How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Measuring Hose and Tube Clamps

What's the best way to determine the clamp size you'll need? Simply measure the outside diameter of your hose with the fitting installed. Some clamps accommodate a range of sizes, so be sure the size you need falls in the middle of that range.

More

Selecting Clamps Using Pipe, Conduit, or Tubing Trade Size

More

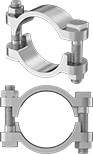

Tight-Seal High-Torque Bolt Clamps for Firm Hose

Clamps offer extra holding power in high-torque applications.

The bolt design provides good strength and creates a 360° seal to prevent leaks. Clamps have fair corrosion resistance. They are for firm plastic and rubber hose. They are not recommended for use with helix wire hose and hydraulic hose. Do not exceed the maximum torque or clamps may be damaged.

Double Bolt—The tightening force is equally distributed between both sides of the clamp. These clamps open completely for easy installation and have reinforced bolt lugs to prevent the clamp from bending out of alignment.

Double Bolt with Saddles—Same as the double-bolt clamps, except these have two saddles to maintain even pressure around large-diameter hose.

Note: When choosing a clamp, measure the outside diameter of your hose with the fitting installed.

Clamp ID Range | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inch | mm | Band Wd. | Max. Torque, in.-lbs. | Drive Style | Hex Size | Reusable | Bolt Type | Head Shape | Each | |

Zinc-Plated Iron with Zinc-Plated Steel Bolt | ||||||||||

Double Bolt | ||||||||||

| 1 3/16" to 1 3/8" | 30.2 to 34.9 | 15/16" | 252 | External Hex | 9/16" | No | Straight | Square | 0000000 | 000000 |

| 1 7/16" to 1 17/32" | 36.5 to 38.9 | 1" | 252 | External Hex | 7/16" | No | Straight | Square | 0000000 | 00000 |

| 1 5/8" to 1 13/16" | 41.3 to 46 | 1 1/4" | 480 | External Hex | 11/16" | No | Straight | Square | 0000000 | 00000 |

| 1 3/4" to 2 3/64" | 44.5 to 52 | 1" | 324 | External Hex | 9/16" | No | Straight | Square | 0000000 | 00000 |

| 2 7/64" to 2 19/64" | 53.6 to 58.3 | 1" | 324 | External Hex | 9/16" | No | Straight | Square | 0000000 | 00000 |

| 2 5/16" to 2 5/8" | 58.7 to 66.7 | 1" | 480 | External Hex | 11/16" | No | Straight | Square | 0000000 | 00000 |

| 2 1/2" to 2 3/4" | 63.5 to 69.9 | 1 3/16" | 480 | External Hex | 11/16" | No | Straight | Square | 0000000 | 00000 |

| 3 1/4" to 3 1/2" | 82.6 to 88.9 | 1 5/32" | 720 | External Hex | 3/4" | No | Straight | Square | 0000000 | 00000 |

Double Bolt with Saddles | ||||||||||

| 3 1/2" to 3 13/16" | 88.9 to 96.8 | 1" | 480 | External Hex | 11/16" | No | Straight | Square | 0000000 | 00000 |

| 3 25/32" to 4 1/16" | 96 to 103.2 | 1" | 480 | External Hex | 11/16" | No | Straight | Square | 0000000 | 00000 |

| 4 1/32" to 4 9/32" | 102.4 to 108.7 | 1" | 480 | External Hex | 3/4" | No | Straight | Square | 0000000 | 00000 |

| 4 1/4" to 4 15/16" | 108 to 125.4 | 1 1/8" | 720 | External Hex | 3/4" | No | Straight | Square | 0000000 | 00000 |

| 4 1/2" to 5 1/4" | 114.3 to 133.4 | 1 1/8" | 720 | External Hex | 3/4" | No | Straight | Square | 0000000 | 00000 |

| 5 1/8" to 5 11/16" | 130.2 to 144.5 | 1 1/8" | 720 | External Hex | 3/4" | No | Straight | Square | 0000000 | 00000 |

| 5 15/16" to 6 1/2" | 150.8 to 165.1 | 1 5/32" | 720 | External Hex | 3/4" | No | Straight | Square | 0000000 | 00000 |

| 6 1/2" to 7 9/16" | 165.1 to 192.1 | 1 1/8" | 720 | External Hex | 3/4" | No | Straight | Square | 0000000 | 00000 |

