 800 | 5 | 6.7 | 95 | 80 | Straight Blade | 3 | 6 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 1,000 | 5 | 8.3 | 133 | 112 | Straight Blade | 3 | 6 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 240 | 1,200 | 5 | 10 | 152 | 128 | Straight Blade | 3 | 6 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe Thawers

For Pipe | Cable | Electrical | Housing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., ft. | Size | Minimum Distance Between Clamps, ft. | Output Current | Input Current | Lg., ft. | Cover Material | Environment Temp. Range, ° F | Connection Type | Phase | Wattage, W | Ht. | Wd. | Dp. | Material | For Surface Material | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Output Current | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 to 100 | 1/2, 3/4, 1, 1 1/4, 1 1/2 | 15 | 320 amp | 13 amp | 20 | TPE | 0 to 80 | Plug In | Single | 1,560 | 8" | 8" | 8" | Steel | Metal | No | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable Output Current | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 to 175 | 1/2, 3/4, 1, 1 1/4, 1 1/2 | 15 | 320 amp 400 amp | 14 amp 20 amp | 20 | TPE | 0 to 80 | Plug In | Single | 2,400 | 8" | 8" | 8" | Steel | Metal | No | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||