How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Fire-Fighting Hose Threads

More

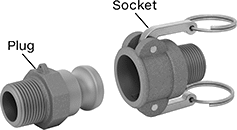

Metal Cam-and-Groove Hose Couplings for Chemicals and Petroleum

Made of metal, these couplings have better durability than plastic cam-and-groove couplings. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug. Couplings are compatible with Andrews, Dixon, Ever-Tite, and PT cam-and-groove couplings.

Aluminum fittings are lighter in weight than 316 stainless steel fittings. They have good corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: 6 Coupling Size and smaller: Fed. Spec. A-A-59326

| Coupling Size | Plug OD | Max. Pressure | Each | |

Aluminum | ||||

|---|---|---|---|---|

| 1/2 | 15/16" | 250 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 1 1/4" | 250 psi @ 72° F | 00000000 | 0000 |

| 1 | 1 7/16" | 250 psi @ 72° F | 00000000 | 0000 |

| 1 1/4 | 1 13/16" | 250 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 2 1/8" | 250 psi @ 72° F | 00000000 | 00000 |

| 2 | 2 1/2" | 250 psi @ 72° F | 00000000 | 00000 |

| 2 1/2 | 3" | 200 psi @ 72° F | 00000000 | 00000 |

| 3 | 3 5/8" | 200 psi @ 72° F | 00000000 | 00000 |

| 4 | 4 3/4" | 150 psi @ 72° F | 00000000 | 00000 |

| 5 | 5 3/4" | 75 psi @ 72° F | 000000000 | 00000 |

| 6 | 6 15/16" | 75 psi @ 72° F | 00000000 | 00000 |

| 8 | 8 7/8" | 50 psi @ 72° F | 000000000 | 000000 |

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: Fed. Spec. A-A-59326

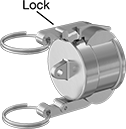

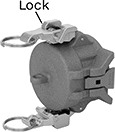

Sockets with locking levers prevent accidental disconnection. The locks engage automatically when the coupling is connected. Press the locks simultaneously to disengage.

Sockets | Replacement Gaskets | Replacement Levers | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Coupling Size | Socket ID | No. of Levers | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | |||

Aluminum with Brass Levers | |||||||||||

| 1 | 1 7/16" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 000000000 | 000000 | 10 | 0000000 | 00000 | 000000000 | 000000 |

| 1 1/4 | 1 13/16" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 00000 |

| 1 1/2 | 2 1/8" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 00000 |

| 2 | 2 1/2" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 00000 |

| 2 1/2 | 3" | 2 | Zinc-Plated Steel | 200 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 00000 |

| 3 | 3 5/8" | 2 | Zinc-Plated Steel | 200 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 4 | 4 3/4" | 2 | Zinc-Plated Steel | 150 psi @ 72° F | 000000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 5 | 5 3/4" | 2 | Zinc-Plated Steel | 75 psi @ 72° F | 000000000 | 000000 | 5 | 0000000 | 00000 | 000000000 | 00000 |

Aluminum with 316 Stainless Steel Levers | |||||||||||

| 1 | 1 7/16" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 00000000 | 00000 |

| 1 1/4 | 1 13/16" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 00000000 | 00000 |

| 1 1/2 | 2 1/8" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 00000000 | 00000 |

| 2 | 2 1/2" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 00000000 | 00000 |

| 2 1/2 | 3" | 2 | Zinc-Plated Steel | 200 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 00000000 | 00000 |

| 3 | 3 5/8" | 2 | Zinc-Plated Steel | 200 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 4 | 4 3/4" | 2 | Zinc-Plated Steel | 150 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 5 | 5 3/4" | 2 | Zinc-Plated Steel | 75 psi @ 72° F | 0000000 | 000000 | 5 | 0000000 | 00000 | 000000000 | 00000 |

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met: 6 Coupling Size and smaller: Fed. Spec. A-A-59326

Sockets | Replacement Gaskets | Replacement Levers | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Coupling Size | Socket ID | No. of Levers | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | |||

