Filter by

Thread Size

Mount Type

Capacity per Mount

Base Material

Overall Height

Base Finish

Stud Material

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

About Leveling Mounts

Choose the right leveling mounts for your floor conditions, equipment weight, and vibration-control needs.

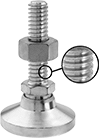

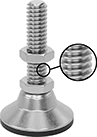

High-Capacity Swivel Leveling Mounts with Threaded Stud

|

Without Cushion |

|

With Cushion |

These mounts level heavier equipment than other similarly sized swivel mounts. In addition to supporting higher capacities, the broad Acme threads adjust with fewer turns of the stud or jam nut than other threads. A ball-and-socket joint in the base swivels to keep equipment level on slightly sloped and pitted floors. For mounting versatility, you can install these mounts in either threaded holes or unthreaded through holes at the bottom of equipment.

303 Stainless Steel Base—The choice for most wet locations, these mounts can withstand repeated washdowns without corroding. However, they won't hold up to cleaning solutions that contain harsh chemicals like 316 stainless steel can.

Zinc-Yellow-Chromate-Plated Steel Base—More corrosion resistant than nickel-plated steel, these mounts are suitable for damp environments. However, they won’t hold up to chemical cleaners, high-pressure washdowns, and other harsh conditions like stainless steel can.

Rubber Cushion—A cushion under the base grips surfaces so vibrating equipment doesn't slide. It also protects floors from scrapes and gouges.

Without Cushion | With Rubber Cushion | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Swivel Range of Motion | Base Dia. | Cap. per Mount, lb. | Overall Ht. | Each | Cap. per Mount, lb. | Overall Ht. | Cushion Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Yellow-Chromate-Plated Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-16 | 1 1/4" | 7.5° | 1" | 1,500 | 1 15/16" | 0000000 | 000000 | 1,125 | 1 15/16" | Neoprene | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-16 | 2 1/2" | 7.5° | 1" | 1,500 | 3 3/16" | 00000000 | 00000 | 1,125 | 3 3/16" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-14 | 2" | 7.5° | 1 1/4" | 3,750 | 2 7/8" | 0000000 | 00000 | 2,815 | 2 7/8" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-14 | 4" | 7.5° | 1 1/4" | 3,750 | 4 7/8" | 00000000 | 00000 | 2,815 | 4 7/8" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 2" | 7.5° | 1 1/4" | 5,625 | 2 7/8" | 0000000 | 00000 | 4,200 | 2 7/8" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 4" | 7.5° | 1 1/4" | 5,625 | 4 7/8" | 00000000 | 00000 | 4,200 | 4 7/8" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 2" | 7.5° | 1 7/8" | 7,500 | 3 1/8" | 0000000 | 00000 | 5,225 | 3 1/8" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 4" | 7.5° | 1 7/8" | 7,500 | 5 1/8" | 0000000 | 00000 | 5,225 | 5 1/8" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 2" | 7.5° | 2 1/2" | 9,000 | 3 1/4" | 0000000 | 00000 | 6,750 | 3 1/4" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 4" | 7.5° | 2 1/2" | 9,000 | 5 1/4" | 00000000 | 00000 | 6,750 | 5 1/4" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 2" | 7.5° | 3" | 11,100 | 3 1/2" | 0000000 | 00000 | 8,325 | 3 1/2" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 4" | 7.5° | 3" | 11,100 | 5 1/2" | 00000000 | 00000 | 8,325 | 5 1/2" | Neoprene | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 3 1/2" | 7.5° | 4" | 30,000 | 5 3/8" | 0000000 | 00000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 6" | 7.5° | 4" | 30,000 | 7 7/8" | 0000000 | 00000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 8" | 7.5° | 4" | 30,000 | 9 7/8" | 00000000 | 00000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-5 | 4" | 7.5° | 6" | 60,000 | 6 3/4" | 0000000 | 000000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-5 | 6" | 7.5° | 6" | 60,000 | 8 3/4" | 00000000 | 000000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 2" | 7.5° | 1 7/8" | 7,500 | 3 1/8" | 00000000 | 00000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 4" | 7.5° | 1 7/8" | 7,500 | 5 1/8" | 00000000 | 00000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 2" | 7.5° | 2 1/2" | 9,000 | 3 1/4" | 00000000 | 00000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 2" | 7.5° | 3" | 11,100 | 3 1/2" | 00000000 | 00000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 3 1/2" | 7.5° | 4" | 30,000 | 5 3/8" | 00000000 | 000000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 6" | 7.5° | 4" | 30,000 | 7 7/8" | 00000000 | 000000 | — | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