| 7 11/16" to 8 3/16" | 195.3 to 208 | 1 3/8" | 1,500 | External Hex | 15/16" | No | Straight | Square | 0000000 | 00000 |

| 8 1/4" to 8 7/8" | 209.6 to 225.4 | 1 3/8" | 1,500 | External Hex | 15/16" | No | Straight | Square | 0000000 | 00000 |

| 8 15/16" to 9 7/8" | 227 to 250.8 | 1 13/32" | 1,500 | External Hex | 15/16" | No | Straight | Square | 0000000 | 00000 |

| 9 15/16" to 11 3/8" | 252.4 to 288.9 | 1 5/8" | 1,500 | External Hex | 15/16" | No | Straight | Square | 0000000 | 000000 |

| 12 3/16" to 14" | 309.6 to 355.6 | 1 7/8" | 2,400 | External Hex | 1 1/8" | No | Straight | Square | 0000000 | 000000 |

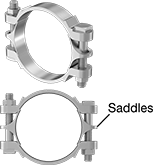

Interlocking Clamps for Hose Fittings for Steam

- Maximum Pressure: 250 psi @ 72° F

- Maximum Vacuum: 28 in. of Hg @ 72° F

- Temperature Range: -20° to 450° F

- Compatible With: Dixon Boss, Dixon Ground Joint

Use with interlocking-clamp hose fittings to replace a damaged clamp. They consist of two halves held together by nuts and bolts. Clamps are strong and durable with fair corrosion resistance.

| For Hose ID | For Hose OD Range | Clamp Material | Each | |

Zinc-Plated Steel | ||||

|---|---|---|---|---|

| 1/2" | 15/16" to 1 1/16" | Zinc-Plated Steel | 0000000 | 000000 |

| 3/4" | 1 5/32" to 1 5/16" | Zinc-Plated Steel | 0000000 | 00000 |

| 3/4" | 1 5/16" to 1 1/2" | Zinc-Plated Steel | 0000000 | 00000 |

| 1" | 1 11/16" to 1 15/16" | Zinc-Plated Steel | 0000000 | 00000 |

Zinc-Plated Iron | ||||

| 1/2" | 1 1/16" to 1 3/16" | Zinc-Plated Iron | 0000000 | 00000 |

| 2" | 2 1/2" to 2 25/32" | Zinc-Plated Iron | 0000000 | 00000 |

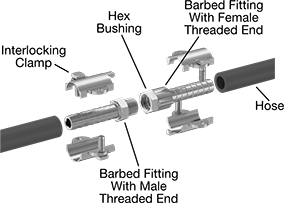

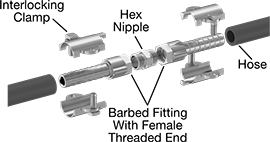

Interlocking-Clamp Hose Fittings for Steam

Also known as ground-joint couplings and boss couplings, these fittings are designed for high-pressure steam heating, humidification, and washdown applications. Insert the barbed end of the fitting into rubber hose, then position the interlocking clamp over the hose and bolt into place with a torque wrench. The clamp firmly grips the hose as it locks into the ring of the barbed end, creating a leak tight seal. The interlocking clamps are not reusable. Fittings are strong and durable with fair corrosion resistance.

Fittings with a female threaded end have a hex bushing (also known as a female spud) that connects to a male interlocking-clamp hose fitting. Replace the hex bushing with a hex nipple (sold separately) to connect two female fittings; the hex nipples are also known as double spuds.

Warning: There is no valve in these couplings. Stop the flow of steam before you disconnect the hose line.

- Maximum Pressure: 250 psi @ 72° F

- Maximum Vacuum: 28 in. of Hg @ 72° F

- Temperature Range: -20° to 450° F

- Attachment Type: Use Interlocking Clamps (included)

- Compatible With: Dixon Boss, Dixon Ground Joint

- Maximum Pressure: 250 psi @ 72° F

- Maximum Vacuum: 28 in. of Hg @ 72° F

- Temperature Range: -20° to 450° F

- Attachment Type: Use Interlocking Clamps (included)

- Compatible With: Dixon Boss, Dixon Ground Joint

Adapters | Replacement Interlocking Clamps | Replacement Hex Bushings | Hex Nipples | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Hose ID | For Hose OD Range | Pipe Size | Thread Type | Clamp Material | Wing Nut Material | Hex Bushing Material | Each | Each | Each | Each | ||||

