About Gears

More

High-Power Metal Gears

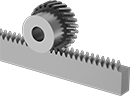

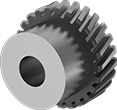

The helical teeth on these gears stay in contact for longer than straight teeth, which allows them to transmit higher loads at higher speeds than spur gears.

For gears to mesh correctly, they must have the same pressure angle and pitch. All of these gears transmit motion in a straight line—make sure to get one left-hand and one right-hand gear. To change speed and torque in your assembly, pair two gears with different numbers of teeth.

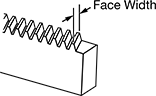

Parallel helical components have a 21 1/2° helix angle so they only transmit motion in a straight line since the helix angle is so small. Made from alloy steel, these gears resist abrasion and are stronger than carbon steel gears. Their teeth are ground, so they're more precise than gears with rolled teeth. Pair them with a rack or a gear that has a different tooth direction.

Gears with hardened teeth have better wear resistance than gears with teeth that are not hardened.

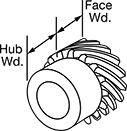

Hub | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Module | Number of Teeth | Helix Angle | Gear Pitch Dia., mm | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Teeth Heat Treatment | Dia., mm | Wd., mm | Each | |

Left Hand | ||||||||||||

Round Bore—4140 Alloy Steel | ||||||||||||

| 1 | 20 | 21 1/2° | 20 | 22 | 8 | 18 | 6 | Hardened | 17 | 10 | 00000000 | 000000 |

| 1 | 30 | 21 1/2° | 30 | 32 | 8 | 18 | 10 | Hardened | 25 | 10 | 00000000 | 000000 |

| 1 | 44 | 21 1/2° | 44 | 46 | 8 | 18 | 10 | Hardened | 30 | 10 | 00000000 | 000000 |

Right Hand | ||||||||||||

Round Bore—4140 Alloy Steel | ||||||||||||

| 1 | 20 | 21 1/2° | 20 | 22 | 8 | 18 | 6 | Hardened | 17 | 10 | 00000000 | 00000 |

| 1 | 30 | 21 1/2° | 30 | 32 | 8 | 18 | 10 | Hardened | 25 | 10 | 00000000 | 000000 |

| 1 | 44 | 21 1/2° | 44 | 46 | 8 | 18 | 10 | Hardened | 30 | 10 | 00000000 | 000000 |