Aluminum with Brass Levers | |||||||||||

| 1/2 | 15/16" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 000000000 | 000000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 3/4 | 1 1/4" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 1 | 1 7/16" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 1 1/4 | 1 13/16" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 1 1/2 | 2 1/8" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 2 | 2 1/2" | 2 | Zinc-Plated Steel | 250 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 2 1/2 | 3" | 2 | Zinc-Plated Steel | 200 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 3 | 3 5/8" | 2 | Zinc-Plated Steel | 200 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 0000 |

| 4 | 4 3/4" | 2 | Zinc-Plated Steel | 150 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 0000 |

| 5 | 5 3/4" | 2 | Zinc-Plated Steel | 75 psi @ 72° F | 000000000 | 00000 | 5 | 0000000 | 00000 | 000000000 | 0000 |

| 6 | 6 15/16" | 2 | Zinc-Plated Steel | 75 psi @ 72° F | 00000000 | 000000 | 5 | 0000000 | 00000 | 000000000 | 00000 |

| 8 | 8 7/8" | 4 | Zinc-Plated Steel | 50 psi @ 72° F | 000000000 | 000000 | 1 | 0000000 | 00000 | 000000000 | 00000 |

Aluminum with 304 Stainless Steel Levers | |||||||||||

| 1/2 | 15/16" | 2 | 300 Series Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 3/4 | 1 1/4" | 2 | 300 Series Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 1 | 1 7/16" | 2 | 300 Series Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 1 1/4 | 1 13/16" | 2 | 300 Series Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 00000 |

| 1 1/2 | 2 1/8" | 2 | 300 Series Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 00000 |

| 2 | 2 1/2" | 2 | 300 Series Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 2 1/2 | 3" | 2 | 300 Series Stainless Steel | 200 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 3 | 3 5/8" | 2 | 300 Series Stainless Steel | 200 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 4 | 4 3/4" | 2 | 300 Series Stainless Steel | 150 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 5 | 5 3/4" | 2 | 300 Series Stainless Steel | 75 psi @ 72° F | 0000000 | 00000 | 5 | 0000000 | 00000 | 000000000 | 00000 |

| 6 | 6 15/16" | 2 | 300 Series Stainless Steel | 75 psi @ 72° F | 0000000 | 000000 | 5 | 0000000 | 00000 | 000000000 | 00000 |

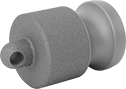

Protective Aluminum Plugs for Cam-and-Groove

Hose Sockets for Chemicals and Petroleum

Use these plugs when you need a cap, bumper, and handle in one piece. Made of aluminum, they will seal your chemical or petroleum line. Since they’re wider than the socket and its levers, the plugs take most of the impact when bumped and dropped. Grab the handle to move and position your hose into place. To install, insert into your cam-and-groove socket and press its levers down.

Metal Cam-and-Groove Hose Couplings for Water

A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

Aluminum couplings are lighter in weight than brass plugs and sockets. They have good abrasion and corrosion resistance thanks to their anodized finish.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

| Coupling Size | Plug OD | Max. Pressure | Each | |

Anodized Aluminum | ||||

|---|---|---|---|---|

| 1/2 | 15/16" | 250 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 1 1/4" | 250 psi @ 72° F | 0000000 | 00000 |

| 1 | 1 7/16" | 250 psi @ 72° F | 0000000 | 00000 |

| 1 1/4 | 1 13/16" | 250 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 2 1/8" | 250 psi @ 72° F | 0000000 | 00000 |

| 2 | 2 1/2" | 250 psi @ 72° F | 0000000 | 00000 |

| 2 1/2 | 3" | 200 psi @ 72° F | 0000000 | 00000 |

| 3 | 3 5/8" | 200 psi @ 72° F | 0000000 | 00000 |

| 4 | 4 3/4" | 150 psi @ 72° F | 0000000 | 00000 |

| 5 | 5 3/4" | 75 psi @ 72° F | 00000000 | 00000 |

| 6 | 6 15/16" | 75 psi @ 72° F | 0000000 | 000000 |

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

Couplings with locking levers prevent accidental disconnection. The locks engage automatically when the coupling is connected. Press the locks simultaneously to disengage.

