How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Metal Tubing

More

Welding Gas Hose with Fittings

- Material:

Grade R Hose: EPDM Rubber

Grade T Hose: Blended Rubber - Color: Green, Red, or Green/Red

- Temperature Range:

Male Fittings: -40° to 120° F

Female Fittings: -40° to 180° F

Hose is abrasion, weather, and ozone resistant.

Green hose has right-hand threads on the fittings.

Red hose has left-hand threads on the fittings.

| For Use With | Welding Hose Grade | Number of Lines | Color | ID | OD | Thread Size | Max. Pressure | 12 1/2 ft. | 25 ft. | 50 ft. | 100 ft. | |

Brass Threaded UNF Female × Brass Threaded UNF Female | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Oxygen, Acetylene, Hydrogen, Natural Gas, MAPP Gas, Propane, Propylene | T | 2 | Green/Red | 1/4" | 9/16" | 9/16"-18 × 9/16"-18 | 200 psi @ 72° F | 000000 | ||||

Welding Gas Hose

- Temperature Range: -40° to 180° F

- Material:

Grade R Hose: EPDM Rubber

Grade T Hose: Blended Rubber - Color: Green, Red, or Green/Red

- Compatible Hose Fittings: Barbed

Made of EPDM rubber, this hose is abrasion, weather, and ozone resistant.

Grade T Hose—It's also oil and flame resistant. Green hose is for oxygen; red hose is for acetylene, hydrogen, MAPP, natural gas, propane, or propylene.

Per Ft. | ||||||||

|---|---|---|---|---|---|---|---|---|

| Welding Hose Grade | Number of Lines | Color | ID | OD | Max. Continuous Lg., ft. | 10-99 | 100-Up | |

200 psi @ 72° F Max. Pressure | ||||||||

| T | 2 | Green/Red | 1/4" | 9/16" | 700 | 0000000 | 00000 | 00000 |

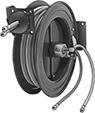

Reels with Welding Hose

Reels come with two abrasion, weather, and ozone resistant hoses. Both lines lock in place when pulled out of the reel; they retract with a quick tug.

Grade T Hose—It's also oil and flame resistant. Green hose is for oxygen and has right-hand threads on the fittings; red hose is for acetylene, hydrogen, MAPP, natural gas, propane, or propylene and has left-hand threads on the fittings.

Reel | Hose | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Welding Hose Grade | Thread Size | Fittings | ID | OD | Lg., ft. | Max. Pressure | Color | Each | |

Neoprene Rubber Hose | ||||||||||||

5" Lg. × 4" Wd. Mounting Base | ||||||||||||

| 21 1/2" | 10 1/2" | 19 1/2" | T | 9/16"-18 × 9/16"-18 | Brass Threaded UNF Female × Brass Threaded UNF Female | 1/4" | 9/16" | 50 | 200 psi @ 72° F | Green/Red | 0000000 | 0000000 |

| 25 1/2" | 10 1/2" | 24" | T | 9/16"-18 × 9/16"-18 | Brass Threaded UNF Female × Brass Threaded UNF Female | 1/4" | 9/16" | 75 | 200 psi @ 72° F | Green/Red | 0000000 | 000000 |

LP Gas Hose with Female Threaded Fittings

- Material: Plastic with Plastic Cover

- Color: Black

Change the fuel source for your propane torch from a fuel cylinder to a propane tank. This hose is often used for extended-use applications, or when a propane tank can’t be moved.

You’ll need two different adapters: one to connect the hose to your torch, and one to connect to the propane tank.

Threaded Hose-to-Propane-Tank Adapters for Compressed Gas

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

These adapters have a male threaded end that connects to a propane tank and a male threaded end that connects to a hose. Fittings are also known as CGA (Compressed Gas Association) fittings. They are brass for good corrosion resistance. Fittings have left-hand threads that are identified with a notch in the nut.

Note: Fittings have a CGA number that corresponds to a specific type of gas. Choose a fitting with the same CGA number as your tank and other system components.

CGA Number | Hose Connection | Tank Connection | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hose | Tank | Thread Size | Thread Type | Thread Direction | Thread Size | Thread Type | Thread Direction | For Use With | Each | |

Brass | ||||||||||

| 023 | 510 | 9/16"-18 | UN/UNF (CGA) | Left Hand | 0.880"-14 | NGO | Left Hand | Acetylene, Butane, Fuel Gases, LP Gas, Natural Gas, Propane | 0000000 | 000000 |

Threaded Hose-to-Propane-Torch Adapters for Compressed Gas

- Maximum Pressure: 200 psi @ 72° F

- Maximum Temperature: 120° F

These adapters allow you to connect a hose to a propane torch. Fittings are also known as CGA (Compressed Gas Association) fittings. They are brass for good corrosion resistance. Fittings have left-hand threads that are identified with a notch in the nut.

Note: Fittings have a CGA number that corresponds to a specific type of gas. Choose a fitting with the same CGA number as your tank and other system components.

CGA Number | Hose Connection | Torch Connection | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hose | Torch | Thread Size | Thread Type | Thread Direction | Thread Size | Thread Type | Thread Direction | For Use With | Each | |

Brass | ||||||||||

| 023 | 600 | 9/16"-18 | UN/UNF (CGA) | Left Hand | 1"-20 | UN/UNF (CGA) | Right Hand | Acetylene, Butane, Fuel Gases, LP Gas, Natural Gas, Propane | 0000000 | 000000 |

Brass Tubing

Frequently used in a wide range of plumbing applications, this tubing holds up well in mildly corrosive environments. Tubing is seamless, so it has a smooth interior for unrestricted flow.

