About Hazardous Location Environmental Ratings

More

About Heaters for Pipes and Tubes

Self-Regulating Heat Cable—Adjusts its heat output in response to surface as well as surrounding temperatures.

Constant-Wattage Heat Cable—Always puts out the designated amount of watts/ft., regardless of the surrounding temperature.

More

Cut-to-Length Constant-Wattage Heaters for Pipes and Tubes

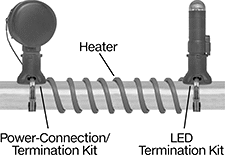

With a cable that supplies the same wattage along the entire length, these heaters remain consistent regardless of the surrounding temperature. All require a temperature switch or controller (sold separately) to regulate heat output. They’re often used to maintain liquid temperature and viscosity and provide freeze protection in pipe and tube systems. To prevent burnout, heaters must not be overlapped and must be in full contact with the surface being heated. All have a plastic cable cover for corrosion resistance and durability. They are FM approved for hazardous locations. A power-connection/termination kit (sold separately) is required.

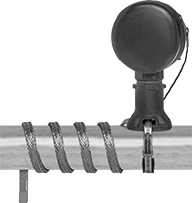

Power-connection/termination kit (sold separately) includes a junction box and a three-point DIN-mount terminal block to attach to your power source. It also includes adhesive, an end cap, and a power-connection cover to seal off the other end of your cable.

Termination kit (sold separately) includes adhesive, an end cap, and a power-connection cover to seal off the non-powered end of your cable.

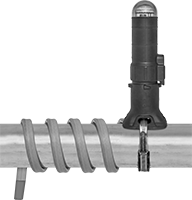

LED termination kit (sold separately) has a high-visibility green LED to indicate when the heater is on. It also includes adhesive, an end cap, and a power-connection cover to seal off the non-powered end of your cable.

Note: Only install these heaters in accessible locations; do not install them behind walls, underground, or in other difficult-to-access areas. Use fiberglass tape or heat-transfer putty to install them directly on surfaces that are free of dirt, grease, and rough edges. Do not use electrical tape, duct tape, metal bands, or wire. To prevent heat loss and protect heaters from moisture and corrosion, wrap them with fiberglass insulation.

Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Watt Density, W/ft. | Wd. | Thick. | Max. Lg., ft. | Environment Temp. Range, °F | Wire Connection Type | Cable Cover Material | For Surface Material | Environmental Rating | For Use Outdoors | 1-99 | 100-Up | |

150° F Max. Heat Output | ||||||||||||

120V AC, Single Phase | ||||||||||||

| 2.5 | 1/2" | 11/32" | 500 | -40° to 400° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 00000000 | 000000 | 000000 |

| 5 | 1/2" | 11/32" | 500 | -40° to 400° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 00000000 | 00000 | 00000 |

| 8 | 1/2" | 11/32" | 500 | -40° to 400° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 00000000 | 00000 | 00000 |

| 10 | 1/2" | 11/32" | 500 | -40° to 400° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 00000000 | 00000 | 00000 |

240V AC, Single Phase | ||||||||||||

| 5 | 1/2" | 11/32" | 500 | -40° to 400° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 00000000 | 00000 | 00000 |

480V AC, Single Phase | ||||||||||||

| 10 | 1/2" | 11/32" | 500 | -40° to 400° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 00000000 | 00000 | 00000 |

300° F Max. Heat Output | ||||||||||||

120V AC, Single Phase | ||||||||||||

| 10 | 1/2" | 11/32" | 500 | -60° to 500° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 00000000 | 00000 | 00000 |

| 15 | 1/2" | 11/32" | 500 | -60° to 500° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 00000000 | 00000 | 00000 |

240V AC, Single Phase | ||||||||||||

| 10 | 1/2" | 11/32" | 500 | -60° to 500° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 00000000 | 00000 | 00000 |

| 15 | 1/2" | 11/32" | 500 | -60° to 500° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 00000000 | 00000 | 00000 |

