Compare over 20 aluminum alloys to find the right material for you—all with material certificates for traceability.

About Composites

More

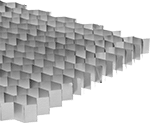

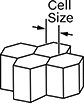

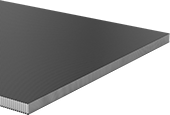

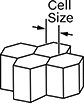

Corrosion-Resistant 3000 Series Aluminum Honeycomb Cores

- Yield Strength: Not Rated

- Hardness: Not Rated

- Temper: Not Rated

The honeycomb design provides a higher strength-to-weight ratio than solid sheets. These cores are often used as a lightweight alternative to solid aluminum and also for sound insulation. 3000 series aluminum stands up to outdoor use, as well as exposure to chemicals. It offers a good combination of strength, formability, and weldability.

| Thick. | Thick. Tolerance | Honeycomb Cell Size | Max. Load Capacity, lbs./sq. in. | Cell Wall Thick. | Temperature Range, °F | 12” × 12” | 24” × 24” | 24” × 48” | |

| 1/4" | -0.008" to 0.008" | 1/2" | 165 | 0.003" | 0° to 180° | 000000 | |||

| 3/8" | -0.008" to 0.008" | 1/2" | 165 | 0.003" | 0° to 180° | 000000 | |||

| 1/2" | -0.008" to 0.008" | 1/2" | 165 | 0.003" | 0° to 180° | 000000 | |||

| 3/4" | -0.008" to 0.008" | 1/2" | 165 | 0.003" | 0° to 180° | 000000 | |||

| 1" | -0.008" to 0.008" | 1" | 75 | 0.003" | 0° to 180° | 000000 | |||

| 1 1/4" | -0.008" to 0.008" | 1" | 75 | 0.003" | 0° to 180° | 000000 | |||

| 1 1/2" | -0.008" to 0.008" | 1" | 75 | 0.003" | 0° to 180° | 000000 |

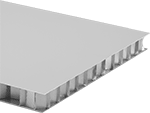

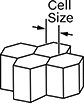

Corrosion-Resistant 3000 Series Aluminum Honeycomb Panels

- Yield Strength: Not Rated

- Hardness: Not Rated

- Temper: Not Rated

A honeycomb core is bonded between two aluminum sheets for rigidity. These panels offer a higher strength-to-weight ratio than solid sheets, so they're often used as a lightweight alternative to solid aluminum. They're also used for sound insulation. They are painted white and covered with a protective peel-off film. 3000 series aluminum stands up to outdoor use, as well as exposure to chemicals. It offers a good combination of strength, formability, and weldability.

| Thick. | Thick. Tolerance | Honeycomb Cell Size | Max. Load Capacity, lbs. | Deflection @ lb. Load | Cell Wall Thick. | Face Thick. | Temperature Range, °F | Each | |

12" × 12" | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8" | -0.020" to 0.020" | 3/8" | 250 | 0.1" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 000000 |

| 1/4" | -0.020" to 0.020" | 3/8" | 525 | 0.02" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 00000 |

| 3/8" | -0.020" to 0.020" | 1/4" | 825 | 0.01" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 00000 |

| 1/2" | -0.020" to 0.020" | 1/4" | 1,125 | 0.01" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 00000 |

| 3/4" | -0.020" to 0.020" | 1/4" | 1,725 | 0.005" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 00000 |

| 1" | -0.020" to 0.020" | 3/4" | 2,125 | 0.005" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 00000 |

24" × 24" | |||||||||

| 1/8" | -0.020" to 0.020" | 3/8" | 250 | 0.4" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 000000 |

| 1/4" | -0.020" to 0.020" | 3/8" | 525 | 0.1" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 000000 |

| 3/8" | -0.020" to 0.020" | 1/4" | 825 | 0.04" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 1/2" | -0.020" to 0.020" | 1/4" | 1,125 | 0.02" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 3/4" | -0.020" to 0.020" | 1/4" | 1,725 | 0.01" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 1" | -0.020" to 0.020" | 3/4" | 2,125 | 0.01" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