Zinc-Plated Steel | ||||||||||||||

| 1/2" | 15/16" to 1 1/16" | 1/2 | NPT | Zinc-Plated Steel | Zinc-Plated Iron | Zinc-Plated Steel | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 |

| 1/2" | 1 1/16" to 1 3/16" | 1/2 | NPT | Zinc-Plated Iron | Zinc-Plated Iron | Zinc-Plated Steel | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 |

| 3/4" | 1 5/32" to 1 5/16" | 3/4 | NPT | Zinc-Plated Steel | Zinc-Plated Iron | Zinc-Plated Steel | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 |

| 3/4" | 1 5/16" to 1 1/2" | 3/4 | NPT | Zinc-Plated Steel | Zinc-Plated Iron | Zinc-Plated Steel | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 |

| 1" | 1 11/16" to 1 15/16" | 1 | NPT | Zinc-Plated Steel | Zinc-Plated Iron | Zinc-Plated Steel | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 |

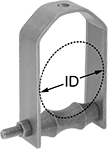

Snug-Hold Threaded-Rod-Mount Clamping Hangers

Load material between the two halves of the ring and adjust the side bolts for a tighter fit than standard threaded-rod-mount clamping hangers and loop hangers. All have a threaded hole on top for mounting with threaded rod.

Zinc-plated iron hangers have mild corrosion resistance.

Epoxy coated iron hangers are corrosion resistant and can be used with copper tubing.

ID | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | Metric, mm | For Pipe Size | For Thread Size | Cap., lbs. | Lg. | Wd. | Ht. | Mounting Hole Dia. | Specifications Met | Each | |

Iron | |||||||||||

| 11/16" | 17 | 3/8 | 3/8"-16 | 180 | 1 13/16" | 9/16" | 1 3/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

| 7/8" | 22 | 1/2 | 3/8"-16 | 180 | 2 1/16" | 9/16" | 1 3/8" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 1/16" | 27 | 3/4 | 3/8"-16 | 180 | 2 1/4" | 9/16" | 1 9/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 5/16" | 33 | 1 | 3/8"-16 | 180 | 2 11/16" | 9/16" | 1 15/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 11/16" | 43 | 1 1/4 | 3/8"-16 | 180 | 3" | 9/16" | 2 5/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 7/8" | 48 | 1 1/2 | 3/8"-16 | 180 | 3 5/16" | 9/16" | 2 9/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 2 3/8" | 60 | 2 | 3/8"-16 | 180 | 3 13/16" | 9/16" | 3" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

| 2 7/8" | 73 | 2 1/2 | 1/2"-13 | 300 | 4 3/4" | 11/16" | 3 5/8" | 1/2" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

| 3 1/2" | 89 | 3 | 1/2"-13 | 300 | 5 9/16" | 13/16" | 4 5/16" | 1/2" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

| 4 1/2" | 114 | 4 | 1/2"-13 | 300 | 6 11/16" | 1 3/16" | 5 1/2" | 1/2" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

Zinc-Plated Iron | |||||||||||

| 11/16" | 17 | 3/8 | 3/8"-16 | 180 | 1 13/16" | 9/16" | 1 3/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 7/8" | 22 | 1/2 | 3/8"-16 | 180 | 2 1/16" | 9/16" | 1 3/8" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 1/16" | 27 | 3/4 | 3/8"-16 | 180 | 2 1/4" | 9/16" | 1 9/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 5/16" | 33 | 1 | 3/8"-16 | 180 | 2 11/16" | 9/16" | 1 15/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 11/16" | 43 | 1 1/4 | 3/8"-16 | 180 | 3" | 9/16" | 2 5/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 7/8" | 48 | 1 1/2 | 3/8"-16 | 180 | 3 5/16" | 9/16" | 2 9/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 2 3/8" | 60 | 2 | 3/8"-16 | 180 | 3 13/16" | 9/16" | 3" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

| 2 7/8" | 73 | 2 1/2 | 1/2"-13 | 300 | 4 3/4" | 11/16" | 3 5/8" | 1/2" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

| 3 1/2" | 89 | 3 | 1/2"-13 | 300 | 5 9/16" | 13/16" | 4 5/16" | 1/2" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

| 4 1/2" | 114 | 4 | 1/2"-13 | 300 | 6 11/16" | 1 3/16" | 5 1/2" | 1/2" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