480V AC, Single Phase | ||||||||||||

| 10 | 1/2" | 11/32" | 500 | -60° to 500° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA | No | 00000000 | 00000 | 00000 |

| 15 | 1/2" | 11/32" | 500 | -60° to 500° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA | No | 00000000 | 00000 | 00000 |

| 20 | 1/2" | 11/32" | 500 | -60° to 500° | Wire Leads | Plastic | Metal | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA | No | 00000000 | 00000 | 00000 |

Cut-to-Length Self-Regulating Heaters for Pipes and Tubes

Also known as self-regulating heat cable, these heaters automatically adjust heat output at different points along their length to account for differences in environmental temperature. They output their full wattage where temperature is low and heat is needed. Where it’s warmer, they output reduced wattage. They’re often used to maintain liquid temperature and viscosity and provide freeze protection in pipe and tube systems. Heaters can be overlapped without creating hot spots or risking burnout. All require a power connection/termination kit (sold separately).

Heaters with a plastic cable cover are rated for use in hazardous locations. They are also more corrosion resistant and durable than heaters without a cable cover.

Power-connection/termination kits include a junction box and a three-point DIN-mount terminal block for attaching your power source. They also include adhesive, an end cap, and a power-connection cover to seal off the other end of your cable.

Termination kits include adhesive, an end cap, and a power-connection cover to seal off the non-powered end of your cable.

LED termination kits have a high-visibility green LED to indicate when the heater is on. They also include adhesive, an end cap, and a power-connection cover to seal off the non-powered end of your cable.

Splice kits let you connect two heating cables. They include adhesive, splice-connection covers, and wire-splicing connectors.

T-splice kits let you create a tee connection between heating cables. They include adhesive, splice-connection covers, and wire-splicing connectors.

Note: Only install these heaters in accessible locations; do not install them behind walls, underground, or in other difficult-to-access areas. Use fiberglass tape or heat-transfer putty to install them directly on surfaces that are free of dirt, grease, and rough edges. Do not use electrical tape, duct tape, metal bands, or wire. To prevent heat loss and protect heaters from moisture and corrosion, wrap them with fiberglass insulation.

Watt Density, W/ft. | Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 50° F | @ 100° F | @ 150° F | Wd. | Thick. | Max. Lg., ft. | Environment Temp. Range, °F | Wire Connection Type | For Surface Material | Environmental Rating | For Use Outdoors | 1-99 | 100-Up | |

With Plastic Cable Cover | |||||||||||||

| 3 | 1.5 | 0.2 | 9/16" | 1/4" | 500 | -60° to 185° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 0000000 | 000000 | 00000 |

| 5 | 2.5 | 1 | 9/16" | 1/4" | 500 | -60° to 185° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 0000000 | 00000 | 0000 |

| 8 | 4.5 | 1.8 | 9/16" | 1/4" | 500 | -60° to 185° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 0000000 | 00000 | 0000 |

| 10 | 5.7 | 2.1 | 9/16" | 1/4" | 500 | -60° to 185° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 0000000 | 00000 | 0000 |

Watt Density, W/ft. | Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 50° F | @ 100° F | @ 150° F | Wd. | Thick. | Max. Lg., ft. | Environment Temp. Range, °F | Wire Connection Type | For Surface Material | Environmental Rating | For Use Outdoors | 1-99 | 100-Up | |

With Plastic Cable Cover | |||||||||||||

| 8 | 4.5 | 1.8 | 9/16" | 1/4" | 500 | -60° to 185° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 0000000 | 000000 | 00000 |

| 10 | 5.7 | 2.1 | 9/16" | 1/4" | 500 | -60° to 185° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 | No | 0000000 | 00000 | 0000 |

Watt Density, W/ft. | Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 50° F | @ 150° F | @ 250° F | Wd. | Thick. | Max. Lg., ft. | Environment Temp. Range, °F | Wire Connection Type | For Surface Material | Environmental Rating | For Use Outdoors | 1-99 | 100-Up | |