24" × 48" | |||||||||

| 1/8" | -0.020" to 0.020" | 3/8" | 125 | 2.8" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 000000 |

| 1/4" | -0.020" to 0.020" | 3/8" | 250 | 0.7" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 00000000 | 000000 |

| 3/8" | -0.020" to 0.020" | 1/4" | 400 | 0.3" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 1/2" | -0.020" to 0.020" | 1/4" | 550 | 0.2" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 3/4" | -0.020" to 0.020" | 1/4" | 850 | 0.1" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

| 1" | -0.020" to 0.020" | 3/4" | 1,125 | 0.04" @ 100 lbs. | 0.003" | 0.032" | 0° to 180° | 0000000 | 000000 |

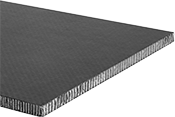

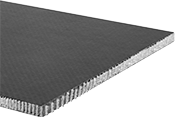

Composite Fiber Aluminum Honeycomb Panels

- Yield Strength: Not Rated

- Hardness: Not Rated

- Temper: Not Rated

An aluminum honeycomb core sandwiched between carbon fiber keeps these sheets strong yet lightweight. The carbon fiber facing gives you the same strength as a honeycomb panel that's entirely made from aluminum but without the weight. Compared to aramid honeycomb panels, these panels have better shear strength. These panels are often used in the automotive and aerospace industry in place of solid aluminum sheets thanks to their high strength-to-weight ratio.

| Thick. | Thick. Tolerance | Honeycomb Cell Size | Face Thick. | Temperature Range, °F | Each | |

12" × 12" | ||||||

|---|---|---|---|---|---|---|

| 1/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 0000000 |

| 1/2" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 3/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 1" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

24" × 24" | ||||||

| 1/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 1/2" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 3/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

| 1" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 000000 |

24" × 48" | ||||||

| 1/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

| 1/2" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

| 3/4" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

| 1" | -0.005" to 0.005" | 1/8" | 0.02" | 32° to 180° | 0000000 | 00000000 |

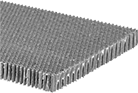

Flexible Aramid Honeycomb Cores

- Color: Orange

- Temperature Range: -100° to 350° F

- Yield Strength: Not Rated

- For Use Outdoors: No

As a strong, lightweight, and buoyant alternative to solid panels, these aramid honeycomb cores are used to make interior wall panels and floor boards in marine, structural, and industrial applications. Compared to aluminum honeycomb cores, they're lightweight and more flexible, so you'll often find them lining boats and high-speed cars. However, they’re not as strong as aluminum cores. Aramid cores also resist flames, self-extinguish without melting or dripping, and are thermal and electrical insulators. Aramid is commonly known as Nomex.

Composite Fiber Aramid Honeycomb Panels

- Face Color: Black

- Temperature Range: -100° to 250° F

- Yield Strength: Not Rated

- For Use Outdoors: No

With an aramid honeycomb core sandwiched between carbon fiber or fiberglass for rigidity, these panels are strong, but lightweight, and won’t conduct heat. Often used as wall panels in structural and insulating applications, they’re a lightweight alternative to solid composite and aluminum honeycomb panels.

Carbon-fiber-faced panels are stronger and more rigid than fiberglass-faced panels, so they resist deforming from bending, twisting, or buckling. They will, however, splinter from high-impact blows. These panels are lighter than fiberglass-faced panels. However, they conduct electricity, so don’t use them around electrical components.

Fiberglass-faced panels are often used around electrical components because they are good electrical insulators. They resist cracks from bumps and hits better than carbon-fiber-faced panels, but are not as strong or lightweight.

| Thickness | Thickness Tolerance | Honeycomb Cell Size | Each | |

12" × 12" | ||||

|---|---|---|---|---|

Carbon Fiber Face | ||||

| 1/8" | -0.03" to 0.03" | 0.125" | 00000000 | 0000000 |

| 1/4" | -0.03" to 0.03" | 0.125" | 00000000 | 000000 |

| 1/2" | -0.06" to 0.06" | 0.125" | 00000000 | 000000 |

Fiberglass Face | ||||

| 1/8" | -0.03" to 0.03" | 0.125" | 00000000 | 000000 |

| 1/4" | -0.03" to 0.03" | 0.125" | 00000000 | 000000 |

| 1/2" | -0.06" to 0.06" | 0.125" | 00000000 | 000000 |