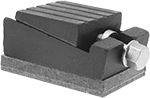

Heavy Duty Rigid Leveling Mounts

|  |

Grooved Surface | Smooth Surface |

The highest capacity mounts we offer, these support up to 110,000 lbs. to level heavy machinery. Rest large equipment, such as CNC and injection molding machines, on top of these mounts and the weight will keep them in place. Turn the hex head bolt with a wrench to adjust the height and angle.

Iron Base and Painted Steel Base—These mounts are best for dry environments since moisture will cause them to rust.

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. per Mount, lb. | Surface Texture | Lg. | Wd. | Overall Ht. | Anchor Hole Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron Base with Zinc-Plated Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,000 | Grooved | 3 9/16" | 6 1/16" | 1 1/8" to 1 3/8" | — | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9,000 | Grooved | 3 5/8" | 5 3/4" | 2 1/4" to 2 5/8" | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15,000 | Grooved | 3 1/2" | 5 3/4" | 2 5/8" to 2 13/16" | 1" | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20,000 | Grooved | 3 1/2" | 6 3/4" | 3" to 3 1/4" | 1 1/8" | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30,000 | Grooved | 3 1/2" | 6 3/4" | 3" to 3 1/4" | 1 1/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Painted Steel Base with Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50,000 | Smooth | 7 7/8" | 9 7/8" | 2 5/16" to 3 1/8" | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 110,000 | Smooth | 15 3/4" | 11 13/16" | 3 1/8" to 3 13/16" | — | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vibration-Damping Heavy Duty Rigid Leveling Mounts

|

Grooved Surface |

The highest capacity vibration-damping mounts we offer. The rubber or felt cushion reduces vibration to protect components and extend your machine’s life. Rest large equipment, such as CNC and injection molding machines, on top of these mounts and the weight will keep them in place. Turn the hex head bolt with a wrench to adjust the height and angle.

Iron Base—These mounts are best for dry environments since moisture will cause them to rust.

Rubber Cushion—In addition to reducing vibration, the cushion grips surfaces so vibrating equipment doesn't slide. It also cuts down on noise and protects floors from scrapes and gouges.

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. per Mount, lb. | Deflection @ Cap. | Surface Texture | Lg. | Wd. | Overall Ht. | Anchor Hole Dia. | Cushion Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron Base with Felt Cushion and Zinc-Plated Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,000 | 0.15" | Grooved | 3 9/16" | 6 1/16" | 1 7/8" to 2 1/8" | — | Felt | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9,000 | 0.15" | Grooved | 3 5/8" | 6" | 3" to 3 3/8" | — | Felt | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30,000 | 0.2" | Grooved | 3 1/2" | 6 3/4" | 3 1/2" to 3 3/4" | 1 1/8" | Felt | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron Base with Rubber Cushion and Zinc-Plated Steel Bolt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15,000 | 0.09" | Grooved | 3 1/2" | 5 3/4" | 3 1/8" to 3 5/16" | 1" | SBR | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20,000 | 0.09" | Grooved | 3 1/2" | 6 3/4" | 3 1/2" to 3 3/4" | 1 1/8" | SBR | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

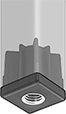

High-Capacity Press-Fit Leveling Mount Inserts

Rated for high load capacity, use these inserts to connect threaded leveling mounts to machinery, instrument bases, and conveyor equipment with tubular legs. These inserts have pass-through holes that are partially threaded at the base. Tap mounts into place with a rubber hammer.

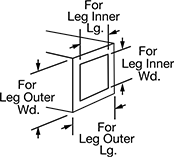

For Square Legs

|

Shown with Brass Insert Installed |

Plastic—The economical choice. These inserts can handle more weight than inserts with brass threads, but may wear out more quickly if frequently adjusted.

Plastic with Brass Insert—Move equipment around your workspace and make frequent adjustments without worrying about stripping the brass threads.