With Plastic Cable Cover | |||||||||||||

| 9 | 6 | 3 | 7/16" | 1/4" | 500 | -75° to 400° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA | No | 00000000 | 000000 | 000000 |

| 12 | 8.5 | 5 | 7/16" | 1/4" | 500 | -75° to 400° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA | No | 00000000 | 00000 | 00000 |

| 15 | 11 | 7 | 7/16" | 1/4" | 500 | -75° to 400° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA | No | 00000000 | 00000 | 00000 |

| 20 | 15 | 10.5 | 7/16" | 1/4" | 500 | -75° to 400° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA | No | 00000000 | 00000 | 00000 |

Watt Density, W/ft. | Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 50° F | @ 150° F | @ 250° F | Wd. | Thick. | Max. Lg., ft. | Environment Temp. Range, °F | Wire Connection Type | For Surface Material | Environmental Rating | For Use Outdoors | 1-99 | 100-Up | |

With Plastic Cable Cover | |||||||||||||

| 12 | 8.5 | 5 | 7/16" | 1/4" | 500 | -75° to 400° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA | No | 00000000 | 000000 | 000000 |

| 20 | 15 | 10.5 | 7/16" | 1/4" | 500 | -75° to 400° | Wire Leads | Metal, Plastic | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G NEC Class III Divisions 1, 2 NEC Zone 1 Groups IIC, IIB, IIA NEC Zone 21 Groups IIIC, IIIB, IIIA | No | 00000000 | 00000 | 00000 |

Hazardous Location Adhesive-Mount Heat Sheets

FM approved, these heat sheets are safe for use in areas with infrequent exposure, such as from a spill or a ventilation system failure, to flammable gases, liquids, and dust. They are flexible and permanently adhere to container surfaces to warm contents without direct contact. All have a watt density of 2.5 W/sq. in. for gentle warming. Heaters require a temperature switch or controller to regulate heat output and should be installed with Dow Corning 736 silicone sealant (both not included).

Note: Do not cut, crease, or overlap these heaters—this will damage the heating element. Use a roller during installation to remove air pockets and ensure direct surface contact. Once heaters have been applied to a surface, they cannot be removed and reused.

Hazardous location environmental ratings indicate whether manufacturers have included safety features in products to facilitate their safe use in a hazardous environment. Before selecting a product for a hazardous location, ensure it is rated for your environment. See About Hazardous Location Environmental Ratings.

O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Wd. | Wattage, W | Voltage | Electrical Phase | Current, A | Thick. | Max. Heat Output, °F | Environment Temp. Range, °F | For Surface Material | Material | Environmental Rating | NEC Hazardous Location Temp. Classification | Each | |

Rectangle | ||||||||||||||

2.5 W/sq. in. Watt Density | ||||||||||||||

| 12" | 6" | 180 | 120V AC | Single | 1.5 | 3/16" | 290° | -60° to 400° | Metal | Silicone Rubber | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G IEC Zone 2 Groups IIB, IIA IEC Zone 22 Groups IIIB, IIIA | T3 (392° F) | 0000000 | 0000000 |

| 12" | 12" | 360 | 120V AC | Single | 3 | 3/16" | 290° | -60° to 400° | Metal | Silicone Rubber | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G IEC Zone 2 Groups IIB, IIA IEC Zone 22 Groups IIIB, IIIA | T3 (392° F) | 0000000 | 000000 |

| 24" | 6" | 360 | 120V AC | Single | 3 | 3/16" | 290° | -60° to 400° | Metal | Silicone Rubber | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G IEC Zone 2 Groups IIB, IIA IEC Zone 22 Groups IIIB, IIIA | T3 (392° F) | 0000000 | 000000 |

| 24" | 12" | 720 | 120V AC | Single | 6 | 3/16" | 290° | -60° to 400° | Metal | Silicone Rubber | NEC Class I Division 2 Groups A, B, C, D NEC Class II Division 2 Groups F, G IEC Zone 2 Groups IIB, IIA IEC Zone 22 Groups IIIB, IIIA | T3 (392° F) | 0000000 | 000000 |