Selecting an Immersion Heater

More

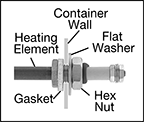

Bend-and-Stay Immersion Heaters with

Through-Wall Fittings for Chemical Solutions

Form these heaters into any shape and install them through container walls with the attached bulkhead fittings. They quickly and efficiently heat liquid through direct contact. All require a temperature switch or controller (sold separately) to regulate heat output. The Incoloy heating element has excellent resistance to harsh chemicals.

Note: Fully immerse the heating element in liquid to prevent heater failure.

Thread | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wattage, W | Watt Density, W/sq. in. | Current, A | Heating Element Lg. | Min. Bend Radius | For Hole Size | Size | Type | Gender | Wire Connection Type | Includes | For Use With | Each | |

120V AC, Single Phase | |||||||||||||

17/64" Dia. | |||||||||||||

| 250 | 30 | 2.1 | 11" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 0000000 |

| 350 | 30 | 2.9 | 15" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 450 | 30 | 3.8 | 20" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 650 | 30 | 5.4 | 27" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 850 | 30 | 7.1 | 35" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 1,000 | 30 | 8.3 | 41" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 1,500 | 30 | 12.5 | 60" | 15/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

5/16" Dia. | |||||||||||||

| 1,300 | 30 | 10.8 | 45" | 1 1/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

240V AC, Single Phase | |||||||||||||

5/16" Dia. | |||||||||||||

| 850 | 30 | 3.5 | 31" | 1 1/16" | 15/32" | 7/16"-20 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

7/16" Dia. | |||||||||||||

| 1,500 | 30 | 6.3 | 41" | 1 1/2" | 11/16" | 5/8"-18 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

| 2,250 | 30 | 9.4 | 60" | 1 1/2" | 11/16" | 5/8"-18 | UNF | Male | Screw Terminals | Flat Washers Gaskets Hex Nuts | Ammonium Hydroxide (0-3%), Ammonium Hydroxide (3-6%), Ethylene Glycol, Nitric Acid (0-3%), Nitric Acid (3-6%), Soap Solutions, Sodium Hydroxide (0-3%), Sodium Hydroxide (3-6%), Water | 0000000 | 000000 |

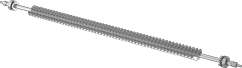

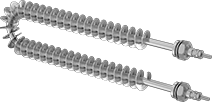

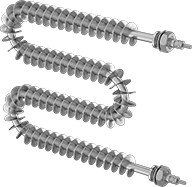

Finned Tubular Heaters for Duct, Ovens, and Dryers

These tubular heaters minimize the risk of sparks and fire from combustible particles in the flow stream, making them a safer choice than open coil heaters. Finned for increased surface area, they quickly dissipate heat in air and inert gas heating systems such as duct heaters and convection ovens. Their sheath, fins, and fittings are made of stainless steel, which resists heat and corrosion better than steel. These heaters require a temperature switch or control (sold separately) to regulate output.

Heaters with end fittings welded on one end have one fitting permanently welded for a secure connection, while the other fitting is loose to create room for tube expansion during heating. The extra space helps prevent damage.

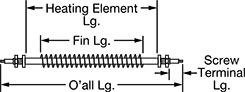

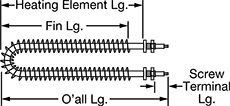

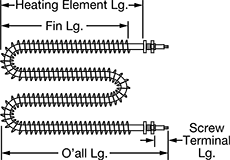

Fin | Heating Element | Screw Terminal | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wattage, W | Watt Density, W/sq. in. | Current, A | Overall Lg. | Maximum Heat Output, °F | Lg. | Dia. | Material | Lg. | Material | Thread Size | Lg. | Each | |

120V AC, Single Phase | |||||||||||||

Straight—Welded on One End | |||||||||||||

| 1,000 | 60 | 8.33 | 23 1/2" | 1200° | 16 1/2" | 15/16" | Stainless Steel | 20" | 304 Stainless Steel | 8-32 | 1 1/8" | 0000000 | 0000000 |

U-Bend—Welded on Both Ends | |||||||||||||

| 1,000 | 60 | 8.33 | 12" | 1200° | 8 3/4" | 15/16" | Stainless Steel | 10 1/4" | 304 Stainless Steel | 8-32 | 1 1/8" | 0000000 | 000000 |

M-Bend—Welded on Both Ends | |||||||||||||

| 1,500 | 60 | 12.5 | 9 1/2" | 1200° | 6 1/4" | 15/16" | Stainless Steel | 7 3/4" | 304 Stainless Steel | 8-32 | 1 1/8" | 0000000 | 000000 |

240V AC, Single Phase | |||||||||||||

Straight—Welded on One End | |||||||||||||

| 2,000 | 80 | 8.33 | 32 1/4" | 1200° | 25" | 1 3/16" | Stainless Steel | 28 1/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |

M-Bend—Welded on Both Ends | |||||||||||||

| 3,000 | 80 | 12.5 | 12 1/4" | 1200° | 9" | 1 3/16" | Stainless Steel | 10 1/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |

| 4,000 | 80 | 16.67 | 15 1/4" | 1200° | 12" | 1 3/16" | Stainless Steel | 13 1/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |

480V AC, Single Phase | |||||||||||||

U-Bend—Welded on Both Ends | |||||||||||||

| 1,000 | 80 | 2.08 | 9 3/4" | 1200° | 6 1/2" | 1 3/16" | Stainless Steel | 7 3/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |

| 2,000 | 80 | 4.17 | 15 3/4" | 1200° | 12 1/2" | 1 3/16" | Stainless Steel | 13 3/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |

| 3,000 | 80 | 6.25 | 22 1/4" | 1200° | 19" | 1 3/16" | Stainless Steel | 20 1/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |

| 4,000 | 80 | 8.33 | 28 1/4" | 1200° | 25" | 1 3/16" | Stainless Steel | 26 1/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |

M-Bend—Welded on Both Ends | |||||||||||||

| 3,000 | 80 | 6.25 | 12 1/4" | 1200° | 9" | 1 3/16" | Stainless Steel | 10 1/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |

| 4,000 | 80 | 8.33 | 15 1/4" | 1200° | 12" | 1 3/16" | Stainless Steel | 13 1/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |

| 6,000 | 80 | 12.5 | 21 1/4" | 1200° | 18" | 1 3/16" | Stainless Steel | 19 1/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |

| 7,000 | 80 | 14.58 | 24 1/4" | 1200° | 21" | 1 3/16" | Stainless Steel | 22 1/4" | 304 Stainless Steel | 10-32 | 1 1/8" | 0000000 | 000000 |