How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Barbed Hose Fittings for Food and Beverage

These fittings are FDA compliant, so they’re suitable for food and beverage applications and won’t impart tastes or odors to the product. Secure barbed ends into plastic or rubber hose with a clamp. These fittings are lightweight with good corrosion resistance.

Nylon fittings have higher strength and temperature resistance than polypropylene ones.

- Maximum Pressure: 205 psi @ 72° F

- Temperature Range: 0° to 230° F

- Attachment Type: Use Worm-Drive Clamps or Bolt Clamps

- Specifications Met: FDA Compliant 21 CFR 177.1500

| For Hose ID | Pipe Size | Color | Each | |

Nylon Plastic | ||||

|---|---|---|---|---|

| 3/16" | 1/4 | Blue | 0000000 | 00000 |

| 1/4" | 1/8 | Blue | 0000000 | 000 |

| 1/4" | 3/8 | Blue | 0000000 | 000 |

| 1/4" | 1/2 | Blue | 0000000 | 000 |

| 3/8" | 1/4 | Blue | 0000000 | 000 |

| 3/8" | 1/2 | Blue | 0000000 | 000 |

| 3/8" | 3/4 | Blue | 0000000 | 000 |

| 1/2" | 1/4 | Blue | 0000000 | 000 |

| 1/2" | 3/8 | Blue | 0000000 | 0000 |

| 1/2" | 3/4 | Blue | 0000000 | 0000 |

| 5/8" | 1/2 | Blue | 0000000 | 0000 |

| 5/8" | 3/4 | Blue | 0000000 | 0000 |

| 3/4" | 1/2 | Blue | 0000000 | 0000 |

- Maximum Pressure: 205 psi @ 72° F

- Temperature Range: 0° to 230° F

- Attachment Type: Use Worm-Drive Clamps or Bolt Clamps

- Specifications Met: FDA Compliant 21 CFR 177.1500

- Maximum Pressure: 205 psi @ 72° F

- Temperature Range: 0° to 230° F

- Attachment Type: Use Worm-Drive Clamps or Bolt Clamps

- Specifications Met: FDA Compliant 21 CFR 177.1500

High-Pressure Barbed Plastic Pipe Fittings for Water

Use these barbed pipe fittings in industrial plumbing, water processing, and water supply applications up to 200 psi. They meet NSF/ANSI Standard 61 for drinking water. Also known as insert fittings, they have a barbed end that slides into semi-flexible plastic pipe and secures with a clamp (sold separately). Since you don't have to wait for cement to dry, they're quicker to install than socket-connect fittings. Fittings are PVC, which has good strength and corrosion resistance. They meet ASTM D1784 specifications and testing requirements for material quality and ASTM D2609 specifications for barb dimensions.

Note: Barbed pipe fittings are measured by pipe size, which is not an actual measured size, but rather an industry designation.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D2609, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Semi-Flexible Polyethylene Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

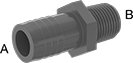

(A) | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Size | Barb OD | Pipe Size (B) | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||

| 1/2 | 0.65" | 3/4 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 0.85" | 1 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 000000000 | 0000 |

| 1 | 1.08" | 1 1/4 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 000000000 | 0000 |

| 1 | 1.08" | 1 1/2 | PVC Plastic | Dark Gray | 160 psi @ 72° F | 000000000 | 0000 |

| 1 1/4 | 1.41" | 1 1/2 | PVC Plastic | Dark Gray | 160 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 1.65" | 2 | PVC Plastic | Dark Gray | 160 psi @ 72° F | 000000000 | 0000 |

| Non-Hardening Thread Sealant | 000000 | Each | 000000 |

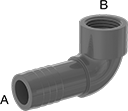

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D2609, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Semi-Flexible Polyethylene Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

(A) | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Size | Barb OD | Pipe Size (B) | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||

| 3/4 | 0.85" | 1/2 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 00000000 | 00000 |

| 1 | 1.08" | 1/2 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 00000000 | 0000 |

| 1 | 1.08" | 3/4 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 00000000 | 0000 |

| 1 1/4 | 1.41" | 1 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 00000000 | 0000 |

| 1 1/2 | 1.65" | 1 | PVC Plastic | Dark Gray | 160 psi @ 72° F | 00000000 | 0000 |

| 2 | 2.11" | 1 1/2 | PVC Plastic | Dark Gray | 160 psi @ 72° F | 00000000 | 0000 |

| Non-Hardening Thread Sealant | 000000 | Each | 000000 |

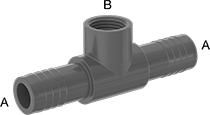

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D2609, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Semi-Flexible Polyethylene Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Inline tees are also known as branch tees.

(A) | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Size | Barb OD | Pipe Size (B) | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||

| 3/4 | 0.85" | 1/2 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 000000000 | 00000 |

| 1 | 1.08" | 1/2 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 000000000 | 0000 |

| 1 | 1.08" | 3/4 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 000000000 | 0000 |

| 1 1/4 | 1.41" | 1/2 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 000000000 | 0000 |

| 1 1/4 | 1.41" | 3/4 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 000000000 | 0000 |

| 1 1/4 | 1.41" | 1 | PVC Plastic | Dark Gray | 200 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 1.65" | 1 | PVC Plastic | Dark Gray | 160 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 1.65" | 1 1/4 | PVC Plastic | Dark Gray | 160 psi @ 72° F | 000000000 | 00000 |

| 2 | 2.11" | 1 | PVC Plastic | Dark Gray | 160 psi @ 72° F | 000000000 | 00000 |

| 2 | 2.11" | 1 1/2 | PVC Plastic | Dark Gray | 160 psi @ 72° F | 000000000 | 00000 |

| Non-Hardening Thread Sealant | 000000 | Each | 000000 |

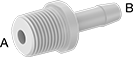

High-Temperature PTFE Pipe Fittings for Chemicals

Extreme temperatures are no problem for these fittings—they’re made of PTFE, so they can withstand a wider temperature range than any of our other plastic pipe fittings for chemicals. They have the chemical resistance to stand up to acid and solvents. Fittings have thick, Schedule 80 walls for heavy duty industrial applications. The material won’t leach contaminates into the line, so these fittings are commonly used in high-purity processes, such as semiconductor and clean room applications. They have a super-smooth interior for unrestricted flow. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns. Fittings meet ASTM D1710 specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

- For Use With: Deionized Water, Hydrochloric Acid, Solvents

- Temperature Range: -450° to 550° F

- Specifications Met: ASTM D1710

- Pipe Nipples and Pipe: Use Schedule 80 PTFE Plastic

- Flanges: Use Schedule 150 PTFE Plastic