For Leg | Thread | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Outer Lg. | Outer Wd. | Inner Lg. | Inner Wd. | Cap. per Mount, lb. | Overall Ht. | , mm | Size | Type | Dp. | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 1/4" | 1 1/4" | 3,500 | 1 3/4" | — | 3/8"-16 | UNC | 1 1/4" | -20 to 170 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 1/4" | 1 1/4" | 3,500 | 1 3/4" | — | 1/2"-13 | UNC | 1 1/4" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 1/4" | 1 1/4" | 3,500 | 1 3/4" | — | 5/8"-11 | UNC | 1 1/4" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 1/4" | 1 1/4" | 3,500 | 1 3/4" | — | 3/4"-10 | UNC | 1 1/4" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 3/8" | 1 3/8" | 3,500 | 1 3/4" | — | 3/8"-16 | UNC | 1 1/4" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 3/8" | 1 3/8" | 3,500 | 1 3/4" | — | 1/2"-13 | UNC | 1 1/4" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 3/8" | 1 3/8" | 3,500 | 1 3/4" | — | 5/8"-11 | UNC | 1 1/4" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 3/8" | 1 3/8" | 3,500 | 1 3/4" | — | 3/4"-10 | UNC | 1 1/4" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 3,500 | 2" | — | 3/8"-16 | UNC | 1" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 3,500 | 2" | — | 1/2"-13 | UNC | 1" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 3,500 | 2" | — | 5/8"-11 | UNC | 1" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 3,500 | 2" | — | 3/4"-10 | UNC | 1" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 7/8" | 1 7/8" | 3,500 | 2" | — | 3/8"-16 | UNC | 1" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 7/8" | 1 7/8" | 3,500 | 2" | — | 1/2"-13 | UNC | 1" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 7/8" | 1 7/8" | 3,500 | 2" | — | 5/8"-11 | UNC | 1" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 7/8" | 1 7/8" | 3,500 | 2" | — | 3/4"-10 | UNC | 1" | -20 to 170 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic with Brass Insert | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 7/8" | 7/8" | 1,100 | 1 3/16" | — | 3/8"-16 | UNC | 7/8" | 30 to 195 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 7/8" | 7/8" | 1,100 | 1 3/16" | — | 1/2"-13 | UNC | 7/8" | 30 to 195 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/16" | 1 3/16" | 1 1/16" | 1 1/16" | 1,200 | 1 5/16" | — | 3/8"-16 | UNC | 7/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 1/4" | 1 1/4" | 1,000 | 1 11/16" | — | 3/8"-16 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 1/4" | 1 1/4" | 1,000 | 1 11/16" | — | 1/2"-13 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 1/4" | 1 1/4" | 1,000 | 1 11/16" | — | 5/8"-11 | UNC | 15/16" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 1/4" | 1 1/4" | 1,000 | 1 11/16" | — | 3/4"-10 | UNC | 1 1/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 1/4" | 1 1/4" | 1,500 | 1 3/4" | — | 3/8"-12 | Acme | 1 1/4" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 1/4" | 1 1/4" | 1,500 | 1 3/4" | — | 1/2"-10 | Acme | 1 1/4" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 5/16" | 1 5/16" | 1,500 | 1 11/16" | 1.5 | M10 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 5/16" | 1 5/16" | 1,500 | 1 11/16" | 1.75 | M12 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 5/16" | 1 5/16" | 1,500 | 1 11/16" | 2 | M16 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 5/16" | 1 5/16" | 1,500 | 1 11/16" | 2.5 | M20 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 3/8" | 1 3/8" | 1,000 | 1 11/16" | — | 3/8"-16 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 3/8" | 1 3/8" | 1,000 | 1 11/16" | — | 1/2"-13 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 3/8" | 1 3/8" | 1,000 | 1 11/16" | — | 5/8"-11 | UNC | 15/16" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1 3/8" | 1 3/8" | 1,000 | 1 11/16" | — | 3/4"-10 | UNC | 1 1/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 1,000 | 1 15/16" | — | 3/8"-16 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 1,000 | 1 15/16" | — | 1/2"-13 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 1,000 | 1 15/16" | — | 5/8"-11 | UNC | 15/16" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 1,760 | 1 15/16" | — | 3/4"-10 | UNC | 1 1/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 2,000 | 2" | — | 3/8"-12 | Acme | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 2,000 | 2" | — | 1/2"-10 | Acme | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 2,000 | 2" | 1.5 | M10 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 2,000 | 2" | 1.75 | M12 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 2,000 | 2" | 2 | M16 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 3/4" | 1 3/4" | 2,000 | 2" | 2.5 | M20 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 7/8" | 1 7/8" | 1,000 | 1 15/16" | — | 3/8"-16 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 7/8" | 1 7/8" | 1,000 | 1 15/16" | — | 1/2"-13 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 7/8" | 1 7/8" | 1,000 | 1 15/16" | — | 5/8"-11 | UNC | 15/16" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1 7/8" | 1 7/8" | 1,760 | 1 15/16" | — | 3/4"-10 | UNC | 1 1/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