Caps | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | Replacement Levers | ||||||||||

| Coupling Size | Socket ID | No. of | Material | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | |||

Anodized Aluminum | ||||||||||||

| 1 | 1 7/16" | 2 | 316 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 00000 | 00000000 | 000000 |

| 1 1/4 | 1 13/16" | 2 | 316 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 00000000 | 00000 |

| 1 1/2 | 2 1/8" | 2 | 316 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 00000000 | 00000 |

| 2 | 2 1/2" | 2 | 316 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 00000000 | 00000 |

| 2 1/2 | 3" | 2 | 316 Stainless Steel | Stainless Steel | 200 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 0000 | 00000000 | 00000 |

| 3 | 3 5/8" | 2 | 316 Stainless Steel | Stainless Steel | 200 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 4 | 4 3/4" | 2 | 316 Stainless Steel | Stainless Steel | 150 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 5 | 5 3/4" | 2 | 316 Stainless Steel | Stainless Steel | 75 psi @ 72° F | 00000000 | 000000 | 5 | 0000000 | 00000 | 000000000 | 00000 |

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

Caps | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | Replacement Levers | ||||||||||

| Coupling Size | Socket ID | No. of | Material | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | |||

Anodized Aluminum | ||||||||||||

| 1/2 | 15/16" | 2 | 304 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 3/4 | 1 1/4" | 2 | 304 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 1 | 1 7/16" | 2 | 304 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 1 1/4 | 1 13/16" | 2 | 304 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 00000 |

| 1 1/2 | 2 1/8" | 2 | 304 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 00000 |

| 2 | 2 1/2" | 2 | 304 Stainless Steel | Stainless Steel | 250 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 2 1/2 | 3" | 2 | 304 Stainless Steel | Stainless Steel | 200 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 0000 | 000000000 | 0000 |

| 3 | 3 5/8" | 2 | 304 Stainless Steel | Stainless Steel | 200 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 4 | 4 3/4" | 2 | 304 Stainless Steel | Stainless Steel | 150 psi @ 72° F | 0000000 | 00000 | 10 | 0000000 | 00000 | 000000000 | 00000 |

| 5 | 5 3/4" | 2 | 304 Stainless Steel | Stainless Steel | 75 psi @ 72° F | 00000000 | 000000 | 5 | 0000000 | 00000 | 000000000 | 00000 |

| 6 | 6 15/16" | 2 | 304 Stainless Steel | Stainless Steel | 75 psi @ 72° F | 0000000 | 000000 | 5 | 0000000 | 00000 | 000000000 | 00000 |

- Maximum Pressure: See table

- Temperature Range: -40° to 200° F

- Specifications Met: Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

Couplings with locking levers prevent accidental disconnection. The locks engage automatically when the coupling is connected. Press the locks simultaneously to disengage.

Use safety-venting sockets and caps to prevent the hose from whipping under pressure as you disconnect it. They have two spring-loaded tabs that grab the plug, so you can open the levers to relieve pressure while the hose stays connected. After releasing the pressure, squeeze the tabs to disconnect the plug.

Caps | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | Replacement Levers | ||||||||||

| Coupling Size | Socket ID | No. of | Material | Pull Ring Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | Each | |||

Anodized Aluminum | ||||||||||||

| 2 | 2 1/2" | 2 | 316 Stainless Steel | Chrome-Plated Steel | 125 psi @ 72° F | 0000000 | 0000000 | 10 | 0000000 | 00000 | 0000000 | 000000 |

| 3 | 3 5/8" | 2 | 316 Stainless Steel | Chrome-Plated Steel | 100 psi @ 72° F | 0000000 | 000000 | 10 | 0000000 | 00000 | 0000000 | 00000 |

| 4 | 4 3/4" | 2 | 316 Stainless Steel | Chrome-Plated Steel | 75 psi @ 72° F | 0000000 | 000000 | 10 | 0000000 | 00000 | 0000000 | 00000 |

Quick-Access Caps for Pin-Lug Fire Hydrants

These caps are the fastest way to access fire hydrants and washdown equipment. To install them, loop the eyebolts over the pin lugs of the hydrant and secure them in place with nuts. In an emergency, break the cap by hitting it or prying it off with a spanner wrench. Caps are aluminum, which is lightweight with good corrosion resistance.

| For Fire Hose Trade Size | Material | Lg. | Each | |

| 2 1/2 | Aluminum | 3 1/2" | 000000 | 000000 |