Filter by

Mount Type

Movement

System of Measurement

Weight Capacity

Inner Ring Width

Base Material

Material

Ring Material

Ring Thickness

Ring Height

Load Securement Type

Application

For Maximum Trailer Weight

Base Width

Anchor Point Type

Export Control Classification Number (ECCN)

DFARS Specialty Metals

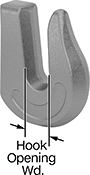

Tow Hooks

Weld On

For Chain | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. Trailer Wt., lb. | Grade | Thk. | Dp. | Ht. | Material | Hook Opening Wd. | Mounting Plate Thk. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Hooks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,500 | 43 | 5/16" | 3 1/8" | 3 7/8" | Steel | 5/8" | 1 1/16" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5,000 | 43 | 3/8" | 2 3/8" | 3" | Steel | 1/2" | 13/16" | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6,500 | 70 | 3/8" | 2 1/4" | 3" | Steel | 9/16" | 11/16" | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9,000 | 43 | 1/2" | 3 1/8" | 3 7/8" | Steel | 11/16" | 1" | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

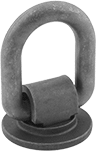

Weld-on-Mount Hoist Rings—For Lifting

|  |

180° Pivot | 180° Pivot and 360° Swivel |

|

180° Pivot |

|

360° Swivel |

Inside Wd. | Overall Ht. | Vert. Cap., lb. | Specs. Met | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

180° Pivot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forged Orange Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 3 1/8" | 3,300 | — | CE Marked | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 3 9/16" | 5,510 | — | CE Marked | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 4" | 8,810 | — | CE Marked | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/8" | 6 3/16" | 22,040 | — | CE Marked | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 11/16" | 5 9/16" | 14,770 | — | CE Marked | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

180° Pivot and 360° Swivel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forged Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 5 1/2" | 5,000 | ASME B30.26 | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 7 5/8" | 10,000 | ASME B30.26 | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 9 1/2" | 24,000 | ASME B30.26 | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Weld-On Tie-Down Rings

Ring | Base | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap. | Inner Wd. | Ht. | Thk. | Style | Dia. | Lg. | Wd. | Material | 1-24 | 25-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1/4" | 3/4" | 3/16" | Round Ring | 5/8" | — | — | Low-Carbon Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 3/8" | 1" | 1/4" | Round Ring | 7/8" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 5/8" | 1 5/16" | 1/4" | Round Ring | 1" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 3/4" | 1 5/8" | 3/8" | Round Ring | 1 1/16" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1" | 2 5/16" | 9/16" | Round Ring | 1 7/16" | — | — | Low-Carbon Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 3/16" | 2 3/8" | 7/16" | Round Ring | 1 11/16" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 1/4" | 2 3/4" | 11/16" | Round Ring | 1 3/4" | — | — | Low-Carbon Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Not Rated | 5/8" | 7/8" | 1/4" | Round Ring | — | 1 1/8" | 1 1/8" | Alloy Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1/2" | 1 1/16" | 3/16" | Round Ring | 3/8" | — | — | 316 Stainless Steel | 000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 5/8" | 1 5/16" | 1/4" | Round Ring | 9/16" | — | — | 316 Stainless Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 3/4" | 1 9/16" | 5/16" | Round Ring | 5/8" | — | — | 316 Stainless Steel | 0000000 | 00000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1" | 2" | 3/8" | Round Ring | 7/8" | — | — | 316 Stainless Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 1/4" | 2 1/2" | 1/2" | Round Ring | 1" | — | — | 316 Stainless Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 1/2" | 3 1/4" | 5/8" | Round Ring | 1 3/8" | — | — | 316 Stainless Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