- Temperature Range: -40° to 200° F

- Compatible with Solder Connect Tube Fittings

- Bendable: No

| OD | Wall Thick. | ID | Max. Pressure | Temper | Temper Rating | 1 ft. | 3 ft. | 6 ft. | |

For Use With Air, Gasoline, Natural Gas, Propane | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8" | 0.02" | 0.085" | 3,000 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 3/16" | 0.032" | 0.124" | 3,000 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1/4" | 0.032" | 0.186" | 2,200 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1/4" | 0.065" | 0.12" | 4,500 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 5/16" | 0.032" | 0.249" | 1,800 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 5/16" | 0.065" | 0.183" | 3,600 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 3/8" | 0.032" | 0.311" | 1,500 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 3/8" | 0.065" | 0.245" | 3,000 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 7/16" | 0.032" | 0.374" | 1,200 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 7/16" | 0.065" | 0.308" | 2,600 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1/2" | 0.02" | 0.46" | 690 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1/2" | 0.032" | 0.436" | 1,100 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1/2" | 0.065" | 0.37" | 2,200 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 9/16" | 0.032" | 0.498" | 980 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 5/8" | 0.025" | 0.575" | 690 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 5/8" | 0.032" | 0.561" | 890 psi @ 72 ° F | H58 | 1/2 Hard | 0000000 | |||

| 5/8" | 0.065" | 0.495" | 1,800 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 3/4" | 0.032" | 0.686" | 750 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 3/4" | 0.065" | 0.62" | 1,500 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 7/8" | 0.032" | 0.811" | 640 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 7/8" | 0.065" | 0.745" | 1,300 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1" | 0.025" | 0.95" | 430 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1" | 0.032" | 0.936" | 560 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1" | 0.065" | 0.87" | 1,200 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 1/8" | 0.032" | 1.061" | 490 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 1/8" | 0.065" | 0.995" | 1,000 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 1/4" | 0.032" | 1.186" | 450 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 1/4" | 0.065" | 1.12" | 910 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 3/8" | 0.032" | 1.311" | 400 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 3/8" | 0.065" | 1.245" | 830 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 1/2" | 0.032" | 1.436" | 370 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 1/2" | 0.065" | 1.37" | 760 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 5/8" | 0.032" | 1.561" | 340 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 5/8" | 0.065" | 1.495" | 700 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 3/4" | 0.032" | 1.686" | 320 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 3/4" | 0.065" | 1.62" | 650 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 7/8" | 0.032" | 1.811" | 300 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 1 7/8" | 0.065" | 1.745" | 610 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 2" | 0.032" | 1.936" | 280 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

| 2" | 0.065" | 1.87" | 570 psi @ 72 ° F | H58 | 1/2 Hard | 00000000 | |||

Quick-Connect Propane Torch Kits

Save time by quickly connecting and disconnecting your propane torch tips to get the right output for your job. Kit can also be used with Apachi, HPG, and propylene. Note: Maximum power output and flame temperature values shown are for use with propane.

1/2" Dia. Tip | 1" Dia. Tip | Pressure Regulator Inlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Power Output, Btu/hr. | Max. Flame Temp., °F | For Soft Soldering Copper Tube Dia. (For Use With) | For Silver Soldering Copper Tube Dia. (For Use With) | Max. Power Output, Btu/hr. | Max. Flame Temp., °F | For Soft Soldering Copper Tube Dia. (For Use With) | For Silver Soldering Copper Tube Dia. (For Use With) | Adjustable Flame | CGA Number | Gender | Each | |

| 8,400 | 3000° | 1 1/2” (Propane) 2 1/2" (Propylene) | 3/4" (Propane) 1 1/4" (Propylene) | 45,300 | 3000° | 4" (Propane) 6" (Propylene) | 2" (Propane) 4" (Propylene) | Yes | CGA 510 | Male | 00000000 | 0000000 |

| Dia. | Max. Power Output, Btu/hr. | Adjustable Flame | Max. Flame Temp., °F | For Soft Soldering Copper Tube Dia. (For Use With) | For Silver Soldering Copper Tube Dia. (For Use With) | Each | |

| 7/16" | 5,300 | Yes | 3000° | 1" (Propane); 1 1/2" (Propylene) | 1/2" (Propane); 1/2" (Propylene) | 00000000 | 0000000 |

| 1/2" | 8,400 | Yes | 3000° | 1 1/2" (Propane); 2 1/2" (Propylene) | 3/4" (Propane); 1 1/4" (Propylene) | 00000000 | 000000 |

| 3/4" | 23,700 | Yes | 3000° | 2 1/2" (Propane); 4" (Propylene) | 1 1/4" (Propane); 2" (Propylene) | 00000000 | 000000 |

| 1" | 45,300 | Yes | 3000° | 4" (Propane); 6" (Propylene) | 2" (Propane); 4" (Propylene) | 00000000 | 000000 |

Torch-to-Propane Tank Hose Assembly

This assembly converts a propane torch (which normally connects to a fuel cylinder) to be used with a propane tank. Commonly used for extended-use applications or when a propane tank cannot be moved.

Torch Connection | Tank Connection | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Hose Lg., ft. | CGA Number | Thread Size | Thread Type | Gender | For Valve Type | CGA Number | Gender | Each | |

| 12 | CGA 600 | 1"-20 | UNF | Male | POL | CGA 510 | Male | 0000000 | 000000 |