Epoxy Coated Iron | |||||||||||

| 1/2" | 12 | __ | 3/8"-16 | 180 | 1 11/16" | 9/16" | 1" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 5/8" | 15 | __ | 3/8"-16 | 180 | 1 3/4" | 9/16" | 1 1/4" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 7/8" | 22 | __ | 3/8"-16 | 180 | 1 15/16" | 9/16" | 1 1/2" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 1/8" | 28 | __ | 3/8"-16 | 180 | 2 1/4" | 9/16" | 1 13/16" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 3/8" | 34 | __ | 3/8"-16 | 180 | 2 5/8" | 9/16" | 2" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 0000 |

| 1 5/8" | 41 | __ | 3/8"-16 | 180 | 2 15/16" | 9/16" | 2 1/4" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

| 2 1/8" | 53 | __ | 3/8"-16 | 180 | 3 7/16" | 9/16" | 2 3/4" | 3/8" | Fed. Spec. WW-H-171E, Type 25; MSS-SP-58-2009, Type 12 | 0000000 | 00000 |

Threaded-Rod-Mount Roller Loop Hangers

A roller on the bottom of these hangers compensates for movement due to expansion and contraction, such as in hydraulic applications. Combine with a threaded rod or other fastener to hang from the ceiling. To mount, slide threaded rod into the unthreaded hole on top of the hanger and secure with a nut (sold separately).

ID | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | Metric, mm | For Pipe Size | For Thread Size | Roller Material | Cap., lbs. | Lg. | Wd. | Ht. | Thick. | Mounting Hole Dia. | Each | |

Steel | ||||||||||||

| 2 3/8" | 60 | 2 | 3/8"-16 | Cast Iron | 150 | 4" | 1 1/4" | 4 3/4" | 3/16" | 7/16" | 0000000 | 000000 |

| 2 7/8" | 73 | 2 1/2 | 1/2"-13 | Cast Iron | 220 | 4 15/16" | 1 1/4" | 6" | 3/16" | 9/16" | 0000000 | 00000 |

| 3 1/2" | 89 | 3 | 1/2"-13 | Cast Iron | 310 | 5 9/16" | 1 1/4" | 6 5/8" | 3/16" | 9/16" | 0000000 | 00000 |

| 4" | 102 | 3 1/2 | 1/2"-13 | Cast Iron | 390 | 6 1/16" | 1 1/4" | 7 1/4" | 9/32" | 9/16" | 0000000 | 00000 |

| 4 1/2" | 114 | 4 | 5/8"-11 | Cast Iron | 470 | 6 3/4" | 1 1/2" | 7 7/8" | 9/32" | 11/16" | 0000000 | 00000 |

| 5 9/16" | 141 | 5 | 5/8"-11 | Cast Iron | 680 | 8 1/2" | 1 3/4" | 9 3/16" | 13/32" | 11/16" | 0000000 | 00000 |

| 6 5/8" | 168 | 6 | 3/4"-10 | Cast Iron | 780 | 9 3/4" | 2" | 10 3/8" | 13/32" | 13/16" | 0000000 | 00000 |

| 8 5/8" | 219 | 8 | 3/4"-10 | Cast Iron | 780 | 12" | 2 1/2" | 12 5/8" | 13/32" | 13/16" | 0000000 | 000000 |

| 10 3/4" | 273 | 10 | 7/8"-9 | Cast Iron | 960 | 14 1/4" | 2 1/2" | 14 15/16" | 13/32" | 15/16" | 0000000 | 000000 |

| 12 3/4" | 324 | 12 | 7/8"-9 | Cast Iron | 1,200 | 16 3/4" | 2 1/2" | 17 3/8" | 17/32" | 15/16" | 0000000 | 000000 |

| 14" | 356 | 14 | 1"-8 | Cast Iron | 1,200 | 18 1/4" | 2 1/2" | 19" | 17/32" | 1 1/8" | 0000000 | 000000 |

| 16" | 406 | 16 | 1"-8 | Cast Iron | 1,200 | 20 1/2" | 2 1/2" | 20 3/4" | 17/32" | 1 1/8" | 0000000 | 000000 |