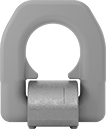

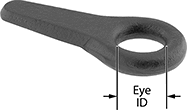

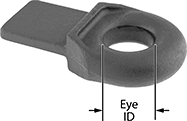

Weld-On Tie-Down Rings

|  |  |  |

Style A | Style B | Style C | Style D |

Ring | Base | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap., lb. | Inner Wd. | Ht. | Thk. | Style | Lg. | Wd. | Ht. | Thk. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 2,000 | 2 9/16" | 2 11/16" | 3/8" | D-Ring | 2" | 15/16" | — | 1/4" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6,600 | 1 1/2" | 3 3/16" | 1/2" | D-Ring | 1 3/8" | 1 15/16" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 11,000 | 1 3/4" | 3 7/16" | 9/16" | D-Ring | 1 5/8" | 1 15/16" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 17,600 | 2" | 4 1/16" | 11/16" | D-Ring | 1 13/16" | 2 3/16" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 29,800 | 2 11/16" | 5 11/16" | 15/16" | D-Ring | 2 1/2" | 3 1/16" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 44,100 | 2 3/4" | 6" | 1 1/16" | D-Ring | 2 1/2" | 3 5/8" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 17,600 | 1 7/8" | 3 3/8" | 9/16" | D-Ring | 5 1/4" | 2 5/8" | 1 1/16" | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 29,800 | 2 3/8" | 4 1/16" | 13/16" | D-Ring | 6 11/16" | 3 1/8" | 1 7/16" | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Red Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 2,100 | 1 7/16" | 2 9/16" | 0.43" | D-Ring | 1 1/4" | 1 1/4" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3,500 | 1 5/8" | 3 1/16" | 0.55" | D-Ring | 1 1/2" | 1 1/2" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 7,100 | 1 7/8" | 3 3/4" | 0.71" | D-Ring | 1 3/4" | 1 3/4" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 12,000 | 2 5/8" | 5 3/8" | 0.94" | D-Ring | 2 3/8" | 2 3/8" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 18,100 | 2 13/16" | 5 3/4" | 1.1" | D-Ring | 2 11/16" | 2 9/16" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 34,200 | 4 3/4" | 8 1/8" | 1 1/2" | D-Ring | 3 3/4" | 4 1/4" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 4,080 | 2 3/8" | 3 1/2" | 1/2" | D-Ring | 2" | 1 5/16" | — | 11/16" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 4,080 | 2 1/2" | 5 1/2" | 1/2" | D-Ring | 2" | 1 5/16" | — | 3/8" | Low-Carbon Steel | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6,130 | 3" | 4 1/4" | 5/8" | D-Ring | 2 1/2" | 1 5/8" | — | 3/8" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 9,120 | 3" | 4 1/2" | 3/4" | D-Ring | 2 1/4" | 1 5/8" | — | 3/8" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 15,500 | 3" | 6" | 1" | D-Ring | 2 1/4" | 2 1/8" | — | 3/8" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 15,500 | 3" | 5 1/2" | 1" | Angled-Bend D-Ring | 2 1/4" | 2 1/8" | — | 1/2" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3,000 | 2 5/16" | 3 5/8" | 1/2" | D-Ring | 2" | 1 3/8" | — | 1/4" | 316 Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 4,500 | 2 15/16" | 4 1/2" | 5/8" | D-Ring | 2 9/16" | 1 3/4" | — | 3/8" | 316 Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6,500 | 2 15/16" | 4 5/8" | 3/4" | D-Ring | 2 9/16" | 1 7/8" | — | 3/8" | 316 Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 8,500 | 3" | 5 1/8" | 1" | D-Ring | 2 9/16" | 2 1/8" | — | 1/2" | 316 Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

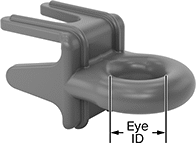

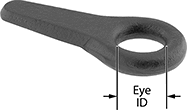

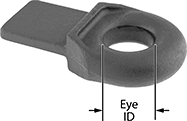

Tow Eyes

|  |

Style 5 | Style 6 |

|  |

Style 7 | Style 8 |

Weld On

|  |

Style 5 | Style 6 |

|  |

Style 7 | Style 8 |

Overall | Eye | Mounting Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Max. Trailer Wt., lb. | Vert. Cap., lb. | No. of Positions | Ht. Adjustment Increments | Dp. | Ht. | Material | Color | ID | Thk. | Wd. | Ht. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Height | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 12,000 | 1,800 | — | — | 8 9/16" | 7/8" | Powder-Coated Steel | Gray | 2" | 7/8" | — | — | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 90,000 | 13,500 | — | — | 9 5/16" | 1 5/8" | Powder-Coated Steel | Gray | 2 3/8" | 1 5/8" | — | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 150,000 | 15,000 | — | — | 11 1/8" | 1 5/8" | Powder-Coated Steel | Gray | 3" | 1 5/8" | — | — | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 100,000 | 15,000 | — | — | 10 1/8" | 5 3/8" | Powder-Coated Steel | Gray | 2 3/8" | 1 5/8" | — | — | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable Height | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 20,000 | 1,000 | 3 | 2" | 8" | 8 1/2" | Powder-Coated Steel | Black | 2 1/2" | 1" | 4" | 8 1/2" | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 20,000 | 1,000 | 5 | 2" | 7 3/4" | 12 1/2" | Powder-Coated Steel | Black | 2 1/2" | 1" | 4" | 12 1/2" | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

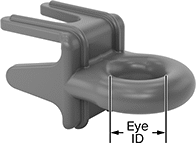

E-Track Plates

Style B |

Style | Wt. Cap., lb. | Lg. | Wd. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Low-Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1,000 | 1" | 4 1/2" | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||