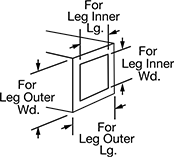

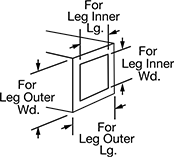

For Rectangular Legs

|  |

Shown with Brass Insert Installed |

Plastic with Brass Insert—Move equipment around your workspace and make frequent adjustments without worrying about stripping the brass threads.

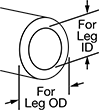

For Round Legs

| |

Shown with Brass Insert Installed |

Plastic with Brass Insert—Move equipment around your workspace and make frequent adjustments without worrying about stripping the brass threads.

For Leg | Thread | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | OD | Cap. per Mount, lb. | Overall Ht. | , mm | Size | Type | Dp. | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic with Brass Insert | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/16" | 1 1/2" | 1,500 | 1 11/16" | 1.5 | M10 | Metric | 1" | -20 to 180 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/16" | 1 1/2" | 1,500 | 1 11/16" | 1.75 | M12 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/16" | 1 1/2" | 1,500 | 1 11/16" | 2 | M16 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 1/2" | 1,000 | 1 11/16" | — | 3/8"-16 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 1/2" | 1,000 | 1 11/16" | — | 1/2"-13 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 1/2" | 1,000 | 1 11/16" | — | 5/8"-11 | UNC | 15/16" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 1/2" | 1,000 | 1 11/16" | — | 3/4"-10 | UNC | 1 1/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 1 11/16" | 1,000 | 1 11/16" | — | 3/8"-16 | UNC | 7/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 1 11/16" | 1,000 | 1 11/16" | — | 1/2"-13 | UNC | 7/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 1 11/16" | 1,000 | 1 11/16" | — | 5/8"-11 | UNC | 7/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 1 15/16" | 1,000 | 1 15/16" | — | 3/8"-16 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 1 15/16" | 1,000 | 1 15/16" | — | 1/2"-13 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 1 15/16" | 1,000 | 1 15/16" | — | 5/8"-11 | UNC | 15/16" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 1 15/16" | 1,760 | 1 15/16" | — | 3/4"-10 | UNC | 1 1/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 2" | 2,000 | 1 15/16" | — | 3/8"-16 | UNC | 1" | 30 to 195 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 2" | 2,000 | 1 15/16" | — | 1/2"-13 | UNC | 1" | 30 to 195 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 13/16" | 2" | 2,000 | 1 15/16" | 1.5 | M10 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 13/16" | 2" | 2,000 | 1 15/16" | 1.75 | M12 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 13/16" | 2" | 2,000 | 1 15/16" | 2 | M16 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 13/16" | 2" | 2,000 | 1 15/16" | 2.5 | M20 | Metric | 1" | -20 to 180 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2" | 2,000 | 1 15/16" | — | 3/8"-16 | UNC | 1" | 30 to 195 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2" | 2,000 | 1 15/16" | — | 1/2"-13 | UNC | 1" | 30 to 195 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 2" | 2,000 | 1 15/16" | — | 5/8"-11 | UNC | 1" | 30 to 195 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 2" | 1,000 | 1 15/16" | — | 3/8"-16 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 2" | 1,000 | 1 15/16" | — | 1/2"-13 | UNC | 3/4" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 2" | 1,000 | 1 15/16" | — | 5/8"-11 | UNC | 15/16" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 2" | 1,760 | 1 15/16" | — | 3/4"-10 | UNC | 1 1/8" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 2 3/8" | 1,700 | 1 15/16" | — | 5/8"-11 | UNC | 1 1/2" | 30 to 195 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||